Professional Documents

Culture Documents

Apcolite Premium Gloss Enamel PDF

Apcolite Premium Gloss Enamel PDF

Uploaded by

Arun RajaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apcolite Premium Gloss Enamel PDF

Apcolite Premium Gloss Enamel PDF

Uploaded by

Arun RajaCopyright:

Available Formats

Finishes for Wood / Wall / Metal Surfaces

PRODUCT CODE 0026 / 0001

Apcolite Premium Gloss Enamel

Asian Paints Apcolite Premium Gloss Enamel imparts a shiny new look to surfaces painted with this finish. It

forms a tough film that is highly resistant to household stains. It thereby serves as a protective armour around

the painted surface.

PRODUCT BENEFITS

High Gloss Finish Stain Gaurd SOLVENT BASED

Apcolite Premium Gloss Enamel gives a mirror like gloss Apcolite Premium Gloss Enamel is a highly washable

for your doors, windows, grills & gates paint, thus you can wipe off most common household

stains easily

Tough and Durable

The oil based film of Apcolite Premium Gloss Enamel

makes it one of the toughest & most durable paints

which forms a protective armour around surfaces * All Asian Paints products contain no added

Lead, Mercury, Arsenic or Chromium

from April 2008.

PRODUCT FEATURES

WASHABILITY COLOURS AVAILABLE COVERAGE

BEST IN CLASS

HIGH

1737* On smooth masonry surface by brushing

MEDIUM

*Currently available in 1737 1 COAT

LOW shades as per the Colourworld

Fandeck 185 - 225

sq.ft/ltr**

AVAILABLE PACKS FINISH

2 COATS

MATT LOW SHEEN HIGH SHEEN HIGH GLOSS 95 - 110

sq.ft/ltr**

SILKY SMOOTH

1 ltr 4 ltr 10 ltr 20 ltr

Also available in 50 ml,100 ml, 200 ml and 500 ml Refer to sheen levels in technical details **Actual coverage may vary from the quoted coverage due

Shelf life: 3 years from date of manufacture (1 year in case to factors such as method and condition of application and

of Gold (M003) & Silver (M002) shades), in original tightly surface roughness and porosity.

closed containers away from direct sunlight and excessive

heat.

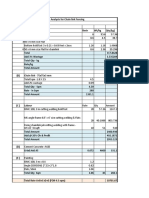

HOW TO APPLY

PRE PAINTING STEPS PAINT APPLICATION PROCESS

APPLICATION CODE THINNER DILUTION % APPLICATION RECOATING

PLASTER New masonry surfaces VISCOSITY1 PERIOD

must be allowed to cure completely. STEP 1

It is recommended to allow 28 days SANDING SAND THE SURFACE WITH SAND PAPER 180 AND WIPE CLEAN

as the curing time for new masonry

surfaces. STEP 2

METAL PRIMER (METAL) / 0005 BRUSH 4 - 10 BRUSH 30 - 40

CLEANING Surface should be DECOPRIME ST (MASONORY) / 0359 MTO* SPRAY 12 - 15 SPRAY 20 - 25 6 - 8 HRS

free from any loose paint, dust or WOOD PRIMER (WOOD) 0007

grease. Growths of fungus, algae STEP 3

or moss should be removed by KNIFING PASTE FILLER (METAL 0016 WATER 6 - 8 HRS

/ WOOD) BASED ON BASED ON

wire brushing and water. In case of OR

REQUIREMENT REQUIREMENT

WALL PUTTY (MASONORY) 1354 MTO 4 - 6 HRS

areas having excessive dampness PUTTY KNIFE

use Asian Paints DampBlock to

STEP 4

limit further dampness. When SANDING SAND THE SURFACE WITH SAND PAPER 180 AND WIPE CLEAN

the underlying surface exhibits

STEP 5

chalkiness, in spite of thorough 0005

METAL PRIMER (METAL) / BRUSH 4 - 10 BRUSH 30 - 40

surface cleaning, use Asian Paints DECOPRIME ST (MASONORY) / 0359 MTO* SPRAY 12 - 15 SPRAY 20 - 25 6 - 8 HRS

SmartCare Exterior Sealer. WOOD PRIMER (WOOD) 0007

FILLING FOR CRACKS For filling STEP 6

masonry upto 3mm use Asian Paints SANDING SAND THE SURFACE WITH SAND PAPER 320 AND WIPE CLEAN

SmartCare Crack Seal.

