Professional Documents

Culture Documents

ST-030 Correct Installation and Handling of Connecting Rods PDF

Uploaded by

Popa MihaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ST-030 Correct Installation and Handling of Connecting Rods PDF

Uploaded by

Popa MihaiCopyright:

Available Formats

GE Power & Water

Michael SCHULLERUS

Service Engineering

GE Jenbacher GmbH & Co OG

Distribution list Achenseestr. 1-3

Jenbach, Subsidiaries, Service Providers A-6200 Jenbach, Austria

T +43 5244 600 3153

michael.schullerus@ge.com

Service Technician Instruction ST-030 13 May 2014

Engine type 2, 3, 4 and 6

Subject Correct installation and handling of connecting rods

Service Technician Instruction ST-030 is intended to ensure that both during production and in the field, only

connecting rods and big-end caps that belong together are assembled together and use of the wrong big-end

caps is avoided.

AFFECTED ENGINES / SCOPE OF THIS BULLETIN

All Type 2, 3, 4 and 6 engines.

DESCRIPTION OF THE FACTS

Correct assembly and handling of connecting rods - all engine types

This Instruction must be observed absolutely both during production and in the field to ensure that only matching

connecting rods and big-end caps are assembled together, and to prevent the use of the wrong big-end caps.

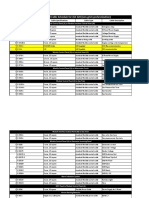

1 Before unbolting the big-end cap from the connecting rod:

Compare the serial numbers on the big-end cap and the connecting rod. The two numbers must be the same.

Serial number = matched pair numbers, applied by the manufacturer (rod and cap)

The serial number, year of manufacture and the machine number must always be identical.

Data about the connecting rod blanks (cast, forged or stamped) is irrelevant for fitting.

Connecting rods from earlier than 2009/2010 may still have the old inscription.

GE PROPRIETARY INFORMATION

The information contained in this document is General Electric Company proprietary information and is disclosed in confidence. It is the property of GE and may not be used, disclosed to

others or reproduced without the express written consent of GE. This includes, but is not limited to, use of the information to create, manufacture, develop or derive any repairs, modifications,

spare parts, designs or configuration changes, or to obtain government or regulatory approval to do so. If consent is given for reproduction in whole or in part, this notice and the notice set

out on each page of this document shall appear in any such reproduction in whole or in part.

ST-030_EN.docx Index: 02 1/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

Connecting rod Big-end cap

Serial number =

matched pair number

Year of manufacture

Machine number

Fig. 01: Current pair numbers

EXAMPLES OF OLD INSCRIPTIONS:

a: Cracked connecting rods of Types 3 and 4 engines:

e.g. 8840E

Fig. 02: Old pair numbers on a blank, e.g. 8840E

b: Types 2 and 6 engines and connecting rods of older designs: the numbers are stamped on with punches.

e.g. S50

Fig. 03: Older pair numbers with stamped numerals, e.g. S50

ST-030_EN.docx Index: 02 2/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

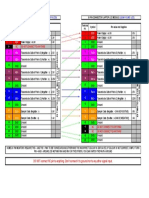

These serial numbers are not always visible from outside after the connecting rods have been fitted in the engine.

Connecting rods must therefore have the cylinder numbers marked on both

sides. Use an oil-resistant paint marker for this, and degrease the surfaces first.

If unmarked connecting rods are removed in the course of a service, the serial

numbers must also be compared and the connecting rods and big-end caps

that belong together marked with the cylinder number.

Fig. 03: Cylinder number applied on both sides with an oil-resistant paint marker

Fig. 04: Marking on the both sides of the connecting rod so that both connecting rods can be identified from the B side through the inspection hole

cover

On Type 6 engines, marking the short side of the big-end cap and connecting rod is sufficient (as there are

inspection hole covers on both sides of the engine).

ST-030_EN.docx Index: 02 3/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

2 Unbolting and refitting the big-end cap

The big-end cap can now be unbolted.

Use protective jaws (aluminium or similar) when clamping the connecting rod in the

vice. Never clamp the connecting rod shank without using protective jaws.

Fig. 05: Inscription

Any intermediate storage of connecting rods and big-end caps must always ensure that the cracked surface cannot

be damaged.

After the connecting rods have all been fitted, check the cylinder numbers again and enter them in the assembly

check list together with their associated serial numbers. Keep the check list with the assembly report after it has been

filled in. One copy should remain on site.

Check-lists are attached with the bulletin, or can be downloaded at any time.

Cracked connecting rods: When paired correctly with the matching cracked

surface, the parting joint is visible as a smooth line.

Fig. 06: Cracked connecting rod with a smooth line

ST-030_EN.docx Index: 02 4/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

Fitting the bearing shell in the connecting rod:

When placing the bearing shell in position, make sure that its locating lip is seated in the middle of the

groove in the connecting rod. Push the bearing shell evenly into the correct position to achieve this.

Fig. 07: Locating lip of the bearing located in the middle of the groove in the connecting rod

Then check the final position of the installed bearing:

Check that the edges of the bearing are parallel with the outer edges of the connecting rod. This ensures that the

bearing shell is not seated with any offset (twisted). The maximum permissible twist according to the drawing is

0.5 mm.

Fig. 08: Twist must not be greater than 0.5 mm

ST-030_EN.docx Index: 02 5/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

3 General information:

Transporting cracked connecting rods:

Cracked connecting rods may only be transported in the assembled condition, i.e. with the matching big-end cap

fitted and the big-end bolts tightened to at least 100 Nm. This prevents any relative motion between the connecting

rod and big-end cap, thereby avoiding any damage to the crack surface.

Note: There is no point in tightening the bolts to the full torque - this only makes it difficult to undo them.

The crack surface must not exhibit any damage. An incorrectly-

fitted big-end cap and its associated connecting rod and bearing

must not be used any more.

Fig. 09: Undamaged connecting rod crack surface

Torques:

The torques for tightening the big-end bolts are set out in the respective Technical Instructions. These are:

for Types 2 and 3 engines..............TA 1902-0212

for Type 4 engines .............................TA 1902-0213

for Type 6-C engines.........................TA 1902-0228C

for Type 6-E/F engines.....................TA 1902-0228E/F

for Type 6-G/H engines ...................TA 1902-0228G/H

Big-end bolts

Big-end bolts from different manufacturers must not be mixed on the same connecting rod.

e.g.: B.B

Fig. 10: Big-end bolt from B.B

ST-030_EN.docx Index: 02 6/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

SERVICE TECHNICIAN INSTRUCTION ST-030

Correct installation and handling of connecting rods

---

RELEVANT DOCUMENTS

All the relevant instructions are part of the plant documentation handed over to every customer on delivery of an

engine. The latest versions of documents referred to here can be downloaded from the Jenbacher web portal

at http://information.jenbacher.com under the heading "Technical Knowledge Base".

• Technical Instruction TA 1902-0212, Screwing and tightening torques for Types 2 and 3 engines

• Technical Instruction TA 1902-0213, Screwing and tightening torques for Type 4 engines

• Technical Instruction TA 1902-0228C, Screwing and tightening torques for Type J6..GS-C engines

• Technical Instruction TA 1902-0228E/F, Screwing and tightening torques for Type J6..GS-E/F engines

• Technical Instruction TA 1902-0228G/H, Screwing and tightening torques for Type J624-G/H engines

REVISION CODE

INDEX DATE DESCRIPTION / REVISION SUMMARY

02 May 13, 2014 Basic revision

01 Jul. 28, 2005 First version of this document

Table 01: Revision history

ST-030_EN.docx Index: 02 7/7

GE PROPRIETARY INFORMATION – CLASS III (CONFIDENTIAL) UNCONTROLLED WHEN PRINTED OR TRANSMITTED ELECTRONICALLY

Use or disclosure of data contained on this sheet is subject to the restrictions on the cover or on the first page.

You might also like

- ST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFDocument5 pagesST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFPopa MihaiNo ratings yet

- Jenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2Document4 pagesJenbacher: 1. Power Shift Diagrams Type 6 Engines in Compliance With ISO 8528, Part 5: - 2ArîfNo ratings yet

- ST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFDocument5 pagesST-135 Steel Pistons, Cylinder Liners, Scraper Rings, Cylinder Head Gaskets PDFPopa MihaiNo ratings yet

- How Nokia Failed to Adapt to Market ChangesDocument5 pagesHow Nokia Failed to Adapt to Market ChangesRiangelli ExcondeNo ratings yet

