Professional Documents

Culture Documents

Eliminating Contamination Related Failures: The Problem

Uploaded by

Saliya RathnayakeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eliminating Contamination Related Failures: The Problem

Uploaded by

Saliya RathnayakeCopyright:

Available Formats

HYDRAULIC PUMP LIFE EXTENSION

HY-PRO FILTRATION Eliminating Contamination Related Failures

How Proper Contamination Control Increases Reliability and Productivity

The Problem

Pumps are the heart of hydraulic systems. When the pump

fails, the entire system is down until the pump is operational

again. This poses a serious threat to any operation relying on

hydraulic systems for productivity. Recently, a hydraulic valve

manufacturer was losing 25 pumps a year on their centralized

hydraulic system at a cost of $2,440 each. That’s only the pump

cost, when you account for maintenance resources, lost oil and

lost production each failure costs ~$25,320.

System analysis showed that fluid contamination was out of

control with an ISO Fluid Cleanliness Code of 22/21/19. That

translates to a minimum of;

20,000 particles per ml > 4µ[c]

10,000 particles per ml > 6µ[c]

2,500 particles per ml > 14µ[c]

The Solution

The manufacturer set an ISO code limit of 17/15/13 and turned to Hy-Pro for help achieving their goal. While

surveying their system, we noticed and addressed three factors contributing to their problems.

1. The hydraulic tanks were open to the environment. This allows the dirt and dust in the environment to find its way

into the fluid. These tanks were sealed to prevent further contamination ingression from the environment.

2. The tanks lacked breathers. Hydraulic tanks should be sealed from the environment but there must be a way to

allow air exchange to occur between the tank and environment as fluid enters and evacuates the tank. Breathers

were added to the tanks to allow this exchange to occur in a controlled manner by removing contamination from

the air entering the reservoir before it reaches the fluid.

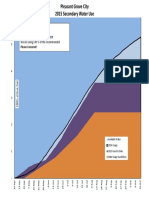

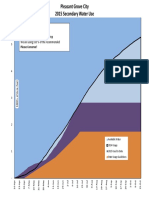

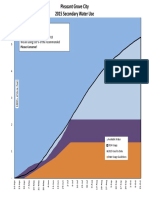

3. A Brand-X 12µ filter element

installed in the offline filtration

system was upgraded to a 6µ Particulate Contamination per Milliliter > Xµ [c]

Hy-Pro DFE Rated G8 Dualglass 20,000

element as more efficient 18,000

filtration would be necessary 16,000

to drop the ISO code below the 14,000

17/15/13 limit. 12,000

10,000

8,000

The Results 6,000

4,000

Fluid analysis samples were taken 2,000

over the following 140 days to 0

verify the condition of the fluid. The

24-Apr

10-Jul

17-Jul

24-Jul

31-Jul

3-Jul

12-Jun

19-Jun

26-Jun

14-Aug

21-Aug

28-Aug

5-Jun

7-Aug

4-Sep

15-May

22-May

29-May

1-May

8-May

final sample returned an ISO Fluid

Cleanliness Code of 12/11/7. That

translates to a maximum of; 4µ

4µ[c] 6µ

6µ[c] 14µ[c]

14µ

40 particles per ml > 4µ[c]

20 particles per ml > 6µ[c]

1 particle per ml > 14µ[c]

Pump failures related to fluid contamination (~$633,000

annually) were eliminated through the 99.8% reduction of

particulate contamination within the fluid. www.hyprofiltration.com

You might also like

- OceanofPDF - Com Alkaline Diet and Herbal Medical by DR Se - Henry BeatDocument112 pagesOceanofPDF - Com Alkaline Diet and Herbal Medical by DR Se - Henry BeatKristine GerbolingoNo ratings yet

- GCSE Gantt Chart FoodDocument1 pageGCSE Gantt Chart FoodnatalleNo ratings yet

- Planned Preventive Maintenance Schedule Template Excel DownloadDocument2 pagesPlanned Preventive Maintenance Schedule Template Excel Downloadotilia_alexandru_175% (20)

- FE Exam - Study ScheduleDocument23 pagesFE Exam - Study ScheduletjclydesdaleNo ratings yet

- SERMON - "Prayer Is Our Most Powerful Weapon" 11.12.2017Document9 pagesSERMON - "Prayer Is Our Most Powerful Weapon" 11.12.2017Jojo Mercolita EstolaNo ratings yet

- Mobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Document50 pagesMobile Tower and Mobile Phone Radiation Hazards - Prof Girish Kumar - June 2013Neha Kumar100% (1)

- Hotel Construction Schedule - TemplateLabDocument2 pagesHotel Construction Schedule - TemplateLabSinta SiraitNo ratings yet

