Professional Documents

Culture Documents

Mastertop 1240 Tds PDF

Uploaded by

Solomon AhimbisibweOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mastertop 1240 Tds PDF

Uploaded by

Solomon AhimbisibweCopyright:

Available Formats

MasterTop® 1240 (Formerly known as Mastertop® 1240 Plus)

Multi component epoxy screed and repair compound

DESCRIPTION ADVANTAGES

MasterTop® 1240 is a multi- component epoxy • High mechanical strength

screed system designed to provide durable and • Impact and abrasion resistant

abrasion resistant protection for concrete floors. • Slip resistant

Applied by trowel in thicknesses of 5mm and • Non tainting

above, MasterTop 1240 may also be suitable for • Excellent chemical resistance

use as a coving or repair medium.

PACKAGING

PRIMARY USES MasterTop® 1240 (pigmented) is supplied as a

MasterTop® 1240 floors have excellent multi component, 3 0 kg pack (including colour

mechanical properties and offer superior pack).

abrasion and wear characteristics for areas

subjected to heavy traffic. MasterTop® 1240 Neutral is supplied as a multi-

component 29.4kg pack.

MasterTop® 1240 has good general chemical

resistance, but as in all corrosive situations a full MasterTop® P 1240 is supplied in 2.1kg units.

analysis of operating and exposure conditions is

required, followed by reference to chemical TYPICAL PHYSICAL MATERIAL

resistance data, to ensure product suitability.

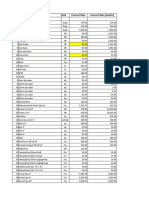

25°C 40°C

MasterTop® 1240 may be used for general Pot Life 40 mins 20 mins

Cure Time 14 hours 10 hours

repairs in floors subject to heavy, abrasive

Compressive strength (ASTM

traffic or for joint arris repairs and reinforcement C579-93)

of heavily trafficked joints. MasterTop 1240 is

7 days 81N/mm² 84N/mm²

non-tainting and is suitable for application where

foodstuffs are processed and stored.

Flexural strength (BS 6319 Part 3) >30N/mm²

Tensile strength (BS 6319 Part 7) 14N/mm²

In continuously wet areas, MasterTop® 1240

floors offer improved safety by providing a slip

resistant finish, through the application of a seal

coat from

Density of mixed material 2.14kg/L

the MasterTop® range, incorporating anti-slip *Abrasion resistance (ASTM 0.50mg/cycle

C501-84)

aggregate.

Bond strength Greater than the

cohesive strength of good

®

MasterTop 1240 may be applied in the quality concrete

following industries

MasterTop® 1240 overcoated with

NB This gives examples only and does not MasterTop® 1210.

constitute a full and comprehensive list. For further

information on application possibilities contact APPLICATION PROCEDURE

BASF Construction Chemicals SA.

• Loading bays PREPARATION:

• Workshops MasterTop® 1240 must be applied to a clean, dry

• Distribution centres substrate free from dust, dirt, oil, grease and other

• Laydown areas contaminants. A clean well prepared surface will

• Production halls ensure adhesion between substrate and overlay.

• Power installations

• Metal processing and engineering

MasterTop® 1240 (Formerly known as Mastertop® 1240 Plus)

NEW CONSTRUCTION PRIMING:

Floors to be coated or overlaid should be at least Prime using MasterTop® P 1240 Mix the two

28 days old unless water reducing admixtures components using a slow speed drill with a

have been incorporated. Consult BASF’s suitable paddle. Mix until uniform consistency is

Technical Services Department for advice. obtained. The components are preweighed and

The removal of laitance and contaminants is best should not be split or divided.

achieved by mechanical means such as vacuum Apply by brush or roller and work well into the

recovery shot blasting or scarifying. surface. Apply according to the stated coverage.

Allow to stand for 20 minutes before applying the

EXISTING CONCRETE MasterTop® 1240 to check for absorption. If the

All contamination must be removed and a sound, surface becomes matt, showing absorption, re-

clean substrate exposed. Mechanical means of prime the surface. Apply the MasterTop 1240

preparation are preferred followed by the removal whilst the primed surface is still tacky. If the

of dust and other loose debris using an industrial primer hardens reprime within 24 hours.

vacuum.

