Professional Documents

Culture Documents

SGS-OI-L2-109 Risk and Hazard Assessment-A4-EN-18-Rev02

Uploaded by

Yulian TutunaruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SGS-OI-L2-109 Risk and Hazard Assessment-A4-EN-18-Rev02

Uploaded by

Yulian TutunaruCopyright:

Available Formats

OPERATIONAL INTEGRITY

MANAGEMENT SYSTEM

RISK AND HAZARD ASSESSMENT

GLOBAL GROUP MINIMUM STANDARD OI-L2-109

Revision: 02

Issue Date: 13 July 2018

Review Date: 13 July 2021

Author: N. Popov

Approver: A. Denielle

REVISION RECORD

Revision: Date: Changes Since Last Issue:

00 09/2013 (Initial issue)

01 09/2016 ‘Who Is This For’ extended to cover various purposes of OIMS Gap Analysis.

‘What Situations Are/Are Not Covered?’ extended to include other locations and

acquisitions.

‘Accountabilities: Manager/Supervisor’ split and re-written. ‘Operational

Integrity’ and ‘Employees and Contractors’ bullets added.

Section 3: new. Sections 4, 5, 6: rewritten

All sections: ‘likelihood’ changed to ‘probability’.

Section 7: Addition to 2nd sentence, added new last sentence.

02 07/2018 Section 10: ‘Reference Documents’ added.

PURPOSE

Group minimum standard to assure compliance with identification and Risk Assessment of HSE hazards, the

evaluation and implementation of control and recovery measures and to document that HSE risks have been

reduced to an acceptable level As Low As Reasonably Practicable (ALARP).

The requirements stated below fully meet Group minimum standards and expectations. All SGS Operations and

Functions shall comply with this Group Minimum Standard and ensure that it is fully implemented within the

corresponding local Level 3 Procedure.

WHO IS THIS FOR?

Managers/Supervisors, Operational Integrity personnel, or any employee conducting an OIMS gap analysis of

various purposes (for development/review of a local Level 3 procedure, an OI audit, a Management Review, etc.).

WHAT SITUATIONS ARE/ARE NOT COVERED?

These requirements apply to:

© SGS Group Management SA - 2018 - All rights reserved - SGS is a registered trademark of SGS Group Management SA

This is an uncontrolled copy when printed, unless signed by an authorised signatory.

The latest revision of this document and the official distribution list are those approved in the OIMS database.

RISK AND HAZARD ASSESSMENT

OI-L2-109 REV. 02 07/2018

PAGE 2 OF 5

All personnel, including employees, clients, and contractors on SGS locations or locations operated by

SGS.

SGS employees and contractors on locations where work is conducted on behalf of SGS.

It also applies to SGS acquisitions.

These requirements do not apply to Client employees operating on their own sites.

NOTE: Mandatory elements are in orange sections.

GROUP MINIMUM REQUIREMENTS

1. ACCOUNTABILITIES

All applicable personnel shall be held accountable for complying with SGS Group and local legal

requirements.

Managers shall:

Be accountable for the successful implementation and results of the Risk Management process.

Ensure Risk Assessments are conducted during the design phase for new projects.

Ensure resources are made available to enable risk assessments to be conducted, effective

barriers are in place and personnel receive the relevant HSE training.

Validate the Risk Assessments through a formal sign-off process.

Supervisors shall:

Ensure appropriate barriers are in place and correctly implemented with all employees and

contractors on all work sites / operations.

Ensure risk assessments remain valid by reviewing them when new / additional hazards are

introduced, or when activities have changed to beyond the scope of the original assessment, or

formal validity of the RA is overdue, whichever occurs first.

Update existing risk assessments as a result of learning from incidents

Ensure there is a systematic categorization of tasks and hazards, that evaluations of risks are

reasonable, and that barriers are practical to implement.

Ensure effective communication of hazards and barriers to the affected personnel.