- Ret Ro Gam Er Iss Ue 168 2017Document116 pagesRet Ro Gam Er Iss Ue 168 2017Albanidis X. Kostas100% (1)

- QradarDocument112 pagesQradarOleg PadurariNo ratings yet

- Ef3e Upper-Inter WL PDFDocument32 pagesEf3e Upper-Inter WL PDFDubravka Kovacevic100% (2)

- Calendar For B.Sc. Engineering & B.Sc. (T & LM) - 2018: 14 Level 3 Level 4Document1 pageCalendar For B.Sc. Engineering & B.Sc. (T & LM) - 2018: 14 Level 3 Level 4Dilhara PinnaduwageNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Technology Vs TechniquesDocument5 pagesTechnology Vs TechniquesPRATIK DARBHE100% (1)

- 2024 Cpa 510Document5 pages2024 Cpa 510Flores Incapoma Bryan EdgarNo ratings yet

- Crop Simulation ModelingDocument33 pagesCrop Simulation Modelingbharat.wwe2001No ratings yet

- Timesheet Amg # 16 Aug 2023 - 15 Sept 2023Document5 pagesTimesheet Amg # 16 Aug 2023 - 15 Sept 2023budi antoNo ratings yet

- 2015 PG Daily PI Water Use Aug 23Document1 page2015 PG Daily PI Water Use Aug 23Karanja KinyanjuiNo ratings yet

- Pt. Pionirbeton Industri: Crushing Test ScheduleDocument8 pagesPt. Pionirbeton Industri: Crushing Test ScheduleNOERNo ratings yet

- ICAEW-Part Time v1.3-AG & FARDocument1 pageICAEW-Part Time v1.3-AG & FARgene houNo ratings yet

- Willingness To Communicate in The Second LanguageDocument6 pagesWillingness To Communicate in The Second LanguageAfifahAbdullahNo ratings yet

- Inhouse Training Addentance1Document1 pageInhouse Training Addentance1Debabrato MukherjeeNo ratings yet

- Market - Opening Bell - ID - 2.8.2021Document14 pagesMarket - Opening Bell - ID - 2.8.2021Atish MukherjeeNo ratings yet

- Design Team Plan Schedule Work From Home: Event List NoDocument2 pagesDesign Team Plan Schedule Work From Home: Event List Nobudug19No ratings yet

- Price Report 20210617eDocument2 pagesPrice Report 20210617eApsara WijemuniNo ratings yet

- Failure Mode Department/Area Equipment: Top Contributors ParetoDocument1 pageFailure Mode Department/Area Equipment: Top Contributors ParetoNaresh_GajjarNo ratings yet

- Opening Bell: September 22, 2021 Market Outlook Today's HighlightsDocument8 pagesOpening Bell: September 22, 2021 Market Outlook Today's HighlightsPorus Saranjit SinghNo ratings yet

- Bahan MeetingDocument16 pagesBahan MeetingtampekbataduahNo ratings yet

- Roster Kerja HSE Tofu AgustusDocument4 pagesRoster Kerja HSE Tofu AgustusYusuf NugrohoNo ratings yet

- Fatigue Management Roster - ProjectDocument1 pageFatigue Management Roster - ProjectNIJESHNo ratings yet

- Form Timeline ScheduleDocument3 pagesForm Timeline ScheduleSyilla ShopeNo ratings yet

- Periodisation TemplateDocument4 pagesPeriodisation TemplateRishika KirtishaNo ratings yet

- B.SC Eng. Academic Calendar - 2021 (Rev. 28-09-2021)Document1 pageB.SC Eng. Academic Calendar - 2021 (Rev. 28-09-2021)IT'S Fake IDNo ratings yet

- B.SC Eng. Academic Calendar - 2021 (Rev. 28-09-2021)Document1 pageB.SC Eng. Academic Calendar - 2021 (Rev. 28-09-2021)IT'S Fake IDNo ratings yet

- 2016 - Calendar 1Document1 page2016 - Calendar 1Chanuka WickramasingheNo ratings yet

- CBSLDocument2 pagesCBSLLahiru DoloswalaNo ratings yet

- 2015 PG Daily PI Water Use June 21Document1 page2015 PG Daily PI Water Use June 21Karanja KinyanjuiNo ratings yet

- AO On WST Adoption (Revised)Document57 pagesAO On WST Adoption (Revised)Oscar CarpioNo ratings yet

- 2015 PG Daily PI Water Use Sept 6Document1 page2015 PG Daily PI Water Use Sept 6Karanja KinyanjuiNo ratings yet

- 2015 PG Daily PI Water Use June 28Document1 page2015 PG Daily PI Water Use June 28Karanja KinyanjuiNo ratings yet

- B.SC Eng. Academic Calendar - 2022 (Rev. 28-09-2021)Document1 pageB.SC Eng. Academic Calendar - 2022 (Rev. 28-09-2021)chamod kariyawasamNo ratings yet

- 2015 PG Daily PI Water Use Oct 11Document1 page2015 PG Daily PI Water Use Oct 11Karanja KinyanjuiNo ratings yet

- 2015 PG Daily PI Water Use Aug 9Document1 page2015 PG Daily PI Water Use Aug 9Karanja KinyanjuiNo ratings yet

- 2015 PG Daily PI Water Use July 19Document1 page2015 PG Daily PI Water Use July 19Karanja KinyanjuiNo ratings yet

- Inverter Technologies in Air ConditionersDocument12 pagesInverter Technologies in Air ConditionersShazeb KamranNo ratings yet

- 2015 PG Daily PI Water Use Aug 16Document1 page2015 PG Daily PI Water Use Aug 16Karanja KinyanjuiNo ratings yet

- Duty Mail 15.12.2018Document6 pagesDuty Mail 15.12.2018Biswajit AcharyaNo ratings yet

- 2015 PG Daily PI Water Use July 5Document1 page2015 PG Daily PI Water Use July 5Karanja KinyanjuiNo ratings yet

- 2016 UoM CalanderDocument1 page2016 UoM CalanderKasun WeerasingheNo ratings yet

- 2015 PG Daily PI Water Use June 14Document1 page2015 PG Daily PI Water Use June 14Karanja KinyanjuiNo ratings yet

- Calendar For B.Sc. Engineering & B.Sc. (T & LM) - 2017Document1 pageCalendar For B.Sc. Engineering & B.Sc. (T & LM) - 2017Dilhara PinnaduwageNo ratings yet

- Chart Title: SESI 1 (7-8) 268 SESI 2 (8-9) 273 +5 +5 SESI 3 (9-10) 269 +1 - 4Document1 pageChart Title: SESI 1 (7-8) 268 SESI 2 (8-9) 273 +5 +5 SESI 3 (9-10) 269 +1 - 4Deka RamadhanNo ratings yet

- 2010 2014 Maintenance CalendarDocument1 page2010 2014 Maintenance CalendaralexanderNo ratings yet

- Asistencia MEDIDA 2009Document1 pageAsistencia MEDIDA 2009izaulparra100% (2)

- Exam Time Table: 2016-2018 Batch (Term III) : # Code Section Course ListDocument1 pageExam Time Table: 2016-2018 Batch (Term III) : # Code Section Course ListKiran MishraNo ratings yet

- Eng Raid PDFDocument1 pageEng Raid PDFMahmoud A. YousefNo ratings yet

- Weekly Progress BM-1 Pckg#2 Cut of Date 7 Apr 2022Document15 pagesWeekly Progress BM-1 Pckg#2 Cut of Date 7 Apr 2022rezky.wagimanNo ratings yet

- Schedule Shop Drawing ArsitekturDocument7 pagesSchedule Shop Drawing Arsitekturprasetyo kristiawanNo ratings yet

- Standardization ReviewDocument8 pagesStandardization ReviewSurya PrakashNo ratings yet

- Parte de Josue y EndañuDocument3 pagesParte de Josue y Endañujos vh-kunNo ratings yet

- HND Project 1 Gantt ChartDocument1 pageHND Project 1 Gantt Chartsteven rogerNo ratings yet

- Project PlanDocument1 pageProject PlanSHIVAM POOJARANo ratings yet

- Simple Time Schedule v0 Rocketsheets - Com - Eyjl7mDocument4 pagesSimple Time Schedule v0 Rocketsheets - Com - Eyjl7mAVNo ratings yet

- 2019 Academic CalendarDocument1 page2019 Academic CalendarDilhara PinnaduwageNo ratings yet

- Calendar For B.Sc. Engineering - 2011: 07 Level 4Document1 pageCalendar For B.Sc. Engineering - 2011: 07 Level 4Kajaruban SurendranNo ratings yet

- Price Report 20220207eDocument2 pagesPrice Report 20220207eLanka RegisterNo ratings yet

- Calendar For B.Sc. Engineering & B.Sc. (T & LM) - 2011: 07 Level 4Document1 pageCalendar For B.Sc. Engineering & B.Sc. (T & LM) - 2011: 07 Level 4Asitha KulasekeraNo ratings yet

- 2013 - Calendar 1Document1 page2013 - Calendar 1Chanuka WickramasingheNo ratings yet

