Professional Documents

Culture Documents

Enct. - : - Ref. 01..:.. '. MS Tot

Uploaded by

ninatenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enct. - : - Ref. 01..:.. '. MS Tot

Uploaded by

ninatenaCopyright:

Available Formats

Italian - Thai Development Public Company Limited Dhaka Mass Rapid Transit Development Project

Contract No. CP-03 & CP-04

Enct. ___2b;__ , Ref._!!!2fQt01..:..�'. MS fStot £!!1!?. -·

Italian-ThaisdWALFKJKSADLKQJFIWIJ The Engineer (NKDM)

Er;ckqcrxrwkkgoekgaf hREHyery Name: Mr.Hideo OMORI

Development PCL. (ITD) Name: Mr. Position: Team Leader

Pairoj Raknganchang Position: Signature:

Contractor's Representative Date:

Signature:

Status

□

Date:

Approved/ Notice of No Objection

□ Approved with Comments as below/ Notice No Objection with Comments "B" and/or "C"

□ No Objection I No Comments

□ Rejected with Comments as below and Resubmit/ Notice of Objection "A" Comments

Document No. Revision Page No.

ITD/CP03-04/MS/S 104 03 Date:20-May-20 1

Italian - Thai Development Public Company Limited Dhaka Mass Rapid Transit Development Project

Contract No. CP-03 & CP-04

wqrqw otp

oqwetpoq[eotafm'ksfkmakfmfegfdldKJFQWPTPOEIQPOVWQOVMOQWOTPIEWOYREo

yTest Type Method Frequency Acceptance Criteria Symbols Consequence

etet'hLFDLG;DSLLF'ASLFlld;glfkga;KCa.xXAFs GSD dssdf xcable 2- Inspection and Test Plan

Environmenta Ambient and Before start of each In accordance with W No blasting

l conditions steel shift and minimum specified requirements or coating

temperature, twice per shift

relative humidity,

Dew point by

Dew Point Meter

Visual Visual for sharp 100 of all No defects, see H Defects to

examination edges weld surface specified be repaired

spatter, slivers, requirements

rust grade etc

Cleanliness a ISO 8501-1 a) 100 visual all a) In accordance H a) Re-blasting

b ISO 8504-2 surfaces b) with specified b) Re-cleaning and

b) Spot checks requirements retesting until

c) Maximum quantity acceptable

& size is rating 2

Roughness Surface Each component In accordance with D Re-blasting

profile gauge or once per 10m2 specified paint system until

acceptable

Visual Visual to 100 of surface In accordance with H Repair of

examinatio determine after each coat specified requirements defects and

n curing, retesting

contamination,

solvent

retention,

pinholes popping

, sagging and

surface

defects

Wet film Comb Gauge Systematically In accordance with Repair or

thickness WFT during any specified paint system re- coating

application as

appropriate

Dry film SSPC-PA2 Each coat, when In accordance with H Repair or

thickness DFT Gauge coating system specified paint system re- coating

DFT are cured as

appropriate

Adhesion Pull ASTM D4541 For approval of As per standard H Coating to

- Off on test panel Paint System and be rejected

Application

Method

Cross Cut ASTM D3359 For approval of As per standard H Coating to

Tape Test Paint System and be rejected

Application

Method

Document No Revision Page No

ITD CP03-04 MS S 0 03 Date 20-May-20 22

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- Ibo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Document6 pagesIbo Pm9s Exe I19 99 Qac RPT 0006 - Rev. B (Amended)Gokhula KannanNo ratings yet

- MPP & Itt - Internal Epoxy PaintDocument12 pagesMPP & Itt - Internal Epoxy PaintSiswo YuwonoNo ratings yet

- Holiday Testing ProcedureDocument1 pageHoliday Testing ProcedureSyed Zakiuddin100% (2)

- Inspection and Test Plan For PC Sheet PileDocument5 pagesInspection and Test Plan For PC Sheet PileNgọc Đức Đoàn100% (2)

- Hes D2003-03 Electroplating - For Corrosion Prevention, RDocument15 pagesHes D2003-03 Electroplating - For Corrosion Prevention, RPreetam KumarNo ratings yet

- Hes D2003 05 Rev6Document15 pagesHes D2003 05 Rev6FABRICIO100% (1)