STEP 7

FILLING FOR HOLES & DENTS FIRST COAT APCOLITE 0001 BRUSH 8 - 10 BRUSH 55 - 60

PREMIUM GLOSS ENAMEL MTO* SPRAY 15 - 20 SPRAY 22 - 25 6 - 8 HRS

In case of dents and holes use 0026

BRUSH / ROLLER / SPRAY

Asian Paints Acrylic Wall Putty or

white cement and fine sand in the STEP 8

SECOND COAT APCOLITE 0001 BRUSH 8 - 10 BRUSH 55 - 60

ratio 1:3 MTO* SPRAY 15 - 20 SPRAY 22 - 25 6 - 8 HRS

PREMIUM GLOSS ENAMEL 0026

Apcolite Premium Gloss Enamel BRUSH / ROLLER / SPRAY

should not be applied on surfaces

/ substrates that are subjected to 1. As measured through a Ford cup.

continuous seepage or dampness. 2. Recoat period is quoted for 25°C and 50% Relative Humidity, these may vary under different conditions.

*

Mineral Turpentine Oil

3. Ensure that the metal substrates are free from oil, grease and rust before paint application.

Finishes for Wood / Wall / Metal Surfaces

HOW TO CHOOSE COLOURS

Browse through Asian Paints colour tools to help you find the right colour combination

COLOUR SPECTRA FAN DECK* APCOLITE ENAMEL SHADE CARD

*These shades are for reference only. Please refer to the Colour Spectra or Colour Palette for correct shade reference

ADDITIONAL INFORMATION

POST PAINTING CARE PRECAUTIONS

For the best performance of the paint, ensure > Do not apply when ambient temperature is less than 10°C or if the temperature might drop to

proper washing and cleaning of all algal and this level within 4 hrs of application.

fungal growth, if any, at regular intervals of > Do not over-thin or over-extend the brush.

six months. > Tint using Asian Paints machine colourants only

> Stir well and strain before use.

TECHNICAL DETAILS > Tinted paints need thorough shaking immediately after tinter addition as well as before use.

a. Drying time: Surface dry time 3 hrs

b. Gloss levels: 75 - 85 on tin plate at 20 Deg

Gloss Head SAFETY FEATURES

c. 1s101/1987 Part 1 Sec 6 35 Deg C (95

Deg F)

> Kindly refer to the MSDS for Asian Paints Apcolite Premium Gloss Enamel which gives detailed

d. Stability of thinned paint: To be used information on safety measures while handling the paint, which is available on request.

within 24 hours

> Store the container with the lid tightly closed in an upright position, in a cool, dry place.

> Keep out of reach of children and away from eatables.

> May be harmful if swallowed. In case of ingestion seek immediate medical attention.

> Wear eye protection during application. In case of contact with eyes, rinse immediately with

plenty of water and seek medical advice.

> In case of skin contact immediately wash skin with soap and plenty of water. Get medical

attention if irritation develops or persists.

> Do not breathe vapour or spray.It is recommended to wear suitable nose pad during sanding

and surface preparation to avoid dust inhalation

> Do not pour leftover paint down the drain or in water courses.

> In the event of spills, contain spillage using sand or earth.

> No added Lead, Mercury or Chromium compounds.

