Professional Documents

Culture Documents

PA12 Smooth High Surface Quality

Uploaded by

Mohamed Sami ADOUANIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PA12 Smooth High Surface Quality

Uploaded by

Mohamed Sami ADOUANICopyright:

Available Formats

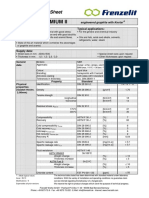

PA12 Smooth

High surface quality

Good quality to price ratio | Excellent surface quality and high level of recreated details | High chemical resistance

General information Method

Material type Nylon 12

Granulation 18 - 90 [μm]

Color Navy Grey

Material refreshing ratio 1 30 [%]

Compatible with ² Lisa & Lisa Pro

Parameters

Tensile Strength 41 [MPa] PN-EN ISO 37:2007

Elongation at Break 13 [%] PN-EN ISO 37:2007

Impact resistance (Charpy test / unnotched) 15 - 20 [KJ/m²] Internal procedure

Shore hardness in type D scale 74 PN-EN ISO 868:2005

Thermal properties

Softening point (Vicat method type A50 / B50) 172 / 155 [°C] PN-EN ISO 306:2014-02

Melting point 182 [°C] Internal procedure

Heat deflection temperature B 143 [°C] PN-EN ISO 75-2:2013-06

Printout density 1.00 [g/cm³] PN-EN ISO 845:2010

Applications

Detailed printouts, structural or mechanical (with complicated internal geometry) elements,

functional prototypes or final parts.

Charpy U- and V-notched impact testing

Nº notch KJ/m²

1. U 5.23

2. V 3.28

Tensile testing

Charpy impact test results for specimens tested using

pendulum of maximum energy of 50 [J], weight of 6.8 [kg] 50

and length of 380 [mm]. 45

40

35

Stress [MPa]

30

Surface roughness 25 Ultimate tensile

20 strength

Roughness

side surface top surface 15

parameter 10 41 [MPa]

5

Ra 9.680 [μm] 6.470 [μm]

0

0 2 4 6 8 10 12 14

Rz 54.184 [μm] 31.633 [μm] Strain [%]

Roughness of test speciments surfaces printed with layer

thickness of 100 [μm].

1 Material refreshing ratio - percent of Fresh powder which has to be mixed with Used (unsintered) powder - to be reused during next print.

² Available as part of the appropriate profile purchased.

Information provided within this document are average values for reference and comparison only. Parameters presented in this specification are subject to change.

Final part properties may vary based on printed part design and print orientation.

You might also like

- Flexa-Grey Specification PDFDocument1 pageFlexa-Grey Specification PDFMohamed Sami ADOUANINo ratings yet

- PA11 Onyx: Superior Durability and ResistanceDocument1 pagePA11 Onyx: Superior Durability and ResistanceMohamed Sami ADOUANINo ratings yet

- Dense, Elastic and Strong: General Information MethodDocument1 pageDense, Elastic and Strong: General Information MethodMohamed Sami ADOUANINo ratings yet

- Soft elastic TPU print materialDocument1 pageSoft elastic TPU print materialMohamed Sami ADOUANINo ratings yet

- F010 PPT LCPC Yves Brosseaud French Methodology For Bituminous Mix DesignDocument63 pagesF010 PPT LCPC Yves Brosseaud French Methodology For Bituminous Mix Designzs zNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- Duracon M25-44Document5 pagesDuracon M25-44AVLight AutomotivesNo ratings yet

- 182590-615ASTRO-N7 CHSM72NDGF-BH 2382x1134x30 EN 20230802Document2 pages182590-615ASTRO-N7 CHSM72NDGF-BH 2382x1134x30 EN 20230802Gilberto SousaNo ratings yet

- TDB HPN - e - 08mm Rollen PDFDocument1 pageTDB HPN - e - 08mm Rollen PDFAnonymous 6VCG1YRdNo ratings yet

- Material: Natural Rubber (NR) : Max Spare Code: NR 70Document1 pageMaterial: Natural Rubber (NR) : Max Spare Code: NR 70Bagus OktiNo ratings yet

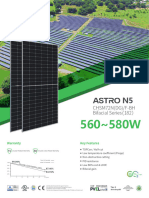

- Astro N5 - CHSM72NDGF BHDocument2 pagesAstro N5 - CHSM72NDGF BHJOGmzNo ratings yet

- (ASTRONERGY) Datasheet - ASTRO N5 - 560 - 580 N-TYPE - MONOFACIALDocument2 pages(ASTRONERGY) Datasheet - ASTRO N5 - 560 - 580 N-TYPE - MONOFACIALdatabasegptropinatiNo ratings yet

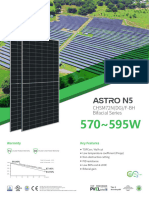

- 1 - (570 595) ASTRO N5 - CHSM72N (DG) F-BH - 2278x1134x30 - 30x28 Frame - EN - 20240105Document2 pages1 - (570 595) ASTRO N5 - CHSM72N (DG) F-BH - 2278x1134x30 - 30x28 Frame - EN - 20240105lahore0022No ratings yet