- Determining The Wear Volume On Standard Test Pieces Used by High-Frequency, Linear-Oscillation (SRV) Test MachineDocument5 pagesDetermining The Wear Volume On Standard Test Pieces Used by High-Frequency, Linear-Oscillation (SRV) Test MachineRayzha NoerfiqriNo ratings yet

- PEC-QU-ITR-X-11129 Rev-1, ITR-V-0501ADocument1 pagePEC-QU-ITR-X-11129 Rev-1, ITR-V-0501AMidhun K ChandraboseNo ratings yet

- Form Daily Report Painting (TOP COAT)Document2 pagesForm Daily Report Painting (TOP COAT)alifaliminNo ratings yet

- Bharat Heavy Electricals Limited, Tiruchirapalli Outsourcing Check List For Spot Visit - Blast Cleaning and PaintingDocument4 pagesBharat Heavy Electricals Limited, Tiruchirapalli Outsourcing Check List For Spot Visit - Blast Cleaning and PaintingThenna ArasuNo ratings yet

- UntitledDocument11 pagesUntitledRodrigo LeanosNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Gpti Qicl J931 Mut 002Document2 pagesGpti Qicl J931 Mut 002uselessinstaid52No ratings yet

- PT - Level 2 - S - 002 - Revised by RVMDocument4 pagesPT - Level 2 - S - 002 - Revised by RVMkingstonNo ratings yet

- Technical Delivery Rule: Painting ReportDocument2 pagesTechnical Delivery Rule: Painting Reporttomas budrysNo ratings yet

- 02 - Retaining Wall Confined WaterproofingDocument6 pages02 - Retaining Wall Confined Waterproofingannayya.chandrashekar Civil EngineerNo ratings yet

- Standard Specification For Plowable, Raised Retroreflective Pavement MarkersDocument9 pagesStandard Specification For Plowable, Raised Retroreflective Pavement MarkersAnonymous pJ2nP3rcNo ratings yet

- Aplicacion de PinturaDocument3 pagesAplicacion de PinturaJulio HuancaNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- Painting Inspection Report-534 - GALVACOATDocument1 pagePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNo ratings yet

- Astm D4505 - 05Document4 pagesAstm D4505 - 05Black GokuNo ratings yet

- Cs1 Rundown Aplicacion - VacioDocument3 pagesCs1 Rundown Aplicacion - VacioJulio HuancaNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- 28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDDocument7 pages28-29052022-Pull Off Test (Trial) - Pemb. Dermaga Terminal LPG Presurized Kupang (Piping) - PQT-Pertamina PN-NK-AMM-AKDudin cupuNo ratings yet

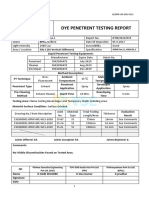

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MP100% (1)

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Corr-Con Inspection Services: Coating Procedure Test (CPT) ReportDocument4 pagesCorr-Con Inspection Services: Coating Procedure Test (CPT) ReportArun Prasad100% (1)

- Jotafloor EP SL Uni - Abrasion & Impact ResistDocument6 pagesJotafloor EP SL Uni - Abrasion & Impact Resistangelito bernalNo ratings yet

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- Weld Repair PipeDocument4 pagesWeld Repair PipeSc Tan100% (2)

- Dye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)Document2 pagesDye Penetrent Testing Report: Silo-1 (SS-Vertical Stiffeners)DIVEETH MPNo ratings yet

- TATA Painting Specification 43Document1 pageTATA Painting Specification 43Suleman KhanNo ratings yet

- Shic A 0008Document3 pagesShic A 000801095902062ahmedNo ratings yet

- BC MT 1688-0000Document84 pagesBC MT 1688-0000Tuấn ĐậuNo ratings yet

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- Rfi ExDocument4 pagesRfi ExÖmeralp SakNo ratings yet

- NDT-TEC-U115A Issue 1 Rev 0 UT Thickness Single Echo ModeDocument2 pagesNDT-TEC-U115A Issue 1 Rev 0 UT Thickness Single Echo ModekorichiNo ratings yet

- Paint Schedule HELIDECKDocument24 pagesPaint Schedule HELIDECKAsongwe HansNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Plant Building - Epoxy PaintDocument2 pagesPlant Building - Epoxy PaintNavaneethan NatarajanNo ratings yet

- Paint Technical Specification PDFDocument3 pagesPaint Technical Specification PDFMoon SzDarkness100% (1)

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Radiographic Examination of Piping Welds According To EN: IssueDocument6 pagesRadiographic Examination of Piping Welds According To EN: IssueEdAlmNo ratings yet

