Professional Documents

Culture Documents

Asset Management Framework

Uploaded by

SreekanthMylavarapuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asset Management Framework

Uploaded by

SreekanthMylavarapuCopyright:

Available Formats

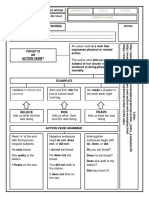

Asset Management Framework Overview - Revision 05

This document is intended to introduce the Asset Management Framework and provide definitions specific to each

Function and Process for initial terminology and scope familiarization. Below is the Asset Management Framework.

The framework is a representation of all the parts and pieces of an Asset Management Program, and how those parts

and pieces are organized.

The Asset Management Program is implemented through six Management Systems, which are Governance, Life

Cycle, Reliability, Spare Part, Work, and Calibration. All Management Systems contain four Functions, each Function

focused on one aspect of the overall Management System. Each Function has four Implementation Mechanisms,

each focused on one aspect of how the Function is executed.

Process is the guiding methodology for how the Function will be performed. People represent the responsibility

assignment and required training for each Process. Data is the information the People utilize to drive daily Process

operation and decision making. Sustainability represents the metrics that measure Data to indicate Process health

and standards which ensure performance repeatability of People.

The Road Map at the bottom provides a sequential implementation path, indicating the order in which Functions are

typically developed and implemented when building an Asset Management Program. It also serves to identify

Functions that require attention as a result of a gap analysis performed on existing Asset Management practices.

Asset Management Framework Overview - Revision 07

GO1 | Leadership Support: Establish leadership of the asset management program including communications,

controls, risk management and continuous improvement.

• GO1.PR1 | Senior Leadership Involvement: Establish senior leadership roles, communications, and

interactions with the asset management program.

• GO1.PR2 | Asset Management Council: Establish a defined group that develops, reviews, and approves

asset management policy, monitors performance, and makes key decisions.

• GO1.PR3 | Risk Management: Identify, categorize, and administer asset management program performance

measures and risk elements.

• GO1.PR4 | Tactical Improvement: Establish a road map to address identified asset management program

gaps to ensure program effectiveness and efficiency.

GO2 | Change Management: Administer, prepare, manage, and reinforce change management.

• GO2.PR1 | Administration: Establish governance and administration of change management.

• GO2.PR2 | Preparing: Establish scope of the change management project, project team organization, and

obtain sponsorship.

• GO2.PR3 | Managing: Develop and implement change management plans.

• GO2.PR4 | Reinforcing: Collect and diagnose change management feedback and use feedback to promote

continuous improvement of change management processes.

GO3 | Budget Management: Prepare and track asset management budget, report deviations, and determine asset

life cycle cost.

• GO3.PR1 | Budget Preparation: Establish process to prepare asset management budget.

• GO3.PR2 | Budget Tracking: Establish process to track asset management budget performance.

• GO3.PR3 | Budget Deviation Reporting: Establish process to report budget deviation.

• GO3.PR4 | Asset Life Cycle Cost: Determine the cost of capital to design, procure, construct, install, operate,

and retire an asset.

GO4 | ISO 55000 Alignment: Ensure the asset management program is aligned with ISO 55000 guidelines.

• GO4.PR1 | Context of the Organization and Leadership: Establish the organization’s mission, message, and

leadership elements that support them.

• GO4.PR2 | Planning: Establish focused asset management plans.

• GO4.PR3 | Support and Operation: Establish personnel awareness of and compliance with asset

management theory and process execution.

• GO4.PR4 | Performance Evaluation and Improvement: Establish processes to assess performance and

manage continuous improvement.

Asset Management Framework Overview - Revision 07

LC1 | Asset Acquisition: Ensure new assets are correctly specified, fully documented, and are maintainable in

preparation to realize maximum useful life through asset management processes.

• LC1.PR1 | Capital Projects: Define the structure and requirements associated with a project.

• LC1.PR2 | Asset Selection: Define information necessary to design and operate the asset.

• LC1.PR3 | Asset Design for Reliability: Integrate design for reliability and total cost of ownership perspective

into acquisition project design.

• LC1.PR4 | Asset Turnover Package: Define content and format of information provided for asset operation

and maintenance.

LC2 | Asset Commissioning: Test, commission, and turnover assets for operation.

• LC2.PR1 | Factory Acceptance Testing: Test and inspect system, facility, or software when fully fabricated

and assembled prior to delivery.

• LC2.PR2 | Site Acceptance Testing: Review and approve system, facility, or software when installed in

operating environment.

• LC2.PR3 | Commissioning Protocols: Validate assets and systems via installation qualification (IQ),

operational qualification (OQ), and performance qualification (PQ).

• LC2.PR4 | Turnover to Operations: Define the conditions that permit an asset to be released for operations.

LC3 | Asset Operation: Define operator care, performance monitoring, critical process parameters, and continuous

improvement.

• LC3.PR1 | Asset Operator Care and Training: Define the types of care tasks operators can perform.

• LC3.PR2 | Asset Performance Monitoring: Collect data from assets to monitor asset health.

• LC3.PR3 | Critical Process Parameters: Identify attributes that must be monitored to detect deviations that

could affect product quality.

• LC3.PR4 | Asset Continuous Improvement: Incorporate lessons learned and adjust processes to improve

asset performance.

LC4 | Asset Disposal: Assess asset health, asset useful life, asset obsolescence, and asset replacement.

• LC4.PR1 | Asset State of Good Repair: Assess assets in terms of their ability to continue to perform their

intended functions over time.

• LC4.PR2 | Asset Useful Life: Establish priority of recapitalization investment relative to calculated criteria.

• LC4.PR3 | Asset Obsolescence: Evaluate availability of spare parts, hardware, software, and technical

support.

• LC4.PR4 | Asset Replacement: Evaluate the cost of repair versus replacement over the asset life cycle.

Asset Management Framework Overview - Revision 07

RE1 | Asset Identification: Identify, organize, and prioritize the assets that make up the asset management program.

• RE1.PR1 | Asset Decision Matrix: Apply rules to decide what is an asset.

• RE1.PR2 | Asset Organization: Create physical and functional relationships between assets and rules for

grouping assets.

• RE1.PR3 | Asset Data Documentation: Create asset records that are accurate and complete.

• RE1.PR4 | Asset Prioritization: Establish relative importance of each asset to the business.

RE2 | Failure Mode Identification: Identify and prioritize the plausible failure modes for each asset or asset group.

• RE2.PR1 | Failure Mode Identification Type: Confirm the analysis methods to be used for failure mode

identification.

• RE2.PR2 | Failure Mode Identification Type Decision Matrix: Apply rules to decide what analysis type will

be applied to each asset group.

• RE2.PR3 | Failure Mode Data Documentation: Create failure mode records that are accurate and complete.

• RE2.PR4 | Failure Mode Prioritization: Establish relative importance of each failure mode to the business.

RE3 | Proactive Task Identification: Identify and implement proactive tasks that prevent or mitigate the effects of

failure.

• RE3.PR1 | Proactive Task Type Decision Matrix: Apply rules to decide the type of task to be selected for a

given failure mode.

• RE3.PR2 | Proactive Task Interval Decision Matrix: Apply rules to decide how often a proactive task is to be

executed.

• RE3.PR3 | Proactive Task Data Documentation: Create proactive task records that are accurate and

complete.

• RE3.PR4 | Proactive Task Assignment: Assign responsibility for proactive task execution.

RE4 | Spare Part Identification: Identify and prioritize the spare parts necessary to support the asset management

program.

• RE4.PR1 | Spare Part Type Decision Matrix: Apply rules to decide how a spare part will be identified for

storeroom management.

• RE4.PR2 | Proactive Task Spare Part Requirement: Identify spare parts necessary to support proactive tasks.

• RE4.PR3 | Spare Part Data Documentation: Create spare part records that are accurate and complete.

• RE4.PR4 | Spare Part Prioritization: Establish relative importance of each spare part to the business.

Asset Management Framework Overview - Revision 07

SP1 | Spare Part Storage: Define where things are stored, and how they are identified, secured, and maintained.

• SP1.PR1 | Spare Part Storage Layout: Define where things are stored and why.

• SP1.PR2 | Spare Part Organization: Define storeroom location and part labeling.

• SP1.PR3 | Spare Part Security: Define how access to spare parts is controlled.

• SP1.PR4 | Spare Part Care: Confirm which assets to maintain while stored and what maintenance is

required.

SP2 | Spare Part Stock Analysis: Define whether and in what quantity parts should be stocked, how they are

documented, and how to manage rotating spares.

• SP2.PR1 | Spare Part Stock Type Decision Matrix: Apply rules to decide the stock type for each spare part.

• SP2.PR2 | Spare Part Stock Quantity Decision Matrix: Apply rules to decide the stock quantity for each

spare part.

• SP2.PR3 | Spare Part Stock Data Documentation: Create spare part records that are accurate and complete.

• SP2.PR4 | Rotating Spare Parts: Manage parts that are physically exchanged in and out of operation.

SP3 | Spare Part Control: Define part procurement, transaction tracking, inventory management assessment, and

administering vendor managed spare parts.

• SP3.PR1 | Spare Part Procurement: Define the protocol for procuring spare parts.

• SP3.PR2 | Spare Part Transaction: Monitor spare part movement and transactions.

• SP3.PR3 | Spare Part Monitoring: Monitor spare part control.

• SP3.PR4 | Vendor Managed Spare Parts: Define which spare parts are vendor managed and describes the

duties and responsibilities of vendor managing parts.

SP4 | Spare Part Kitting: Define the location, security, reservation, and disbursement of kitted parts.

• SP4.PR1 | Spare Part Kitting Layout: Define the location of kitted spare parts.

• SP4.PR2 | Spare Part Kitting Security: Define access control scheme for kitted spare parts.

• SP4.PR3 | Spare Part Kitting Initiation: Describe the actions necessary to request and reserve kitted spare

parts.

• SP4.PR4 | Spare Part Kitting Fulfillment: Describe how kitted spare parts are disbursed and unused kitted

parts returned.

Asset Management Framework Overview - Revision 07

WO1 | Work Identification: Prepare work for introduction into the work control system, to include routine,

emergent, outage, and contractor work.

• WO1.PR1 | Routine Work Identification: Define how issues are introduced into the corrective maintenance

workflow.

• WO1.PR2 | Emergent Work Identification: Define how emergencies are classified and are introduced into

the corrective maintenance workflow.

• WO1.PR3 | Outage Work Identification: Define how shutdown work is classified and introduced into the

corrective maintenance workflow.

• WO1.PR4 | Contractor Work Identification: Define how work to be performed by contractors is classified

and introduced into the maintenance workflow.

WO2 | Work Planning: Prepare work for execution by identifying necessary repairs, resources, support, priority, and

duration of identified work.

• WO2.PR1 | Routine Work Planning: Define how routine work is prepared for execution.

• WO2.PR2 | Emergent Work Planning: Define how emergency work is prepared for execution.

• WO2.PR3 | Outage Work Planning: Define how shutdown work is prepared for execution.

• WO2.PR4 | Contractor Work Planning: Define how work performed by contractors is prepared for

execution.

WO3 | Work Scheduling: Identify and coordinate what the organization intends to accomplish with available

resources in an upcoming time period.

• WO3.PR1 | Routine Work Scheduling: Define how routine work is scheduled for execution.

• WO3.PR2 | Emergent Work Scheduling: Define how emergency work is scheduled for execution.

• WO3.PR3 | Outage Work Scheduling: Define how shutdown work is scheduled for execution.

• WO3.PR4 | Contractor Work Scheduling: Define how work performed by contractors is scheduled for

execution.

WO4 | Work Execution: Restore or maintain asset functionality in accordance with work order requirements.

• WO4.PR1 | Routine Work Execution: Define how routine work is performed.