Operational Integrity shall:

Provide training material for Risk Assessment process

Facilitate meetings and assure the process is implemented according to the Group minimum

requirements.

Review activities and established barriers to assess if risks have been reduced to As Low As

Reasonably Practicable (ALARP).

Employees and Contractors shall:

Comply with SGS Group and local legal requirements and shall understand their critical roles and

responsibilities identified from the Risk Management process.

Be involved in the risk assessment process to identify hazards, risks and Barriers.

Implement the outcomes of Risk Assessments (supported by the supervisor).

Have the responsibility to “Stop Work Authority” if they have doubts about the hazards and

effectiveness of the barriers; refer to the Group Minimum Standard OI-L2-324 Stop Work Process.

© SGS Group Management SA - 2018 - All rights reserved - SGS is a registered trademark of SGS Group Management SA

This is an uncontrolled copy when printed, unless signed by an authorised signatory.

The latest revision of this document and the official distribution list are those approved in the OIMS database.

RISK AND HAZARD ASSESSMENT

OI-L2-109 REV. 02 07/2018

PAGE 3 OF 5

2. DEFINITIONS

ALARP – As Low as Reasonably Practicable – The point at which the costs (in time, money and

effort) of further risk reduction is grossly disproportionate to the risk reduction achieved.

Barrier – A risk Control or a Recovery Measure. Barriers provide the means of preventing an event

or incident, or of mitigating the consequences. A Barrier can be an item of equipment or a human

intervention.

Control – In the context of managing risk a type of Barrier that is a means of preventing an

incident. Controls can be engineering, procedural or behavioural.

Hazard – A hazard is an agent that has the potential to harm the health and safety of people or to

damage assets, the environment, or reputation.

Recovery Measure – A Barrier that reduces the consequences of the release of a hazard as a

result of an incident. Recovery Measures can be engineering, procedural or behavioural

measures.

Risk – A risk is the potential for realisation of unwanted, negative consequences from a hazard.

The combination of the probability and consequence(s) of a specified hazardous event occurring,

including the severity of injury or ill health that may be caused by the event or exposure(s).

Risk Assessment (RA) – A step in the Risk Management process. Risk Assessment is measuring

two quantities of the risk, the magnitude of the potential consequences, and the probability that the

consequences will occur. Risk assessments can be qualitative or quantitative, depending on the

method for evaluating the two risk quantities.

Risk Assessment Matrix (RAM) – A tool that standardizes qualitative risk assessment and

facilitates the categorization of risk from hazards to people, assets, environment, and company

reputation.

Risk Management – Coordinated activities to direct and control an organisation with regard to risk.

3. RISK ASSESMENT EXPECTATIONS

Risk Assessments shall be conducted on all hazards and activities (such as task, operation, project,

acquisition, etc.) performed or planned by SGS Group with the following expectations to be met:

a) There shall be a systematic and documented identification of hazards and HSE impacts of all

planned and ongoing SGS activities.

b) Hazard and impact information shall be used in conjunction with information on operational

practices (actual and proposed), in order to make an assessment of risk in terms of probability and

severity.

c) Risk assessment information shall be used to determine Barriers (risk controls and recovery

measures) to minimize risks to an acceptable level ALARP.

d) The feasibility of barriers shall be assessed with reference to the magnitude of the risk, the Global

OIMS minimum requirements, and the commercial and business needs of SGS.

e) In the case of new projects / major modifications or mergers/acquisitions, the hazard identification

and risk assessments shall be conducted at a stage early enough for barriers to be incorporated in

the design stage.

f) Risk Assessments are dynamic and must be reviewed and updated whenever a procedure,

process or method of work is changed, when non-routine tasks are undertaken, or every three

years, whichever comes first.

g) Local Procedures shall ensure that hazard and risk assessment information and documentation is

communicated to those persons involved or impacted by the activity.

h) Under no circumstances is an activity to be performed without a clear understanding of the hazards

involved and implementation of those barriers that are to be used to minimise risks to an

acceptable level, ALARP.

