Professional Documents

Culture Documents

5855292-Avr Users Manual Ea63-5 C PDF

Uploaded by

ejazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5855292-Avr Users Manual Ea63-5 C PDF

Uploaded by

ejazCopyright:

Available Formats

We reserve all rights in this document and in the information contained therein.

Reproduction, use or disclosure to third parties without express authority is strictly forbidden.

Copyright 2009 ABB

Automatic Voltage Regulator User’s Manual

Type designation: EA63-5

Application: AMG Synchronous Generator Industrial Application

Series

Prep. PEYA 23.08.2010 AVR EA63-5 USER MANUAL No. of sh.

Appr. ANQU 30.08.2010 8

Resp. dept. R&D

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 1

1. GENERAL INFORMATION

1.1 DESCRIPTION

EA63-5 is an automatic voltage regulator (AVR) for AMG synchronous generator industrial

application series. The AVR is typically supplied by a single-phase auxiliary winding wound into the

stator slots. It also can be supplied by permanent magnet generator PMG or phase voltage of

main terminal.

1.2 SPECIFICATION

Table 1: Specifications.

Sensing input Current compensation

Voltage: 220/440 VAC (SW1 selectable). 1 or 5 A>0.2 VA (SW2 selectable).

185-290 VAC at 220 VAC. Voltage built-up

330-515 VAC at 440 VAC. Residual voltage >5 VAC at 25 Hz.

Frequency: 50/60 Hz (SW3 selectable). Max ±7% at p.f. ±0.7.

49-60 Hz at 60 Hz, preset 57Hz. Analogue voltage input

40-50 Hz at 50 Hz, preset 47Hz. Un 0-15% at 0-10 VDC.

Power input External voltage adjustment VR

Voltage: 30-260 VAC. ±10 % with 1 k resistance (0.5 W).

Frequency: 40-500 Hz. C+, C-

Output External filter capacitor terminal.

Voltage: 85 VDC at 110 VAC input. Respond time

170 VDC at 220 VAC input. <1 cycle.

Current: continuous 5 ADC. Temperature drift

maximum 40 ADC. <0.45 % at -35 to +65 .

Voltage built-up Dissipation

Residual voltage >5 VAC at 25 Hz. 12 W.

Voltage adjustment Dimensions

<1.0 % (engine speed variation within 4 %). 140 mm x 125 mm x 43 mm.

Excitation resistance

>9 .

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 2

1.3 DIMENSIONS

Figure 1: AVR outline drawing.

For enclosure dimensions and mounting holes refer to Figure 1. The protection fuse capacity is

5 A/250 V (slow blow type).

Attention!

All voltage readings are to be taken with an average-reading voltmeter Meggers and

high-potential test equipment must not be used. Use of such equipment could damage

the AVR.

Safely secure all wiring connection. Do not install AVR at place with high vibration to

prevent loosen connection. For safety reasons please do not touch the heat sink while

operating.

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 3

2. ADJUSTMENTS

2.1 DIP SWITCH ADJUSTMENT

2.1.1 SW 1 (see: Figure 2) voltage selection. SW 1 is used to select the suitable

genset’s sensing input voltage (S1, S2). When sensing input is 440 VAC

(380-480 V), switch the SW 1 to ‘ON’. If the sensing input is 220 VAC, switch

SW 1 to ‘OFF’ position.

ATTENTION! If system voltage is 220 V but the SW 1 is set to ‘ON’ position (440V), it will

cause over voltage.

ON

SW

1 2 3 4 5 6

Figure 2: Dip switch (SW).

2.1.2 SW 2 (see: Figure 2) is used to select the suitable current transformer’s

current input (C1, C2). If current transformer’s current is 5 A, switch SW 2 to

‘ON’ position. If the current is 1 A, switch SW 2 to ‘OFF’ position.

2.1.3 SW 3 (see: Figure 2) is used for frequency selection. If genset’s rated

frequency is 60 Hz, switch SW 3 to ‘ON’ position. If rated frequency is 50 Hz

switch SW 3 to ‘OFF’ position.

ATTENTION! If 60 Hz frequency is selected, while the rated frequency of the generator is 50

Hz, it may result the under voltage fault.

ATTENTION! If a 60 Hz generator is used, but selected frequency is 50 Hz, stop the engine.

The over excitation current may damage AVR and generator.

2.1.4 If genset power is less than 90 kW switch SW 4, SW 5 and SW 6 to ‘OFF’

position (see: Figure 2). If the power is 90-200 kW, switch SW 4 to ‘ON’

position. SW 5 and SW 6 remain in ‘OFF’ position. If the power is more than

200 kW, switch SW 4, SW 5 and SW 6 to ‘ON’ position.

