Professional Documents

Culture Documents

Extreme Hot Start-Up Check List

Uploaded by

SreekanthMylavarapuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extreme Hot Start-Up Check List

Uploaded by

SreekanthMylavarapuCopyright:

Available Formats

Organization:

Raj West Power Limited

Project:

8 x 135 MW

LIGNITE BASED THERMAL POWER PLANT, BHADRESH

Doc. Title:

Unit Extreme Hot start up Check list

Doc No:

RWPL/OPR/CL_

Issue Date: No of Sheets:

02/09/2013

(including cover sheet)

6

Revision Record:

1 R0 - Rakesh Kr. Singh First Release nil

S. Revision Date of Prepared by Nature of Revision Remarks

No No. Revision

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

Raj West Power Limited

Doc. NO. RWPL/OPR/CL_001

Unit Extreme-Hot start up Check List

Date: 03/09/2013

Page: Page 2 of 6

Sr. Verification /

Activity Check

No Remarks

1 Ensure PTWs related to respective areas are returned before normalizing the system &

taking system into service.

2 HT/LT side on 6.6 KV/415 V supply charged, DC voltage, UPS, Battery chargers are

healthy & in service.

3 Ensure all monitoring & testing instrument are put in service & are normal.

4 All protections & interlocks are in service.

5 Ensure Bed material filling system through.

6 Ensure all coal feeders outlet gate is closed.

7 Ensure CW System is started (refer doc. no. RWPL/OPR/SOP_007) & maintain CW

header pressure 0.20Mpa to 0.23Mpa.

8 Ensure ACW System is started (refer doc. no. RWPL/OPR/SOP_005) & maintain CW

header pressure > 0.40Mpa.

9 Ensure CCCW System is started (refer doc no. RWPL/OPR/SOP_006) & maintain

CCCW header pressure > 0.45Mpa.

10 Ensure PAC/IAC with dryer is started (refer doc no. RWPL/OPR/SOP_002) & header

pressure > 0.65Mpa.

11 Ensure local drum gauge glass & hydra step in service.

12 Ensure oil gun cleaning is done & atomization test completed.

13 Ensure LDO line flushing up to oil gun completed & oil strainer cleaned.

14 Ensure LDO pump is lined up & started (refer doc. no. RWPL/OPR/SOP_004) & put in

long recirculation with discharge pressure 2.5Mpa.

15 Ensure hot well make up system is lined up to maintain normal hot well level (650mm to

750mm).

16 Ensure CEP & condensate system is lined up then Start CEP in recirculation.

17 Ensure Deaerator level normal (1800mm to 1900mm) and its pegging has been charged

from PRDS (adjacent unit).

18 Ensure BFP & feed-water system is lined up then start BFP in recirculation.

19 Ensure drum filled up to –100 to –150 mm by using CEP or BFP according to drum

pressure.

20 Ensure Chemical dozing system ready (start dozing by consulting to chemist).

21 Ensure ESP is ready for charging.

Sr. Verification /

Activity Check

No Remarks

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

Raj West Power Limited

Doc. NO. RWPL/OPR/CL_001

Unit Extreme-Hot start up Check List

Date: 03/09/2013

Page: Page 3 of 6

22 Ensure all soot blowers are in retracted condition & soot blower valve is in close

condition.

23 Ensure Coal handling system ready & Coal filled in bunkers.

24 Ash handling system ready.

25 Ensure MSV & IBV are closed and in healthy condition.

26 Ensure HP-LP Bypass oil pumps are healthy & recirculation pump ON.

27 Ensure U valve blower, ID fan, SA fan, PA fan lined up and air path through.

28 Ensure two U valve blower are started (refer doc. No. RWPL/OPR/SOP_043) & ensure

proper air flow to both U seal. Put third one on link mode (CV of U seal header to PA

header should be closed & in AUTO mode). Maintain discharge pressure 47KPa

29 Ensure both ID fans are started (refer doc. No. RWPL/OPR/SOP_010) & furnace draft is

between – 50 Pa to + 50 Pa.