MIXING:

Uneven concrete should be levelled to produce a Mixing should be carried out using a forced action

roughened flat surface. Where repairs are mixer such as a Creteangle or Mixal Mixer.

required they can be carried out using Add the base, reactor and colour pack to the mixer

MasterTop® 1240 filled out with additional completely emptying the contents of the

aggregate or, if time allows, a suitable product containers. Mix for 1 minute until a uniform colour

from the MasterEmaco® range. is achieved. Slowly add the aggregate component

and mix for a further 3 minutes until a uniform

Expansion, control and isolation joints in concrete colour and consistency is achieved.

substrates should be carried through Mixing times should be varied according to

MasterTop® 1240 floors and filled with a temperature but typically 4 minutes in total is

suitable sealant from the BASF range. sufficient. It is important to maintain constant

mixing times throughout the contract, to ensure

Prior to application MasterTop® 1240 should be consistent colour and to avoid introducing

stored under cover in air-conditioning and excessive air into the system.

protected from extremes of temperature which

may cause inconsistent workability, finish and cure MasterTop® 1240 systems are supplied in

times of the mixed material. preweighed packs which should not be split or

divided. It is important to use complete packs.

During application in cold weather, correct

conditioning is essential, application should be

halted if the ambient or substrate temperature is

likely to fall below 10°C. Consideration should be

given to the substrate or base slab as it is likely to

be considerably colder than the surrounding air

temperatures. When temperatures exceed 35°C,

working times will be reduced significantly.

MasterTop® 1240 (Formerly known as Mastertop® 1240 Plus)

SEALING SAFETY PRECAUTIONS

The finished surface must be sealed with either As with all chemical products, care should be

MasterTop 1200 for a clear seal coat or MasterTop taken during use and storage to avoid contact with

1210 for a colored seal coat. Consult BASF's eyes, mouth, skin and foodstuffs (which can also

Technical Services Department for further details. be tainted with vapour until product is fully cured or

Good curing is essential for resin-based materials dried). Treat splashes to eyes and skin

to ensure specified performance. A minimum immediately. If accidentally ingested, seek

temperature of 10°C should be maintained during medical attention. Reseal containers after use.

the curing period by the use of additional heating,

if necessary. NOTE

Field service, where provided, does not constitute

COVERAGE supervisory responsibility. For additional

information contact your local BASF

PRIMER representative.

Minimum 0.2kg/m².

BASF reserves the right to have the true cause of

®

MasterTop 1240 – 3 0 kg unit yields any difficulty determined by accepted test

1 4 . 3 8 litres (including colour pack) methods.

EQUIPMENT CARE QUALITY AND CARE

All products originating from BASF Construction

Remove uncured MasterTop® 1240 using Xylene.

Chemicals South Africa are manufactured under a

management system independently certified to

STORAGE conform to the requirements of the quality,

Store out of direct sunlight, clear of the ground on environmental and occupational health & safety

pallets protected from rainfall. Avoid excessive standards ISO 9001, 2008.

compaction and protect from extremes of

temperatures. * Properties listed are based on laboratory controlled tests.

Failure to comply with the recommended storage ® = Registered trademark of the BASF-Group in many countries.

conditions may result in premature deterioration of

the product or packaging. For specific storage

advice consult BASF's Technical Services

Department.

The technical information and application advice given in this BASF publication are based on the present state of

STATEMENT OF our best scientific and practical knowledge. As the information herein is of a general nature, no assumption can be

RESPONSIBILITY made as to a product's suitability for a particular use or application and no warranty as to its accuracy, reliability or

completeness either expressed or implied is given other than those required by law. The user is responsible for

checking the suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by

NOTE BASF either orally or in writing may be followed, modified or rejected by the owner, engineer or contractor since

they, and not BASF, are responsible for carrying out procedures appropriate to a specific application.