- Avm Imnr44 17aDocument2 pagesAvm Imnr44 17aRani HendrikusNo ratings yet

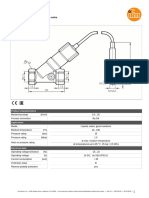

- Flow Transmitters With Non-Return Valve: SBT34XKX10KG/O/USDocument3 pagesFlow Transmitters With Non-Return Valve: SBT34XKX10KG/O/USthiyagarajan vNo ratings yet

- Formula Performance Archives: SeriesDocument13 pagesFormula Performance Archives: SeriesElias QuirozNo ratings yet

- Greene Tweed Arlon 1000 Typical Property SheetDocument3 pagesGreene Tweed Arlon 1000 Typical Property SheetYang WangNo ratings yet

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Document2 pagesFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCONo ratings yet

- Eversted Filters-Plan-G2 g3 g4 Technical-Data-Sheet en PDFDocument3 pagesEversted Filters-Plan-G2 g3 g4 Technical-Data-Sheet en PDFIna IoanaNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Datasheet Mfvas Mo 144 575wDocument2 pagesDatasheet Mfvas Mo 144 575wsollen.energiasolarNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Datasheet Feroform T814Document1 pageDatasheet Feroform T814njsmith5No ratings yet

- Cut 65Cnc: Modern, Effective, Industrial Plasma CutterDocument2 pagesCut 65Cnc: Modern, Effective, Industrial Plasma CutterRafik Mohamed AlhajiNo ratings yet

- EFPMDocument4 pagesEFPMJamin SmtpngNo ratings yet

- Avm Imnr62 17aDocument2 pagesAvm Imnr62 17aRani HendrikusNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Material Flyer - TECAMID 6 FRT NaturalDocument1 pageMaterial Flyer - TECAMID 6 FRT Naturalkgrier8966No ratings yet

- Straight Pipes EN 13480-3 Chap. 6.1 CalculationDocument1 pageStraight Pipes EN 13480-3 Chap. 6.1 CalculationmasatusNo ratings yet

- Polyacetal (POM) : Polyplastics Co., LTDDocument19 pagesPolyacetal (POM) : Polyplastics Co., LTDPhuoc Thinh TruongNo ratings yet

- Lec9 - Taguchi Optimization DoEDocument23 pagesLec9 - Taguchi Optimization DoEFELIX KEUYANo ratings yet

- 1000 MM PolytheleneDocument1 page1000 MM PolytheleneJaokNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- SSGC'S Design Requirements For 60 MT LPG Tank As Per Asme Section Viii Div. 1 Edition 2013Document2 pagesSSGC'S Design Requirements For 60 MT LPG Tank As Per Asme Section Viii Div. 1 Edition 2013MuhammadShabbirNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- Hertzian Contact Stress Calculator.Document3 pagesHertzian Contact Stress Calculator.Nitesh Kumar SoniNo ratings yet

- EN GB TDS WEICON Ceramic BLDocument4 pagesEN GB TDS WEICON Ceramic BLfadialkasrawiNo ratings yet

- Elastocoat C 6335-101Document4 pagesElastocoat C 6335-101Cristina AndronescuNo ratings yet

- UK NatureFlex NPFDocument2 pagesUK NatureFlex NPFHavir GhteuNo ratings yet

- Avm Imnr70 17aDocument2 pagesAvm Imnr70 17aRani HendrikusNo ratings yet

- Filter Elements: FeaturesDocument14 pagesFilter Elements: FeaturesJamin SmtpngNo ratings yet

- Operating Range Recommended Applications: Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDocument7 pagesOperating Range Recommended Applications: Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsMontasserNo ratings yet

- FT - Imp Pumps NMT - Max - 32 - 120 - FDocument1 pageFT - Imp Pumps NMT - Max - 32 - 120 - FsssddssNo ratings yet

- Job Number Sheet AnalysisDocument4 pagesJob Number Sheet AnalysisJONHCENA13No ratings yet

- TDS UBE NYLON 1024B, CastDocument1 pageTDS UBE NYLON 1024B, CastAlexander ShvetsNo ratings yet

- Superlite: Superlite Asbestos Free Gp-150Document4 pagesSuperlite: Superlite Asbestos Free Gp-150blahblahNo ratings yet

- Technical Data Sheet for ABS Dinarex Black polymerDocument2 pagesTechnical Data Sheet for ABS Dinarex Black polymerHrafnaet SorgenNo ratings yet

- 487-tds s1s15 g30-4247 Dinarex Eng PDFDocument2 pages487-tds s1s15 g30-4247 Dinarex Eng PDFtebanzalesNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- Desmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Document2 pagesDesmopan 453 DPS 041: 400 Grade Series, Ester / Shore Hardness D 50 - 54Johnny SyluanciaNo ratings yet

- 3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0Document1 page3d Systems Accura 25 Datasheet Usen 2018 07 11 Web - 0Pankaj ShahNo ratings yet

- Ficha Tecnica Mirafi RS580iDocument2 pagesFicha Tecnica Mirafi RS580idaniel trejoNo ratings yet