30 Ensure both SA fans are started (refer doc. No. RWPL/OPR/SOP_011).

31 Ensure both PA fans are started (refer doc. No. RWPL/OPR/SOP_009).

Ensure loading of PA fan is increased (upto 90,000 Nm³/hr) for proper fluidization of bed

32

material & check for fluidization through view glass.

33 Ensure loading of SA fan is increased (upto 60,000 Nm³/hr).

Ensure RH side gas damper is closed & maintain 30% to 40% of rated air flow (Air flow

34

should be > 138,000 Nm³/hr).

Ensure economizer recirculation valve is open if there is no feed water flow through

35

economiser.

36 Ensure MFT is reset by purging or Hot start PB & LDO in longest recirculation.

37 Ensure EBD and CBD lines are through to maintain drum level -100mm.

38 Ensure ESP fields are OFF & rapping motors are ON. So as to avoid chances of fire.

Lit up Ignition Duct one Oil Gun each side if bed temp.<350. (Take other pair according to

39

need.)

40 Ensure ignition Duct Outlet temp <800 ºC also Flue gas temp rise < 85 oC/hr.

Sr. Verification /

Activity Check

No Remarks

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

Raj West Power Limited

Doc. NO. RWPL/OPR/CL_001

Unit Extreme-Hot start up Check List

Date: 03/09/2013

Page: Page 4 of 6

TURBINE & GENERATOR STATUS REQUIRED:

41 All monitoring & testing instrument are put in service & normal .

MOT level > 1670mm & AC lube oil pump running with discharge header pressure

42 0.3Mpa ± 0.05Mpa.& AC Jacking oil pump running with discharge header pressure 15

MPa ± 1.5 MPa.

43 Turbine is on barring gear.

44 Heaters are ready with water side valves open & steam side valves closed

45 Water seal for GSC, LPH-6 and LPH-7 header charged & established.

46 Vacuum pumps are lined up.

47 HP bypass / LP bypass valves are closed.

48 All MAL drains & Extraction are closed.

49 AVR & Excitation system ready.

50 GT ready, GT breaker& isolators ready.

51 EH oil Pump healthy & Recirculation Pump ON.

52 Ensure that MS line drains & vent are open.

53 Charge MS line by slowly opening IBV. Then open MS stop valve and close IBV.

54 Ensure that PRDS, Gland sealing header drains are open .

Ensure the PRDS header & Gland sealing line from PRDS or MS (refer doc.no.

55

RWPL/OPR/SOP_054) upto gland sealing header control valve is charged.

Ensure GS header is charged (maintain header pressure 12-15 KPa & temperature 250-

56

325oC).

57 Ensure gland steam exhauster fan start after giving the gland sealing.

58 Ensure vacuum breaker valve close then start vacuum pumps and pull vacuum.

Sr. Verification /

Activity Check

No Remarks

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

Raj West Power Limited

Doc. NO. RWPL/OPR/CL_001

Unit Extreme-Hot start up Check List

Date: 03/09/2013

Page: Page 5 of 6

Start the coal inching when average bed temp.> 325˚C and Monitor the Bed temp. & %

59

O2

60 Gradually increase the coal feeding and gradually decrease the oil consumption.

Ensure rate of rise of cyclone inlet temperature should be less than 80˚C/hr & metal

61

temperature difference of top & bottom of drum less than 50˚C.

62 Ensure outer metal temperature of ignition duct & u-seal is normal at all locations.

Ensure CT fans are lined up & started (refer doc.no. RWPL/OPR/SOP_031) to maintain

63

CW inlet temperature between 30˚C to 34˚C.

64 Ensure HRH & CRH line drains are open.

65 Ensure HP/LP bypass oil pump lined up & started (refer doc.no. RWPL/OPR/SOP_034).

66 Ensure that all MAL & EXT drains are open.

67 Ensure that HP/LP bypass system is charged at vacuum <- 88Kpa.

68 PRDS & GS drains can be throttled to minimum at appropriate header temperature.

Ensure that the opening of HP/LP bypass is increased to achieve the MS temperature

69

510˚C at 4.5 Mpa pressure & RH steam temperature 480˚C.

