Professional Documents

Culture Documents

Application Data Sheet: Martin Flow-Aid Products

Uploaded by

tacosanchezbrayanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Data Sheet: Martin Flow-Aid Products

Uploaded by

tacosanchezbrayanCopyright:

Available Formats

APPLICATION DATA SHEET

Martin® Flow-Aid Products

Plant Name: Contact Person:

Address: Telephone: Fax:

City: Email:

State: Zip Code: Date:

Material Conditions

Type of Material:

Weight: lb per Cubic Foot: or kg per Cubic Meter:

Moisture Content: Dry Wet Moisture %

Temperature of Material: Ambient High degrees F C

Condition: Coarse Granular Fine Powder Sticky

Particle Size: Compaction Level of Material: Hard Soft

Vessel Information

Shape of Vessel:

Square/Rectangle Round Chute Other

Vessel Material: Steel Stainless Concrete Wood Other

Wall Thickness: in mm Vessel Lined: Yes No

Vessel Construction: Welded Bolted

Vessel Lining Material: Lining Thickness: in mm

Vibrating Bottom Installed: Yes No

Currently in Use: Yes No

Discharge Frequency: Continuous Intermittent

Method of Discharge: Belt Screw Hopper Other

Complete Dimensional Information or Supply Drawings

Standard of Measurement: Inches/Feet Millimeters/Meters

C B

B

A____ F____

A____ A____

B A B____ G____

C

A B____ B____

A C____

C____ C____

D E

D____

C D____ D____ D

D

E____

E____ F

E

G

Note: Please attach drawings and/or digital photographs if available.

Indicate flow problem area on drawing.

Form No. L3718-08/12

© Martin Engineering Company 2006, 2012

APPLICATION DATA SHEET

Type of Problem

Flow Problem: Bridging Rat-holing Packing Clinging to Sides

Describe the Problem:

Where does it occur:

Material presently built up? Yes No

Thickness of material build-up: in mm

Volume of material build-up: lbs ton

Length of time build-up has been present:

Current Solution

Current method being used: (ie. hitting with hammer, poking)

Flow aids presently being used or used previously:

How often and duration current method used in 24-hour period:

Effect current method has on the material/ problem:

Power Availability

Power Preference: Electric Pneumatic Hydraulic

Pneumatic: Pressure Available: psi bar

Volume Available: CFM cm3/min

Filter and/or Dryer on Air Line? Yes No

Distance from existing air supply to application: in mm

Electric: Frequency 50 Hz 60 Hz

Phase Power Single-Phase Three-Phase

Voltage:

Explosion Proof Equipment needed: Yes No

Method of Control: Timer PLC Solenoid Manual

Type of cycle used: Manual Timed Internals Automatically During Discharge

Automatically Under No-Flow Conditions

Desired outcome/expectations of the Flow-Aid System:

Martin Engineering USA To submit the completed form please

One Martin Place fax to 309-594-2432

Neponset, IL 61345-9766 USA Attention: Flow-Aids Technical Support

800 544 2947 or 309 852 2384 or click here to email

Fax 800 814 1553 vibration@martin-eng.com

www.martin-eng.com

Form No. L3718-08/12

© Martin Engineering Company 2006, 2012

You might also like

- Block Brush WorksheetDocument1 pageBlock Brush WorksheetAssanNo ratings yet

- VbandTboltApplicationDataSheetREV EDocument1 pageVbandTboltApplicationDataSheetREV EmasNo ratings yet

- Application Data Sheet Safeline Metal Detection and X-RayDocument1 pageApplication Data Sheet Safeline Metal Detection and X-RayARTHUR RAMSES ASSOUMOU KABLANNo ratings yet

- I Feeder Application Design CalculationsDocument2 pagesI Feeder Application Design Calculationsarsaniose100% (1)

- DCP Monitoring Report With HeaderDocument3 pagesDCP Monitoring Report With HeaderGerald MaimadNo ratings yet

- FS01082019 Silo Solutions Application Data Sheet PDFDocument2 pagesFS01082019 Silo Solutions Application Data Sheet PDFRadovan75No ratings yet

- MeasurIT Tideflex Application Data Sheet Tideflex Effluent System 0803Document1 pageMeasurIT Tideflex Application Data Sheet Tideflex Effluent System 0803cwiejkowskaNo ratings yet

- Floating Suction Data Sheet - 1Document1 pageFloating Suction Data Sheet - 1Pepe LLangarí ArizoNo ratings yet

- Aiv01102019 Airmatic Flow Aid Application Data SheetDocument2 pagesAiv01102019 Airmatic Flow Aid Application Data SheetIldico KovacsNo ratings yet