© SGS Group Management SA - 2018 - All rights reserved - SGS is a registered trademark of SGS Group Management SA

This is an uncontrolled copy when printed, unless signed by an authorised signatory.

The latest revision of this document and the official distribution list are those approved in the OIMS database.

RISK AND HAZARD ASSESSMENT

OI-L2-109 REV. 02 07/2018

PAGE 4 OF 5

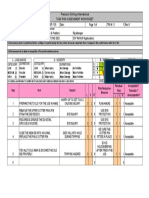

4. RISK ASSESMENT PROCESS

Effective identification of hazards, assessment of those risks associated with any given hazard or

activity, and implementation of barriers is best performed by following the listed guidelines:

a) Identify Activities to be performed.

b) Identify all Hazards associated with each activity.

c) Identify “existing” Barriers (barriers already in place).

d) Assign an “initial” risk rating for each hazard (by determining probability and severity of potential

consequences) utilising L4-109-01 Risk Assessment Matrix. The “initial” risk rating takes into

consideration the existing barriers already in place.

e) Assess the tolerability of the initial risk (if the initial risk is deemed at an acceptable level ALARP).

f) If the initial risk is not deemed ALARP the Risk Assessment Team will then identify further barriers

(refer to section “Risk Mitigation Hierarchy”) and re-assess those activities and hazards considering

further barriers that manage risk to an acceptable level ALARP.

g) Assign “reduced” risk rating. The “reduced” risk must be deemed As Low As Reasonably

Practicable (ALARP); no more than that which can reasonably be achieved. If after all barriers as

set by the Risk Mitigation Hierarchy have been evaluated and the reduced risk is still greater than

ALARP, the Risk Assessment Team will revisit the activity in an attempt to achieve a rating that is

ALARP. If this cannot be accomplished, the activity cannot be done without the express written

permission of the senior manager on site, and after consultation with Client representatives, where

applicable.

h) Record risk assessment results on L4-109-02 Risk Assessment Form.

i) Implement the barriers as required and communicate the Risk Assessment information.

j) Review and revise the Risk Assessment whenever new / additional hazards are introduced, or

when activities have changed to beyond the scope of the original assessment, or when formal

validity of the RA is overdue, whichever comes first.

5. RISK ASSESSMENT TEAM

A Risk Assessment Team shall be constituted to evaluate each hazard and/or activity performed on all

sites/projects. The Risk Assessment Team shall consist of a minimum number of 3 with the makeup as

follows:

Person who performs and/or experienced in the activity.

Risk Assessment moderator. Someone trained in the Risk Assessment process.

Another person not related to the activity being assessed.

Technical Specialists (where required).

6. USING THE RISK ASSESSMENT MATRIX (RAM)

The Risk Assessment Matrix (RAM) is used to classify each risk associated with the hazard or activity

being evaluated. It measures the probability of a negative consequence and the amount of harm

(severity) that consequence may cause to people, assets, environment, and reputation. All four

categories of harm are to be assessed for each hazard/activity.

The Incident Reporting and Management, OI Audit, and OI Non-conformity standards/procedures must

be aligned to use the RAM for managing/assessing actual incidents, near-misses, hazards/risks and

non-compliances.

© SGS Group Management SA - 2018 - All rights reserved - SGS is a registered trademark of SGS Group Management SA

This is an uncontrolled copy when printed, unless signed by an authorised signatory.

The latest revision of this document and the official distribution list are those approved in the OIMS database.

RISK AND HAZARD ASSESSMENT

OI-L2-109 REV. 02 07/2018

PAGE 5 OF 5

7. RISK MITIGATION HIERARCHY

Once hazards are identified and risks are evaluated, Barriers must be identified and implemented to

reduce risk to achieve an acceptable level of risk As Low As Reasonably Practicable (ALARP). The risk

mitigation hierarchy is as follows in order:

a) Elimination,

b) Substitution,

c) Engineering controls,

d) Administrative controls,

e) Personal Protective Equipment.