BASF Construction Chemicals South Africa (Pty) Ltd

852 Sixteenth Road, Midrand

PO Box 2803, Halfway House, 1685

Tel: +27 11 203 2405 Fax: +27 11 203 2679

www.master-builders-solutions.basf.co.za

You might also like

- Mastertop 1240 Plus PDFDocument4 pagesMastertop 1240 Plus PDFFrancois-No ratings yet

- Mastertop 1240 TdsDocument3 pagesMastertop 1240 Tdsdilshad khanNo ratings yet

- Mastertop 1210 - TdsDocument3 pagesMastertop 1210 - TdstechnbksNo ratings yet

- Mastertop 1210 TdsDocument2 pagesMastertop 1210 TdsAhmed AssafNo ratings yet

- Mastertop 1200 TdsDocument2 pagesMastertop 1200 TdsAhmed AssafNo ratings yet

- Mastertop 1740m 12-04Document3 pagesMastertop 1740m 12-04djrote4No ratings yet

- Mastertop 1330: Polyurethane, Protective Traffic-Deck Coating SystemDocument3 pagesMastertop 1330: Polyurethane, Protective Traffic-Deck Coating SystemFrancois-No ratings yet

- 17 - TDS - Mastertop 1250 Epoxy MosaicDocument4 pages17 - TDS - Mastertop 1250 Epoxy MosaicaahtagoNo ratings yet

- BASF MasterTop 1205 Data SheetDocument3 pagesBASF MasterTop 1205 Data SheetAhmed AssafNo ratings yet

- MasterTop 1210 - MYSG - v2.0219Document2 pagesMasterTop 1210 - MYSG - v2.0219Muhammad AzrinNo ratings yet

- Mastertop 1255: Decorative Aggregate-Based Resin Flooring SystemDocument3 pagesMastertop 1255: Decorative Aggregate-Based Resin Flooring SystemFrancois-No ratings yet

- Mastertop 1230 Plus PDFDocument3 pagesMastertop 1230 Plus PDFFrancois-No ratings yet

- TDS - Mastertop 1240 PlusDocument3 pagesTDS - Mastertop 1240 PlusVenkata RaoNo ratings yet

- Mastertop 1221 A PDFDocument3 pagesMastertop 1221 A PDFFrancois-No ratings yet

- Mastertop 1210 Plus PDFDocument3 pagesMastertop 1210 Plus PDFFrancois-No ratings yet

- Basf Mastertop 1205 Tds PDFDocument3 pagesBasf Mastertop 1205 Tds PDFEn CivilNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- Mastertop 1240: Epoxy Based High Strength Mortar Flooring SystemDocument2 pagesMastertop 1240: Epoxy Based High Strength Mortar Flooring Systemdilshad khanNo ratings yet

- MasterTop 1205 - MYSG - v2. 0219Document2 pagesMasterTop 1205 - MYSG - v2. 0219Muhammad AzrinNo ratings yet

- Mastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Two Component Solvent Free High Build Epoxy Floor CoatingFrancois-No ratings yet

- Mastertop 1324: Seamless, Self-Smoothing Heavy Duty Polyurethane Based Flooring SystemDocument4 pagesMastertop 1324: Seamless, Self-Smoothing Heavy Duty Polyurethane Based Flooring SystemFrancois-No ratings yet

- Mastertop 1207 TdsDocument3 pagesMastertop 1207 TdsAhmed IbrahimNo ratings yet

- Basf Masteremaco S 488 v1 TdsDocument2 pagesBasf Masteremaco S 488 v1 Tdsraahul_nNo ratings yet

- MasterTop 430Document32 pagesMasterTop 430Ahmad ElghazolyNo ratings yet

- Mastertop 564Document2 pagesMastertop 564Doby Yuniardi100% (1)

- Masteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortardepakmunirajNo ratings yet

- Masteremaco S 348Document2 pagesMasteremaco S 348shahzadNo ratings yet

- Mastertop TC 458 PDFDocument3 pagesMastertop TC 458 PDFFrancois-No ratings yet

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- Mastertop 1273 As: Description PackagingDocument3 pagesMastertop 1273 As: Description PackagingShaik J MohamedNo ratings yet

- 09 - TDS - Mastertop 1205Document3 pages09 - TDS - Mastertop 1205aahtagoNo ratings yet

- Masteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 488: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarAvinash PrajapatiNo ratings yet

- BASF - MasterEmaco N 5200CI - TDSDocument3 pagesBASF - MasterEmaco N 5200CI - TDSKelvinNo ratings yet

- Mastertop 1110 TdsDocument3 pagesMastertop 1110 Tdssr2011glassNo ratings yet

- BASF MasterEmaco S488Document2 pagesBASF MasterEmaco S488HJNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- MasterEmaco - S 348 v2Document2 pagesMasterEmaco - S 348 v2Umeshchandra PatilNo ratings yet

- TDS - Mastertop 1105Document3 pagesTDS - Mastertop 1105Venkata Rao100% (1)

- Masterseal Traffic 1330 TdsDocument3 pagesMasterseal Traffic 1330 TdsSolomon AhimbisibweNo ratings yet

- Masterseal TC 254 - TdsDocument2 pagesMasterseal TC 254 - TdsHanyNo ratings yet

- Mastertop 1240i M App 12-04Document2 pagesMastertop 1240i M App 12-04djrote4No ratings yet

- Basf Mastertop 1240 Tds PDFDocument2 pagesBasf Mastertop 1240 Tds PDFHari HaranNo ratings yet

- TDS - Mastertop 1740Document3 pagesTDS - Mastertop 1740Venkata RaoNo ratings yet

- Mastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingDocument3 pagesMastertop 1205: Three Component Solvent Free High Build Epoxy Floor CoatingEngTamerNo ratings yet

- MasterProtect 300 Asean v3-0415Document2 pagesMasterProtect 300 Asean v3-0415Muhammad Fadhil ImansyahNo ratings yet

- BASF Masterseal 540 PDFDocument2 pagesBASF Masterseal 540 PDFJM Subion100% (1)

- MasterTop 1205Document71 pagesMasterTop 1205Ahmad ElghazolyNo ratings yet

- MasterEmaco - S 348 v1Document2 pagesMasterEmaco - S 348 v1vahab_shaik0% (1)

- Masteremaco - S 348 v2Document2 pagesMasteremaco - S 348 v2shahzadNo ratings yet

- X-Tech UraFloor CSDocument2 pagesX-Tech UraFloor CSLONG LASTNo ratings yet

- Mastertop® BC 372Document4 pagesMastertop® BC 372Marko ZgbNo ratings yet

- Masterseal 540: Flexible, Polymer Cement Waterproofing SlurryDocument2 pagesMasterseal 540: Flexible, Polymer Cement Waterproofing SlurryRicky Reung100% (1)

- Mastertop TC 405 W PDFDocument3 pagesMastertop TC 405 W PDFFrancois-No ratings yet

- TDS MasterSeal-540Document2 pagesTDS MasterSeal-540Taposh PaulNo ratings yet

- Mastertop DAF PDFDocument4 pagesMastertop DAF PDFFrancois-No ratings yet

- MasterTop 1200 EngDocument3 pagesMasterTop 1200 EngMohiuddin MuhinNo ratings yet

- Mastertop SR 1 and 3 TdsDocument2 pagesMastertop SR 1 and 3 Tdsmuhammednaar32No ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Drawings - ENYAU BRIDGE 1-8mDocument10 pagesDrawings - ENYAU BRIDGE 1-8mSolomon AhimbisibweNo ratings yet

- Reinforced Concrete Design, Performance and Applications by Sharon RobinsonDocument194 pagesReinforced Concrete Design, Performance and Applications by Sharon RobinsonSolomon AhimbisibweNo ratings yet

- Soil Module by AbaqusDocument124 pagesSoil Module by AbaqusThànhNamNo ratings yet

- Dynamic Response of Moving LoadDocument31 pagesDynamic Response of Moving LoadSolomon AhimbisibweNo ratings yet

- Wind Load Calculation On Walls Calculation of Wind Loads On External WallsDocument29 pagesWind Load Calculation On Walls Calculation of Wind Loads On External WallsSolomon AhimbisibweNo ratings yet