• WO4.PR2 | Emergent Work Execution: Define how emergency work is performed.

• WO4.PR3 | Outage Work Execution: Define how shutdown work is performed.

• WO4.PR4 | Contractor Work Execution: Define how work by contractors is performed.

Asset Management Framework Overview - Revision 07

CA1 | Calibration Administration: Define rules for calibration program requirements, ensuring program compliance,

use of contracted services, and instrument life cycle activities.

• CA1.PR1 | Calibration Program Requirements: Establish program requirements and how they are

administered.

• CA1.PR2 | Calibration Program Compliance: Create checks and balances for program compliance.

• CA1.PR3 | Calibration Contracted Services: Establish controls for alignment between service provider

processes and internal program expectations.

• CA1.PR4 | Instrument Life Cycle: Establish controls for replacing, reusing, quarantining, and disposing of

instruments.

CA2 | Calibration Measurement: Define rules for measuring and test equipment specifications, traceability,

certification, and storage.

• CA2.PR1 | Measuring and Test Equipment Specifications: Create rules for measuring and test equipment

accuracy, accuracy ratios, or test uncertainty ratios.

• CA2.PR2 | Measuring and Test Equipment Traceability: Create guidelines for how local measuring and test

equipment can be traced to governing standards.

• CA2.PR3 | Measuring and Test Equipment Certification: Create guidelines for how local measuring and test

equipment meet certification and conformance requirements.

• CA2.PR4 | Measuring and Test Equipment Storage: Establish controlled storage of measuring and test

equipment.

CA3 | Calibration Discrepancy: Establish methods for discrepancy trending, review, notification, and use of reverse

traceability.

• CA3.PR1 | Calibration Discrepancy Trending: Establish methods for trending out of tolerance or poor

performing instruments.

• CA3.PR2 | Calibration Discrepancy Review: Establish a calibration discrepancy review protocol.

• CA3.PR3 | Calibration Discrepancy Notification: Establish a calibration discrepancy notification protocol.

• CA3.PR4 | Calibration Discrepancy Reverse Traceability: Create guidelines for when and how to perform

reverse traceability.

CA4 | Calibration Optimization: Develop calibration specifications, intervals, analytics, and verification guidelines.

• CA4.PR1 | Calibration Specifications: Create rules for calibration accuracy, accuracy ratios, or test

uncertainty ratios.

• CA4.PR2 | Calibration Interval Decision Matrix: Apply rules to decide how often a calibration is to be

executed.

• CA4.PR3 | Calibration Advanced Analytics: Establish a method to proactively diagnose impending

instrument problems.

• CA4.PR4 | Calibration Verification: Create guidelines for verifying when calibration is required outside of set

intervals.

Asset Management Framework Overview - Revision 07

You might also like

- Reliability Maturity Matrix: ©2015 Fred SchenkelbergDocument1 pageReliability Maturity Matrix: ©2015 Fred Schenkelbergmzai2003100% (1)

- Welcome To IEN 754: Reliability and Maintainability EngineeringDocument16 pagesWelcome To IEN 754: Reliability and Maintainability EngineeringSherif El-soudyNo ratings yet

- TQM 4th ChapterDocument31 pagesTQM 4th ChapterWaleed Tahir ChNo ratings yet

- Eliminating Defects Through Equipment ReliabilityDocument6 pagesEliminating Defects Through Equipment ReliabilityAriefNo ratings yet

- Ebook Types of Maintenance The Complete GuideDocument21 pagesEbook Types of Maintenance The Complete GuideMohsen MalakoutiNo ratings yet

- Dynamic Scheduling: E.J. (Ted) ListerDocument26 pagesDynamic Scheduling: E.J. (Ted) Listermichal_slawinskiNo ratings yet

- Opportunity Plan: Target Account SellingDocument10 pagesOpportunity Plan: Target Account SellingJavier Ramirez83% (6)

- Setting KRA and Goal Setting WorkshopDocument26 pagesSetting KRA and Goal Setting WorkshopDeekhsha KherNo ratings yet