When selecting and implementing Barriers preference shall be given to those at the top of the risk

mitigation hierarchy.

8. RECORD RETENTION

Records shall be managed and retained as required by the Group Minimum Standard, OI-L2-715

Records Management.

9. TRAINING REQUIREMENTS

Training shall be managed and conducted as required by the Group Minimum Standard, OI-L2-112

Employee Training, Competency, and Certification.

10. REFERENCE DOCUMENTS

OI-L2-112 Employee Training, Competency, and Certification

OI-L2-715 Records Management

OI-L2-323 Permit to Work

OI-L2-324 Stop Work Process

10.1 FORMS

10.1.1 RISK ASSESSMENT M ATRIX

OI-L4-109-01 Risk Assessment Matrix

10.1.2 RISK ASSESSMENT FORM

OI-L4-109-02 Risk Assessment Form

10.2 ATTACHMENTS

10.2.1 RISK ASSESSMENT IN SOP

OI-L4-109-03 Risk Assessment in SOP

10.2.2 RISK MITIGATION HIERARCHY

OI-L4-109-04 Risk Mitigation Hierarchy

10.2.3 GUIDANCE: RISK ASSESSMENT IMPLEMENTATION

OI-L4-109-05 Guidance: Risk Assessment Implementation

__________________________________________________________________________________________

** End of Document **

Controlled printed copies carry authorised signature here.........................................................

__________________________________________________________________________________________

© SGS Group Management SA - 2018 - All rights reserved - SGS is a registered trademark of SGS Group Management SA

This is an uncontrolled copy when printed, unless signed by an authorised signatory.

The latest revision of this document and the official distribution list are those approved in the OIMS database.

You might also like

- 04 - Risk ManagementDocument27 pages04 - Risk ManagementTatak Bay AhmedNo ratings yet

- Short Service Employees ProcedureDocument6 pagesShort Service Employees ProcedureriamegaNo ratings yet

- Contractor HSE Management ProgramDocument12 pagesContractor HSE Management ProgramAhmed IbrahimNo ratings yet

- Pro 4-5-0001!1!06 Lifting OperationsDocument11 pagesPro 4-5-0001!1!06 Lifting OperationsHSE PULAI ANo ratings yet

- EHS BHP BillitonDocument28 pagesEHS BHP Billitonkusumawardati100% (1)

- Changing Turbo An Equipment (WS)Document6 pagesChanging Turbo An Equipment (WS)John KalvinNo ratings yet

- PT Tabea Bersinar Abadi Hygiene ProcedureDocument4 pagesPT Tabea Bersinar Abadi Hygiene ProcedureNovida Rosalia Sinaga0% (1)

- IH Plan GoalsDocument3 pagesIH Plan GoalsKukuh WidodoNo ratings yet

- AzSPU First Aid Management ProgrammeDocument12 pagesAzSPU First Aid Management ProgrammeAmir M. ShaikhNo ratings yet

- HSE-P-17 Setting and Reviewing HSE Objectives Issue 1.1Document5 pagesHSE-P-17 Setting and Reviewing HSE Objectives Issue 1.1eng20072007No ratings yet

- Manage Occupational Health RisksDocument2 pagesManage Occupational Health RisksKhalid El MasryNo ratings yet

- Npe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesDocument1 pageNpe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesilhamNo ratings yet

- ERP Editable Flow ChartDocument1 pageERP Editable Flow ChartVictorNo ratings yet

- Precision Drilling International Task Risk Assessment WorksheetDocument2 pagesPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Hazard identification and risk assessmentDocument2 pagesHazard identification and risk assessmentfadhil azharNo ratings yet

- Safety checklist and reportsDocument16 pagesSafety checklist and reportsAdrianus PramudhitaNo ratings yet

- Espoo ReportDocument38 pagesEspoo Reportraka9009No ratings yet

- HSE Procedure For HSE Planning and AuditingDocument5 pagesHSE Procedure For HSE Planning and AuditingOkba SekiouNo ratings yet