- Drawings - ENYAU BRIDGE 2-15mDocument10 pagesDrawings - ENYAU BRIDGE 2-15mSolomon AhimbisibweNo ratings yet

- Improving Metacognition: A Case Study of A Business Critical Thinking CourseDocument19 pagesImproving Metacognition: A Case Study of A Business Critical Thinking CourseSolomon AhimbisibweNo ratings yet

- Critical Thinking ToolkitDocument1 pageCritical Thinking ToolkitSolomon AhimbisibweNo ratings yet

- Moment Distribution Method of AnalysisDocument1 pageMoment Distribution Method of AnalysisSolomon AhimbisibweNo ratings yet

- Critical Thinking-Appeal To ReasonDocument1 pageCritical Thinking-Appeal To ReasonSolomon AhimbisibweNo ratings yet

- Critical Thinking in Technology StudentsDocument6 pagesCritical Thinking in Technology StudentsSolomon AhimbisibweNo ratings yet

- InterviewDocument21 pagesInterviewSolomon AhimbisibweNo ratings yet

- Yield Line Method for Slabs with Different SupportsDocument144 pagesYield Line Method for Slabs with Different SupportsUmed ADA-ALSATARNo ratings yet

- Critical Thinking Sample Test With AnswersDocument3 pagesCritical Thinking Sample Test With AnswersSolomon Ahimbisibwe0% (1)

- Automatic Yield-Line Analysis of Practical Slab Configurations Via Discontinuity Layout OptimizationDocument17 pagesAutomatic Yield-Line Analysis of Practical Slab Configurations Via Discontinuity Layout OptimizationSolomon AhimbisibweNo ratings yet

- Structural Design of High Rise BuildingsDocument142 pagesStructural Design of High Rise BuildingsOscar Zúñiga Cuevas100% (1)

- Structural Design: A (In D (In) B T B H/T I (In Z S I (In R LP (FT) LDocument3 pagesStructural Design: A (In D (In) B T B H/T I (In Z S I (In R LP (FT) LRAFAELNo ratings yet

- Structral Design Laboratory: Lab ManualDocument72 pagesStructral Design Laboratory: Lab ManualSolomon AhimbisibweNo ratings yet

- 3 Storey Academic Building Structural Analysis and DesignDocument78 pages3 Storey Academic Building Structural Analysis and DesignSolomon AhimbisibweNo ratings yet

- Sample Admission Test For MS Civil Engineering Degree ProgramDocument2 pagesSample Admission Test For MS Civil Engineering Degree ProgramDhiraj ShakyaNo ratings yet

- Design & Analysis of Multi Storeyed Building (G+10) by Using Stadd Pro V8i (Series 4)Document4 pagesDesign & Analysis of Multi Storeyed Building (G+10) by Using Stadd Pro V8i (Series 4)engyana engyyyNo ratings yet

- Professional Engineering Work: January 2014Document21 pagesProfessional Engineering Work: January 2014Solomon AhimbisibweNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- ANALYSIS AND DESIGN OF A THREE-STOREY BUILDINGDocument49 pagesANALYSIS AND DESIGN OF A THREE-STOREY BUILDINGDebashishParida89% (9)

- Am STR 06048 01Document46 pagesAm STR 06048 01Solomon AhimbisibweNo ratings yet

- RC Design PDFDocument58 pagesRC Design PDFZerihun IbrahimNo ratings yet

- Ph.D. Preliminary Examination AnalysisDocument24 pagesPh.D. Preliminary Examination AnalysisRAFAELNo ratings yet

- Repair&Rehabilitationofstructures (Electiveiii) 1493024074Document1 pageRepair&Rehabilitationofstructures (Electiveiii) 1493024074Solomon AhimbisibweNo ratings yet

- Analysis & Design of Reinforced Concrete Structures: Hussam Ali MohammedDocument4 pagesAnalysis & Design of Reinforced Concrete Structures: Hussam Ali MohammedSolomon AhimbisibweNo ratings yet

- Products CatalogueDocument60 pagesProducts CatalogueSolomon Ahimbisibwe100% (7)

- Titanium Di OxideDocument57 pagesTitanium Di Oxideakshit patidar100% (1)