70 Ensure all RH drains are closed.

71 Check that EH oil pump is lined up & then start it (refer doc.no. RWPL/OPR/SOP_035).

72 Check that turbine trip at back up panel is reset.

73 Check that master trip relay is reset at SCADA/switchyard.

Ensure that turbine stop valve is opened from DCS & rolling of turbine is started (refer

74 doc.no. RWPL/OPR/SOP_055)& ensure barring gear is automatically dis-engaged after

starting of rolling.

75 Keep watch on vibration & bearing temperature during rolling.

76 Ensure that turbine speed is raised to 500 (@100rpm per minute).

Ensure the lube oil temp. is near 40˚C,maintain it by opening return occw motorise

77

valve.

78 Ensure that overall checking of turbine is done at 500rpm within 5minutes.

Ensure that the rotating speed is raised to 3000 rpm (@250rpm per minute) & warm up

79

for 5 minutes.

Sr. Verification /

Activity Check

No Remarks

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

Raj West Power Limited

Doc. NO. RWPL/OPR/CL_001

Unit Extreme-Hot start up Check List

Date: 03/09/2013

Page: Page 6 of 6

80 Ensure at turbine speed 1200 rpm, JOP should AUTO stop.

81 Ensure AOP is stopped at 3000 rpm and MOT exhaust fan is running.

82 Ensure all isolator of GT bay is closed corresponding to main bus ½.

Ensure auto/manual selector switch is in ‘AUTO’ & generator breaker selection is

83

‘CLOSE’ in generator panel.

84 Ensure the field breaker is closed.

85 Make excitation ‘ON’and ensure CB11/CB12 is selected.

86 Match the generator voltage & frequency with grid.

87 Make synchronization on ‘AUTO’ in DEH.

88 Select engage AUTO SYNCHRONISATION in DEH.

89 Start synchronization & synchronize the unit (refer doc.no. RWPL/OPR/SOP_055).

90 After synchronization, ensure that load is raised to 10MW (@1MW/min).

Ensure that ESP is ready for charging & charge ESP when all oil gun is removed & ESP

91

inlet flue gas temperature Is greater than 110˚C.

After that ensure that load is raised to 40MW,(all MAL drains should be closed at 30MW

92

load).

93 Ensure that UAT is taken in service before 18MW load.

94 Ensure that all LP heaters are taken in service at 27MW load.

95 Ensure that turbine casing drains & MS line drains closed at 34MW load.

96 Ensure that the drum level is put in 3 elements.

97 Ensure that LP drip pump is started at 60 MW.

Ensure MS temperature & pressure is increased as per extreme hot start up curve &

98

increase loading of ID/SA/PA fan as per requirement.

Ensure with continuously rising temperature & pressure, load is added to rated load

99

(135 MW) @ 6MW/min.

100 Ensure that the HP heaters are charged at 50MW load.

101 Raise the load gradually to 135 MW @ 6 MW/Min.

Approved by: Control status Issued & Controlled by:

**Pramod kumar nanda **Rajeev kumar singh

DGM (O&M) AGM (Operation)

** As the document is computer generated, hence there is no need for signature

You might also like

- Cold Start Up Check ListDocument6 pagesCold Start Up Check ListSreekanthMylavarapuNo ratings yet

- 7 CompressorDocument2 pages7 CompressorMithun Singh RajputNo ratings yet

- Opgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpDocument5 pagesOpgs 0 BLR Opn 19-26-00 Sop For DM Initial Fill PumpAnbu MathiNo ratings yet

- 08-SOP of ASH SLURRY PUMPDocument5 pages08-SOP of ASH SLURRY PUMPMithun Singh RajputNo ratings yet

- EOP of Instrument Air Failure-FinalDocument3 pagesEOP of Instrument Air Failure-FinalSantanu BasakNo ratings yet

