FIRE FIGHTING CALCULATIONS

FAWSEC CAMPUS PROJECT

Client :M/s. Fawsec Educational Company

Consultant :M/s. AJI

Main Contractor :M/s. Mosad Al-Saleh

Trade Contractor :M/s. Gulf Engineering Co.

Prepared by : Engr. Kamal Ram Approved by : Engr. Taha Hassan

� 1

FIRE PROTECTION HYDRAULIC CALCULATION

Index ……………………………………………………………………………………………………..….1

1.0 Codes and Design Standards……………………………….………..………………………….2

2.0 Project Description………………………………………….…………………………..…….......3

3.0 Hydraulic Calculations Report…………….……………………………………….…..…….......3

4.0 Sprinkler System Hydraulic Calculation……….……………………………….……..…….......4

5.0 Standpipe System Calculation………….…………..………………………………..…….......12

6.0 Appendices & Tables …………………………………………………………………………….19

Appendix A: Table [Link] Hazen-Williams C values

Appendix B: Table [Link] Sprinkler Discharge Characteristics Identification

Appendix C: Table [Link] Water supply requirements for pipe schedule sprinkler

System

Appendix D: Density/Area curves

Appendix E: Table [Link].1 Hose Streams Demand and Water Supply Duration

Requirements for Hydraulically Calculated System

7.0 Drawings & Diagrams …………………………...……………………………………………….21

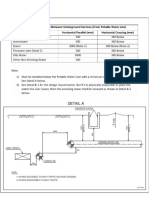

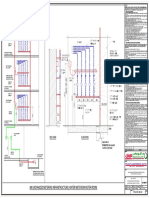

SD-FP-CAL-01: Remote Area Location

SD-FP-CAL-02: Schematic 3D Riser Diagram for Sprinkler System – Partial (1)

SD-FP-CAL-03: Schematic 3D Riser Diagram for Sprinkler System – Partial (2)

SD-FP-CAL-04: Schematic 3D Riser Diagram for Standpipe System

SD-FP-CAL-05: Riser Diagram (2D) for Sprinkler and Standpipe System

1

� 2

1.0 CODES AND DESIGN STANDARDS

The following codes will be used in the design of the Fire Protection System:

NFPA National Fire Protection Association

NFPA – 10 Standard for potable extinguishers

NFPA – 13 Standard for the installation of sprinkler system

NFPA – 14 Standard for the installation of standpipe and hose system

NFPA – 20 Standard for the installation of stationary pumps for fire protection

NFPA – 101 Standard for life safety code

NFPA – 2001 Standard on Clean Agents Fire Extinguishing Systems

KFD Kuwait Fire Department

2

� 3

2.0 PROJECT DESCRIPTION

The building is protected by a combined wet sprinkler and hose system. Building comprises of two

basement for parking and six towers. Two towers up to six floors, three towers up to 14 floors and

one tower up to seventeen floor.

3.0 HYDRAULIC CALCULATION REPORT

Design Data:

1 Occupancy Classification : Ordinary Hazard - 1

2 System Type : Wet System

3 Remote Area Location : Level - 17

4 Remote Area Size : 1500 ft²

5 Density : 0.15 gpm / ft²

6 Nos. of Sprinkler Calculated : 14 Nos.

7 Coverage per sprinkler : 130 ft²

8 K - Factor : 5.6

Calculation Summary:

1 Flow from Sprinkler Head : 365.57 gpm

2 Flow from internal FHR : 50 gpm

3 Flow from Standpipe : 500 gpm

4 Total Water Supply Demand : 915.57 gpm

Select a Fire Pump with 1000 GPM flow.

1 Pressure demand for Sprinkler System : 159.93 psi (10.87 Bar)

2 Pressure demand for Standpipe System : 184.40 psi (12.54 Bar)

Select a Fire Pump with 185 psi @ 1000 GPM.

3

� 4

4.0 Sprinkler System Hydraulic Calculations:

Scope:

The calculation presentation related to this project characteristics and strategies for Fire

Fighting works. The calculations are based on NFPA Standards.

General Data:

The calculations is for Fire Sprinkler and Hose System for the building on the basis of

Ordinary hazard - 1(due to parking in the basement).

Water Data:

Density ………………………… 1000 kg/m3

Dynamic Viscosity …………… 0.896 mPa.s @ 25 C

FORMULAS

The following formula shall be used through the hydraulic calculation software:

Hazen – Williams Formula

4.52 Q 1.85

P=

C 1.85d 4.87

Where:

P = Frictional resistance in Psi per foot of pipe

Q = Flow in gpm

C = Friction loss coefficient (Refer to appendix. A)

d = Actual internal diameter of pipe in inches

For SI units, the following equation shall be used:

Qm 1.85

Pm = 6.05 x 105

C 1.85d m4.87

Where:

Pm = Frictional resistance in Bar per meter of pipe

Qm = Flow in liter per minute

C = Friction loss coefficient (refer to appendix. A)

dm = Actual internal diameter of pipe in mm

4

� 5

Residual Pressure

Calculation shall be done based on a minimum residual pressure of 36 psi at the remote fire hose reel

cabinet, and 15 psi at the most remote sprinkler head.

