Professional Documents

Culture Documents

Bevcon-Friedrich Vibrating Feeder

Bevcon-Friedrich Vibrating Feeder

Uploaded by

DxFx0 ratings0% found this document useful (0 votes)

55 views2 pagesfeeder

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfeeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

55 views2 pagesBevcon-Friedrich Vibrating Feeder

Bevcon-Friedrich Vibrating Feeder

Uploaded by

DxFxfeeder

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

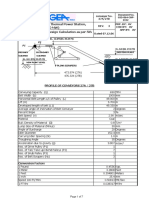

BENCON NIBRATING FEEDERS

= beveor

Poteet)

Steel Industry

PN eae

Cement

eee aati

uate

eee

Boe sai

ot ue

|uaries.

Features of Bevcon Vibrating Feeders

» Built tough for long service life adopting Geod Manufacturing

Procedures(GMP). Under technical collaboration with

FRIEDRICH - Germany, who are the pioneers in the field

of vibration technology.

Ri

Heavy Duty trough.

> Low friction liners for better wear resistance,

> Fitted with efficient Vibrator Motors.

° Dust Proof Operation friendly cover design with

provision of Dust Extraction Hoods

» Flow adjusting Slide Gate.

> Effective Skirt Plate Arrangement.

Variable Capacity Arrangement.

> Easy to Install

>» Maintenance free.

POCO R eet ce as eee

SET

ITS

aan on Con ad Seer

BFR-30 60 300 X 600 X 200 350 = 200 900 - 1500 0.30 - 0.35

BFR-SO 80 500 x 800 X 200 250 - 350 900 - 1500 035-04

‘BFR-SO 100 ‘500 x 1000 x 200 300 - 350 900 - 1500) 03-04

BFR-65 100 650 X 1000 x 250 400 - 450 900 - 1500 04-06

BF R-ES 125 1650 1250 x 250 400 - 500 900 - 1500 04-06

BFR-80 140 800 x 1400 x 300 500 - 650 900 - 1500 06-44

‘BFR-80 165 ‘800 X 1650 x 300, 650-750 900 - 1500 06-14

‘BFR-105 150 1050 X 1500 x 300 750 - 850 900 - 1500) 06-14

BFR-105 175 41050 X 1750 x 300 ‘800 - 900 900 - 1500 06-14

BFR-25 200 4250 x 2000 x 300, 1000 900 - 1500 44-20

IEEE TD

Computer designed deck with rugged drive structure that handles 7 Feeder is provided with special Rubber / Polymer / Ste

large lumpy materials with greater reliability. flow & extended life of the feeder

ners for efferent

>The springs are of special alloy steels, designed and selected with

Isolation efficiencies of 96-99 % to minimize the vibration of mounting

structures,

The unbalanced motors ar

World-class, Highly Efficient, Reliable &

Maintenance Free,

oF

has been built wth high quality standards and tested in-house

for better performance.

Varying capacities can be obtained by simple way of adjusting fy weight

settings.

Vibrator motor generates high centrifugal force with less power Precise control of flow rate adjustments through variable frequency drives

‘consumption. (optional).

Beocon Wayors Seraices :

11We precisely engineer the feeders withthe combinelion of Throat Opening, Deck Length, Angle of Repose, Deck Slope, Flow Adjustments,

Dust 6

jes with reduced operating costs.

ations, Hopper Layout. etc are applied to specific application resulting larger capac

|1 We extend our engineering services right from Concept to Commissioning of the equipment for the application as required by you

IAI India sales & service network for prompt and efficient aftersales support

NOTE: Specifications ang other details are subject to change without notice because of continuous improvements

‘Oualliy Material andling, Crushing & Sereening Equipment From: ‘Website www beveonwayars com

BEVCON WAYORS PVT. LTD.

Corporate Office : G. F., Kavya Apts, Madhuranagar, Hyderabad - 500 038, A, P., INDIA.

‘Tel : 040-2373 7643, 2373 2628, Fax : 040-2375 0435, 2373 3626, E-Mail : info@bevconwayors.com

ne + Chennai » Kolkata’ > New Delhi + Raipur » Jamshedpur » Coimbatore + Bhubaneshwar + Ahmedabad

Design & Developed by Corporate Carimuniatons Team of Bevcon Mayors

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Gas Pipe SizingDocument1 pageGas Pipe SizingDxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument4 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- Screw Take-Up Device UR6: Conveyor ComponentsDocument1 pageScrew Take-Up Device UR6: Conveyor ComponentsDxFxNo ratings yet

- Clip Image001Document11 pagesClip Image001DxFxNo ratings yet

- Screw Take-Up Device Ur1 Ur7: Conveyor ComponentsDocument1 pageScrew Take-Up Device Ur1 Ur7: Conveyor ComponentsDxFxNo ratings yet

- ET-3100-M-45008 1/15 Sohar Pelletizing PL Ant Pellet System-General Technical Specification of Vibrating Feeder Detailed Engineeri NG ADocument15 pagesET-3100-M-45008 1/15 Sohar Pelletizing PL Ant Pellet System-General Technical Specification of Vibrating Feeder Detailed Engineeri NG ADxFxNo ratings yet

- BW MicroDocument4 pagesBW MicroDxFxNo ratings yet

- Et 3173 M 45003 - BDocument15 pagesEt 3173 M 45003 - BDxFxNo ratings yet

- Screw T-Up2 PDFDocument1 pageScrew T-Up2 PDFDxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFxNo ratings yet

- E.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDocument14 pagesE.VAIN001-IE1-0001 Revisions: Oman Industrial Complex - Phase I Project Rules & Guideline Interface ConceptDxFxNo ratings yet

- FMC Syntron Vibrating FeedersDocument36 pagesFMC Syntron Vibrating FeedersDxFxNo ratings yet

- Bevcon Grizzly FeederDocument2 pagesBevcon Grizzly FeederDxFxNo ratings yet

- TRF Unbalance Motor Feeder & ScreenDocument4 pagesTRF Unbalance Motor Feeder & ScreenDxFxNo ratings yet

- Alwasy Step Ahead in TechnologyDocument6 pagesAlwasy Step Ahead in TechnologyDxFx100% (1)

- Calculating Idler L10 LifeDocument8 pagesCalculating Idler L10 LifeDxFxNo ratings yet

- Conveyor Design DraftDocument25 pagesConveyor Design DraftDxFxNo ratings yet

- 1732 - Square BarDocument6 pages1732 - Square BarDxFxNo ratings yet

- Is.12213.1987vibro Feeder PDFDocument9 pagesIs.12213.1987vibro Feeder PDFDxFxNo ratings yet

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADxFxNo ratings yet

- Manual Calculation - Con36eDocument2 pagesManual Calculation - Con36eDxFxNo ratings yet

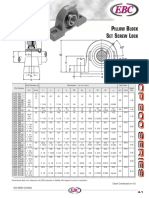

- P B S S L: Illow Lock ET Crew OCKDocument2 pagesP B S S L: Illow Lock ET Crew OCKDxFxNo ratings yet