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- Bolgatanga-Bawku-Pulmakom Road: Climate Change Risk Assessment and GHG Emissions CalculationDocument38 pagesBolgatanga-Bawku-Pulmakom Road: Climate Change Risk Assessment and GHG Emissions CalculationSérgio CoutoNo ratings yet

- Oil Blowout Contingency Planning and CountermeasuresDocument6 pagesOil Blowout Contingency Planning and Countermeasuresdaburto2No ratings yet

- Valeura Hse Management SystemDocument19 pagesValeura Hse Management SystemMuhammad SuhaibNo ratings yet

- P 21 Vehicle Management Procedure Rev02Document21 pagesP 21 Vehicle Management Procedure Rev02godwinNo ratings yet

- BP Driving Safety ProcedureDocument11 pagesBP Driving Safety ProcedureKama EfendiyevaNo ratings yet

- Al Asab Hse Presentation July-14Document15 pagesAl Asab Hse Presentation July-14Sri DharanNo ratings yet

- Road & Traffic Safety Procedure: Pars Oil & Gas CompanyDocument29 pagesRoad & Traffic Safety Procedure: Pars Oil & Gas CompanyKostan AbdillahNo ratings yet

- HSE MS Bridging Ducument Between UCD and SinopecDocument12 pagesHSE MS Bridging Ducument Between UCD and SinopecbilouNo ratings yet

- Ohs ManualDocument98 pagesOhs ManualAyodeji Fasan SimeonNo ratings yet

- Change Out Rig Tong DiesDocument1 pageChange Out Rig Tong DiesAbdul Hameed OmarNo ratings yet

- Daily Progress Report HSE: Date 17/9/18 Equipments UsedDocument1 pageDaily Progress Report HSE: Date 17/9/18 Equipments Usedjithin shankarNo ratings yet

- HSE Manual Rev00Document328 pagesHSE Manual Rev00Nikoleta HirleaNo ratings yet

- Chevron Annual Report SupplementDocument68 pagesChevron Annual Report SupplementLaurentiu CiobotaricaNo ratings yet

- Shale Gas StudyDocument276 pagesShale Gas StudyFelipe CorrêaNo ratings yet

- BOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Document21 pagesBOND-NG18000096-GBRG2-HX5880-00001 - HSSE Plan - C01a-Sign2Jude EdohorNo ratings yet

- HSE Bridging Document for ONGC-Quippo Drilling OperationsDocument27 pagesHSE Bridging Document for ONGC-Quippo Drilling OperationsbilouNo ratings yet

- Managing Director ReportDocument2 pagesManaging Director ReportLayes AhmedNo ratings yet

- AzSPU Noise Management and Hearing Conservation ProgrammeDocument12 pagesAzSPU Noise Management and Hearing Conservation ProgrammeAmir M. Shaikh100% (1)

- Safety For Business Travel PolicyDocument14 pagesSafety For Business Travel PolicyZaitoon NadeemNo ratings yet

- Safety Case Guideline: Engineers Australia Practice NoteDocument24 pagesSafety Case Guideline: Engineers Australia Practice NoteHtoo Htoo KyawNo ratings yet

- Managing Health For Field Operations in Oil and Gas ActivitiesDocument44 pagesManaging Health For Field Operations in Oil and Gas Activitiesadeoye_okunoyeNo ratings yet

- Pre-Spud InspectionDocument6 pagesPre-Spud InspectionHany100% (2)

- Pertamina EP - Goldwater TMT Balance Sheet AnalysisDocument76 pagesPertamina EP - Goldwater TMT Balance Sheet AnalysisidancielersNo ratings yet

- 2 Travel Abroad PolicyDocument23 pages2 Travel Abroad PolicyMyGTMOAngel2009No ratings yet

- Sop-4 Gas CylindersDocument7 pagesSop-4 Gas CylindersArieNo ratings yet

- BGPI-HSSE-012 Minimum PPE Requirements PDFDocument4 pagesBGPI-HSSE-012 Minimum PPE Requirements PDFDale WearpackNo ratings yet