- First PT New Template - CarpentryDocument4 pagesFirst PT New Template - CarpentryrebrebprincipeNo ratings yet

- Recipient of DCP Survey and Monitoring Checklist 1Document4 pagesRecipient of DCP Survey and Monitoring Checklist 1Rodjone BinondoNo ratings yet

- School IT SurveyThe title "TITLE School IT SurveyDocument3 pagesSchool IT SurveyThe title "TITLE School IT SurveyJoelle M. CruzNo ratings yet

- Mobile Questionnaire Appendix IDocument7 pagesMobile Questionnaire Appendix IVikas DadhwalNo ratings yet

- CDD 0200 Application For Building Permit Part I 12-06-2018Document4 pagesCDD 0200 Application For Building Permit Part I 12-06-2018Alexander DaltonNo ratings yet

- 1ST Quarterly Exam in TleDocument4 pages1ST Quarterly Exam in TleMaria Patricia MerañaNo ratings yet

- Questionaire 1 Mechanical PretreatmentDocument2 pagesQuestionaire 1 Mechanical PretreatmentLuis Ernesto Rodríguez RodríguezNo ratings yet

- Department of Education: (If Recipient Pls. Check)Document3 pagesDepartment of Education: (If Recipient Pls. Check)Ice JimenezNo ratings yet

- Hilti HST submission folderDocument104 pagesHilti HST submission folderKawser HossainNo ratings yet

- Hazardous Material Declaration Form: Item(s) To Be Declared: NoDocument1 pageHazardous Material Declaration Form: Item(s) To Be Declared: NoCV. Anugerah Bumi NusantaraNo ratings yet

- Philadelphia County Highway Permit ChecklistDocument4 pagesPhiladelphia County Highway Permit ChecklistYang SunmanNo ratings yet

- Document 2Document541 pagesDocument 2Mary AhmedNo ratings yet

- Loyalist College of Applied Arts & Technology Application FormDocument2 pagesLoyalist College of Applied Arts & Technology Application Formdaljit8199No ratings yet

- JibbereishDocument1 pageJibbereishdwelch12969No ratings yet

- New 8D FormatDocument1 pageNew 8D FormatNURUL HIDAYAH BT IBRAHIM / UPMNo ratings yet

- Design Application Data: Oxidation DitchDocument1 pageDesign Application Data: Oxidation DitchΔημητρηςΣαρακυρουNo ratings yet

- Spindle Nose Data Sheet For ChuckDocument2 pagesSpindle Nose Data Sheet For ChuckPruthvi RajaNo ratings yet

- Evaporator Coil Spec SheetDocument1 pageEvaporator Coil Spec Sheetessjrs1No ratings yet

- Computer Repair Form DetailsDocument1 pageComputer Repair Form DetailsArt DollosaNo ratings yet

- Day 1 ATC88Document41 pagesDay 1 ATC88Azhar GulzarNo ratings yet

- FDPP Request For Rectification Form V2 1Document1 pageFDPP Request For Rectification Form V2 1Bennybert AlejoNo ratings yet

- RSWM LTDDocument16 pagesRSWM LTDAkshat DosiNo ratings yet

- ACFrOgAXA mqfRbdpaNEcZ1kHXMVTWT 8As-GD32alaN2CBn5BLS5F5KkTFB6GwGYYBR2ZY1cnPAV 938-JTmbls8Ln5Hq0RG50iYKTHuljlqWY87meQ5n0uyIJ5prqJme7PN3TPUthBIIBLaZkLDocument1 pageACFrOgAXA mqfRbdpaNEcZ1kHXMVTWT 8As-GD32alaN2CBn5BLS5F5KkTFB6GwGYYBR2ZY1cnPAV 938-JTmbls8Ln5Hq0RG50iYKTHuljlqWY87meQ5n0uyIJ5prqJme7PN3TPUthBIIBLaZkLNathan AlegriaNo ratings yet

- Mock Recall LogDocument3 pagesMock Recall LogDerren Ivy Shine VeñigasNo ratings yet

- Prmg90 Cce Question Sec 1,2,3Document31 pagesPrmg90 Cce Question Sec 1,2,3bomyboomNo ratings yet

- Test Bank For Principles of Micro Economics 2nd by OpenstaxDocument29 pagesTest Bank For Principles of Micro Economics 2nd by Openstaxpatrickgarciaewzrbtosai100% (18)

- 2127 P Application Package 2021 0503Document60 pages2127 P Application Package 2021 0503the next miami100% (1)

- Student Registration / Admission Form: Personal DetailsDocument4 pagesStudent Registration / Admission Form: Personal DetailsArhanaNo ratings yet

- Flat Brim 5 Panel Camp Snapback HIAC TemplateDocument5 pagesFlat Brim 5 Panel Camp Snapback HIAC TemplateChad OngNo ratings yet