- Cylinder Head: Maintenance InstructionDocument12 pagesCylinder Head: Maintenance InstructionReny NapitupuluNo ratings yet

- X20CM0985 1 Eng - V1.42Document72 pagesX20CM0985 1 Eng - V1.42rushaNo ratings yet

- Technical Instruction No.: Isolated operation - generalDocument10 pagesTechnical Instruction No.: Isolated operation - generalArîf100% (1)

- Jenbacher 1902-0228E Technical Instruction Screwing TorqueDocument6 pagesJenbacher 1902-0228E Technical Instruction Screwing TorqueArîf100% (2)

- J420V06 enDocument4 pagesJ420V06 enMarianoNo ratings yet

- Service Technician Instruction: Dia - Ne Xt4 HmiDocument7 pagesService Technician Instruction: Dia - Ne Xt4 HmiAhad Khalil100% (3)

- Gas MixerDocument38 pagesGas Mixershahzad67% (3)

- Jenbacher Technical Instruction General ConditionsDocument4 pagesJenbacher Technical Instruction General ConditionsArîf100% (1)

- Jenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsDocument4 pagesJenbacher JMS 616 GS-N.L Natural Gas Module Technical SpecsMartin KratkyNo ratings yet

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocument13 pages208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNo ratings yet

- TA 1499-0300 Masurari Si Setari LEANOX PDFDocument12 pagesTA 1499-0300 Masurari Si Setari LEANOX PDFPopa MihaiNo ratings yet

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocument13 pages208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNo ratings yet

- 208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSDocument13 pages208 - 1 - 1 Production Line 2009 208 - 1 - 3: Spare Parts For Preventive Maintenance J 208 GSPopa MihaiNo ratings yet

- ST-030 Correct Installation and Handling of Connecting Rods PDFDocument7 pagesST-030 Correct Installation and Handling of Connecting Rods PDFPopa MihaiNo ratings yet

- GE Power Retrofitting Sensor Modules to Improve Engine MonitoringDocument38 pagesGE Power Retrofitting Sensor Modules to Improve Engine MonitoringPopa MihaiNo ratings yet

- ST-124 New Gear Train PDFDocument21 pagesST-124 New Gear Train PDFPopa MihaiNo ratings yet

- GE Power & Water Gear Train InspectionDocument5 pagesGE Power & Water Gear Train InspectionPopa MihaiNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- TA 1400-0100 Procedura de Rodaj A Motoarelor (TIMPI) PDFDocument10 pagesTA 1400-0100 Procedura de Rodaj A Motoarelor (TIMPI) PDFPopa MihaiNo ratings yet

- 1 X Jgs 420-Bl-BopDocument25 pages1 X Jgs 420-Bl-Bophaji atinNo ratings yet

- GE Type 3 Technical Instructions 07-30-2012 - Isolated OperationDocument224 pagesGE Type 3 Technical Instructions 07-30-2012 - Isolated OperationSerg MarushkoNo ratings yet

- Extended DIA - Ne XT - AccessDocument2 pagesExtended DIA - Ne XT - Accesslaiquz zaman33% (3)

- Service Bulletin: GE PowerDocument4 pagesService Bulletin: GE PowerPopa Mihai100% (1)

- Jenbacher: 1. Ignition System: - 1Document2 pagesJenbacher: 1. Ignition System: - 1ArîfNo ratings yet

- Schaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Document249 pagesSchaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Muhammad Mujtaba TariqNo ratings yet

- GE - 200802 - Technical Specs Jenbacher Type 6 PDFDocument2 pagesGE - 200802 - Technical Specs Jenbacher Type 6 PDFsakthivelNo ratings yet

- GE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLDocument24 pagesGE Type 3 TECHNICAL SPECIFICATION OF THE CONTROLSerg MarushkoNo ratings yet

- Jenbacher: 1100-0110 Boundary Conditions For GE Jenbacher Gas EnginesDocument12 pagesJenbacher: 1100-0110 Boundary Conditions For GE Jenbacher Gas EnginesArîfNo ratings yet

- Jenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Document14 pagesJenbacher: 1. Key To Module Diagrams and Technical Schema: - 1Jamil Ahmed100% (1)

- 320Document61 pages320Rashid Mahmood JaatNo ratings yet

- PT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345Document369 pagesPT Indah Jaya II + III: 2 X JMS 620 GS-N.L J C345SaasiNo ratings yet