- Ark Emad 362Document13 pagesArk Emad 362La Vita E BellaNo ratings yet

- Ningbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1Document1 pageNingbo Brightfast Co.,Ltd: Certificate of Quality En10204 3.1amicikicikNo ratings yet

- Hanwha Total PP BJ550Document2 pagesHanwha Total PP BJ550Nguyễn Hồng NamNo ratings yet

- CFB Boiler - Site Inspection Guidelines and ProtocolDocument100 pagesCFB Boiler - Site Inspection Guidelines and ProtocolXcdxtvNo ratings yet

- Hitachi Zaxis Excavators Outperform Competition in Trenching and Truck LoadingDocument9 pagesHitachi Zaxis Excavators Outperform Competition in Trenching and Truck LoadingWai Yan LinNo ratings yet

- Ultrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Document26 pagesUltrasonic Test Procedure AWS D1.1 (NDE Procedure For Structure)Taufik SantosoNo ratings yet

- Aw60 40le Zip in PDFDocument10 pagesAw60 40le Zip in PDFJosé Monteiro100% (2)

- Measuring Viscosity at High Shear Rate and High Temperature by Tapered Bearing SimulatorDocument7 pagesMeasuring Viscosity at High Shear Rate and High Temperature by Tapered Bearing SimulatorBurcu TaşçıNo ratings yet

- SopDocument3 pagesSopanon_437292096No ratings yet

- Cat4100 o LokDocument76 pagesCat4100 o LokavonegNo ratings yet

- SFD Is 800 2007Document118 pagesSFD Is 800 2007Angel VargasNo ratings yet

- 11 D Equipment Data SheetDocument4 pages11 D Equipment Data SheetFernando RomeroNo ratings yet

- Exterior Components Pa 44 PDFDocument4 pagesExterior Components Pa 44 PDFA320viatorNo ratings yet

- Aquaglide BrochureDocument2 pagesAquaglide BrochureBenicio Joaquín Ferrero BrebesNo ratings yet

- TANCET 2022 eligibility qualifications for postgraduate civil engineering programsDocument25 pagesTANCET 2022 eligibility qualifications for postgraduate civil engineering programskamaleshwar bNo ratings yet

- Parts Manual: CMP15/18/20s L FX15/18 L-2Document157 pagesParts Manual: CMP15/18/20s L FX15/18 L-2Marcio50% (2)

- Tower Drawing 100 FeetDocument3 pagesTower Drawing 100 FeetMian M Khurram100% (3)

- D28 CR Engl PDFDocument181 pagesD28 CR Engl PDF劉功暹No ratings yet

- Estimating The Negative Skin FrictionDocument10 pagesEstimating The Negative Skin FrictionM TaufikNo ratings yet

- Forces in Truss Members with Different Load PositionsDocument8 pagesForces in Truss Members with Different Load PositionswahtoiNo ratings yet

- (20837429 - Polish Maritime Research) Design and Strength Calculations of The Tripod Support Structure For Offshore Power PlantDocument11 pages(20837429 - Polish Maritime Research) Design and Strength Calculations of The Tripod Support Structure For Offshore Power PlantLuthfi Rasyid100% (1)

- Schneider GV2 Motor Circuit BreakerDocument19 pagesSchneider GV2 Motor Circuit BreakeruuraydinNo ratings yet

- Cumene Storage Tank DesignDocument8 pagesCumene Storage Tank DesignMaria Eloisa Angelie ArellanoNo ratings yet

- 32-11-12 AssemblyDocument3 pages32-11-12 AssemblyJosua SilaenNo ratings yet

- DFW Fluid End Expendables Line SheetDocument4 pagesDFW Fluid End Expendables Line SheetriskvisionNo ratings yet

- Selection of Gas CompressorsDocument5 pagesSelection of Gas CompressorsstreamtNo ratings yet

- Cavitation DamageDocument18 pagesCavitation Damagescata1117No ratings yet

- Disabled Systems: Customer Name Reference Product Series NoDocument17 pagesDisabled Systems: Customer Name Reference Product Series NoАлександр КачеишвилиNo ratings yet

- Dynamic Slip-Ratio Estimation and Control of Antilock Braking Systems Using An Observer-Based Direct Adaptive Fuzzy-Neural ControllerDocument11 pagesDynamic Slip-Ratio Estimation and Control of Antilock Braking Systems Using An Observer-Based Direct Adaptive Fuzzy-Neural ControllerPavan SandeepNo ratings yet

- Kemppi Wiseroot en USDocument5 pagesKemppi Wiseroot en USDimitris NikouNo ratings yet

- GRFP01 Gr11 Ch01toCh06Document126 pagesGRFP01 Gr11 Ch01toCh06AidanNo ratings yet

- Benefit KomtraxDocument19 pagesBenefit KomtraxDaniel Garnando KristianNo ratings yet

- Big Blaster® Hurricane Air Blaster PDFDocument52 pagesBig Blaster® Hurricane Air Blaster PDFZahir KhiraNo ratings yet