- Aboitiz Subcontractor's Profile FormDocument6 pagesAboitiz Subcontractor's Profile FormRizza Jane ArriesgadoNo ratings yet

- D D MM Y Y Y Y: Account Operation InstructionsDocument6 pagesD D MM Y Y Y Y: Account Operation InstructionsPinaki MishraNo ratings yet

- Industry AnalysisDocument2 pagesIndustry AnalysisPrateek JainNo ratings yet

- Chapter 1 Text BankDocument28 pagesChapter 1 Text Bank张佩菁No ratings yet

- CSS 1st QTR Test Question Lec 2019-2020Document6 pagesCSS 1st QTR Test Question Lec 2019-2020Shelaniejean LimNo ratings yet

- Deviation Request FormDocument1 pageDeviation Request FormSachin SinghNo ratings yet

- Premium Reduction & Delivery Improvement: Champion - SponsorDocument40 pagesPremium Reduction & Delivery Improvement: Champion - Sponsorjitendrasutar1975No ratings yet

- UCCA Application For Admission Form 3Document2 pagesUCCA Application For Admission Form 3Akinlabi HendricksNo ratings yet

- M&M 270Document19 pagesM&M 270pipyirNo ratings yet

- HPD-DRG-002-1 Custody and Control Form (Form DT-002B - Copy For The Collection Site) - WES - Rev 04 OLD FROMDocument1 pageHPD-DRG-002-1 Custody and Control Form (Form DT-002B - Copy For The Collection Site) - WES - Rev 04 OLD FROMmbyedithNo ratings yet

- St. Aloysius Gonzaga Academy Inc.: A B C DDocument5 pagesSt. Aloysius Gonzaga Academy Inc.: A B C DLovely PachecoNo ratings yet

- FS04 MarketingDocument5 pagesFS04 MarketingNguyễn Khánh LinhNo ratings yet

- SF - RE500 + Rebar (May 2013)Document65 pagesSF - RE500 + Rebar (May 2013)Danny LeungNo ratings yet

- Other MCQ CH 1 To 6Document90 pagesOther MCQ CH 1 To 6EmmaNo ratings yet

- Unconfined Compression TestDocument1 pageUnconfined Compression Testমোঃ হাসান ইমামNo ratings yet

- GMAW - 2020 Districts PDFDocument5 pagesGMAW - 2020 Districts PDFbob walkerNo ratings yet

- Inquiry Fill-Out FormDocument6 pagesInquiry Fill-Out FormBülent KabadayiNo ratings yet

- Pengukuran Debir Air Form SheetDocument1 pagePengukuran Debir Air Form SheetRajekwesi Bird FarmNo ratings yet

- TC Form Withdrawal RequestDocument8 pagesTC Form Withdrawal RequestHarrenNo ratings yet

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationFrom EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationRating: 5 out of 5 stars5/5 (4)

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- Cellulosic stick electrode for vertical-down pipe weldingDocument1 pageCellulosic stick electrode for vertical-down pipe weldingtacosanchezbrayanNo ratings yet

- Martin Hurricane Air Cannon: Operator's Manual M3737Document44 pagesMartin Hurricane Air Cannon: Operator's Manual M3737tacosanchezbrayanNo ratings yet

- B Boehler-Fox-Cel Se en v1Document1 pageB Boehler-Fox-Cel Se en v1tacosanchezbrayanNo ratings yet

- Link EivorDocument1 pageLink EivortacosanchezbrayanNo ratings yet

- M3747Document20 pagesM3747Ta Van NghiemNo ratings yet

- 6 Pack Program: Factory Refurbished Air Cannon ValvesDocument2 pages6 Pack Program: Factory Refurbished Air Cannon ValvestacosanchezbrayanNo ratings yet

- Martin Hurricane Air Cannon: Technical Data SheetDocument2 pagesMartin Hurricane Air Cannon: Technical Data Sheettacosanchezbrayan100% (1)

- Brochure Air Cannons L3748Document12 pagesBrochure Air Cannons L3748tacosanchezbrayanNo ratings yet

- Martinplus Silo Solutions: Storage Vessel Cleaning Service and ProductsDocument8 pagesMartinplus Silo Solutions: Storage Vessel Cleaning Service and ProductstacosanchezbrayanNo ratings yet

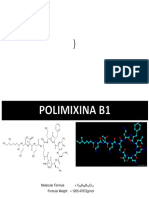

- MOLECULES IN 3DDocument6 pagesMOLECULES IN 3DtacosanchezbrayanNo ratings yet

- Polimixina b1Document2 pagesPolimixina b1tacosanchezbrayanNo ratings yet

- Guia de Autoevaluacion AmbientalDocument6 pagesGuia de Autoevaluacion AmbientalSergio LorenzoNo ratings yet