- Daily HSE Summary Report 16-02-2018Document3 pagesDaily HSE Summary Report 16-02-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Internship SafetyDocument34 pagesInternship SafetyDakshit ItaliaNo ratings yet

- Invitation to Tender for Painting WorksDocument42 pagesInvitation to Tender for Painting WorksOkeymanNo ratings yet

- Jojonomic HSE Solution - Package-RevisiDocument4 pagesJojonomic HSE Solution - Package-Revisihimawan sutantoNo ratings yet

- 7010 - Subcontractor Performance Assessment FormDocument4 pages7010 - Subcontractor Performance Assessment FormRifatRahmatullahNo ratings yet

- HSE Annual Report 2011 PDFDocument10 pagesHSE Annual Report 2011 PDFHasanuddin HAMIDNo ratings yet

- ISO 18001 ChecklistDocument6 pagesISO 18001 ChecklistRashid100% (1)

- 2 32 2 1 13 01-CS-ProcedureDocument30 pages2 32 2 1 13 01-CS-ProcedureMahmoud SaiedNo ratings yet

- IADC Incident StatisticsDocument15 pagesIADC Incident StatisticsAnisBelhajAissaNo ratings yet

- Contoh HSEMSDocument66 pagesContoh HSEMSDale WearpackNo ratings yet

- 00 - Petrobel IMS Overview FinalDocument52 pages00 - Petrobel IMS Overview FinalAhmed El AmraniNo ratings yet

- Heat Stress MGMT ProgramDocument24 pagesHeat Stress MGMT ProgramPrathap KamarajNo ratings yet

- DNV GL HSE Risk AssessmentDocument3 pagesDNV GL HSE Risk AssessmentWilliam VazquezNo ratings yet

- Risk AnalysisDocument125 pagesRisk AnalysisDennise ShughniNo ratings yet

- RA Folder Jan 12Document83 pagesRA Folder Jan 12mouben100% (2)

- BSI ISO14001 Assessment Checklist UK enDocument4 pagesBSI ISO14001 Assessment Checklist UK enSamuel Maclean ArthurNo ratings yet

- Code of Integrity - English VersionDocument10 pagesCode of Integrity - English VersionVictor Rizal FilosofiNo ratings yet

- Your Certification Process Explained - FSSC and ISO22000 PDFDocument14 pagesYour Certification Process Explained - FSSC and ISO22000 PDFYulian TutunaruNo ratings yet

- Your Certification Process Explained - FSSC and ISO22000 PDFDocument14 pagesYour Certification Process Explained - FSSC and ISO22000 PDFYulian TutunaruNo ratings yet

- Best Practice Manual: For Soya Bean Cultivation in The Danube RegionDocument50 pagesBest Practice Manual: For Soya Bean Cultivation in The Danube RegionYulian TutunaruNo ratings yet

- Grape Wine - Generic HACCP PlanDocument9 pagesGrape Wine - Generic HACCP PlanYulian Tutunaru100% (1)

- Intimex Xuan Loc - Porfolio - 2022 (Autosaved)Document11 pagesIntimex Xuan Loc - Porfolio - 2022 (Autosaved)VyDangNo ratings yet

- Chap 123 AAADocument10 pagesChap 123 AAAHà Phương TrầnNo ratings yet

- MANGILIMAN, Neil Francel Domingo (Sep 28)Document8 pagesMANGILIMAN, Neil Francel Domingo (Sep 28)Neil Francel D. MangilimanNo ratings yet

- Property Assessed Clean EnerDocument41 pagesProperty Assessed Clean Enermd shoebNo ratings yet

- Provisions, Contingent Liabilities and Contingent Assets: Problem 1: True or FalseDocument6 pagesProvisions, Contingent Liabilities and Contingent Assets: Problem 1: True or FalseKim HanbinNo ratings yet