Version No. VN01/01/2014

Version No. VN01/01/2014. Please note that this datasheet supersedes all previous versions

For Feedback/complaints, write to Marketing Manager Services, Asian Paints Limited, 6A, Shantinagar, Santacruz(E), Mumbai 400 055, India

You might also like

- Kubota Front Loader La 211Document29 pagesKubota Front Loader La 211Mark Dubravec40% (5)

- BẢNG MÀU JOTUN 1-Màu kết cấu thép PDFDocument2 pagesBẢNG MÀU JOTUN 1-Màu kết cấu thép PDFphuocquocNo ratings yet

- BBS Retaining Wall + FootingDocument11 pagesBBS Retaining Wall + FootingmanishjonwNo ratings yet

- Name of Work: Rate Analysis For Valve Chamber (1.5 M X 1.5 M X 1 M)Document5 pagesName of Work: Rate Analysis For Valve Chamber (1.5 M X 1.5 M X 1 M)Vijay SinghNo ratings yet

- Case Study IIT Kanpur Green BuildingDocument5 pagesCase Study IIT Kanpur Green BuildingAnand Chavan Projects-Quality75% (8)

- Cement Reconciliation ExampleDocument4 pagesCement Reconciliation ExampleDevenderNo ratings yet

- B-15 Misc. Water Proof1Document19 pagesB-15 Misc. Water Proof1Akhlaq Hussain0% (1)

- ECMAS Terrace Waterproofing SolutionsDocument8 pagesECMAS Terrace Waterproofing SolutionsLokesh DvNo ratings yet

- Kei Ar Cables PDFDocument5 pagesKei Ar Cables PDFrajaNo ratings yet

- Monopol 456 HBDocument2 pagesMonopol 456 HBPammy JainNo ratings yet

- Material Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/MDocument5 pagesMaterial Quantities MIX Cement (Bags/m) Sand/M Granite/M Lime/Mjmarkunongo_69397286No ratings yet

- MTC For ThermocolDocument2 pagesMTC For ThermocolhariprasadNo ratings yet

- Karnataka PWD SR 11-12Document446 pagesKarnataka PWD SR 11-12NITESH SINGHNo ratings yet

- 1123 PDFDocument9 pages1123 PDFvijayunityNo ratings yet

- Wooden Floor SpecificationDocument2 pagesWooden Floor SpecificationraviNo ratings yet

- DSR RA16 17 PWD WorkingDocument46 pagesDSR RA16 17 PWD WorkingSarinNo ratings yet

- Acfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgDocument2 pagesAcfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgSrinivas SukhavasiNo ratings yet

- Rate-Analysis GHFDocument64 pagesRate-Analysis GHFSandeep VishwakarmaNo ratings yet

- Item Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDocument9 pagesItem Material Unit Remark SR No Material Coeff. Excl Wastage Wastage Factor Material Co-EffDeepak KaushikNo ratings yet

- Jay JagannathaDocument2 pagesJay JagannathaRanjan Kumar TaraiNo ratings yet

- Basic Rate of Materials: S.No. Description Unit Rate RemarksDocument29 pagesBasic Rate of Materials: S.No. Description Unit Rate RemarksNishan GajurelNo ratings yet

- Amendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - SpecificationDocument3 pagesAmendment No. 3 March 2017 TO Is 1786: 2008 High Strength Deformed Bars and Wires For Concrete Reinforcement - Specificationraviteja036No ratings yet

- Abstract Estimate: Description Rate AmountDocument8 pagesAbstract Estimate: Description Rate AmountPUMANo ratings yet

- K102-2 - Final Account - BOQ - Reshaun Plumbing PDFDocument4 pagesK102-2 - Final Account - BOQ - Reshaun Plumbing PDFSharon FarmerNo ratings yet

- Built Up Area Basis MaterialDocument2 pagesBuilt Up Area Basis MaterialHossen Ali MollahNo ratings yet

- Chainlink Fenc. RaDocument6 pagesChainlink Fenc. Rasri projectssNo ratings yet

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- Is 1948 1961 R 1996Document21 pagesIs 1948 1961 R 1996Nagaraju Chinta100% (4)

- Cross Drainage Works BOQ RATESDocument4 pagesCross Drainage Works BOQ RATESvmpandey100% (2)

- Norms For Cement Consumption PDFDocument3 pagesNorms For Cement Consumption PDFJai prakash keshriNo ratings yet

- Is 2314 1986 PDFDocument14 pagesIs 2314 1986 PDFsixramesh123No ratings yet

- DSR PuneDocument9 pagesDSR PunedigvijayjagatapNo ratings yet

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785Document9 pagesAshirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785mohd shirazNo ratings yet

- Final Estimate-04 Nos. New TubewellDocument16 pagesFinal Estimate-04 Nos. New Tubewellankur yadavNo ratings yet

- MasterEmaco - S 348 v1Document2 pagesMasterEmaco - S 348 v1vahab_shaik0% (1)

- Bills of Quantities (Boq) : Construction of Rear Side Boundary Wall at SRCCDocument3 pagesBills of Quantities (Boq) : Construction of Rear Side Boundary Wall at SRCCGokul NathNo ratings yet

- IRUSSOR-Cement CoefficientsDocument11 pagesIRUSSOR-Cement CoefficientsLAXMI NARAYAN PRADHAN100% (1)

- Spectrum Engineering Services: Section:-1 Civil WorksDocument1 pageSpectrum Engineering Services: Section:-1 Civil WorksHasmit PrajapatiNo ratings yet

- Estimating and Costing MaterialDocument42 pagesEstimating and Costing MaterialQuestion paperNo ratings yet

- Rate Analysis Earthen Dam (13-14)Document123 pagesRate Analysis Earthen Dam (13-14)Mehta MalayNo ratings yet

- Teamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689Document6 pagesTeamagri Industrial Corporation: 103 West City Plaza, 66 West Ave., Quezon City Tel. No. +632921-1983, 709-9689leslieNo ratings yet

- Providing and Laying Integral Cement Based Water Proofing Treatment IncDocument5 pagesProviding and Laying Integral Cement Based Water Proofing Treatment IncEr R RamanNo ratings yet

- Design Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutDocument3 pagesDesign Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutMuneer HaiderNo ratings yet

- No Loading and Unloading Charges Allowed For Machinery Loading and UnloadingDocument235 pagesNo Loading and Unloading Charges Allowed For Machinery Loading and UnloadingSarinNo ratings yet

- IRC 047.1972 Builtup SPray GroutDocument12 pagesIRC 047.1972 Builtup SPray GroutTk SubhashNo ratings yet

- WTP Cost Estimate PDFDocument13 pagesWTP Cost Estimate PDFSurangaGNo ratings yet

- FREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghDocument10 pagesFREQUENCY OF TEST & ACCEP. LIMITS Ajit Pratap SinghAjit P. SinghNo ratings yet

- Experimental Study On Partial Replacement of Cement Using AlccofineDocument8 pagesExperimental Study On Partial Replacement of Cement Using AlccofineNavik BhandariNo ratings yet

- PU Resin Data Rate AnalysisDocument1 pagePU Resin Data Rate AnalysishsclNo ratings yet

- Kolkata Metro Fare ChartDocument3 pagesKolkata Metro Fare ChartUtpalSahaNo ratings yet

- Mahakalipadpu Wardrobe Rate Analysis & EstimationDocument2 pagesMahakalipadpu Wardrobe Rate Analysis & EstimationPrakash RaoNo ratings yet

- Paving Flooring and DadoDocument17 pagesPaving Flooring and DadozfrlNo ratings yet

- BBS Deck Slab-For One SpanDocument1 pageBBS Deck Slab-For One SpanRavindra RaoNo ratings yet

- Timber and Plywood 1Document22 pagesTimber and Plywood 1yash goyalNo ratings yet

- Detailed Estimate For Sanitary WorksDocument5 pagesDetailed Estimate For Sanitary Worksbehroze aminNo ratings yet

- Schedule-of-rates-MI 2014-15Document151 pagesSchedule-of-rates-MI 2014-15Vinisha RaoNo ratings yet

- ME-1 Things To RememberDocument7 pagesME-1 Things To Rememberlebronman58No ratings yet

- Materials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e AggregatesDocument19 pagesMaterials Price List: August, 2020 Item Material Unit Basic Price Source GH T e L e P H o N e Aggregatesmissowusu100% (1)

- Dmart QuotationDocument1 pageDmart QuotationSarinNo ratings yet

- Mir 001Document2 pagesMir 001MCCIN L&WNo ratings yet

- Premium Satin Enamel: Finishes For Wood / Wall / Metal SurfacesDocument6 pagesPremium Satin Enamel: Finishes For Wood / Wall / Metal SurfacesAr. Libin K BabyNo ratings yet

- Apcolite Premium Matt EnamelDocument2 pagesApcolite Premium Matt EnamelAnmol SidanaNo ratings yet

- Innovators Facade-Proposal For IMS 6Document1 pageInnovators Facade-Proposal For IMS 6Anand Chavan Projects-QualityNo ratings yet

- How To of A Mask: Put On, Use, Take Off and DisposeDocument1 pageHow To of A Mask: Put On, Use, Take Off and DisposeAnand Chavan Projects-QualityNo ratings yet

- ISO 9001 Internal Auditor PDFDocument1 pageISO 9001 Internal Auditor PDFAnand Chavan Projects-QualityNo ratings yet

- KDMAL0211679000 Samsung C & T India Private Limited: Establishment ID Establishment NameDocument3 pagesKDMAL0211679000 Samsung C & T India Private Limited: Establishment ID Establishment NameAnand Chavan Projects-QualityNo ratings yet

- ISO 9001 Awareness PDFDocument1 pageISO 9001 Awareness PDFAnand Chavan Projects-QualityNo ratings yet

- CQI/IRCA Approved ISO 9001:2015 Lead Auditor: Course ContentsDocument1 pageCQI/IRCA Approved ISO 9001:2015 Lead Auditor: Course ContentsAnand Chavan Projects-QualityNo ratings yet

- Iso 9001:2015 Internal Auditor'S Training Time-Table Day 1 Time Programme For The DayDocument3 pagesIso 9001:2015 Internal Auditor'S Training Time-Table Day 1 Time Programme For The DayAnand Chavan Projects-QualityNo ratings yet

- C2V1 - MyBusinessBudget - SettingOutDocument7 pagesC2V1 - MyBusinessBudget - SettingOutAnand Chavan Projects-QualityNo ratings yet

- C3V5 - MyBusinessBudget - Prep ReportsDocument10 pagesC3V5 - MyBusinessBudget - Prep ReportsAnand Chavan Projects-QualityNo ratings yet

- Inprocess Rework/Rejection Log: Fabrication and AssemblyDocument2 pagesInprocess Rework/Rejection Log: Fabrication and AssemblyAnand Chavan Projects-QualityNo ratings yet

- VOC Gigaplex PDFDocument1 pageVOC Gigaplex PDFAnand Chavan Projects-QualityNo ratings yet

- Essential 2014Document5 pagesEssential 2014Anand Chavan Projects-QualityNo ratings yet

- C2V4 - MyBusinessBudget - RelationshipDocument8 pagesC2V4 - MyBusinessBudget - RelationshipAnand Chavan Projects-QualityNo ratings yet

- Suzlon Pune Case Study Green BuildingDocument10 pagesSuzlon Pune Case Study Green BuildingAnand Chavan Projects-Quality100% (1)

- WST 2100 Pbach R Me 0042Document206 pagesWST 2100 Pbach R Me 0042teamlc100% (1)

- Research Note Buddha'S Life Depicted in The Sculpturs of KakrebiharDocument7 pagesResearch Note Buddha'S Life Depicted in The Sculpturs of KakrebiharLekh LekhNo ratings yet

- Wcfs2019 FlyerDocument10 pagesWcfs2019 FlyerZhi Yung TayNo ratings yet

- Chapter 1 - Production and Operations ManagementDocument4 pagesChapter 1 - Production and Operations Managementhello_khayNo ratings yet

- Continuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingDocument12 pagesContinuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingudayNo ratings yet

- Winsor Pilates - Tips, and Some Exercises To DoDocument8 pagesWinsor Pilates - Tips, and Some Exercises To DoudelmarkNo ratings yet

- Attachment 1 PDFDocument2 pagesAttachment 1 PDFHuy DoanNo ratings yet

- Prostructure SuiteDocument8 pagesProstructure SuiteArshal AzeemNo ratings yet

- CERDEC Fact Sheet - CREW Duke V3Document1 pageCERDEC Fact Sheet - CREW Duke V3RDECOM CERDECNo ratings yet

- Agibta, Sri Pinta. Rekonstruksi Fosil PoriferaDocument5 pagesAgibta, Sri Pinta. Rekonstruksi Fosil PoriferaSri Pinta Agibta GintingNo ratings yet

- Jan 17 S3Document30 pagesJan 17 S34ydprasadNo ratings yet

- Circular Dichroism of Protein: PC3267 Updated in Jan. 2007Document7 pagesCircular Dichroism of Protein: PC3267 Updated in Jan. 2007Chellam Gayathri SubashNo ratings yet

- Steinforth - Balladoole v.1Document4 pagesSteinforth - Balladoole v.1Renan M. BirroNo ratings yet

- Long Quiz in Physical Science Grade 11Document2 pagesLong Quiz in Physical Science Grade 11Kelly Ann PanganibanNo ratings yet

- Topography - AmravatiDocument32 pagesTopography - AmravatiHi-End SurveysNo ratings yet

- 2 Iwonder 1-4 Answer KeyDocument3 pages2 Iwonder 1-4 Answer KeyAlina CheNo ratings yet

- Finfet: (Fin Shaped Field Effect Transistor)Document14 pagesFinfet: (Fin Shaped Field Effect Transistor)Harish Kumar PuvvadaNo ratings yet

- Farkhanda Anwar W/O Muhammad Farooq 43 Iqbal Block Ittifaq Town LHRDocument1 pageFarkhanda Anwar W/O Muhammad Farooq 43 Iqbal Block Ittifaq Town LHRFoad AhmedNo ratings yet

- Sample Business Plan 1 2021 2022Document23 pagesSample Business Plan 1 2021 2022Claudio MatarazzoNo ratings yet

- Grade 7 Algebra Expressions and Equations inDocument4 pagesGrade 7 Algebra Expressions and Equations inYesan SellanNo ratings yet

- 2012 f550 Manual PDFDocument450 pages2012 f550 Manual PDFJuma RefaccionariasNo ratings yet

- Bliley P/N: Nvg47A1282: Rohs Compliant ProductDocument3 pagesBliley P/N: Nvg47A1282: Rohs Compliant ProductGabrielitoNo ratings yet

- CamNorte APTCDocument17 pagesCamNorte APTCStella Marie VillagenNo ratings yet

- JyothishaPrakaasham MeenaVijayaDocument52 pagesJyothishaPrakaasham MeenaVijayaAnonymous 5mSMeP2j100% (1)

- Dallas Music Shop Zagreb CD LagerDocument174 pagesDallas Music Shop Zagreb CD Lagervjeran rukavinaNo ratings yet

- Seminar Presentation 7Document60 pagesSeminar Presentation 7emma_ade92007No ratings yet

- Report On Bharti Airtel Limited: Institute of Marketing and ManagementDocument26 pagesReport On Bharti Airtel Limited: Institute of Marketing and Managementsimply_cooolNo ratings yet

- MDP408a Lecture08Document42 pagesMDP408a Lecture08Hisham Ahmed FouadNo ratings yet

- Online Smu Natural Science Text BookDocument32 pagesOnline Smu Natural Science Text BookspmajishNo ratings yet