- 4 Vacuum PumpDocument4 pages4 Vacuum PumpMithun Singh Rajput100% (1)

- Cep Startup and ShutdownDocument5 pagesCep Startup and ShutdownAnonymous W9VINoTzaNo ratings yet

- 220 KV Transfer Buschangeover & IsolationDocument7 pages220 KV Transfer Buschangeover & IsolationSreekanthMylavarapuNo ratings yet

- PA Fan SOP in Standard FormatDocument2 pagesPA Fan SOP in Standard FormatSantanu Basak100% (1)

- Opgs 0 BLR Opn 19-27-00 Sop For DM Make Up PumpDocument5 pagesOpgs 0 BLR Opn 19-27-00 Sop For DM Make Up PumpAnbu MathiNo ratings yet

- SOP For HSD UnloadingDocument5 pagesSOP For HSD UnloadingAbraham DeVilliers50% (2)

- Bahp Water PumpDocument4 pagesBahp Water PumpMithun Singh RajputNo ratings yet

- Sop HRSGDocument26 pagesSop HRSGSalmanEjazNo ratings yet

- SABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingDocument15 pagesSABIYA - OP.4.1 - Gas Turbine Operaiton - Compressor WashingAbdelaziz EldeebNo ratings yet

- SOP OperationDocument68 pagesSOP OperationPamela Bradley100% (1)

- Jindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Document4 pagesJindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Chandramani PatelNo ratings yet

- Sop LRSB BlowerDocument6 pagesSop LRSB BlowerApnrl maincontrolroom100% (1)

- Emrsn HTP 001 A1Document7 pagesEmrsn HTP 001 A1Karthik BanariNo ratings yet

- Ni 23110018 CRV 03 R0Document3 pagesNi 23110018 CRV 03 R0Umer KhanNo ratings yet

- Work - Instruction 66-33KV TRANSFORMERDocument5 pagesWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Work Procedure For Pre-CommissioningDocument19 pagesWork Procedure For Pre-CommissioningTrustEmma100% (3)

- SOP For HSD UnloadingDocument5 pagesSOP For HSD UnloadingAnonymous W9VINoTza88% (8)

- WHRB SopDocument13 pagesWHRB SopShambhu Mehta100% (2)

- SOP For Grid FailureDocument9 pagesSOP For Grid FailureAmit BiswasNo ratings yet

- 18 SOP For MD BFPDocument7 pages18 SOP For MD BFPAmit BiswasNo ratings yet

- Sop SDV-R3Document11 pagesSop SDV-R3Budbud YuaNo ratings yet

- JAS-EPC-SP-DYN-20-R1-PR-003 Pump Hydrotest Procedure - RevbDocument7 pagesJAS-EPC-SP-DYN-20-R1-PR-003 Pump Hydrotest Procedure - RevbAgus SuriptoNo ratings yet

- Opgs 0 BLR Opn 19-29-00 Sop For CCCW SystemDocument7 pagesOpgs 0 BLR Opn 19-29-00 Sop For CCCW SystemAnbu MathiNo ratings yet

- Condenser Flood TestDocument14 pagesCondenser Flood Testsrigirisetty208100% (1)

- Btg-Sop035 Stator Water SystemDocument5 pagesBtg-Sop035 Stator Water Systemarunrajmech09No ratings yet

- Silo D-PumpDocument2 pagesSilo D-PumpMithun Singh RajputNo ratings yet

- 400 KV MSDS-1, JSPL Angul: Title Department Maintenance Format For Transformer Department: Electrical &instrumentationDocument16 pages400 KV MSDS-1, JSPL Angul: Title Department Maintenance Format For Transformer Department: Electrical &instrumentationAnonymous vcadX45TD7No ratings yet

- Comment - Tubrine Performance Test Rev 07Document7 pagesComment - Tubrine Performance Test Rev 07guzfistekNo ratings yet

- SOP For Turbine ChecklistDocument11 pagesSOP For Turbine Checklistpradeep.selvarajanNo ratings yet