- t600 Coupe (1) CompressedDocument294 pagest600 Coupe (1) CompressedAmin MombiniNo ratings yet

- Stand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsDocument1 pageStand-By Aggregate Deutz MWM TBG 616 V12: Technical DetailsKamieshiNo ratings yet

- Jenbacher 1.946kW Biogas Engine Module Technical SpecsDocument4 pagesJenbacher 1.946kW Biogas Engine Module Technical SpecsMartin KratkyNo ratings yet

- JGS 420 B05 - 1500 KW (Nox - 500)Document11 pagesJGS 420 B05 - 1500 KW (Nox - 500)Ibrahim Ahmed FarrukhNo ratings yet

- 624 JGS-NL-electric Wiring Diagram PDFDocument617 pages624 JGS-NL-electric Wiring Diagram PDFPopa MihaiNo ratings yet

- ST-156 Compatibility Between DIA - NE WIN and DIA - NE XT PDFDocument6 pagesST-156 Compatibility Between DIA - NE WIN and DIA - NE XT PDFPopa MihaiNo ratings yet

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDocument2 pagesReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNo ratings yet

- Diane WinDocument15 pagesDiane Winimranbseee100% (2)

- (PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressDocument5 pages(PDF) Maintenance Schedule For Gas Genset - GE JENBACHER - CompressArie AozNo ratings yet

- ST-108 Lenox Seting PDFDocument4 pagesST-108 Lenox Seting PDFPopa MihaiNo ratings yet

- Especificação Técnica - TD 20729-0Document39 pagesEspecificação Técnica - TD 20729-0Geovane FonsecNo ratings yet

- TTEM AGS CG170 Cg260 MWM CATERPILLARDocument51 pagesTTEM AGS CG170 Cg260 MWM CATERPILLARR TONYNo ratings yet

- Amjad Textile JH827 - 2196246 - 258Document279 pagesAmjad Textile JH827 - 2196246 - 258Shahzad AhmadNo ratings yet

- Expt 6 The Split Phase MotorDocument4 pagesExpt 6 The Split Phase MotorCapalar KyleNo ratings yet

- Iil C249Document206 pagesIil C249Khalid RafiqNo ratings yet

- Instructions On Nox Measurements and Leanox Settings: Technical InstructionDocument16 pagesInstructions On Nox Measurements and Leanox Settings: Technical InstructionAli QaziNo ratings yet

- DEUTZ Gas Engine Limit - Oil AnalysisDocument13 pagesDEUTZ Gas Engine Limit - Oil Analysisgilar herliana putraNo ratings yet

- JMS 612 GS-N.L: Jenbacher Gas EnginesDocument4 pagesJMS 612 GS-N.L: Jenbacher Gas EngineshadNo ratings yet

- PandarosDocument9 pagesPandarosTempest_LNo ratings yet

- JMS 320 GS-B.L: Jenbacher Gas EnginesDocument4 pagesJMS 320 GS-B.L: Jenbacher Gas EnginesSergioNo ratings yet

- Fuel SystemDocument1 pageFuel SystemJamil Ahmed100% (1)

- 0006 Maintenance Schedule TCG2020K PDFDocument8 pages0006 Maintenance Schedule TCG2020K PDFMd Iqbal HossainNo ratings yet

- 1400-0100 enDocument3 pages1400-0100 enKopi BrisbaneNo ratings yet

- Tecjet™ 110 Gas Regulation and Metering Valve / Actuator SystemDocument54 pagesTecjet™ 110 Gas Regulation and Metering Valve / Actuator SystemAnonymous LfeGI2hMNo ratings yet

- MWM TCG2032 Tem I/o CG260Document61 pagesMWM TCG2032 Tem I/o CG260R TONYNo ratings yet

- Jenbacher: 5.1.1 DescriptionDocument12 pagesJenbacher: 5.1.1 DescriptionJamil Ahmed100% (1)

- TBG616K PDFDocument4 pagesTBG616K PDFTyler GoodwinNo ratings yet

- GE Power Service Technician Instruction for Jenbacher Engine Gear Train InspectionDocument6 pagesGE Power Service Technician Instruction for Jenbacher Engine Gear Train InspectionPopa MihaiNo ratings yet