- The Application of Machine Learning and Deep LearnDocument20 pagesThe Application of Machine Learning and Deep LearnFran MoralesNo ratings yet

- Grade 8 Term 1 NotesDocument26 pagesGrade 8 Term 1 NotesShadow WalkerNo ratings yet

- Exercise 1 Key PDF Cost of Goods Sold InvenDocument1 pageExercise 1 Key PDF Cost of Goods Sold InvenAl BertNo ratings yet

- Company Profile: Inside Look at Leading Jacket ManufacturerDocument41 pagesCompany Profile: Inside Look at Leading Jacket ManufacturerVanika SharmaNo ratings yet

- Trade AgreementDocument6 pagesTrade AgreementFRANCIS EDWIN MOJADONo ratings yet

- Hypothesis-Driven DevelopmentDocument2 pagesHypothesis-Driven DevelopmentMuhammad El-FahamNo ratings yet

- Credit Portfolio Management of Bangladesh Krishi Bank: CreditportfoliomanagementofbangladeshkrishibankDocument7 pagesCredit Portfolio Management of Bangladesh Krishi Bank: CreditportfoliomanagementofbangladeshkrishibankBokulNo ratings yet

- Social Support For Expatriates Through Virtual Platforms: Exploring The Role of Online and Offline ParticipationDocument33 pagesSocial Support For Expatriates Through Virtual Platforms: Exploring The Role of Online and Offline ParticipationAniss AitallaNo ratings yet

- Purchase Decision ThesisDocument4 pagesPurchase Decision Thesisafcmayfzq100% (2)

- Adani Ports Financial RatiosDocument2 pagesAdani Ports Financial RatiosTaksh DhamiNo ratings yet

- Power TradingDocument6 pagesPower TradingKhyati GuptaNo ratings yet

- Parfums Cacharel de L'Oréal 1997-2007:: Decoding and Revitalizing A Classic BrandDocument21 pagesParfums Cacharel de L'Oréal 1997-2007:: Decoding and Revitalizing A Classic BrandrheaNo ratings yet

- Draft Law Making Process in IndiaDocument28 pagesDraft Law Making Process in IndiaMeraNo ratings yet

- Commentary: Ophthalmic Increasing Operations ofDocument2 pagesCommentary: Ophthalmic Increasing Operations ofDurval SantosNo ratings yet

- Conceptual Framework and Accounting Standards OverviewDocument170 pagesConceptual Framework and Accounting Standards OverviewJ LagardeNo ratings yet

- A Study On Consumer Buying Behavior of Young Adults Towards Coffee BrandDocument13 pagesA Study On Consumer Buying Behavior of Young Adults Towards Coffee BrandRomeo ChuaNo ratings yet

- E-Commerce Website Using MERN StackDocument5 pagesE-Commerce Website Using MERN StackIJRASETPublicationsNo ratings yet

- Invoice 39774Document1 pageInvoice 39774Global Computer AcademyNo ratings yet

- South Est BankDocument78 pagesSouth Est BankGolpo MahmudNo ratings yet

- PQ 0620-CombinedDocument55 pagesPQ 0620-CombinedMISODZI CHIBAKWENo ratings yet

- #34 Naranjo V Biomedica Health Care (Magsino)Document2 pages#34 Naranjo V Biomedica Health Care (Magsino)Trxc MagsinoNo ratings yet

- UD BUANA Trial BalanceDocument1 pageUD BUANA Trial Balancerasaz deviNo ratings yet

- Solved - Shown in The Figure Below Is A Simplified Dynamic ...Document2 pagesSolved - Shown in The Figure Below Is A Simplified Dynamic ...juenkkinNo ratings yet

- Accounting InformationDocument3 pagesAccounting Informationnenette cruzNo ratings yet

- Which HR Bundles Are Utilized in Social Enterprises (Slide)Document2 pagesWhich HR Bundles Are Utilized in Social Enterprises (Slide)serofNo ratings yet