- Integrated Startup Procedure1Document8 pagesIntegrated Startup Procedure1moturuappalasreenuNo ratings yet

- Monthly PM - IACDocument3 pagesMonthly PM - IACMuhammad RosihanNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonratNo ratings yet

- Work - Instruction Transformer 33-11KV TRANSFORMERDocument5 pagesWork - Instruction Transformer 33-11KV TRANSFORMERTAHIR HUSAINNo ratings yet

- (Form GNQ 17) Aircoolers Pre Commissioning Checklist 1Document140 pages(Form GNQ 17) Aircoolers Pre Commissioning Checklist 1eugene mejidanaNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- 16699120CP LWDocument23 pages16699120CP LWAnonymous G9t3IVfL4JNo ratings yet

- Dosing Pumps ChecklistDocument2 pagesDosing Pumps ChecklistDeshan Sing100% (1)

- Milestone Audit Checklist Cum Report Before Rolling & SynchronisationDocument4 pagesMilestone Audit Checklist Cum Report Before Rolling & SynchronisationHolly SmithNo ratings yet

- Field Operator: Diploma in Mechanical EngineeringDocument5 pagesField Operator: Diploma in Mechanical Engineeringjohn MNo ratings yet

- Accumulator Draw Down TestDocument8 pagesAccumulator Draw Down Testadeelsn100% (4)

- E39 Ahsop 06Document11 pagesE39 Ahsop 06Sanjit SinghNo ratings yet

- Black Out Operation - SopDocument2 pagesBlack Out Operation - SopMahadev Kovalli0% (1)

- Over SpeedingDocument9 pagesOver Speedingsachdev.ashwani6802100% (1)

- ATE-ODC-QCP-M-005 Rev 02 Surface Preparation CoatingDocument21 pagesATE-ODC-QCP-M-005 Rev 02 Surface Preparation CoatingDevam RajNo ratings yet

- BauerDocument3 pagesBauerTC Atilla KarakaşNo ratings yet

- 6 Esp BlowerDocument2 pages6 Esp BlowerMithun Singh RajputNo ratings yet

- NITON - HYDRO TEST PROCEDURE - Rev.0Document6 pagesNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

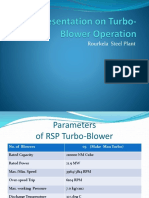

- Turbo-Blower Operation - PPSXDocument12 pagesTurbo-Blower Operation - PPSXSyed Safiur Rahman100% (1)

- PS TSX 606 00 17Document8 pagesPS TSX 606 00 17Boubacar FofanaNo ratings yet

- 04-Commissioning Plan For Condensate and LP Ã + - SS - + Á-+Ë Á - Á - ÈÀ ©Document20 pages04-Commissioning Plan For Condensate and LP Ã + - SS - + Á-+Ë Á - Á - ÈÀ ©Arnel Añabieza GumbanNo ratings yet

- Opgs-0-Blr-Opn-19-30-00 - Sop For CompressorsDocument7 pagesOpgs-0-Blr-Opn-19-30-00 - Sop For CompressorsAnbu MathiNo ratings yet

- Standard Operating Procedure FOR Vacuum PumpDocument7 pagesStandard Operating Procedure FOR Vacuum Pumpsambhu100% (2)

- Mohammad Shadab Khan - Field OperatorDocument6 pagesMohammad Shadab Khan - Field OperatorDonNo ratings yet

- CV en 13Document2 pagesCV en 13SreekanthMylavarapuNo ratings yet

- Balancing MethodsDocument20 pagesBalancing MethodsSreekanthMylavarapuNo ratings yet

- Using System 1 Web DisplayDocument31 pagesUsing System 1 Web DisplaySreekanthMylavarapuNo ratings yet

- Silica AnalyzerDocument114 pagesSilica Analyzerdenios09No ratings yet

- 9245 Single Channel On-Line Sodium Analyzer-Operator ManualDocument130 pages9245 Single Channel On-Line Sodium Analyzer-Operator Manualdenios09No ratings yet