- ST-117 Gear Train Inspection PDFDocument6 pagesST-117 Gear Train Inspection PDFPopa MihaiNo ratings yet

- AMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationDocument9 pagesAMPSEAL Automotive Plug Connector and Header Assembly: Application SpecificationАндрей9No ratings yet

- 15Lb Countertop Electric Fryer: Owners ManualDocument16 pages15Lb Countertop Electric Fryer: Owners ManualPollaxo TrcNo ratings yet

- W 2100m0 - Revision PDFDocument6 pagesW 2100m0 - Revision PDFPopa MihaiNo ratings yet

- TA 1100-0111 Operare Si Intretinere PDFDocument12 pagesTA 1100-0111 Operare Si Intretinere PDFPopa MihaiNo ratings yet

- W 8050m6 - Crankshaft Main Bearings PDFDocument6 pagesW 8050m6 - Crankshaft Main Bearings PDFPopa MihaiNo ratings yet

- TA 1531-0001 Instalarea Convectorului Catalitic Si Al Sondei Lambda PDFDocument6 pagesTA 1531-0001 Instalarea Convectorului Catalitic Si Al Sondei Lambda PDFPopa MihaiNo ratings yet

- W 0200m0 - Control Rod Assembly Throttle Valveactuator PDFDocument6 pagesW 0200m0 - Control Rod Assembly Throttle Valveactuator PDFPopa MihaiNo ratings yet

- W 0200m6 - Control Rod Assembly Throttle Valveactuator PDFDocument6 pagesW 0200m6 - Control Rod Assembly Throttle Valveactuator PDFPopa MihaiNo ratings yet

- Ta 1400-0154 KLS98 PDFDocument19 pagesTa 1400-0154 KLS98 PDFPopa Mihai100% (1)

- W 8023m0 - Exhaust Gas Turbocharger PDFDocument6 pagesW 8023m0 - Exhaust Gas Turbocharger PDFPopa MihaiNo ratings yet

- W 8023m6h - Exhaust Gas Turbocharger PDFDocument4 pagesW 8023m6h - Exhaust Gas Turbocharger PDFPopa MihaiNo ratings yet

- Managing Jenbacher Gas Engines Service ManualDocument1 pageManaging Jenbacher Gas Engines Service ManualPopa MihaiNo ratings yet

- Managing Jenbacher Gas Engines Service ManualDocument1 pageManaging Jenbacher Gas Engines Service ManualPopa MihaiNo ratings yet

- TA 1100-0111 Operare Si Intretinere PDFDocument12 pagesTA 1100-0111 Operare Si Intretinere PDFPopa MihaiNo ratings yet

- ST-156 Compatibility Between DIA - NE WIN and DIA - NE XT PDFDocument6 pagesST-156 Compatibility Between DIA - NE WIN and DIA - NE XT PDFPopa MihaiNo ratings yet

- ST-149 Connecting Rod and Bearing PDFDocument5 pagesST-149 Connecting Rod and Bearing PDFPopa MihaiNo ratings yet

- ST-117 Gear Train Inspection PDFDocument6 pagesST-117 Gear Train Inspection PDFPopa MihaiNo ratings yet

- ST-138 Crankcase Ventilation PDFDocument32 pagesST-138 Crankcase Ventilation PDFPopa MihaiNo ratings yet

- ST-153 Oil, Oil Filter and Blow-By Filter Lifetime, Oil Consumption, Knocking Events PDFDocument4 pagesST-153 Oil, Oil Filter and Blow-By Filter Lifetime, Oil Consumption, Knocking Events PDFPopa MihaiNo ratings yet

- GE Power Service Technician Instruction for Jenbacher Engine Gear Train InspectionDocument6 pagesGE Power Service Technician Instruction for Jenbacher Engine Gear Train InspectionPopa MihaiNo ratings yet

- ST-108 Lenox Seting PDFDocument4 pagesST-108 Lenox Seting PDFPopa MihaiNo ratings yet

- Understanding The American Education SystemDocument6 pagesUnderstanding The American Education SystemCastor JavierNo ratings yet

- HACCP Plan With Flow Chart-1Document23 pagesHACCP Plan With Flow Chart-1Anonymous aZA07k8TXfNo ratings yet

- Differendial Pressure Flow MetersDocument1 pageDifferendial Pressure Flow Metersborn2engineerNo ratings yet

