Professional Documents

Culture Documents

Angus lmb40 Titan Monitor

Uploaded by

Haris ShahidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Angus lmb40 Titan Monitor

Uploaded by

Haris ShahidCopyright:

Available Formats

www.angusfire.co.

uk

Titan LMB40 Bronze Fire Monitor

Nominal flow 4,000 l/min @ 7 bar

560 SSM

The Angus LMB40 bronze fire monitor

is a simple and reliable design with a

hand lever for movement and hand

locks in both the horizontal and

vertical axis. Stainless steel ball race

bearings are used for the horizontal

and vertical movement.

Computer designed guide vanes cast

into the body reduce turbulence and

553 220

spin in the water stream lowering

pressure loss and improving jet reach.

All Angus bronze monitors are based (Monitor illustrated includes optional fog/jet nozzle)

on a proven low maintenance design

developed over 10 years of world-wide

service.

Body materials

~418

Bronze body to EN CC491K, equivalent

to LG2, ASTM B30, and UNI 7013

31/2" BSP M

302

Copper Zinc Lead Tin

85% 5% 5% 5%

Steering arm – SS316

Locking handles Duraplast on SS316

shafts 4" ANSI 150 FF

Bearing materials

553 220

Stainless steel (SS316) ball race bearing

on both axis with Viton seals rated up

to 120°C

Inlet connection

Standard flange 4” ANSI 150 FF.

286

(DIN and non standard flange options

available)

~418

Outlet connection

31/2" BSP M

31/2” BSP M (NH optional)

302

Operating pressure

Design pressure 16 bar

Hydraulic factory test pressure 24 bar

Performance

Pressure loss at 4,000 l/min 3.5 bar. 4" ANSI 150 FF

(For pressure losses at other flow rates

refer to the pressure loss graph.)

Weights and dimensions Note: when a large foam cannon is fitted a balance weight may have to be

Weight 26 kg fitted to the monitor control handle.

286

ref: 6399/06/07 page: 1 of 2

Titan LMB40

-50°

Movement

85°

360º continuous rotation in the horizontal plane

+85º / -50º movement in the vertical plane

360°

Stop to Stop

-50° Optional paint finish

Surface preparation Solvent cleaning

Primer coat Epoxy 30µm

Intermediate coat Epoxy grey 40µm

360°

360°

Stop to Stop

Continuous Finish coat Polyurethane 40µm Red RAL3000

Total dry film thickness 110µm

360° Length and height of monitor

4 Continuous water jet

3 Maximum water throw 82m* at an

angle of 32º

FRICTION LOSS - bar

2

Maximum height 47m* at an angle

of 75º

* Based on a FJ4000 nozzle, a flow of 4,000

1 l/min and a monitor inlet pressure of 12 bar.

0.9

0.8 Note: The jet throw depends on a

0.7 number of variables such as wind

0.6 direction, type and concentration of

0.5

foam in the water and the condition

0.4 of the monitor water ways and

0.3 nozzle.

For throw and height calculations at

1000

2000

3000

4000

5000

900

different inlet pressures and flows

and for different nozzles and angles

FLOW RATE - l/min refer to the Angus interactive

electronic data sheet.

Outlet nozzle options Fog/Jet Nozzles

Bronze bodies, manual controlled,

fog/jet nozzles with shut off:

FJ20 range: 200 to 2000 l/min

47m

Bronze bodies, manual controlled,

fog/jet nozzles:

FJ 1300 to 4000 l/min 82m

Stainless steel barrel with bronze base,

Maximum throw

aspirating foam cannons:

Foam Cannons

FC 800 to 4000 l/min

Stainless steel water jet pipes:

WC 1500 and 3000 l/min

A range of dry powder nozzles is also

available – refer to Angus Fire

All foam cannons come with the

option of a manually operated

spreader.

All nozzles and branchpipes come

with the option of a self inducing

foam connection.

(For technical details of nozzles and

branchpipes see separate data sheets.)

The Angus monitor range includes bronze models up to 8,500 l/min and stainless steel models up to 30,000 l/min.

Most models are available with lever or gearbox control, automatic oscillation or with hydraulic or electric remote control.

All are suitable for use where explosive atmospheres may be present.