- AA 00 a-MX 1001 Preservation Manual DFCUDocument1,467 pagesAA 00 a-MX 1001 Preservation Manual DFCUSreekanthMylavarapuNo ratings yet

- Peer Control Data Interface Implementation Guide EXDOC-XX84-en-110Document136 pagesPeer Control Data Interface Implementation Guide EXDOC-XX84-en-110SreekanthMylavarapuNo ratings yet

- Seal CodingDocument3 pagesSeal CodingSreekanthMylavarapuNo ratings yet

- 220 KV Bus ChangeoverDocument5 pages220 KV Bus ChangeoverSreekanthMylavarapuNo ratings yet

- 400 KV Bus Changeover &isolationDocument4 pages400 KV Bus Changeover &isolationSreekanthMylavarapuNo ratings yet

- 220 KV Transfer Buschangeover & IsolationDocument7 pages220 KV Transfer Buschangeover & IsolationSreekanthMylavarapuNo ratings yet

- How To Perform Criticality Analysis To Prioritize Asset MaintenanceDocument22 pagesHow To Perform Criticality Analysis To Prioritize Asset MaintenanceSreekanthMylavarapuNo ratings yet

- 6.6 KV Switchgear Charging & IsolationDocument12 pages6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNo ratings yet

- 220 KV Bus Charging & IsolationDocument6 pages220 KV Bus Charging & IsolationSreekanthMylavarapuNo ratings yet

- SMP PH AnalyserDocument4 pagesSMP PH AnalyserSreekanthMylavarapuNo ratings yet

- SMP - Oil in WaterDocument22 pagesSMP - Oil in WaterSreekanthMylavarapuNo ratings yet

- SMP SilicaDocument25 pagesSMP SilicaSreekanthMylavarapuNo ratings yet

- SMP TSDocument3 pagesSMP TSSreekanthMylavarapuNo ratings yet

- SMP PSDocument3 pagesSMP PSSreekanthMylavarapuNo ratings yet

- 13IPAHDocument208 pages13IPAHSreekanthMylavarapuNo ratings yet

- 165ZSBDocument37 pages165ZSBSreekanthMylavarapuNo ratings yet

- 13ISREDocument128 pages13ISRESreekanthMylavarapuNo ratings yet

- Steam Turbine Turbine Oil Care Maintenance Maintenance InstructionsDocument11 pagesSteam Turbine Turbine Oil Care Maintenance Maintenance InstructionsSreekanthMylavarapuNo ratings yet

- Steam Turbine Remedial Actions For Maintenance Off-Normal Operating ConditionsDocument5 pagesSteam Turbine Remedial Actions For Maintenance Off-Normal Operating ConditionsSreekanthMylavarapuNo ratings yet

- 164NBTDocument110 pages164NBTSreekanthMylavarapuNo ratings yet

- Steam Turbine Turbine Oil Care Maintenance Maintenance InstructionsDocument11 pagesSteam Turbine Turbine Oil Care Maintenance Maintenance InstructionsSreekanthMylavarapuNo ratings yet

- Steam Turbine Testing of Maintenance Turbine Stress Controller (TSC)Document4 pagesSteam Turbine Testing of Maintenance Turbine Stress Controller (TSC)SreekanthMylavarapuNo ratings yet

- Steam Turbine Acquisition and Archiving Maintenance of Operating Data Procedural InstructionDocument3 pagesSteam Turbine Acquisition and Archiving Maintenance of Operating Data Procedural InstructionSreekanthMylavarapuNo ratings yet

- PC Hardware Servicing Teacher's GuideDocument7 pagesPC Hardware Servicing Teacher's GuidedanballaisNo ratings yet

- Marketing Information Systems & Market ResearchDocument20 pagesMarketing Information Systems & Market ResearchJalaj Mathur100% (1)

- Release Notes Xcode 4.5.2Document7 pagesRelease Notes Xcode 4.5.2Anonymous gdJiDHNo ratings yet

- 232-002101-00 Rev A SonicWALL WXA 5000 Getting Started GuideDocument18 pages232-002101-00 Rev A SonicWALL WXA 5000 Getting Started GuideFreddy Olivares CortesNo ratings yet