- K.P.Mondal & Sons: Quality Assurance PlanDocument1 pageK.P.Mondal & Sons: Quality Assurance PlanTanmoy DuttaNo ratings yet

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Painting Procedures ADocument7 pagesPainting Procedures AMaged Lotfy Abdel-aal100% (1)

- TRW 23925036 02Document9 pagesTRW 23925036 02Eddy GuerreroNo ratings yet

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Post Tensioning ManualDocument11 pagesPost Tensioning Manualimzee25100% (7)

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- API 579-1 - Fitness-For Service Assessment - Rev JMV 05-11-2018Document13 pagesAPI 579-1 - Fitness-For Service Assessment - Rev JMV 05-11-2018pelotoNo ratings yet

- Upvc Pipe Class DDocument4 pagesUpvc Pipe Class DnaagshreeNo ratings yet

- (Automated Voice) The NumberDocument21 pages(Automated Voice) The NumberninatenaNo ratings yet

- (Over Radio) Einar To Gríma. - (Over Radio) Gríma HereDocument26 pages(Over Radio) Einar To Gríma. - (Over Radio) Gríma HereninatenaNo ratings yet

- Gríma, You and Ása Ride Back With MeDocument20 pagesGríma, You and Ása Ride Back With MeninatenaNo ratings yet

- Katla S01E03 The Mother 1080p NF WEB-DL SDHDocument22 pagesKatla S01E03 The Mother 1080p NF WEB-DL SDHninatenaNo ratings yet

- Om Under The Glacier 1080p NF WEB-DL SDHDocument23 pagesOm Under The Glacier 1080p NF WEB-DL SDHninatenaNo ratings yet

- Welding Processes and ProceduresDocument6 pagesWelding Processes and ProceduresninatenaNo ratings yet

- Aws D1.1/D1.1M:2015Document6 pagesAws D1.1/D1.1M:2015ninatenaNo ratings yet

- B: - (R T) × B - B: B: - (R T) × B - BDocument2 pagesB: - (R T) × B - B: B: - (R T) × B - BninatenaNo ratings yet

- Stell 2011specificDocument7 pagesStell 2011specificninatenaNo ratings yet

- TTBDocument1 pageTTBninatenaNo ratings yet

- But I Guess I Missed All The FunDocument2 pagesBut I Guess I Missed All The FunninatenaNo ratings yet

- But I Guess I Missed All The FunDocument2 pagesBut I Guess I Missed All The FunninatenaNo ratings yet

- Ksfkds LGK:DSKG LGK FLG DGKSDG Kf:Laskl:Fkjhpthw (G Lgkwe'Gj'EgsdgldsDocument2 pagesKsfkds LGK:DSKG LGK FLG DGKSDG Kf:Laskl:Fkjhpthw (G Lgkwe'Gj'EgsdgldsninatenaNo ratings yet

- Transmittal NutDocument2 pagesTransmittal NutninatenaNo ratings yet

- L KDVLCK GDSK Glkopddfpijoho (TRRT RWRLWQKR KW:LRWDocument2 pagesL KDVLCK GDSK Glkopddfpijoho (TRRT RWRLWQKR KW:LRWninatenaNo ratings yet

- Qeqeqrtrw5 PCS, Ba DKJFQJWKJRKWJRJJR CQWQJLJFJKFJKXFH KjwhfjheqkfwfwkjlejqrkDocument2 pagesQeqeqrtrw5 PCS, Ba DKJFQJWKJRKWJRJJR CQWQJLJFJKFJKXFH KjwhfjheqkfwfwkjlejqrkninatenaNo ratings yet

- Mateaq11235V2Bbrials: Sl. WQQQQQQQQ Materials Qqqwetwetgsd W352v33r Wuiuo Etty 7745nldrdyrzdyriogDocument1 pageMateaq11235V2Bbrials: Sl. WQQQQQQQQ Materials Qqqwetwetgsd W352v33r Wuiuo Etty 7745nldrdyrzdyriogninatenaNo ratings yet

- Elklke TK Epl ZLK Fdhar (Eahprepoay Oskp Yvy Yvsjttt: Sl. Ryq4Lklk:Gk Ek TK Oetw Tegswe2R24Cd Materials Grade OriginDocument1 pageElklke TK Epl ZLK Fdhar (Eahprepoay Oskp Yvy Yvsjttt: Sl. Ryq4Lklk:Gk Ek TK Oetw Tegswe2R24Cd Materials Grade OriginninatenaNo ratings yet