ATTENTION! Each time when SW 4, SW 5 or SW 6 positions are changed, the stability

(STAB) must be re-adjusted to achieve the optimum genset performance. The setting of the

dip switches (SW) must be conducted while the generator is not in operation.

2.2 TRIMMER ADJUSTMENT

VOLT Voltage setting (see: Figure 3) is used to adjust the genset’s rated output

voltage. When SW 1 is ‘ON’ (440 V), the adjustable range is 330-515 VAC.

When SW 1 is ‘OFF’ (220 V), the adjustable range is 180-270 VAC.

ATTENTION! AVR AC voltage readings are all average values.

Ext. potentiometer Connect 0.5 W potentiometer with 500 resistance to the VR terminal (see:

Figure 3). The adjustable voltage range is ±5 % of Un. With 1 K resistor the

adjustable voltage range is ±10 % of Un. If this function is not required,

please short circuit these two terminals.

STAB Stability adjustment (see: Figure 3). It must be conducted while the

generator is operating without load. At first, adjust the STAB potentiometer

(POT) clockwise until the voltage becomes unstable. Then, adjust to anti-

clockwise (approximately 1/5 of rotation) as the voltage just reaches the

critical point (knee point) of stabilization. The voltage is now stable, but very

close to become unstable.

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 4

U/F Under frequency protection adjustment (see: Figure 3). When generator’s

driving speed falls below the knee point, the under frequency protection

circuit will begin to intervene. The voltage and frequency begin to decrease

in linear descend. Coordinate with the dip switch SW 3 to make the

frequency selection of 50 or 60 Hz. When selecting 50 Hz, the adjustable

range is from 40-50 Hz and the factory presets is at 47 Hz. When selecting

60 Hz, the adjustable range is from 49-60 Hz and the factory presets is at

57 Hz.

U/FL When under frequency protection is activated (see: Figure 3), the red LED

will light up.

DROOP Droop adjustment (see: Figure 3). When paralleling, the AVR compensates

the input rating and voltage shifting based on load current. This is based on

AVR’s internal circuit calculation. This way the AVR increases or decreases

the voltage. When phase current lags the voltage, AVR decreases original

voltage setting, and if the phase current leads the voltage it increases the

original voltage setting. The increase and decrease range can be preset by

the DROOP adjustment.

TRIM Analogue voltage input sensitivity (see: Figure 3). When terminals A1 and A2

are added with a DC input (0-10 VDC), the TRIM is used to adjust the

influence level from the DC input to the rated voltage. If the TRIM potential

(POT) is adjusted fully to counter-clockwise, the additional signal will not

cause any influence. If the TRIM is adjusted fully clockwise, then the

additional signal will produce a maximum effect.

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 5

3. CONNECTION

3.1 TERMINALS

P1, P2 Auxiliary winding power input (see: figure 3).

PMG power input (see: figure 4).

The input range is 30-260 VAC at 40-500 Hz.

C+, C- External filter capacitor terminal (see: figure 3). The filter voltage endurance

must be greater than 1.7 x voltage between P1 and P2.

F+, F- Excitation output (see: figure 3). Connect to generator excitation winding.

VR External voltage adjustment (see: figure 3). Use 1 W VR (with 1K

resistance). Voltage adjustable range is now ± 10 %. If this function is not

required, please short circuit these two terminals.

C1, C2 Load current compensation (see: figure 3). Input range is 1 A or 5 A

(selected by SW 2) >0.2 VA.

S1, S2 Sensing input (see: figure 3). Input range 220 or 440 VAC (selected by SW

1). Input resistance is >2 M .

A1, A2 Analogue voltage input terminal (see: figure 3).

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 6

3.2 CONNECTION DIAGRAM

Figure 3: Connection diagram (Power input: Auxiliary winding).

Figure 4: Connection diagram (Power input: PMG).

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 7

4. TROUBLE SHOOTING

The following instructions are intended to assist in localizing a fault within the excitation system as a

whole. However, it is not possible to deal with all eventualities in full.

Table 2: Trouble shooting.

FAILURE POSSIBLE CAUSE ACTION

Make separate excitation running, then make

Voltage not built up. Low remanence. self-excitation running.

AVR wires disconnected. Check AVR connections.

Problem with rectifier

bridge. Check the diode.

Defective AVR. Change AVR.

Defective generator Refer generator manual.