- 11 - Surrogate Constraints 1968Document9 pages11 - Surrogate Constraints 1968asistensi pakNo ratings yet

- SDA HLD Template v1.3Document49 pagesSDA HLD Template v1.3Samuel TesfayeNo ratings yet

- Supreme Court upholds return of unrepaired truckDocument35 pagesSupreme Court upholds return of unrepaired truckJeffreyReyesNo ratings yet

- LCD PinoutsDocument1 pageLCD PinoutsPablo Daniel MagallanNo ratings yet

- Joint Ventures Synergies and BenefitsDocument5 pagesJoint Ventures Synergies and BenefitsleeashleeNo ratings yet

- Instruction Manual For Spider S3 and Spider S4Document6 pagesInstruction Manual For Spider S3 and Spider S4Syah KamalNo ratings yet

- Log-PASSAT IMMO-WVWZZZ3CZ7E064873-266870km-165825miDocument13 pagesLog-PASSAT IMMO-WVWZZZ3CZ7E064873-266870km-165825miMihalciuc AlexandruNo ratings yet

- Land Sale Dispute Interest Rate CaseDocument3 pagesLand Sale Dispute Interest Rate CaseAnne MiguelNo ratings yet

- Court Invalidates Mortgage Due to Bank's Lack of DiligenceDocument10 pagesCourt Invalidates Mortgage Due to Bank's Lack of DiligenceTokie TokiNo ratings yet

- Instrument Landing SystemDocument35 pagesInstrument Landing SystemDena EugenioNo ratings yet

- Hospital Management System Synopsis and Project ReportDocument152 pagesHospital Management System Synopsis and Project ReportKapil Vermani100% (1)

- Supreme Court: Arsenio C. Villalon, Jr. For Petitioner. Labaguis, Loyola, Angara & Associates For Private RespondentDocument43 pagesSupreme Court: Arsenio C. Villalon, Jr. For Petitioner. Labaguis, Loyola, Angara & Associates For Private RespondentpiaNo ratings yet

- Normalization Castuera BSCS2CDocument8 pagesNormalization Castuera BSCS2CRichard, Jr. CastueraNo ratings yet

- Assignment 2Document21 pagesAssignment 2api-445531772No ratings yet

- Upliftment of Recto AveDocument6 pagesUpliftment of Recto AveFrance CortezanoNo ratings yet

- Three Wire MethodDocument4 pagesThree Wire MethodmaivizhiNo ratings yet

- Analysis and Design of BeamsDocument12 pagesAnalysis and Design of BeamsHasanain AlmusawiNo ratings yet

- C++ Module 2Document58 pagesC++ Module 2Kaye CariñoNo ratings yet

- Importance of Social Administration for Social WorkersDocument7 pagesImportance of Social Administration for Social Workersanderson mahundiNo ratings yet

- Solucionario Capitulo 1 Gruber Porque Estudiamos Finanzas PublicasDocument5 pagesSolucionario Capitulo 1 Gruber Porque Estudiamos Finanzas PublicasDemetrio Pardo HerreraNo ratings yet

- Electricity Began With Man's Curiosity On The Peculiar Ability of Amber and Lodestone To Attract Other Material.Document2 pagesElectricity Began With Man's Curiosity On The Peculiar Ability of Amber and Lodestone To Attract Other Material.Axle Rose CastroNo ratings yet

- Russian Federation Country Codes from World Development IndicatorsDocument262 pagesRussian Federation Country Codes from World Development IndicatorsMuhammad Talha TalhaNo ratings yet

- Fnce 220: Business Finance: Lecture 6: Capital Investment DecisionsDocument39 pagesFnce 220: Business Finance: Lecture 6: Capital Investment DecisionsVincent KamemiaNo ratings yet

- CPAR Summary - WK 144Document6 pagesCPAR Summary - WK 144NagarajNo ratings yet

- The Sssessential List of Microsoft Outlook Keyboard ShortcutsDocument3 pagesThe Sssessential List of Microsoft Outlook Keyboard Shortcutsabidaliabid1No ratings yet

- Nimt Institute of Method & Law, Greater Noida: "Legal Bases and Issues in Scrapping Article 370"Document12 pagesNimt Institute of Method & Law, Greater Noida: "Legal Bases and Issues in Scrapping Article 370"Preetish Sahu100% (1)