Angus is a company assessed to ISO 9001:2000

© Angus Fire. Angus Fire reserves the right to modify any specification without prior notice. ref: 6399/06/07 page: 2 of 2

THAME PARK ROAD, THAME, OXFORDSHIRE, OX9 3RT, ENGLAND

Tel: +44 (0)1844 265000 Fax: +44 (0)1844 265156

e-mail: general.enquiries@kiddeuk.co.uk

You might also like

- Angus (Fire Monitor)Document2 pagesAngus (Fire Monitor)Zack LeeNo ratings yet

- Titan GMB50: Bronze Fire Monitor Nominal Flow 5,000 L/minDocument2 pagesTitan GMB50: Bronze Fire Monitor Nominal Flow 5,000 L/minsunu_usaktiNo ratings yet

- 6399 LMB40 1Document2 pages6399 LMB40 1Haris ShahidNo ratings yet

- High Pressure FiltersDocument92 pagesHigh Pressure FiltersThabangNo ratings yet

- High Pressure FiltersDocument108 pagesHigh Pressure FiltersKristine ReyesNo ratings yet

- G Style - Pneumatic DatasheetDocument2 pagesG Style - Pneumatic DatasheetMehemmed MelikovNo ratings yet

- 199 Imi EkoguardDocument2 pages199 Imi EkoguardEngr KamalNo ratings yet

- Bourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CaseDocument3 pagesBourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CasecarlosNo ratings yet

- Ball Valves: 3-Way SeriesDocument8 pagesBall Valves: 3-Way SerieslorenzoNo ratings yet

- Titan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minDocument2 pagesTitan OMB40: Bronze Fire Monitor Nominal Flow 4,000 L/minZhagiNo ratings yet

- Fire Monitor 611 Nozzle 823bc Spartan CatalogDocument2 pagesFire Monitor 611 Nozzle 823bc Spartan CatalogFajar HidayatNo ratings yet

- RF Series: Low Pressure FiltersDocument10 pagesRF Series: Low Pressure FiltersRestu OktapianaNo ratings yet

- Model 3201 Liquid Level Controller: FeaturesDocument8 pagesModel 3201 Liquid Level Controller: Featuresio1_roNo ratings yet

- Model Stainless Steel Pumps: 3M (2 Pole)Document4 pagesModel Stainless Steel Pumps: 3M (2 Pole)FilipNo ratings yet

- Ebara 3m DatasheetDocument2 pagesEbara 3m DatasheetIkechukwu UzoNo ratings yet

- 6424-1 LMS30 PDFDocument2 pages6424-1 LMS30 PDFadventure11111100% (1)

- Datasheet 1803 enDocument2 pagesDatasheet 1803 enPhan Việt AnhNo ratings yet

- Manual Sandvik Ds 421-cDocument4 pagesManual Sandvik Ds 421-cchristian100% (1)

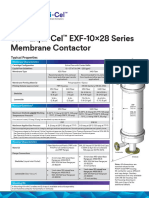

- Liqui-Cel EXF-10x28 Data Sheet LC-1031Document2 pagesLiqui-Cel EXF-10x28 Data Sheet LC-1031LuisAngelCordovadeSanchezNo ratings yet

- BX SeriesDocument2 pagesBX Seriesaaron mufukNo ratings yet

- S92 S93 Pneumatic 2020 01Document12 pagesS92 S93 Pneumatic 2020 01juan carlos suaNo ratings yet

- WIKA Stainless Steel Bourdon Tube Pressure GaugeDocument3 pagesWIKA Stainless Steel Bourdon Tube Pressure GaugeDennis MendozaNo ratings yet

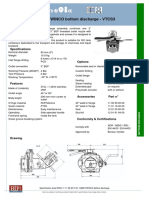

- 3'' (ND80) TWINCO Bottom Discharge - VTCS3: SpecificationsDocument2 pages3'' (ND80) TWINCO Bottom Discharge - VTCS3: Specificationsyounes1980No ratings yet

- Jetting AccessoriesDocument24 pagesJetting AccessoriesJairitoDuboisNo ratings yet

- Alfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332Document3 pagesAlfa Laval TJ Sanimagnum Rotary Spray Head Product Leaflet Ese00332apri andi setyawanNo ratings yet

- Liqui Cel EXF Series 10x28 DatasheetDocument2 pagesLiqui Cel EXF Series 10x28 Datasheetwongpengchiong7205No ratings yet

- D-Direct-Coupled Volute Pumps PDFDocument73 pagesD-Direct-Coupled Volute Pumps PDFMahfudz FauziNo ratings yet