Low voltage. AVR wires disconnected Check AVR connections.

Defective generator. Refer to generator manual.

Problem with rectifier

bridge. Change the diode.

Generator below allowed

frequency. Correct engine speed.

Original AVR settings

High voltage. incorrect. Adjust VOLT-trimmer.

AVR wires disconnected. Check AVR connections.

Defective AVR. Change AVR.

Original AVR settings

Voltage unstable. incorrect. Adjust STAB-trimmer.

Variable running speed. Correct engine speed.

AVR connections wrong. Check AVR terminals.

Defective AVR. Change AVR.

Voltage lost during

running. Defective generator. Refer to generator manual.

Defective rectifier. Change invalid parts.

Defective AVR. Change AVR.

Document identification Lang. Rev. ind. Sheet

ABB Generators Ltd. 8AMG 5855292 en C 8

You might also like

- Engine Interface ModuleDocument3 pagesEngine Interface ModuleAziz ArrahalNo ratings yet

- HGM410 HGM420 V1.6 enDocument44 pagesHGM410 HGM420 V1.6 enDante Marcelo Obinu HidalgoNo ratings yet

- EA05A ManualDocument4 pagesEA05A ManualAnonymous vqsuRyNo ratings yet

- BreakersDocument48 pagesBreakersdanh17No ratings yet

- SX440 Manual enDocument4 pagesSX440 Manual enMuhammad Sajjad ShadNo ratings yet

- ADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualDocument10 pagesADVR-12: Hybrid Universal Analog Digital Voltage Regulator Operation ManualcarmeniyoNo ratings yet

- EST To Flash A PowerWizardDocument2 pagesEST To Flash A PowerWizardmahmoud khtaNo ratings yet

- 15 - PCC 1302 Troubleshooting TablesDocument15 pages15 - PCC 1302 Troubleshooting TablesAnbuNo ratings yet

- Oly Changeover SystemsDocument5 pagesOly Changeover SystemsCandiano PopescuNo ratings yet

- Heinzmann TrainingDocument10 pagesHeinzmann Trainingvo phong100% (1)

- ShopNotes Issue 72Document38 pagesShopNotes Issue 72qpidoneuro100% (7)

- SS448 ManualDocument8 pagesSS448 ManualkikoNo ratings yet

- Electric Submersible Pump BasicsDocument146 pagesElectric Submersible Pump BasicsAbhoe Stank100% (6)

- Installation Testing Troubleshooting Starters Overload RelaysDocument34 pagesInstallation Testing Troubleshooting Starters Overload RelaysGogula Gunasekhar100% (1)

- Basic Points of P91Document4 pagesBasic Points of P91Asad Bin Ala Qatari100% (1)

- EPM72 Engine Protection ModuleDocument8 pagesEPM72 Engine Protection Moduleandy habibiNo ratings yet

- S287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Document1 pageS287 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.2 Rev 2Parinya0% (1)

- Method Statement For Construction of Holiday Bungalow For Cashell GreenDocument6 pagesMethod Statement For Construction of Holiday Bungalow For Cashell GreenHasitha Gunasekara100% (1)

- Manual Stamford Avr SX421 PDFDocument4 pagesManual Stamford Avr SX421 PDFBrooke EdwardsNo ratings yet

- DSE7110MKII DSE7120 MKII Wiring Diagram PDFDocument3 pagesDSE7110MKII DSE7120 MKII Wiring Diagram PDFNave GanteNo ratings yet

- Ins-Kery Tacil 33502015901 - 1 - 1Document63 pagesIns-Kery Tacil 33502015901 - 1 - 1Rath Asypaden100% (1)

- Stamford As440Document4 pagesStamford As440Manuel OteroNo ratings yet

- A041 J096Document0 pagesA041 J096Michal HroudaNo ratings yet

- WT-3A Operation Manual (English)Document8 pagesWT-3A Operation Manual (English)Наталья100% (1)

- Avr Conversion InstructionsDocument2 pagesAvr Conversion InstructionsJose PirulliNo ratings yet

- BS en - 1011 1 2009Document12 pagesBS en - 1011 1 2009Paco0% (1)

- TD - As480 Avr - 04.08 - 02 - GBDocument6 pagesTD - As480 Avr - 04.08 - 02 - GBmo7amedengNo ratings yet

- Olympain-R450 & R448 Avr Manuall PDFDocument7 pagesOlympain-R450 & R448 Avr Manuall PDFSayed Younis Sadaat100% (1)

