Professional Documents

Culture Documents

SAES-Q-010 & 011 (Non-Shrink and Epoxy Grout)

Uploaded by

Nino Celso AstilleroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAES-Q-010 & 011 (Non-Shrink and Epoxy Grout)

Uploaded by

Nino Celso AstilleroCopyright:

Available Formats

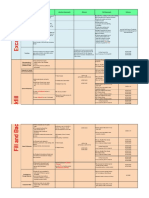

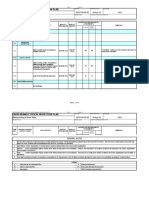

SAES-Q-010 (Cement-Based, Non-Shrink Grout for Structural and Equipment Grouting)

4. Modification to Process Industry Practice STS03600

> Minimum 28 days compressive strength shall be 34.5 MPa (5,000 psi)

> Cementitious grout minimum 28 days compressive strength shall be 13.8 MPa (2,000 psi) and shall

be used for any of the following:

•Structural Base Plate

•Anchor Bolts

•Columns and Precast Members

> Total Dissolved Solids (TDS) 500 parts per million (ppm)

> Testing

•Two (2) sets of three (3) test cubes in the field

•Curing cubes in the field for 3 days

•Test one (1) cube for 7 days and one (1) cube for 28 days

SAES-Q-011 (Epoxy Grout for Machinery Support)

4. Modification to Process Industry Practice STS03601

> All components, resin, hardener, and aggregate shall be properly labeled, including batch numbers,

shelf life and storage requirements

> Grout shall be applied only when surrounding temperatures are between 15C a n d 32C unless

otherwise specified in the manufacturer's data sheets

> Expansion joints should be placed at approximately 1.2 m to 1.8 m intervals in the grout foundation

> A layered combination of non-shrink cement and epoxy grout may be used, as permitted

by SAES-Q-007 for large baseplates that have structural webs deeper than 230 mm

> If the grout pour is 100 mm or deeper, the grout manufacturer recommendations for installing

reinforcement rebars shall be followed.

> Testing

•Minimum sample frequency is one per shipment or per manufacturing lot of grout.

•Compressive strength and Linear Shrinkage

> Minimum Compressive Strength 80 Mpa (12,000 psi) at 7 days

> Maximum Linear Shrinkage : 0.080 percent

> Minimum Bond Strength of Epoxy Grout to concrete - 2,000 psi (14Mpa)

You might also like

- 09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsDocument4 pages09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsFiras AlbaweiNo ratings yet

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDocument2 pagesSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNo ratings yet

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDocument2 pagesSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNo ratings yet

- Saic-Q-1035 Sub-Base & Base CourseDocument5 pagesSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNo ratings yet

- SAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionDocument8 pagesSAIC-Q-1041 Asphalt Pavement Prime Coat & Tack Coating InspectionAbdul HannanNo ratings yet

- 09 Samss 088Document4 pages09 Samss 088Moustafa BayoumiNo ratings yet

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Document5 pagesSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- SAES-B-069 Editorial Revision (10-28-2021)Document11 pagesSAES-B-069 Editorial Revision (10-28-2021)Daniel Meana100% (1)

- Aramco Civil ReviewerDocument10 pagesAramco Civil ReviewerTayyab AchakzaiNo ratings yet

- Precast Concrete Design and Construction RequirementsDocument5 pagesPrecast Concrete Design and Construction RequirementsNino Celso Astillero100% (2)

- Precast Concrete Design and Construction RequirementsDocument5 pagesPrecast Concrete Design and Construction RequirementsNino Celso Astillero100% (2)

- SAES-A-114 (Excavation and Backfill)Document4 pagesSAES-A-114 (Excavation and Backfill)Nino Celso AstilleroNo ratings yet

- SAES-A-114 (Excavation and Backfill)Document4 pagesSAES-A-114 (Excavation and Backfill)Nino Celso AstilleroNo ratings yet

- SAES-A-114 (Excavation and Backfill)Document4 pagesSAES-A-114 (Excavation and Backfill)Nino Celso AstilleroNo ratings yet

- Aggregates and Concrete SpecificationsDocument2 pagesAggregates and Concrete SpecificationsNino Celso AstilleroNo ratings yet

