Professional Documents

Culture Documents

Engine Operation and Maintenance Manual-130

Uploaded by

primmughal0 ratings0% found this document useful (0 votes)

23 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views1 pageEngine Operation and Maintenance Manual-130

Uploaded by

primmughalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

IGNITION SYSTEM MAINTENANCE

10. Position coil with the word “TOP” on flange oriented

NOTICE toward exhaust manifold. Secure coil with three lock

Exercise caution to avoid bumping the electrodes into washers and hex nuts and tighten to specifications

the spark plug carrier. Bumping the electrodes against (see Figure 4.10-11). See Ignition System in

the spark plug carrier may change the spark plug gap. Table 1.15-14 Critical Engine Torque Values on

page 1.15-20 for specific torque values.

5. Install spark plug into inner sleeve using spark plug

socket tool (P/N 475037) (see Figure 4.10-9). 2

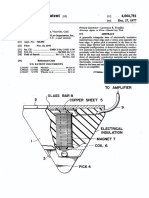

Figure 4.10-11

1 - Hex Nut 3 - Hex Nuts

Figure 4.10-9 2 - Ignition Coil

6. Torque spark plug to specifications. See Ignition Harness Connector

System in Table 1.15-14 Critical Engine Torque 11. Install ignition harness connector onto coil (see

Values on page 1.15-20 for specific torque values. Figure 4.10-11).

7. Lightly coat inside surface of extension boot and

O-ring on coil end of spark plug extension with Krytox BORESCOPE INSPECTION

GPL-206 (see Figure 4.10-8).

1. Disconnect ignition coil harness connector from coil

8. Install extension onto spark plug through valve cover (see Figure 4.10-12).

using extension pliers (see Figure 4.10-4 and Figure

4.10-10).

1

Figure 4.10-12: Valve Cover Assembly

Figure 4.10-10 1 - Ignition Coil 2 - Capscrews

Harness Connector

9. Install new O-ring on nose of coil.

FORM 6319-2

4.10-4 © 8/2012

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Chevron Aries TDSDocument2 pagesChevron Aries TDSprimmughalNo ratings yet

- Safety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianDocument28 pagesSafety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianprimmughalNo ratings yet

- Renolin Unisyn CLP 460Document9 pagesRenolin Unisyn CLP 460primmughalNo ratings yet

- Safety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianDocument28 pagesSafety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianprimmughalNo ratings yet

- Safety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianDocument22 pagesSafety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: Technicianprimmughal100% (1)

- Safety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianDocument18 pagesSafety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianprimmughalNo ratings yet

- Safety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: TechnicianDocument22 pagesSafety: Unit Number: Customer: Date: Hour Meter Reading: Country: Location: Engine/Comp Model: Providence: Technicianprimmughal100% (1)

- Compressor FS604 Data SheetDocument4 pagesCompressor FS604 Data SheetprimmughalNo ratings yet

- Waukesha Engine Operation and Maintenance Manual-46Document1 pageWaukesha Engine Operation and Maintenance Manual-46primmughalNo ratings yet

- Waukesha Engine Operation and Maintenance Manual-45Document1 pageWaukesha Engine Operation and Maintenance Manual-45primmughalNo ratings yet

- Waukesha Engine Operation and Maintenance Manual-43Document1 pageWaukesha Engine Operation and Maintenance Manual-43primmughalNo ratings yet

- Engine Operation and Maintenance Manual-131Document1 pageEngine Operation and Maintenance Manual-131primmughalNo ratings yet

- Engine Operation and Maintenance Manual-127 PDFDocument1 pageEngine Operation and Maintenance Manual-127 PDFprimmughalNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkDocument9 pagesIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgNo ratings yet

- Desktop 10 QA Exam Prep Guide PDFDocument16 pagesDesktop 10 QA Exam Prep Guide PDFShiva RungtaNo ratings yet

- 1213-23-Si-Og RR GecDocument8 pages1213-23-Si-Og RR Gecvkj5824No ratings yet

- Technical Data: Digital and Millivolt Gas HeatersDocument2 pagesTechnical Data: Digital and Millivolt Gas HeatersDenis CuraNo ratings yet

- RDocument17 pagesRduongpndngNo ratings yet

- 12556/gorakhdham Exp Third Ac (3A)Document2 pages12556/gorakhdham Exp Third Ac (3A)Lovkesh GoyalNo ratings yet

- Esu Tester WhoDocument5 pagesEsu Tester WhoquezonNo ratings yet

- Pedoman Planologi PDFDocument187 pagesPedoman Planologi PDFRetno Kartika SariNo ratings yet

- Manual Instructions For Using Biometric DevicesDocument6 pagesManual Instructions For Using Biometric DevicesramunagatiNo ratings yet

- Digital Design Course FileDocument191 pagesDigital Design Course FileCharan NethaNo ratings yet

- Applichem Case-SCM Sec B Group-2Document11 pagesApplichem Case-SCM Sec B Group-2Ayush RanjanNo ratings yet

- Definition of EbookDocument14 pagesDefinition of EbookNurul IzzahNo ratings yet

- Delta Tester 9424 Training ModuleDocument35 pagesDelta Tester 9424 Training ModuleNini FarribasNo ratings yet

- List of The Registered UAE CompaniesDocument3 pagesList of The Registered UAE Companiesirfan aminNo ratings yet

- BextexDocument14 pagesBextexBishawnath RoyNo ratings yet

- Ship-Like Target Design For Underwater Explosion Experiments PDFDocument92 pagesShip-Like Target Design For Underwater Explosion Experiments PDFFernando Raúl LADINONo ratings yet

- Mode ReversionsDocument15 pagesMode ReversionsISHAANNo ratings yet

- U.S. Patent 4,064,781, Guitar Pick, Issued 1977.Document3 pagesU.S. Patent 4,064,781, Guitar Pick, Issued 1977.Anonymous a7S1qyXNo ratings yet

- An 4160Document8 pagesAn 4160aurumstar2000No ratings yet

- SM PC300 350 LC 8Document1,025 pagesSM PC300 350 LC 8dedy imranNo ratings yet

- Concrete Construction Article PDF - Site Casting Exposed Aggregate WallsDocument1 pageConcrete Construction Article PDF - Site Casting Exposed Aggregate WallssonofalexanderNo ratings yet

- Tears of My Enemies Funny Juice Box Enamel Pin BaDocument1 pageTears of My Enemies Funny Juice Box Enamel Pin BaBoban StojanovićNo ratings yet

- Multilin 369Document5 pagesMultilin 369Edo RossNo ratings yet

- Usability Engineering (Human Computer Intreraction)Document31 pagesUsability Engineering (Human Computer Intreraction)Muhammad Usama NadeemNo ratings yet

- MIS Officer Job Description and Person SpecificationDocument3 pagesMIS Officer Job Description and Person SpecificationviewpawanNo ratings yet

- Manual de TallerDocument252 pagesManual de TallerEdison RodriguezNo ratings yet

- Topaz Towers In-Building DASDocument25 pagesTopaz Towers In-Building DASSudheera IndrajithNo ratings yet

- Bearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and ParametersDocument31 pagesBearer Independent Call Control Protocol (Cs2) and Signalling System No.7 - Isdn User Part General Functions of Messages and Parameterssahil_chandna25No ratings yet

- Technical Report Route To IEng GuidanceDocument11 pagesTechnical Report Route To IEng GuidanceECCNo ratings yet

- Spam DetectionDocument142 pagesSpam DetectionRahul GantaNo ratings yet