- Lee 3410Document2 pagesLee 3410Saliya RathnayakeNo ratings yet

- Lube Oil in Lube Oil Analysis PHPDocument4 pagesLube Oil in Lube Oil Analysis PHPSaliya RathnayakeNo ratings yet

- English For General Academic Purpose CATDocument3 pagesEnglish For General Academic Purpose CATSaliya RathnayakeNo ratings yet

- EnglishDocument3 pagesEnglishSaliya RathnayakeNo ratings yet

- Lee 3410Document2 pagesLee 3410Saliya RathnayakeNo ratings yet

- Dlaik Wxyh: MicrocontrollersDocument1 pageDlaik Wxyh: MicrocontrollersSaliya RathnayakeNo ratings yet

- Cad Doc 23Document15 pagesCad Doc 23Saliya RathnayakeNo ratings yet

- Perfgauge2 PDFDocument1 pagePerfgauge2 PDFSaliya RathnayakeNo ratings yet

- Airborne & Structure-Borne Ultrasound As A Key Component of Predictive MaintenanceDocument27 pagesAirborne & Structure-Borne Ultrasound As A Key Component of Predictive MaintenanceSaliya RathnayakeNo ratings yet

- IR Sensor Infrared Obstacle Sensor Module Has Builtin IR Transmitter and IR Receiver That Sends Out IR Energy and Looks ForDocument12 pagesIR Sensor Infrared Obstacle Sensor Module Has Builtin IR Transmitter and IR Receiver That Sends Out IR Energy and Looks ForRavi RajanNo ratings yet

- Sumande - Field Work No.8 - Azimuth Traverse Using Theodolite and TapeDocument10 pagesSumande - Field Work No.8 - Azimuth Traverse Using Theodolite and TapeCedrix SumandeNo ratings yet

- Lecture 1-2Document19 pagesLecture 1-2neri biNo ratings yet

- 6438Document285 pages6438Ume UmaraNo ratings yet

- Form AK - Additional PageDocument3 pagesForm AK - Additional PagekatacumiNo ratings yet

- Renaissance Logistics BrochureDocument40 pagesRenaissance Logistics BrochureNichel D'SouzaNo ratings yet

- Project Management Quality Management PlanDocument9 pagesProject Management Quality Management PlanPriya100% (1)

- MEC Activities TimelineDocument13 pagesMEC Activities TimelineFranz Xavier GarciaNo ratings yet

- Air Quality Report - SWDocument43 pagesAir Quality Report - SWromesh 96No ratings yet

- Inventory Adjustment Template IifDocument6 pagesInventory Adjustment Template IifABDULKARIM HAJI YOUSUFNo ratings yet

- Acoustic Laster Final-1Document15 pagesAcoustic Laster Final-1Aisha SadiNo ratings yet

- Chapter 24 - Glass and Glazing PDFDocument14 pagesChapter 24 - Glass and Glazing PDFpokemonNo ratings yet

- Maryada Purushotham RamDocument1 pageMaryada Purushotham RamNithin SridharNo ratings yet

- Waking Up Gasping For Air Anxiety, Falling Asleep, Acid RefluxDocument1 pageWaking Up Gasping For Air Anxiety, Falling Asleep, Acid RefluxAstra CardinalNo ratings yet

- Effects of Adiabatic Flame Temperature On Flames CharacteristicDocument12 pagesEffects of Adiabatic Flame Temperature On Flames CharacteristicAhmed YasiryNo ratings yet

- Analisis Riil Jawaban 3.6Document6 pagesAnalisis Riil Jawaban 3.6muhammad nur chalim100% (1)

- Innovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemDocument8 pagesInnovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemRakesh BiswasNo ratings yet

- Google - Selftestengine.professional Cloud Network Engineer - Brain.dumps.2023 May 04.by - Jared.97q.vceDocument11 pagesGoogle - Selftestengine.professional Cloud Network Engineer - Brain.dumps.2023 May 04.by - Jared.97q.vceahme imtiazNo ratings yet

- Knowage Baby Steps PDFDocument230 pagesKnowage Baby Steps PDFworkflow m3cNo ratings yet

- ISO 542 (Sampling OIlseeds)Document12 pagesISO 542 (Sampling OIlseeds)FIDEL CANELOS100% (2)

- Ajna Meditation1Document3 pagesAjna Meditation1Daouda CISSENo ratings yet

- Measure and IntegralDocument5 pagesMeasure and Integralkbains7No ratings yet

- CEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsDocument26 pagesCEOCOR 87 Cathodic Disbonding of Steelpipe CoatingsMAHESH CHANDNo ratings yet