- DS421 8-4301-ADocument4 pagesDS421 8-4301-AchristianNo ratings yet

- Compact Cylinder ISO 21287 GuideDocument16 pagesCompact Cylinder ISO 21287 GuidejeffersonfriasNo ratings yet

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDocument2 pagesFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNo ratings yet

- Catalog f9 05 40Document3 pagesCatalog f9 05 40Leydiivonne Cortes NorbertoNo ratings yet

- Dobermann SV SW As 3 A Export enDocument54 pagesDobermann SV SW As 3 A Export enTecnor Lalin MaquinariaNo ratings yet

- Choke Technical Handbook PDFDocument13 pagesChoke Technical Handbook PDFCesar GouroNo ratings yet

- 02-Pipe Fittings PDFDocument12 pages02-Pipe Fittings PDFSaid Ahmed SalemNo ratings yet

- FT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Document7 pagesFT44 Carbon Steel Ball Float Steam Traps (DN15 To DN50)Liêm HàNo ratings yet

- Gauge PressureDocument5 pagesGauge PressureMuhammad IhsanNo ratings yet

- Bell & Gossett: Engineered For LifeDocument4 pagesBell & Gossett: Engineered For LifeAngel GomezNo ratings yet

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- Explosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetDocument4 pagesExplosion Proof Stainless Steel Vertical Float Switch APG FS 400 Series DatasheetachmadinNo ratings yet

- Pressure GaugeDocument2 pagesPressure GaugeVishnu PatilNo ratings yet

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocument14 pagesBakerSPD Choke Tech Handbook 5-9-06 PDFTg TarroNo ratings yet

- Hexagonal Bar Stock Needle Valve: HBNV SeriesDocument6 pagesHexagonal Bar Stock Needle Valve: HBNV SeriesMohamed RaafatNo ratings yet

- Sanimagnum Rotary SprayDocument3 pagesSanimagnum Rotary Sprayeder.flavioparraNo ratings yet

- Catalogo Actuador BrayDocument12 pagesCatalogo Actuador Braynacho richardNo ratings yet

- 5 Catalogue Winway DBB Valve-MinDocument19 pages5 Catalogue Winway DBB Valve-MinAsyadullah Al-FatihNo ratings yet

- NKP G NKM G Ts EngDocument59 pagesNKP G NKM G Ts EngSTEPAN RAZINNo ratings yet

- S1.4.5.) Datasheet PRESSURE GAUGEDocument3 pagesS1.4.5.) Datasheet PRESSURE GAUGEEkoNo ratings yet

- Hydrant ValvesDocument4 pagesHydrant ValvesoscarninanNo ratings yet

- Machining Duplex Stainless Steels: Shop Sheet 103Document4 pagesMachining Duplex Stainless Steels: Shop Sheet 103Adrian CeplinschiNo ratings yet

- Barton 199 DPU Data SheetDocument4 pagesBarton 199 DPU Data Sheetmfg_serviciosNo ratings yet

- CO2 & ABC Extg - ExportDocument1 pageCO2 & ABC Extg - Exportvienbinh2003No ratings yet

- 2015 Unifire Hand Held Nozzle CatalogDocument21 pages2015 Unifire Hand Held Nozzle CatalogDennis MartinusNo ratings yet

- Standard Monitor RangeDocument7 pagesStandard Monitor RangeDaniel Carmona AriasNo ratings yet

- UWI-203 TP Medium Capacity Portable Welding InverterDocument2 pagesUWI-203 TP Medium Capacity Portable Welding InverterChris TeohNo ratings yet

- CX SeriesDocument2 pagesCX Seriesaaron mufukNo ratings yet

- Pumpworks 610-BB3Document6 pagesPumpworks 610-BB3Padmanabhan VenkateshNo ratings yet

- HERODocument2 pagesHEROozéias salvino cardosoNo ratings yet

- Ebara TD FSA1Document28 pagesEbara TD FSA1Ismar MineplanNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- MonitorsDocument8 pagesMonitorsseluarbolaNo ratings yet

- 11-4567 JS Activation Tifs RefreshDocument14 pages11-4567 JS Activation Tifs Refreshedgardiaz5519No ratings yet

- 889 BC Nozzle: Angus Hi-Combat Style 889 BC Self Inducing Monitor NozzleDocument2 pages889 BC Nozzle: Angus Hi-Combat Style 889 BC Self Inducing Monitor NozzleHaris ShahidNo ratings yet

- LTN Nozzles: Angus Long Throw NozzlesDocument2 pagesLTN Nozzles: Angus Long Throw NozzlesHaris ShahidNo ratings yet