- Let's Drink A Coffee To Talk About: The Raci MatrixDocument4 pagesLet's Drink A Coffee To Talk About: The Raci MatrixJohann MenesesNo ratings yet

- CMRP OverviewDocument2 pagesCMRP OverviewBabatunde Abiodun OluboriNo ratings yet

- AA 00 a-MX 1001 Preservation Manual DFCUDocument1,467 pagesAA 00 a-MX 1001 Preservation Manual DFCUSreekanthMylavarapuNo ratings yet

- RCM Ii: Reliability-Centred Maintenance IIDocument2 pagesRCM Ii: Reliability-Centred Maintenance IIMinh ChauNo ratings yet

- 220 KV Bus Charging & IsolationDocument6 pages220 KV Bus Charging & IsolationSreekanthMylavarapuNo ratings yet

- RC 14001 StandardDocument7 pagesRC 14001 StandardMohammed Mehran100% (1)

- Cold Start Up Check ListDocument6 pagesCold Start Up Check ListSreekanthMylavarapuNo ratings yet

- Project Proposal Template 19Document6 pagesProject Proposal Template 19Siddanth DeswalNo ratings yet

- CH 14 Work StudyDocument65 pagesCH 14 Work StudySurogste MibusontadNo ratings yet

- Key Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilityDocument7 pagesKey Performance Indicators For Stores and MRO - Reliabilityweb - A Culture of ReliabilitytohemaNo ratings yet

- 400 KV Bus Changeover &isolationDocument4 pages400 KV Bus Changeover &isolationSreekanthMylavarapuNo ratings yet

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNo ratings yet

- Inventory Management PowerPoint PresentationDocument30 pagesInventory Management PowerPoint PresentationHisaan KamranNo ratings yet

- Milliken Performance System TPM 1656557395Document14 pagesMilliken Performance System TPM 1656557395David Armando Chico OreNo ratings yet

- UptimeDowntimeEventTracking RTtech - SRowlandsDocument56 pagesUptimeDowntimeEventTracking RTtech - SRowlandsalisterjosephNo ratings yet

- Module 1 of Strategic ManagementDocument19 pagesModule 1 of Strategic Managementdil0424No ratings yet

- The 7 Basic Quality Tools: Michele CanoDocument60 pagesThe 7 Basic Quality Tools: Michele Canoeko4fxNo ratings yet

- Building Assets MGMT Plan 7VG 150331Document230 pagesBuilding Assets MGMT Plan 7VG 150331Sazali KhamsanNo ratings yet

- MAINTENANCE MANAGEMENT GUIDEDocument63 pagesMAINTENANCE MANAGEMENT GUIDEChoirul WahyuNo ratings yet

- Implement Six Sigma PlanDocument27 pagesImplement Six Sigma PlanYuvanesh Yuvan100% (1)

- SMP SilicaDocument25 pagesSMP SilicaSreekanthMylavarapuNo ratings yet

- CMRP, Pillar4Document89 pagesCMRP, Pillar4mmblakoshaNo ratings yet

- AMP CAMA MMP Single Pages 2021 2022 Updated Mar. 1Document8 pagesAMP CAMA MMP Single Pages 2021 2022 Updated Mar. 1Home UserNo ratings yet

- Prioritize Asset Maintenance with Criticality AnalysisDocument22 pagesPrioritize Asset Maintenance with Criticality AnalysisSreekanthMylavarapuNo ratings yet

- Asset Management and Maintenance JournalDocument60 pagesAsset Management and Maintenance JournalrdknnissaNo ratings yet

- ISO 55000 - Asset Management Systems - PPT - Jim Dieter - February 2013 PDFDocument37 pagesISO 55000 - Asset Management Systems - PPT - Jim Dieter - February 2013 PDFCristian GarciaNo ratings yet

- Session-2 & 3 Quality - Evolution of QualityDocument20 pagesSession-2 & 3 Quality - Evolution of Qualitymatten yahyaNo ratings yet