(Refer to Appendix C)

Density Flow

Based on ordinary hazard occupancy as per NFPA-13, the minimum density flow shall be (0.1 – 0.15)

gpm/sq. feet based on area operation to cover 1500 sq. feet.

(Refer to Appendix D)

Hose Stream Demand & Duration Time

Based on ordinary hazard occupancy the water demand each fire hose reel station shall be 50 gpm, and

the fire water supply duration shall be 60 min. as a minimum.

(Refer to Appendix E)

Fire Water Drain size

Drain sizing is related to riser size as per NFPA code

(Refer to Appendix F)

5

� 6

6

� 7

7

� 8

8

� 9

9

� 10

10

� 11

11

� 12

5.0 Standpipe System Hydraulic Calculations:

Residual Pressure

Calculation shall be done based on a minimum residual pressure of 65 psi (4.5 Bar) at the hydraulically

most remote 1 1/2” hose station.

(Refer to Section 5.7-1, NFPA 14)

Flow Rate

Calculation shall be done based on a minimum flow rate of 250 gpm at the two hydraulically most remote

1 1/2” hose station connections on the standpipe and at the topmost.

(Refer to Section 5.9-1, NFPA 14)

12

� 13

13

� 14

14

� 15

15

� 16

16

� 17

17

� 18

18

� 19

6.0 APPENDICES

(Appendix A)

Table [Link] Hazen-Williams C values

Pipe or Tube C Value*

Unlined cast or ductile iron 100

Black steel (dry system including 100

preaction)

Black steel (wet system including 120

preaction)

Galvanized (all) 120

Plastic (listed) all 150

140

Cement-lined cast or ductile iron

Copper Tube or stainless steel 150

Asbestos Cement 140

Concrete 140

(Appendix B)

Table [Link] Sprinkler Discharge Characteristics Identification

K-factor Thread

Nominal Range K-factor Range Percent of Nominal Type

K- factor ( gpm/ (psi)1/2 ( dm3 / min/ (kpa)1/2) K-5.6 Discharge

( gpm/

(psi)1/2

1.4 1.3 - 1.5 1.9 - 2.2 25 1/2 in. NPT

1.9 1.8 - 2.0 2.6 - 2.9 33.3 1/2 in. NPT

2.8 2.6 - 2.9 3.8 - 4.2 50 1/2 in. NPT

4.2 4.0 - 4.4 5.9 - 64 75 1/2 in. NPT

1→ 5.6 5.3 - 5.8 7.6 - 8.4 100 1/2 in. NPT

2→ 8 7.4 - 8.2 10.7 - 11.8 140 3/4 in. NPT

or

1/2 in. NPT

11.2 11.0 - 11.5 15.9 - 16.6 200 1/2 in. NPT

or

3/4 in. NPT

14 13.5 - 14.5 19.5 - 20.9 250 3/4 in. NPT

16.8 16.0 - 17.6 23.1 - 25.4 300 3/4 in. NPT

19.6 18.6 - 20.6 27.1 - 30.1 350 1/2 in. NPT

22.4 21.3 - 23.5 31.1 - 34.3 400 1/2 in. NPT

25.2 23.9 - 26.5 34.9 - 38.7 450 1/2 in. NPT

28 26.6 - 29.4 38.9 - 43.0 500 1/2 in. NPT

1→ Standard pendant / upright Sprinkler

2→ Extend coverage sidewall Sprinkler

19

� 20

(Appendix C)

Table [Link] Water Supply Requirements for Pipe Schedule Sprinkler Systems

Minimum Residual

Occupancy Acceptable Flow at base of Riser

Pressure Required (including hose Stream Allowance) Duration

Classification

(psi) (gpm)

Light hazard 15 500 - 750 30 - 60

Ordinary hazard 20 850 - 1500 60 - 90

Note: For SI units, 1gpm= 3.785L/min ; 1 psi = 0.0689bar

(Appendix D)

Density / area curves. The water supply for sprinklers only shall be determined either from the density /

area curves of Figure shown below.

Density (mm/min)

2.0 4.1 6.1 8.1 10.2 12.2 14.3 16.3

5000 465

Ex

Ex

Area of Sprinkler operation (m2)

Area of Sprinkler operation (ft2)

tr

tr

4000 372

aH

aH

az

az

ad

ad

Gr

Gr

ou

ou

3000 279

p1

p2

Ord

Ord

ina

ina

Ligh

2500 232

ry 2

ry 1

t

2000 186

1500 139

0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

Density (gpm/ft2)

(Appendix E)

Table [Link].1 Hose Stream Demand and Water Supply Duration

Requirements for Hydraulically Calculated System

Total Combined

Duration

Occupancy Inside Hose (gpm) Inside and Outside

( minutes)

Hose (gpm)

Light hazard 0 , 50 , or 100 100 30

Ordinary hazard 0 , 50 , or 100 250 60 - 90

Extra hazard 0 , 50 , or 100 500 90 - 120

Note: For SI units, 1gpm= 3.785L/min.

20

�21

�22

�23

�24

�25