- Angus Hi-Combat Style 837 BC Monitor NozzleDocument2 pagesAngus Hi-Combat Style 837 BC Monitor NozzleHaris ShahidNo ratings yet

- Titan FJ 1300 - 8500: Fog / Jet Nozzle RangeDocument2 pagesTitan FJ 1300 - 8500: Fog / Jet Nozzle RangeHaris ShahidNo ratings yet

- Titan FJ 1300 - 8500: Fog / Jet Nozzle RangeDocument2 pagesTitan FJ 1300 - 8500: Fog / Jet Nozzle RangeHaris ShahidNo ratings yet

- Chapter 8 Nuc - PhyDocument14 pagesChapter 8 Nuc - PhyHaris ShahidNo ratings yet

- Chapter 4 Nuc - PhyDocument11 pagesChapter 4 Nuc - PhyHaris ShahidNo ratings yet

- Chapter 4 Nuc - PhyDocument11 pagesChapter 4 Nuc - PhyHaris ShahidNo ratings yet

- Chapter: 7 Nuclear Energy and ForcesDocument15 pagesChapter: 7 Nuclear Energy and ForcesHaris ShahidNo ratings yet

- JumpStart To Activated Economics in Aspen HYSYS V8.4Document4 pagesJumpStart To Activated Economics in Aspen HYSYS V8.4Haris ShahidNo ratings yet

- Color Coding For Data Entry in The Economics SuiteDocument5 pagesColor Coding For Data Entry in The Economics SuiteHaris ShahidNo ratings yet

- Math X (Science) PIIDocument9 pagesMath X (Science) PIIHaris ShahidNo ratings yet

- Planning and Scheduling of Crude Oil Distribution in A Petroleum PlantDocument8 pagesPlanning and Scheduling of Crude Oil Distribution in A Petroleum PlantHaris ShahidNo ratings yet

- Chapter 8 Nuc - PhyDocument14 pagesChapter 8 Nuc - PhyHaris ShahidNo ratings yet

- Aga Khan Math ExamDocument5 pagesAga Khan Math ExamHaris ShahidNo ratings yet

- Math X (General) PI 2016Document8 pagesMath X (General) PI 2016Haris ShahidNo ratings yet

- Chapter: 7 Nuclear Energy and ForcesDocument15 pagesChapter: 7 Nuclear Energy and ForcesHaris ShahidNo ratings yet

- Math X (General) PII 2016Document10 pagesMath X (General) PII 2016Haris ShahidNo ratings yet

- Math IX (General) PII 2016Document10 pagesMath IX (General) PII 2016Haris ShahidNo ratings yet

- Math IX (General) PI 2016Document7 pagesMath IX (General) PI 2016Haris ShahidNo ratings yet

- Math III PII 2016Document5 pagesMath III PII 2016Haris ShahidNo ratings yet

- Math IV Paper I - II 2016Document10 pagesMath IV Paper I - II 2016Haris ShahidNo ratings yet

- Components Max. Marks Marks. ObtainedDocument5 pagesComponents Max. Marks Marks. ObtainedHaris ShahidNo ratings yet

- Math VIII P2 2016Document9 pagesMath VIII P2 2016Haris ShahidNo ratings yet

- 8 Ceteralized VIII Math P1 KeyDocument5 pages8 Ceteralized VIII Math P1 KeyHaris ShahidNo ratings yet

- 7 Class VII Paper II - MathDocument11 pages7 Class VII Paper II - MathHaris ShahidNo ratings yet

- Group 4 - Lab Assignment Size Exclusion ChromatographyDocument14 pagesGroup 4 - Lab Assignment Size Exclusion ChromatographyHasni Abdul RahimNo ratings yet

- Forensic Science International: Marianne Hädener, Sina Vieten, Wolfgang Weinmann, Hellmut MahlerDocument6 pagesForensic Science International: Marianne Hädener, Sina Vieten, Wolfgang Weinmann, Hellmut MahlerlunahermannNo ratings yet

- Duke 2018-19Document219 pagesDuke 2018-19Manasi GhadageNo ratings yet

- Chapter 2 Atoms Molecules and IonsDocument32 pagesChapter 2 Atoms Molecules and IonsCheska CapioNo ratings yet

- Lesson 1 Nature of Analytical ChemistryDocument46 pagesLesson 1 Nature of Analytical ChemistryWendy ManguisiNo ratings yet