- LCE Risk-Based Asset Management ReportDocument11 pagesLCE Risk-Based Asset Management ReportPola7317No ratings yet

- AMM - Chapter 1Document50 pagesAMM - Chapter 1Azizan RamlyNo ratings yet

- Mod 5 01 Cause&Effect Mar 02Document20 pagesMod 5 01 Cause&Effect Mar 02drustagiNo ratings yet

- SMP PH AnalyserDocument4 pagesSMP PH AnalyserSreekanthMylavarapuNo ratings yet

- Predictive Modelling Foropave - NZ RR PDFDocument87 pagesPredictive Modelling Foropave - NZ RR PDFGaneshNo ratings yet

- Passenger Ship Crisis Management and Human BehaviorDocument65 pagesPassenger Ship Crisis Management and Human BehaviorPelayo García-Pardo Martín-Serrano100% (1)

- SMP - Oil in WaterDocument22 pagesSMP - Oil in WaterSreekanthMylavarapuNo ratings yet

- Visual Checklist Slide Template: This Is A Sample Text. Insert Your Desired Text HereDocument8 pagesVisual Checklist Slide Template: This Is A Sample Text. Insert Your Desired Text HereGian ZandonàNo ratings yet

- Assets Management Policy and Strategies. ICPAK PDFDocument39 pagesAssets Management Policy and Strategies. ICPAK PDFNassir CeellaabeNo ratings yet

- Fox Solutions: M-9, MIDC, AMBAD, NASHIK 422 010 Maharashtra, IndiaDocument11 pagesFox Solutions: M-9, MIDC, AMBAD, NASHIK 422 010 Maharashtra, IndiaPranoti JoshiNo ratings yet

- Infrastructure Asset Register MaintenanceDocument19 pagesInfrastructure Asset Register MaintenanceTino MatsvayiNo ratings yet

- Audit progress chartDocument2,411 pagesAudit progress chartUmangtarangNo ratings yet

- Comrehensive Exam MteDocument48 pagesComrehensive Exam MteLourie Mie Anarna100% (1)

- Compass ISO 55001 Assets ManagementDocument7 pagesCompass ISO 55001 Assets ManagementaodyNo ratings yet

- Grounded Theory of The Roots and Emergence of Coaching PDFDocument729 pagesGrounded Theory of The Roots and Emergence of Coaching PDFJoão SevilhanoNo ratings yet

- Operations Management TQMDocument16 pagesOperations Management TQMKnt Nallasamy Gounder100% (2)

- TravelDocument41 pagesTravelRishika BhatiaNo ratings yet

- Project Plan and Gantt ChartDocument4 pagesProject Plan and Gantt ChartCarla Jeanne KindahanNo ratings yet

- Total Productive MaintenanceDocument21 pagesTotal Productive MaintenanceFernanda MarquesNo ratings yet

- Building Asset Performance FrameworkDocument27 pagesBuilding Asset Performance FrameworkRisya rantikaNo ratings yet

- PM TM 02-Maintenance PlanningDocument9 pagesPM TM 02-Maintenance PlanningAnkitNo ratings yet

- Acad98 004R1Document66 pagesAcad98 004R1michael1971No ratings yet

- Maintenance Management Best Practice - 01 04 2014Document270 pagesMaintenance Management Best Practice - 01 04 2014Mahmoud GamalNo ratings yet

- Bali Conference Programme - Final - LR PDFDocument8 pagesBali Conference Programme - Final - LR PDFgosalhs9395No ratings yet

- Leading vs Lagging Indicators: Guide to Determining Performance MetricsDocument6 pagesLeading vs Lagging Indicators: Guide to Determining Performance MetricsOmar HassanNo ratings yet

- Assessment Criteria - MaintenanceDocument14 pagesAssessment Criteria - MaintenanceTin NguyenNo ratings yet

- T Mu Am 02001 STDocument62 pagesT Mu Am 02001 STjesus_yustasNo ratings yet

- Failure Mode and Effect Analysis (FMEA)Document23 pagesFailure Mode and Effect Analysis (FMEA)Parandhaman GRNo ratings yet