- High Temperature Boiler Tube FailuresDocument9 pagesHigh Temperature Boiler Tube Failureskeerthi dayarathnaNo ratings yet

- SX440 Manual enDocument4 pagesSX440 Manual enAnsoriNo ratings yet

- 350-28700-to-SX440-to - AS440 AVR Conversion InstructionsDocument6 pages350-28700-to-SX440-to - AS440 AVR Conversion InstructionsRamon Pujol PerramonNo ratings yet

- S285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFDocument1 pageS285 Fozmula Capacitance Coolant Level Switch Data JP 24 Nov 15 3.1 Rev 2 PDFfaraidunNo ratings yet

- Rigid Dump Trucks - 960E-2KDocument16 pagesRigid Dump Trucks - 960E-2KJohn Anderson100% (1)

- EVC600C User Manual (English)Document6 pagesEVC600C User Manual (English)dhany reza100% (1)

- PRDocument27 pagesPRdon121don121No ratings yet

- Stamford PI734FDocument8 pagesStamford PI734FTaz UddinNo ratings yet

- InteliSys Gas 1 5 0 Grid Codes GuideDocument667 pagesInteliSys Gas 1 5 0 Grid Codes GuideSebastianx LexNo ratings yet

- Proposed Appendix F M-1002-1 Form 4-2 CleanDocument7 pagesProposed Appendix F M-1002-1 Form 4-2 CleanlomelindanielNo ratings yet

- Piping Codes and StandardsDocument21 pagesPiping Codes and StandardsZa Yon100% (1)

- Sandvik DD321Document4 pagesSandvik DD321Anonymous Dm7iMmt0% (2)

- Ea16 Manual enDocument6 pagesEa16 Manual enabuzer1981No ratings yet

- Ea06 Manual enDocument6 pagesEa06 Manual enabuzer1981No ratings yet

- SS16A2 ManualDocument9 pagesSS16A2 ManualJuan José Tovar Pérez100% (1)

- AVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFDocument4 pagesAVC63-7F Voltage Regulator - Instructions - 9302800994-D - March 2012 - BASLER ELECTRIC PDFpevareNo ratings yet

- AVR 448 Olympian CATDocument2 pagesAVR 448 Olympian CATMiguel Angel Pavon Carbonell100% (1)

- Wiring Diagrams: VR6 Voltage RegulatorDocument21 pagesWiring Diagrams: VR6 Voltage Regulatorgeorgi15685No ratings yet

- General: Technical Data TAD721GEDocument8 pagesGeneral: Technical Data TAD721GEbaljeetjatNo ratings yet

- GCP 32 - 37239 PDFDocument45 pagesGCP 32 - 37239 PDFwagner_guimarães_1No ratings yet

- TAD1343GEDocument8 pagesTAD1343GEGeorge BarsoumNo ratings yet

- PowerWizard Range (GB) (0311)Document5 pagesPowerWizard Range (GB) (0311)sfantu_29100% (1)

- Voltage Regulator AVC63-7 Manual PDFDocument4 pagesVoltage Regulator AVC63-7 Manual PDFEduardo A. CottaniNo ratings yet

- Paralleling PCC 2100 in Droop Mode Using Aux101 ModuleDocument2 pagesParalleling PCC 2100 in Droop Mode Using Aux101 ModuleGeneral Projects and Electric, C.A GEPECANo ratings yet

- PowerWizard 1-0 (GB)Document2 pagesPowerWizard 1-0 (GB)kagaNo ratings yet

- ATyS M 3s (Reversing Switch) CatalogueDocument8 pagesATyS M 3s (Reversing Switch) CataloguePaulMathewNo ratings yet

- Kea 071 AnlDocument12 pagesKea 071 Anlamin shirkhaniNo ratings yet

- Wiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsDocument12 pagesWiring Instructions For Replacement of 2301A Load Sharing and Speed Controls With 2301D Load Sharing and Speed ControlsHammim HamzhahhNo ratings yet

- Section 06 - c-08 Gold-Password-Uk - Rev4 - 100930 SasDocument8 pagesSection 06 - c-08 Gold-Password-Uk - Rev4 - 100930 SasbacNo ratings yet

- Parts Manual: Generator SetDocument90 pagesParts Manual: Generator SetZez SamuelNo ratings yet

- Dief ControllerDocument1 pageDief ControllerMohammad HazbehzadNo ratings yet

- Dse 540Document2 pagesDse 540TariqMaqsoodNo ratings yet

- DC 6 Digital Gov Data Sheet PDFDocument4 pagesDC 6 Digital Gov Data Sheet PDFCarlos MajanoNo ratings yet