- The Profesional's Advisor On ProceedureDocument136 pagesThe Profesional's Advisor On ProceedureINSTECH ConsultingNo ratings yet

- Chapter 3Document23 pagesChapter 3PreethaSureshNo ratings yet

- Calorimetry SheetDocument26 pagesCalorimetry SheetAbdullahNo ratings yet

- 2023 CHEMISTRY F3 P2 QS T2 Exam Teacher - Co - .KeDocument9 pages2023 CHEMISTRY F3 P2 QS T2 Exam Teacher - Co - .Kealooben2No ratings yet

- Gold in New Brunswick, CanadaDocument8 pagesGold in New Brunswick, CanadaART'S PLACENo ratings yet

- FevicolDocument10 pagesFevicolashutoshkumar5549No ratings yet

- AISI 4140 - 42Cr4Mo2Document2 pagesAISI 4140 - 42Cr4Mo2rajbir_singh75% (4)

- 0160e-Welding Procedures Data Sheet PDFDocument1 page0160e-Welding Procedures Data Sheet PDFShane SNo ratings yet

- CRT, Crte: Vertical, Multistage, Centrifugal Titanium PumpsDocument36 pagesCRT, Crte: Vertical, Multistage, Centrifugal Titanium Pumpsost lsblNo ratings yet

- Home Reading About Civil EngineeringDocument4 pagesHome Reading About Civil EngineeringseryozhNo ratings yet

- Thermal Engineering for 500 MW BoilerDocument31 pagesThermal Engineering for 500 MW BoilerRituraaj Singh RajputNo ratings yet

- In Plant Training report-TCCDocument2 pagesIn Plant Training report-TCCSabiya KabeerNo ratings yet

- Starflam PA66 25VDocument2 pagesStarflam PA66 25VjahabarsathickNo ratings yet

- Ulma Offer Summary 32011 GarlandsDocument47 pagesUlma Offer Summary 32011 GarlandsSarah Layadi100% (1)

- Industrial Lead Acid Batteries: Types and Their SelectionDocument5 pagesIndustrial Lead Acid Batteries: Types and Their SelectionSellappan MuthusamyNo ratings yet

- Pipe Fittings STDDocument4 pagesPipe Fittings STDimrancenakkNo ratings yet

- Vanadium (V) OxideDocument6 pagesVanadium (V) OxidedearbhupiNo ratings yet

- A comparative study on Poly (ε-caprolactone) film degradation atDocument8 pagesA comparative study on Poly (ε-caprolactone) film degradation atHugo David Enriquez EspinosaNo ratings yet

- Basic NDT - PT QB - 1Document23 pagesBasic NDT - PT QB - 1prabhakaran.SNo ratings yet

- Direct Contact Chilling and Freezing ofDocument30 pagesDirect Contact Chilling and Freezing ofAnonymous sZbhHCQYNo ratings yet

- 04 Samss 003Document4 pages04 Samss 003Moustafa Bayoumi100% (1)

- Lecture 1A.1: Introduction To Steel's Role in Construction in EuropeDocument64 pagesLecture 1A.1: Introduction To Steel's Role in Construction in Europealadinmf1No ratings yet

- EKOplus BS TypeaDocument2 pagesEKOplus BS TypeaAhmedRamadanNo ratings yet

- Chemical Reaction Unit Test - QuizizzDocument4 pagesChemical Reaction Unit Test - QuizizzAngkita KiranaNo ratings yet

- Pipeline Defect Assessment ManualDocument18 pagesPipeline Defect Assessment Manualhadi13775% (4)

- 3 Annexures: Annexure 1: Production DetailsDocument53 pages3 Annexures: Annexure 1: Production Detailsmarcela walterosNo ratings yet

- Conductive Plastics For Electrical and Electronic Applications PDFDocument4 pagesConductive Plastics For Electrical and Electronic Applications PDFsonchemenNo ratings yet

- CIVIL MATERIAL RATESDocument25 pagesCIVIL MATERIAL RATESNishan GajurelNo ratings yet

- Operating TablesDocument31 pagesOperating TablesJeffersonGutiérrez67% (3)