- Crane Maintenance ProcedureDocument3 pagesCrane Maintenance ProcedureAravin KumarNo ratings yet

- Identifying Critical Assets Guidelines PDFDocument19 pagesIdentifying Critical Assets Guidelines PDFTeodora Dobrică100% (1)

- 2.06 SIPOC DiagramDocument4 pages2.06 SIPOC DiagramJulioRomeroNo ratings yet

- Kaizen Continuous Improvement TrainingDocument7 pagesKaizen Continuous Improvement TrainingMadeleine ThomasNo ratings yet

- Engineering Supply Chain Resilience: SCRM - Lecture 4Document26 pagesEngineering Supply Chain Resilience: SCRM - Lecture 4Abdur RafayNo ratings yet

- Equipment Criticality AnalysisDocument20 pagesEquipment Criticality AnalysisArmandoNo ratings yet

- Implementation of Kaizen and 5S in Plastic PipeDocument6 pagesImplementation of Kaizen and 5S in Plastic Pipeaman tembhekarNo ratings yet

- TAM ManualDocument392 pagesTAM ManualMaidan KimyaNo ratings yet

- The Scoreboard ForDocument47 pagesThe Scoreboard Foraldihani70100% (2)

- Asset Data in The APM ImplementationDocument18 pagesAsset Data in The APM ImplementationYousuf HasaniNo ratings yet

- ISO Certification Activity PlanDocument2 pagesISO Certification Activity PlanvfuntanillaNo ratings yet

- Balancing MethodsDocument20 pagesBalancing MethodsSreekanthMylavarapuNo ratings yet

- Silica AnalyzerDocument114 pagesSilica Analyzerdenios09No ratings yet

- Using System 1 Web DisplayDocument31 pagesUsing System 1 Web DisplaySreekanthMylavarapuNo ratings yet

- CV en 13Document2 pagesCV en 13SreekanthMylavarapuNo ratings yet

- 9245 Single Channel On-Line Sodium Analyzer-Operator ManualDocument130 pages9245 Single Channel On-Line Sodium Analyzer-Operator Manualdenios09No ratings yet

- 220 KV Transfer Buschangeover & IsolationDocument7 pages220 KV Transfer Buschangeover & IsolationSreekanthMylavarapuNo ratings yet

- Peer Control Data Interface Implementation Guide EXDOC-XX84-en-110Document136 pagesPeer Control Data Interface Implementation Guide EXDOC-XX84-en-110SreekanthMylavarapuNo ratings yet

- Seal CodingDocument3 pagesSeal CodingSreekanthMylavarapuNo ratings yet

- 220 KV Bus ChangeoverDocument5 pages220 KV Bus ChangeoverSreekanthMylavarapuNo ratings yet

- Extreme Hot Start-Up Check ListDocument6 pagesExtreme Hot Start-Up Check ListSreekanthMylavarapuNo ratings yet

- 13IPAHDocument208 pages13IPAHSreekanthMylavarapuNo ratings yet

- SMP PSDocument3 pagesSMP PSSreekanthMylavarapuNo ratings yet

- SMP TSDocument3 pagesSMP TSSreekanthMylavarapuNo ratings yet

- Steam Turbine Oil MaintenanceDocument11 pagesSteam Turbine Oil MaintenanceSreekanthMylavarapuNo ratings yet

- 165ZSBDocument37 pages165ZSBSreekanthMylavarapuNo ratings yet

- 164NBTDocument110 pages164NBTSreekanthMylavarapuNo ratings yet

- Steam Turbine Testing of Maintenance Turbine Stress Controller (TSC)Document4 pagesSteam Turbine Testing of Maintenance Turbine Stress Controller (TSC)SreekanthMylavarapuNo ratings yet

- 13ISREDocument128 pages13ISRESreekanthMylavarapuNo ratings yet

- Turbine Oil Maintenance GuideDocument11 pagesTurbine Oil Maintenance GuideSreekanthMylavarapuNo ratings yet