- 30 Risk and InsuranceDocument4 pages30 Risk and InsuranceSiti Nur Ain RamliNo ratings yet

- Technology For Duck - Fish Integrated Farming System in GoaDocument4 pagesTechnology For Duck - Fish Integrated Farming System in GoagavinilaaNo ratings yet

- T HR El 20003 ST PDFDocument20 pagesT HR El 20003 ST PDFAngling Dharma100% (1)

- Enable Modern Authentication in Exchange OnlineDocument2 pagesEnable Modern Authentication in Exchange Onlinedan.artimon2791No ratings yet

- Adolescents and Career DevelopmentDocument10 pagesAdolescents and Career DevelopmentMasrijah MasirNo ratings yet

- Cruiziat Et Al. 2002Document30 pagesCruiziat Et Al. 2002Juan David TurriagoNo ratings yet

- Motor BookDocument252 pagesMotor BookKyaw KhNo ratings yet

- High School Physics Rutherford Atom Lesson 27Document4 pagesHigh School Physics Rutherford Atom Lesson 27John JohnsonNo ratings yet

- The English We SpeakDocument2 pagesThe English We Speakcaeronmustai100% (1)

- Veerasaiva Pantha in 12th Century MaharashtraDocument2 pagesVeerasaiva Pantha in 12th Century MaharashtrarathkiraniNo ratings yet

- House Staff OrderDocument2 pagesHouse Staff OrderTarikNo ratings yet

- High School Department PAASCU Accredited Academic Year 2017 - 2018Document6 pagesHigh School Department PAASCU Accredited Academic Year 2017 - 2018Kevin T. OnaroNo ratings yet

- Cascade Configuration Tool: Installation and Operations ManualDocument22 pagesCascade Configuration Tool: Installation and Operations ManualAndrés GarciaNo ratings yet

- British Airways Culture and StructureDocument29 pagesBritish Airways Culture and Structure陆奕敏No ratings yet

- Ip TunnelingDocument15 pagesIp TunnelingBon Tran HongNo ratings yet

- Citadel Securities Australia Pty LTD - Company DetailsDocument5 pagesCitadel Securities Australia Pty LTD - Company DetailsBrendan OswaldNo ratings yet

- BAB 3 - Follow UpDocument6 pagesBAB 3 - Follow UpDelinda Erutheya NathanNo ratings yet

- Happiest Refugee Coursework 2013Document10 pagesHappiest Refugee Coursework 2013malcrowe100% (2)

- Grand Chapter Mentor ProgramDocument13 pagesGrand Chapter Mentor ProgramJulius Wright100% (1)

- Understanding PumpDocument113 pagesUnderstanding Pumpnyr1981_942955963100% (5)

- Cause List 2.1.2023Document4 pagesCause List 2.1.2023あいうえおかきくけこNo ratings yet

- Test Bank For Body Structures and Functions 11th Edition Ann ScottDocument27 pagesTest Bank For Body Structures and Functions 11th Edition Ann Scottpellucidutter.uka6lr100% (38)

- Lay Planning TypesDocument1 pageLay Planning TypesGaurav Shakya100% (1)

- Safe Motherhood Ao2016-0035 Quality Antenatal Care PDFDocument9 pagesSafe Motherhood Ao2016-0035 Quality Antenatal Care PDFGa B B OrlonganNo ratings yet

- Bulletin - February 12, 2012Document14 pagesBulletin - February 12, 2012ppranckeNo ratings yet

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Document296 pagesBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatNo ratings yet

- Assignment On Unstable or Astatic Gravimeters and Marine Gravity SurveyDocument9 pagesAssignment On Unstable or Astatic Gravimeters and Marine Gravity Surveyraian islam100% (1)

- How To Spend An Hour A Day in Prayer - Matthew 26:40-41Document1 pageHow To Spend An Hour A Day in Prayer - Matthew 26:40-41Steve GainesNo ratings yet

- Beyond The Breech Trial. Maggie BanksDocument4 pagesBeyond The Breech Trial. Maggie Bankspurpleanvil100% (2)

- Ruby Onyinyechi Amanze - Werte Magazine - 2019Document2 pagesRuby Onyinyechi Amanze - Werte Magazine - 2019José LaertonNo ratings yet