- B-TVS-M: Metallized BOPP FilmDocument2 pagesB-TVS-M: Metallized BOPP FilmSayed FathyNo ratings yet

- FMS Layout TypesDocument21 pagesFMS Layout TypesVimal KekNo ratings yet

- Sheet Metal WorkDocument6 pagesSheet Metal Workriwajkarki57No ratings yet

- BS EN 10162 2003 Cold Rolled Steel Sections Technical Delivery Conditions Dimensions and Cross Sectional TolerancesDocument23 pagesBS EN 10162 2003 Cold Rolled Steel Sections Technical Delivery Conditions Dimensions and Cross Sectional TolerancesKader Boucenna100% (1)

- Arshad CVDocument4 pagesArshad CVAli BaseejiNo ratings yet

- Gauge and Weight Chart For Sheet SteelDocument2 pagesGauge and Weight Chart For Sheet SteelFrancisco Carbone-Mora Campos0% (1)

- Sheetmetal Solutions Pvt Ltd - Laser Cutting and Bending Machines Reliability GuaranteedDocument4 pagesSheetmetal Solutions Pvt Ltd - Laser Cutting and Bending Machines Reliability GuaranteedVinith PachiappanNo ratings yet

- General Specification of Residential Buildings (Prime Quality)Document4 pagesGeneral Specification of Residential Buildings (Prime Quality)AftabAhmedBhattiNo ratings yet

- Laminated Object Manufacturing (LOM)Document19 pagesLaminated Object Manufacturing (LOM)PritamKumarPradhan100% (3)

- Completed Non-Ferrous Alloys ProjectDocument9 pagesCompleted Non-Ferrous Alloys ProjectCarlin Sylvester100% (2)

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- Spiral Corrugated Pipe - 12" To 144" in Diameter PDFDocument5 pagesSpiral Corrugated Pipe - 12" To 144" in Diameter PDFBhaumik MerchantNo ratings yet

- Tests for adhesive compounds in marine environmentsDocument7 pagesTests for adhesive compounds in marine environmentsironfaceNo ratings yet

- Lecture 9 Roofing Materials, Tileworks, EtcDocument31 pagesLecture 9 Roofing Materials, Tileworks, EtcArlene Joy G. ValentinNo ratings yet

- MT 1 Lab Manual PDFDocument40 pagesMT 1 Lab Manual PDFrajamanickam sNo ratings yet

- Exhibit B-30 InsulationDocument7 pagesExhibit B-30 Insulationsethu1091No ratings yet

- NX Tooling: Siemens PLM SoftwareDocument16 pagesNX Tooling: Siemens PLM SoftwarePRAKASHNo ratings yet

- Selection of Material and Hardware Used in Press ToolDocument22 pagesSelection of Material and Hardware Used in Press ToolVipul MetaNo ratings yet

- 1602Document6 pages1602umair186No ratings yet

- Cemented Tunsten Carbide Metalforming Grades ChartDocument2 pagesCemented Tunsten Carbide Metalforming Grades Chartflytorahul100% (3)

- Tata Durashine ManualDocument16 pagesTata Durashine ManualBudha SinghNo ratings yet

- Maruti Car ManufactureDocument37 pagesMaruti Car ManufactureVema AbhiramNo ratings yet

- Sheet Metal Pattern DevelopmentDocument6 pagesSheet Metal Pattern Developmentpamopar86% (7)

- CTS FitterDocument37 pagesCTS Fitterrajum465100% (1)

- ASTM D2688 Standard Test Method For Corrosivity of Water in The Absence of Heat Transfer (Weight Loss Method)Document7 pagesASTM D2688 Standard Test Method For Corrosivity of Water in The Absence of Heat Transfer (Weight Loss Method)EdwinMauricioMacabeo100% (2)

- Installation Technology NotesDocument86 pagesInstallation Technology NotesBenson MuimiNo ratings yet

- Studies in Conservation - The Maladies of Mill-Produced Metal in Modern ArtDocument8 pagesStudies in Conservation - The Maladies of Mill-Produced Metal in Modern ArtJoão Henrique Ribeiro BarbosaNo ratings yet

- Ibs Steel Frame Almst CmpleteDocument36 pagesIbs Steel Frame Almst Cmpletesharifah atiqahNo ratings yet

- HVAC, Ductwork, CoatingDocument6 pagesHVAC, Ductwork, CoatingwvwintersNo ratings yet

- Adhiparasakthi Engineering College Department of Mechanical EngineeringDocument27 pagesAdhiparasakthi Engineering College Department of Mechanical EngineeringKms BasheerNo ratings yet