- Eliza Budarz - B6.1 Why Are Metals Useful.Document11 pagesEliza Budarz - B6.1 Why Are Metals Useful.Eliza BudarzNo ratings yet

- CT01 IntroDocument63 pagesCT01 IntroNicolae Raresh NonuNo ratings yet

- General Chemistry Che 101: Prof. Moavin Islam PHD Ficorr Mim Ceng (Mvi)Document88 pagesGeneral Chemistry Che 101: Prof. Moavin Islam PHD Ficorr Mim Ceng (Mvi)Irfanul HoqueNo ratings yet

- Gifts of The Essential Oils - Adam Barralet, Vanessa Jean Boscarello OvensDocument14 pagesGifts of The Essential Oils - Adam Barralet, Vanessa Jean Boscarello OvensAura100% (1)

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Boundaries - Homework (#2)Document20 pagesBoundaries - Homework (#2)azulenmarNo ratings yet

- PV Isotherms of Real Gases ExperimentDocument14 pagesPV Isotherms of Real Gases ExperimentMarielle PerejonNo ratings yet

- Beckosol 12-035 Short Oil Non-Drying Alkyd: Product Code: 12035-00Document2 pagesBeckosol 12-035 Short Oil Non-Drying Alkyd: Product Code: 12035-00Manoj Lalita GoswamiNo ratings yet

- Sikaflex-291 - PDSDocument2 pagesSikaflex-291 - PDSRade PesteracNo ratings yet

- 2-RLT9VZ10S16D5 Low - Pressure - FiltersDocument1 page2-RLT9VZ10S16D5 Low - Pressure - FiltersNibin OdukkathilNo ratings yet

- SEO-Optimized Title for Physics, Chemistry and Mathematics DocumentDocument19 pagesSEO-Optimized Title for Physics, Chemistry and Mathematics DocumentHarshul SingalNo ratings yet

- New Biochemical and Physicochemical Insights On A Muskmelon (Cucumis Melo (L.) ) ChitinaseDocument12 pagesNew Biochemical and Physicochemical Insights On A Muskmelon (Cucumis Melo (L.) ) ChitinaseEdnésioNo ratings yet

- Assessment of Fib Bulletin 90 Design Provisions Fo PDFDocument23 pagesAssessment of Fib Bulletin 90 Design Provisions Fo PDFangelaNo ratings yet

- Enabling Assessment 2-1, Chemical SafetyDocument12 pagesEnabling Assessment 2-1, Chemical SafetyMikhaella RicoNo ratings yet

- BIOMOLECULESDocument26 pagesBIOMOLECULESVicky VigneshNo ratings yet

- Biochem Reviewer Module 1 2Document9 pagesBiochem Reviewer Module 1 2cam broquelNo ratings yet

- Applications of Capsaicin in Food Industry: Functionality, Utilization and StabilizationDocument19 pagesApplications of Capsaicin in Food Industry: Functionality, Utilization and StabilizationAlonso Ornelas GonzalezNo ratings yet

- Handgun-MUS601010101QUICK GUIDE A4 ING v2Document2 pagesHandgun-MUS601010101QUICK GUIDE A4 ING v2dongNo ratings yet

- MSDS MX - 99 Gentian Blue PDFDocument4 pagesMSDS MX - 99 Gentian Blue PDFrenitaNo ratings yet

- Assignment-1: Physical Chemistry: Na (Sodium Sir)Document2 pagesAssignment-1: Physical Chemistry: Na (Sodium Sir)Aaryan KeshanNo ratings yet

- Biochemistry by Raymond S Ochs Full ChapterDocument41 pagesBiochemistry by Raymond S Ochs Full Chaptercharlie.heiliger836100% (19)

- Cambridge IGCSE™: Combined Science 0653/32 May/June 2020Document10 pagesCambridge IGCSE™: Combined Science 0653/32 May/June 2020Hin Wa LeungNo ratings yet

- Transistor Current ComponentsDocument3 pagesTransistor Current ComponentsDiptendu MitraNo ratings yet

- CEM152 Syllabus 2020Document9 pagesCEM152 Syllabus 2020Mona JoeNo ratings yet

- Numerical Simulation of The Effect of Sa/Pa On Combustion and Flow Characteristics in A Front-Rear Burner 400 Mwe BoilerDocument9 pagesNumerical Simulation of The Effect of Sa/Pa On Combustion and Flow Characteristics in A Front-Rear Burner 400 Mwe BoilerFaridNo ratings yet