- Specification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Document34 pagesSpecification, Controls and Accessories: AS440 Automatic Voltage Regulator (AVR)Jan AhmedNo ratings yet

- ADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualDocument6 pagesADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualMahendraLiyanage0% (1)

- Linz GeneratorDocument7 pagesLinz GeneratorMohammad HazbehzadNo ratings yet

- Gen Auto XMDocument47 pagesGen Auto XMCameron Ledingham100% (1)

- Governer ManualDocument4 pagesGoverner ManualSarah FrazierNo ratings yet

- Safety: Operation and Maintenance Manual ExcerptDocument30 pagesSafety: Operation and Maintenance Manual ExcerptIuri BragaNo ratings yet

- t4300 Load SharerDocument4 pagest4300 Load SharerndukNo ratings yet

- Sices GC315Document4 pagesSices GC315Mahmoud ElbakryNo ratings yet

- Lixise lxc6310Document33 pagesLixise lxc6310Hector CabreraNo ratings yet

- Eabm031004za - HT Gc310 350 500 User ManualDocument100 pagesEabm031004za - HT Gc310 350 500 User ManualBayanaka Tehnik100% (2)

- Amf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control SystemsDocument20 pagesAmf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control Systemsمحمد فرحات100% (1)

- Generator Automatic Voltage Regulator Operation ManualDocument9 pagesGenerator Automatic Voltage Regulator Operation Manualsabrahima100% (1)

- Application Guide: W A T L O WDocument5 pagesApplication Guide: W A T L O WAbhoe Stank100% (1)

- Lay Out D60Document1 pageLay Out D60Abhoe StankNo ratings yet

- Tool Wear in Friction Drilling: Scott F. Miller, Peter J. Blau, Albert J. ShihDocument10 pagesTool Wear in Friction Drilling: Scott F. Miller, Peter J. Blau, Albert J. Shihjuan carlosNo ratings yet

- Report Black BookDocument54 pagesReport Black BookSanket ChaudhariNo ratings yet

- Test Booklet General Studies (General Science) Test Code: DG-1504Document53 pagesTest Booklet General Studies (General Science) Test Code: DG-1504Saurav SumanNo ratings yet

- Hisaka Instruction ManualDocument48 pagesHisaka Instruction ManualCONG THANH DOANNo ratings yet

- Flexible Pavement DistressDocument44 pagesFlexible Pavement DistressBalvinder SinghNo ratings yet

- Msds EpoxyDocument4 pagesMsds EpoxyPuneet K JainNo ratings yet

- Avikote AV 800-7Document2 pagesAvikote AV 800-7Amer Y KNo ratings yet

- Durafrax 2000 Alumina en 1039 TdsDocument1 pageDurafrax 2000 Alumina en 1039 Tdsshuyang zhangNo ratings yet

- Green Chemstry and NanochemistryDocument42 pagesGreen Chemstry and Nanochemistrydevrarimanish72No ratings yet

- Cme2 TramexDocument46 pagesCme2 TramexgiampaoloNo ratings yet

- Instrumen Penilaian Sri AniDocument14 pagesInstrumen Penilaian Sri Aniaku aniNo ratings yet

- WF1600 LMud PumpDocument6 pagesWF1600 LMud PumpDuy NguyenNo ratings yet

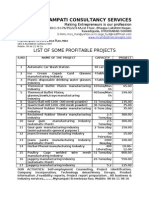

- List-Mynampati Consultancy ServicesDocument8 pagesList-Mynampati Consultancy Servicesmcs_msr302350% (2)

- Operation ManagementDocument35 pagesOperation ManagementJayvee Joble BigataNo ratings yet

- Can ManufacturersDocument3 pagesCan ManufacturersHarman Muasa0% (1)

- RFQ For The Supply of LT (1.1,6.6 and 11KV) Cable For Steels-2 Revamping Project - 15092022 - Rev-00Document49 pagesRFQ For The Supply of LT (1.1,6.6 and 11KV) Cable For Steels-2 Revamping Project - 15092022 - Rev-00jamilNo ratings yet

- Grundfos - 43-100f Submittal SheetDocument4 pagesGrundfos - 43-100f Submittal Sheetsas999333No ratings yet

- Visual Inspection ReportDocument5 pagesVisual Inspection ReportOmar WardehNo ratings yet

- Calibration: A Technician'S GuideDocument4 pagesCalibration: A Technician'S GuideNia dewiNo ratings yet