- Steam Turbine Remedial Actions For Maintenance Off-Normal Operating ConditionsDocument5 pagesSteam Turbine Remedial Actions For Maintenance Off-Normal Operating ConditionsSreekanthMylavarapuNo ratings yet

- Steam Turbine Operating Data ArchivingDocument3 pagesSteam Turbine Operating Data ArchivingSreekanthMylavarapuNo ratings yet

- 1) IntroductionDocument62 pages1) IntroductionSanjay RagupathyNo ratings yet

- Krispy Kreme Doughnuts, Inc.: Statement of The ProblemDocument4 pagesKrispy Kreme Doughnuts, Inc.: Statement of The Problemmeann colinaNo ratings yet

- Competing For Advantage 3rd Edition by Hoskisson Hitt Ireland and Harrison ISBN Solution ManualDocument28 pagesCompeting For Advantage 3rd Edition by Hoskisson Hitt Ireland and Harrison ISBN Solution Manualirene100% (27)

- Intellectual Capital PDFDocument159 pagesIntellectual Capital PDFMiguelNo ratings yet

- Revised Guidelines Do 42 - School HeadsDocument23 pagesRevised Guidelines Do 42 - School HeadsGene E. CruzNo ratings yet

- Jack WalshDocument6 pagesJack WalshjoohaverNo ratings yet

- VP Defense Programs General Manager in Washington DC Resume Chris D'AscenzoDocument3 pagesVP Defense Programs General Manager in Washington DC Resume Chris D'AscenzoChrisDAscenzoNo ratings yet

- Go to Market Strategy OverviewDocument1 pageGo to Market Strategy OverviewNaga ChaitanyaNo ratings yet

- Chapter Two Company and Marketing StrategyDocument10 pagesChapter Two Company and Marketing StrategyMatt MNo ratings yet

- Public AdministrationDocument4 pagesPublic AdministrationLawrenceNo ratings yet

- Questions of Character Badaracco EbsDocument11 pagesQuestions of Character Badaracco EbsFalakNo ratings yet

- How To Manage Clever PeopleDocument37 pagesHow To Manage Clever PeopleFrancisco TrigueirosNo ratings yet

- CSTP 2 Estrada 9 30 17Document8 pagesCSTP 2 Estrada 9 30 17api-380179279No ratings yet

- Principles of Management - BbaDocument3 pagesPrinciples of Management - Bbavijay21010% (1)

- PMBOK 6 - Cuadro Completo de Procesos - InglésDocument1 pagePMBOK 6 - Cuadro Completo de Procesos - InglésJuan MendozaNo ratings yet

- MPeskin Leadership EssayDocument8 pagesMPeskin Leadership EssayMax PeskinNo ratings yet

- A Magazine For Chief Human Resource Officers and Their TeamsDocument20 pagesA Magazine For Chief Human Resource Officers and Their TeamsLama SayariNo ratings yet

- Strategic Options For Building CompetitivenessDocument53 pagesStrategic Options For Building Competitivenessjeet_singh_deepNo ratings yet

- Public Personnel HRP GuideDocument15 pagesPublic Personnel HRP Guidensaid_31No ratings yet

- ACC-EFQM Excellence Model 2003 ENGDocument44 pagesACC-EFQM Excellence Model 2003 ENGTakis RappasNo ratings yet

- Jack Stahl's Detailed Oriented LeadershipDocument2 pagesJack Stahl's Detailed Oriented LeadershipPrincess MagpatocNo ratings yet

- SUPPLY CHAIN HOMEWORKDocument2 pagesSUPPLY CHAIN HOMEWORKTuấn Dũng TrươngNo ratings yet

- Action Verbs & Skills WordsDocument5 pagesAction Verbs & Skills Words14896451No ratings yet

- Telenor Recruitment, Selection, Training, Compensation, Performance Management and International IhrmDocument23 pagesTelenor Recruitment, Selection, Training, Compensation, Performance Management and International IhrmAli Farooqui89% (9)