- Aggregates and Concrete SpecificationsDocument2 pagesAggregates and Concrete SpecificationsNino Celso AstilleroNo ratings yet

- Aggregates and Concrete SpecificationsDocument2 pagesAggregates and Concrete SpecificationsNino Celso AstilleroNo ratings yet

- 175 000003Document1 page175 000003zhangNo ratings yet

- QC CIVIL VOL 2 SS 7aevfrDocument26 pagesQC CIVIL VOL 2 SS 7aevfrSudhanNo ratings yet

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Document2 pagesSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Document2 pagesSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Document2 pagesSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- Saes A 114Document2 pagesSaes A 114Nino Celso AstilleroNo ratings yet

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Document7 pages1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNo ratings yet

- Concrete Industry Codes and StandardsDocument5 pagesConcrete Industry Codes and Standardsmohd khajaNo ratings yet

- Civil Engineering Technical Question and AnswersDocument15 pagesCivil Engineering Technical Question and AnswersSudhan100% (1)

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet

- SAES-Q-005 (Concrete Foundations)Document1 pageSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroNo ratings yet

- SAES-Q-005 (Concrete Foundations)Document1 pageSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroNo ratings yet

- SAES-Q-005 (Concrete Foundations)Document1 pageSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroNo ratings yet

- Saes Q 001 Saes-Q-006Document5 pagesSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Concrete Works Inspection & TestingDocument9 pagesConcrete Works Inspection & Testingkbldam100% (2)

- QC Inspector Written Test AnswersDocument40 pagesQC Inspector Written Test Answersmohd khajaNo ratings yet

- PIP STS03601 Epoxy GroutDocument8 pagesPIP STS03601 Epoxy GroutSandip SurNo ratings yet

- Process Industry Practice PIP - Structural Nonshrink Cementitious Grout SpecificationDocument10 pagesProcess Industry Practice PIP - Structural Nonshrink Cementitious Grout SpecificationFachreza AkbarNo ratings yet

- SABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteDocument26 pagesSABP-Q-010 Mix Design and Construction of Sulfur Extended Asphalt ConcreteMr. Moses Imagoro100% (1)

- SAES-Q-010 & 011 (Non-Shrink and Epoxy Grout)Document1 pageSAES-Q-010 & 011 (Non-Shrink and Epoxy Grout)Nino Celso Astillero100% (1)

- Back FillDocument3 pagesBack Fillcevhos100% (1)

- Saudi Aramco Precast Concrete Installation PlanDocument10 pagesSaudi Aramco Precast Concrete Installation PlanNaushad AlamNo ratings yet

- SAES-Q-010 Cement Based, Non-Shrink Grout PDFDocument4 pagesSAES-Q-010 Cement Based, Non-Shrink Grout PDFWaqar Ahmed100% (1)

- Concrete Batch PlantDocument7 pagesConcrete Batch Plantراجہ شہزاد انورNo ratings yet

- Saes Q 001Document22 pagesSaes Q 001irfan hussainNo ratings yet

- South Ghawar Project Inspection Unit (SGPIU) Test For QC Inspector (Earthwork/Paving)Document4 pagesSouth Ghawar Project Inspection Unit (SGPIU) Test For QC Inspector (Earthwork/Paving)Khurram ShehzadNo ratings yet

- Qaqc Inspector QuestionaireDocument4 pagesQaqc Inspector QuestionaireNiño Celso AstilleroNo ratings yet

- Saudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilSatheesh Rama SamyNo ratings yet

- Saes A 204Document22 pagesSaes A 204محمد العيسوى100% (2)

- Home Interior Exterior - Civil Inspector Interview Question and AnswerDocument5 pagesHome Interior Exterior - Civil Inspector Interview Question and AnswerZeeshanAliNo ratings yet

- Saic Q 1014Document2 pagesSaic Q 1014Hussain Nasser Al- NowiesserNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistAbdul Hannan100% (1)

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilDocument11 pagesSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadNo ratings yet

- Saep 119Document11 pagesSaep 119Demac SaudNo ratings yet

- Saudi Aramco Concrete Coating ProcedureDocument10 pagesSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- 02225Document6 pages02225uddinnadeemNo ratings yet

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDocument2 pagesSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanNo ratings yet

- Saudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CDocument3 pagesSaudi Aramco Inspection Checklist: Cast-In-Place Concrete Formwork Stripping Inspection SAIC Q-1016 15-Nov-17 MAH-SA-CAbdul HannanNo ratings yet

- Saes A 114Document26 pagesSaes A 114abaanNo ratings yet

- Satip M 100 07Document10 pagesSatip M 100 07munnaNo ratings yet

- Saudi Aramco piping inspection checklistDocument3 pagesSaudi Aramco piping inspection checklistEswari AnandNo ratings yet

- SAES Q 001 Table ExposureDocument4 pagesSAES Q 001 Table ExposureKhurram ShehzadNo ratings yet

- 5-Notes For Building Related Activities-2Document9 pages5-Notes For Building Related Activities-2Eshaal NoreenNo ratings yet

- SAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTDocument5 pagesSAUDI ARAMCO CAST-IN-PLACE CONCRETE FORMWORK INSPECTION CHECKLISTNaushad AlamNo ratings yet

- Sika Grout - 114 SaDocument3 pagesSika Grout - 114 SaGavriel NgNo ratings yet

- SATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementDocument2 pagesSATIP-Q-001-01 Portland Cement Concrete - Batch Plants ManagementAbdul HannanNo ratings yet

- SAES-Q-012 (Criteria For Dessign & Construction of Precast & Prestressed Concrete)Document3 pagesSAES-Q-012 (Criteria For Dessign & Construction of Precast & Prestressed Concrete)Nino Celso AstilleroNo ratings yet

- Satip Q 001 03Document10 pagesSatip Q 001 03munnaNo ratings yet

- Saes A 208Document14 pagesSaes A 208nadeemNo ratings yet

- 6 Pavement Quality Concrete PPT by Deepak ThamanDocument6 pages6 Pavement Quality Concrete PPT by Deepak ThamanThaman Thaman100% (1)

- MYKAnchor HF66Document2 pagesMYKAnchor HF66cekicdjNo ratings yet

- MOC General Specifications for Prestressed Concrete StructuresDocument3 pagesMOC General Specifications for Prestressed Concrete StructuresAbdul Wahab JamilNo ratings yet

- Grouting Works Details for DFCU-HRRL ProjectDocument12 pagesGrouting Works Details for DFCU-HRRL Projectkranthi kumarNo ratings yet

- Fosroc Nitowrap Carbon Fibre SheetDocument4 pagesFosroc Nitowrap Carbon Fibre Sheetalexcus1539No ratings yet

- Classification of Roads and Thier DetailsDocument6 pagesClassification of Roads and Thier DetailsNino Celso AstilleroNo ratings yet

- 0506Document11 pages0506Nino Celso AstilleroNo ratings yet

- 0507Document6 pages0507Nino Celso AstilleroNo ratings yet

- 05-8-95transportation and Placing of ConcreteDocument5 pages05-8-95transportation and Placing of ConcreteNino Celso AstilleroNo ratings yet

- 0502Document7 pages0502Nino Celso AstilleroNo ratings yet

- 0505Document8 pages0505Nino Celso AstilleroNo ratings yet

- Types of Loads On StructureDocument3 pagesTypes of Loads On StructureNino Celso AstilleroNo ratings yet

- Why Bitumen is Used for Road Construction: Properties & AdvantagesDocument5 pagesWhy Bitumen is Used for Road Construction: Properties & AdvantagesNino Celso AstilleroNo ratings yet

- 0503Document5 pages0503Nino Celso AstilleroNo ratings yet

- 0506Document11 pages0506Nino Celso AstilleroNo ratings yet

- 7 TYPES OF ROAD MARKINGS As Per IRCDocument11 pages7 TYPES OF ROAD MARKINGS As Per IRCNino Celso AstilleroNo ratings yet

- Types of Plumbing and Drainage Systems in BuildingsDocument7 pagesTypes of Plumbing and Drainage Systems in BuildingsNino Celso AstilleroNo ratings yet

- What Is Septic TankDocument4 pagesWhat Is Septic TankHari RNo ratings yet

- 2103 PDFDocument8 pages2103 PDFNino Celso AstilleroNo ratings yet

- Quality Control Turn Over EngineerDocument2 pagesQuality Control Turn Over EngineerNino Celso AstilleroNo ratings yet