0% found this document useful (0 votes)

560 views1 pageNew 8D Format

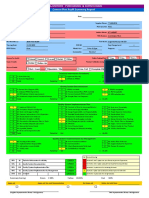

This document outlines an 8D problem solving process. It includes sections for forming a team to address the problem, describing the problem in detail, determining the root cause, identifying why the problem was not detected, corrective actions, preventative actions, and follow up. The problem involved a defect found in a part affecting a customer. The root cause analysis determined the problem was due to inexperienced workers and dull cutter blades. The corrective actions involved training and blade replacement. Preventative actions included updating relevant documents to prevent similar issues.

Uploaded by

NURUL HIDAYAH BT IBRAHIM / UPMCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

560 views1 pageNew 8D Format

This document outlines an 8D problem solving process. It includes sections for forming a team to address the problem, describing the problem in detail, determining the root cause, identifying why the problem was not detected, corrective actions, preventative actions, and follow up. The problem involved a defect found in a part affecting a customer. The root cause analysis determined the problem was due to inexperienced workers and dull cutter blades. The corrective actions involved training and blade replacement. Preventative actions included updating relevant documents to prevent similar issues.

Uploaded by

NURUL HIDAYAH BT IBRAHIM / UPMCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd