Professional Documents

Culture Documents

HW 2

Uploaded by

Nikos VaxevanidisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HW 2

Uploaded by

Nikos VaxevanidisCopyright:

Available Formats

ME 363 Homework No.

2 Name Due: 9/20/2011

1. The following data are collected during a tensile test in which the starting gage length =5.0

in. and the cross sectional area=0.1 in2.

Load 0 4000 5180 6200 6500 6200 4600

Length 0 5.009 5.25 5.6 5.88 6.12 6.4

The maximum load is 6500 lbs and the final data point occurred immediately prior to failure.

(a) Plot the engineering stress-strain curve and the true stress-strain curve.

(b) Determine the yield strength Y and modulus of elasticity E.

(c) Determine the tensile strength TS.

(d) Determine the strength coefficient, K, and the strain hardening exponent. Be sure not to

use the data after the necking point.

2. A tensile test for an aluminum alloy yielded the following data:

Modulus of elasticity 10×106 psi (69 ×103

MPa)

Yield strength 25,000 psi (175 MPa)

Tensile strength 50,000 psi (350 MPa)

Strength coefficient, K 60,000 psi (400 MPa)

Strain hardening index, 0.15

n

The fracture occurred when ε=0.35.

(a) Determine the resilience.

(b) Calculate the value of ductility.

(c) Determine the value of toughness.

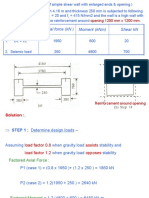

3. Hardness problem (see Figure 2.12 in the textbook)

(a) Solve textbook 2.54.

(b) Solve textbook 2.57.

4. A bar 0.5 m long is stretched to the strain of 0.12 and then stress relieved. The yield stress of

this material is 600 MPa and E=200 GPa. The plastic deformation is described by the strain

hardening equation σ = K εn with K=760 MPa and n=0.2. Determine the length of the bar after

the external stress is relieved.

You might also like

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Gujarat Technological UniversityDocument4 pagesGujarat Technological Universitythe grayNo ratings yet

- Emm 302 Solid and Structural Mechanics 1Document4 pagesEmm 302 Solid and Structural Mechanics 1anniemusyimiNo ratings yet

- Closed-Book Practice-Ch 06 (2016!07!31)Document8 pagesClosed-Book Practice-Ch 06 (2016!07!31)JuanNo ratings yet

- Material Yr1 - Tutorial 6Document16 pagesMaterial Yr1 - Tutorial 6Ahmed TahaNo ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- CCB 241 - Assignment 1 - Due On 21 Feb. 2023Document7 pagesCCB 241 - Assignment 1 - Due On 21 Feb. 2023aaschlysebakisoNo ratings yet

- Ejercicos Propuestos R1 Deformacion AxialDocument6 pagesEjercicos Propuestos R1 Deformacion AxialeliasNo ratings yet

- Question Bank: Module 1:design For Static StrengthDocument22 pagesQuestion Bank: Module 1:design For Static Strengthcrazy hjNo ratings yet

- Binder 1Document4 pagesBinder 1Muhammad Rizqi RamadhanNo ratings yet

- Aula 4 - ExercíciosDocument16 pagesAula 4 - ExercíciosGustavo ChavesNo ratings yet

- Ass 1Document3 pagesAss 1Yonas BelaynehNo ratings yet

- FoM - LCF QuestionsDocument5 pagesFoM - LCF Questionsbharath kumarNo ratings yet

- Internal Assessment Examination-II: Part-A (Answer All The Questions)Document2 pagesInternal Assessment Examination-II: Part-A (Answer All The Questions)VVCET - MechNo ratings yet

- Load (N) Length (MM) : SolutionDocument8 pagesLoad (N) Length (MM) : Solutionاحمد الشوافيNo ratings yet

- 6 PDFDocument8 pages6 PDFmegaNo ratings yet

- MEP 4th Ed 2019 Worked Sols Chap 03Document16 pagesMEP 4th Ed 2019 Worked Sols Chap 0319-133 Joy Frando PinemNo ratings yet

- Midterm Exam (Sec)Document11 pagesMidterm Exam (Sec)Sherwin ConcepcionNo ratings yet

- ME 303 Study Set PDFDocument44 pagesME 303 Study Set PDFFajar RumantoNo ratings yet

- Assignment 5 SolutionsDocument6 pagesAssignment 5 Solutionsdan4booksNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityJaineshNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- ESO205 - 22-23 - Assignment 11 ModifiedDocument2 pagesESO205 - 22-23 - Assignment 11 ModifiedThe BS ChannelNo ratings yet

- Materials Science 2018Document1 pageMaterials Science 2018ParthibanNo ratings yet

- Flexural TestDocument8 pagesFlexural TestNawaf Al-TamimiNo ratings yet

- Dme QP Series 1 2019Document1 pageDme QP Series 1 2019AADARS M SNo ratings yet

- Som Test-1 NotesDocument5 pagesSom Test-1 NotesHarsha HarapanahalliNo ratings yet

- Assignment 1 Mech 321 Properties and Failure of Materials Jan 2009Document2 pagesAssignment 1 Mech 321 Properties and Failure of Materials Jan 2009DSGNo ratings yet

- WWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)Document3 pagesWWW - Manaresults.Co - In: (Common To Me, MCT, MMT, Ae, Ame, MSNT)mahendra babu mekalaNo ratings yet

- Shear KN Moment (KNM) Axial Force (KN) : LoadingDocument15 pagesShear KN Moment (KNM) Axial Force (KN) : LoadingVenkat Deepak SarmaNo ratings yet

- Fatigue of Materials Solved Problems UnlockedDocument20 pagesFatigue of Materials Solved Problems UnlockedMAT-LIONNo ratings yet

- HW Ch7 1Document12 pagesHW Ch7 1Chenhg ChengNo ratings yet

- Chapter 4 Tensile TestingDocument7 pagesChapter 4 Tensile TestingعلياسماعيلNo ratings yet

- Solution Manual Mechanical Engineering Principles John Bird 4Document7 pagesSolution Manual Mechanical Engineering Principles John Bird 4ridwansadelyNo ratings yet

- Machine Design Question PaperDocument2 pagesMachine Design Question Papersushil.vgi100% (1)

- Home Assignment 5Document2 pagesHome Assignment 5SantoshNo ratings yet

- Tsu m23 Practice Problems Reinforced Concrete DesignDocument2 pagesTsu m23 Practice Problems Reinforced Concrete DesignMark Lester ValdozNo ratings yet

- Cven306 502 Hw06 SolutionDocument5 pagesCven306 502 Hw06 SolutiontwinbedtxNo ratings yet

- Be Summer 2018Document2 pagesBe Summer 2018Swastik PanchalNo ratings yet

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- Problems Solutions On Fracture MechanicsDocument50 pagesProblems Solutions On Fracture MechanicsRajesh N Priya Gopinathan100% (5)

- CE411 Midterm ReviewDocument20 pagesCE411 Midterm ReviewVios, Allen Rafael M.No ratings yet

- Shear Wall ExampleDocument15 pagesShear Wall ExampleAnnamalai VaidyanathanNo ratings yet

- STRENGTH OF MATERIALS 1st Unit QBDocument4 pagesSTRENGTH OF MATERIALS 1st Unit QBCharith NukalaNo ratings yet

- Show That Natural Strains Are Additive While Conventional Strains Are Not. 2. Derive Equation 2.2.13. 3Document4 pagesShow That Natural Strains Are Additive While Conventional Strains Are Not. 2. Derive Equation 2.2.13. 3shifatNo ratings yet

- Engineering Material: Assignment # 01Document3 pagesEngineering Material: Assignment # 01Hussain AliNo ratings yet

- ENG782S2Document8 pagesENG782S2Emperor RocaNo ratings yet

- CH 07Document12 pagesCH 07Madeline NgoNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological Universityfeyayel990No ratings yet

- Assignment 2 - 2023 - SolutionsDocument23 pagesAssignment 2 - 2023 - SolutionsLinhan ChuNo ratings yet

- 18me52 Dme 1 Febarch 2022Document22 pages18me52 Dme 1 Febarch 2022Thirumal K SNo ratings yet

- DMCB 2423 CHPT 7-Tutorial.-SolutionDocument11 pagesDMCB 2423 CHPT 7-Tutorial.-Solutionzul hilmiNo ratings yet

- Solutions To AssignmentDocument22 pagesSolutions To AssignmentNeo TarunNo ratings yet

- Tutorials:: Stress & Strain - Axial LoadingDocument9 pagesTutorials:: Stress & Strain - Axial LoadingafifezzatNo ratings yet

- Lesson 4 Analysis & Design of Doubly-Reinforced BeamsDocument12 pagesLesson 4 Analysis & Design of Doubly-Reinforced Beamsrose ann claveriaNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- Assignment 5 (Group) - 220110 - 003126Document7 pagesAssignment 5 (Group) - 220110 - 003126MOHAMMAD AELEEF BIN PATRICK A20ET0356No ratings yet

- LE1 Problem Set PDFDocument14 pagesLE1 Problem Set PDFJunhong BapNo ratings yet

- Mechanics of Solids GTU PapersDocument17 pagesMechanics of Solids GTU Papersvaibhav shahNo ratings yet

- E-50 - Aeroengine Gearbox Design - BAPT 09 - P 595Document6 pagesE-50 - Aeroengine Gearbox Design - BAPT 09 - P 595Nikos VaxevanidisNo ratings yet

- E-26 - Knowledge Based Systems Support in Micro-Manufacturing - 2006Document10 pagesE-26 - Knowledge Based Systems Support in Micro-Manufacturing - 2006Nikos VaxevanidisNo ratings yet

- SANSON D'ABBEVILLE, Nicolas - 1686 - Ottoman Emp in AsiaDocument1 pageSANSON D'ABBEVILLE, Nicolas - 1686 - Ottoman Emp in AsiaNikos VaxevanidisNo ratings yet

- E-22 - Icmen 2005-EdmDocument8 pagesE-22 - Icmen 2005-EdmNikos VaxevanidisNo ratings yet

- E-29 - AITC 06 - Shot Peening - Trib Behavior - Parma, Italy, 2006Document8 pagesE-29 - AITC 06 - Shot Peening - Trib Behavior - Parma, Italy, 2006Nikos VaxevanidisNo ratings yet

- E-38 - AWJM of TRIP Steels - MIT 2007 SloveniaDocument8 pagesE-38 - AWJM of TRIP Steels - MIT 2007 SloveniaNikos VaxevanidisNo ratings yet

- E-33 - Q in 2ndary Educ in Greece - SH - ICQME 2007Document11 pagesE-33 - Q in 2ndary Educ in Greece - SH - ICQME 2007Nikos VaxevanidisNo ratings yet

- Road Network of Crete in Tabula Peutingeriana - 2007Document16 pagesRoad Network of Crete in Tabula Peutingeriana - 2007Nikos VaxevanidisNo ratings yet

- WYLD, James - Ca 1854 BalkansDocument1 pageWYLD, James - Ca 1854 BalkansNikos VaxevanidisNo ratings yet

- The Clàsh The 0nly Band That MatteredDocument255 pagesThe Clàsh The 0nly Band That MatteredNikos VaxevanidisNo ratings yet

- Kiepert - Balkans Ca 1883 (Large)Document1 pageKiepert - Balkans Ca 1883 (Large)Nikos VaxevanidisNo ratings yet

- IMANE 2020 presentation - Reconstruction of aTAA - (ΕΛΚΕ)Document12 pagesIMANE 2020 presentation - Reconstruction of aTAA - (ΕΛΚΕ)Nikos VaxevanidisNo ratings yet

- MP Cat 56 - USDocument40 pagesMP Cat 56 - USNikos VaxevanidisNo ratings yet

- Content ServerDocument13 pagesContent Serverwin1234onaNo ratings yet

- Medfract1 in Procedia Struct. IntegrityDocument8 pagesMedfract1 in Procedia Struct. IntegrityNikos VaxevanidisNo ratings yet

- IMANE 2020 presentation - A computational wall mechanics study of an aTAA - (ΕΛΚΕ)Document6 pagesIMANE 2020 presentation - A computational wall mechanics study of an aTAA - (ΕΛΚΕ)Nikos VaxevanidisNo ratings yet

- hw1 SolDocument4 pageshw1 SolNikos VaxevanidisNo ratings yet

- E 363 Homework No. 1Document1 pageE 363 Homework No. 1Nikos VaxevanidisNo ratings yet

- A Neural Network-Assisted Finite Element Analysis of Cold Flat Rolling - 2008Document10 pagesA Neural Network-Assisted Finite Element Analysis of Cold Flat Rolling - 2008Nikos VaxevanidisNo ratings yet

- HW3Document1 pageHW3Nikos VaxevanidisNo ratings yet

- FAIM - 2020 - Procedia (FNL)Document8 pagesFAIM - 2020 - Procedia (FNL)Nikos VaxevanidisNo ratings yet

- HW3 SolDocument4 pagesHW3 SolNikos VaxevanidisNo ratings yet

- Forming Project ManualDocument4 pagesForming Project ManualNikos VaxevanidisNo ratings yet

- Explicit Versus Implicit FEM in Rolling - 1990 PDFDocument10 pagesExplicit Versus Implicit FEM in Rolling - 1990 PDFNikos VaxevanidisNo ratings yet

- Correlation of Surface Roughness Parameters With Operational Variables in Turning of A New Aluminum Matrix Steel Particulate Composite: A Multi-Parameter AnalysisDocument10 pagesCorrelation of Surface Roughness Parameters With Operational Variables in Turning of A New Aluminum Matrix Steel Particulate Composite: A Multi-Parameter AnalysisNikos VaxevanidisNo ratings yet

- Explicit Versus Implicit FEM in Rolling - 1990 PDFDocument10 pagesExplicit Versus Implicit FEM in Rolling - 1990 PDFNikos VaxevanidisNo ratings yet

- Tribology in Metal Rolling - Ann. CIRP, 49 (2) (2000)Document24 pagesTribology in Metal Rolling - Ann. CIRP, 49 (2) (2000)Nikos Vaxevanidis100% (1)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionFrom EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionRating: 3.5 out of 5 stars3.5/5 (129)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Modeling, Dynamics, and Control of Electrified VehiclesFrom EverandModeling, Dynamics, and Control of Electrified VehiclesRating: 5 out of 5 stars5/5 (1)

- Design and Operation of Human Locomotion SystemsFrom EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNo ratings yet

- Robotics: Designing the Mechanisms for Automated MachineryFrom EverandRobotics: Designing the Mechanisms for Automated MachineryRating: 4.5 out of 5 stars4.5/5 (8)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)