- The Sims 4 Cheats For PC: Platform. If You've DiscoveredDocument2 pagesThe Sims 4 Cheats For PC: Platform. If You've DiscoveredDean Joyce AlborotoNo ratings yet

- HDPE Pipe InstallationDocument7 pagesHDPE Pipe InstallationJeferson Binay-an100% (1)

- Truss Operating Manual: Version 7aDocument28 pagesTruss Operating Manual: Version 7adoyoudeNo ratings yet

- 3.1 Turbine and GoverningDocument90 pages3.1 Turbine and GoverningYudo Heru PribadiNo ratings yet

- Operating Check List For Disel Generator: Date: TimeDocument2 pagesOperating Check List For Disel Generator: Date: TimeAshfaq BilwarNo ratings yet

- Eaton Lumark Nightfalcon SpecDocument4 pagesEaton Lumark Nightfalcon Specluis torresNo ratings yet

- SYS600 System ConfigurationDocument256 pagesSYS600 System ConfigurationDang JinlongNo ratings yet

- Tabla 1-1 (W Shapes)Document17 pagesTabla 1-1 (W Shapes)Leonardo ZambranoNo ratings yet

- Design of Slab FormsDocument27 pagesDesign of Slab FormsZevanyaRolandTualaka100% (1)

- Relay Performance Testing: Jay Gosalia Vice President of Engineering and Marketing Doble Engineering Company, USADocument40 pagesRelay Performance Testing: Jay Gosalia Vice President of Engineering and Marketing Doble Engineering Company, USArashid rahmanNo ratings yet

- PKG 101 Principles of Packaging Quiz 1ADocument2 pagesPKG 101 Principles of Packaging Quiz 1AuknowgaryNo ratings yet

- MM LabDocument4 pagesMM LabJstill54No ratings yet

- Clean Energy Council Installers Checklist PDFDocument3 pagesClean Energy Council Installers Checklist PDFAndre SNo ratings yet

- Imovie Presentation Rubric EfDocument1 pageImovie Presentation Rubric Efapi-239838395No ratings yet

- Ba 206 LPC 03Document13 pagesBa 206 LPC 03rachna357No ratings yet

- Classifications of KeysDocument13 pagesClassifications of KeyssyampnaiduNo ratings yet

- Mobile Networks and ApplicationsDocument232 pagesMobile Networks and ApplicationsrabrajNo ratings yet

- CATIA Cloud of PointsDocument141 pagesCATIA Cloud of Points4953049530100% (1)

- Syllabus For Management 120A Intermediate Accounting - Spring 2009Document6 pagesSyllabus For Management 120A Intermediate Accounting - Spring 2009John KimNo ratings yet

- Management Information System KFCDocument29 pagesManagement Information System KFCTamilSelvan0% (1)

- Oil-Less Decal Transfer: Copyfun WhiteDocument1 pageOil-Less Decal Transfer: Copyfun WhiteIgor Cece GigoNo ratings yet

- Kinematics of MachinesDocument2 pagesKinematics of MachinesBhavesh J MakwanaNo ratings yet

- Manual Do Consumo de Gases DC - TruLaser - 1030 - 2011-08-09 - METRIC - VERSIONDocument65 pagesManual Do Consumo de Gases DC - TruLaser - 1030 - 2011-08-09 - METRIC - VERSIONveraNo ratings yet

- 1 Input Data: Profis Anchor 2.8.1Document7 pages1 Input Data: Profis Anchor 2.8.1Manu MohanNo ratings yet

- 8.4.2 Detecting The Presence/Absence of Paper: Pickup RollerDocument2 pages8.4.2 Detecting The Presence/Absence of Paper: Pickup RollerHERL NEIL BilbaoNo ratings yet

- Lecture-4: Data Communication and Computer NetworksDocument24 pagesLecture-4: Data Communication and Computer NetworksSaifuddin Mohammed TarekNo ratings yet