Professional Documents

Culture Documents

Project Standard Specification: Meters and Gages 15122 - Page 1/10

Uploaded by

adel rihanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Standard Specification: Meters and Gages 15122 - Page 1/10

Uploaded by

adel rihanaCopyright:

Available Formats

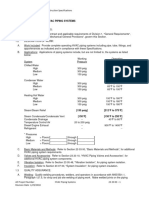

<Project Title>

PROJECT STANDARD SPECIFICATION

SECTION 15122 - METERS AND GAGES

PART 1 - GENERAL

0.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to this Section.

0.2 SUMMARY

A. This Section includes meters and gages for mechanical systems and water meters installed

outside the building.

B. Related Sections include the following:

1. Division 2 Section "Water Distribution" for water meters outside the building.

2. Division 13 Sections for fire-pump flow-measuring systems.

3. Division 15 Section "Fuel Gas Piping" for gas meters.

4. Mechanical equipment Sections that specify meters and gages as part of factory-

fabricated equipment.

C. Utility-Furnished Products: Water meters shall be furnished by the contractor to site, ready

for installation. Where install exposed to weather conditions, meters and gauges shall be

corrosion resistant.

0.3 SUBMITTALS

A. Product Data: Include scale range, ratings, and calibrated performance curves for each

meter, gage, fitting, specialty, and accessory specified.

B. Shop Drawings: Include schedule indicating manufacturer's number, scale range, fittings,

and location for each meter and gage.

C. Product Certificates: Signed by manufacturers of meters and gages certifying accuracies

under specified operating conditions and compliance with specified requirements.

D. Shop Drawings: For brackets for duct-mounting thermometers.

E. Maintenance Data: For meters and gages to include in maintenance manuals specified in

Division 1. Include data for the following:

1. Flow-measuring systems.

2. Flowmeters.

3. Thermal-energy flowmeters.

4. Water meters.

METERS AND GAGES 15122 - Page 1/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

0.4 QUALITY ASSURANCE

A. Comply with applicable portions of ASME and ISA standards or approved equal pertaining

to construction and installation of meters and gages.

B. Uniformity/standardization of meters and gages furnished, of a single manufacturer, shall be

maintained throughout the airport facilities.

PART 2 - PRODUCTS

0.1 THERMOMETERS, GENERAL

A. Scale Range: Temperature ranges for services listed are as follows:

1. Domestic Hot Water: 0 to 115 deg. C, with 1-degree scale divisions.

2. Domestic Cold Water: minus 18 to plus 38 deg. C, with 1-degree scale divisions .

3. Condenser Water: minus 18 to plus 70 deg. C, with 1-degree scale divisions.

4. Chilled Water: minus 18 to plus 38 deg. C, with 1-degree scale divisions.

B. Accuracy: Plus or minus 1 percent of range span or plus or minus one scale division to

maximum of 1.5 percent of range span.

0.2 LIQUID-IN-GLASS THERMOMETERS

A. Description: ASTM E 1.

B. Case: Die cast and aluminum finished in baked-epoxy enamel, glass front, spring secured,

230 mm long.

C. Adjustable Joint: Finish to match case, 180-degree adjustment in vertical plane, 360-degree

adjustment in horizontal plane, with locking device.

D. Tube: Red or blue reading, organic-liquid filled with magnifying lens.

E. Scale: Satin-faced nonreflective aluminum with permanently etched markings.

F. Stem: Copper-plated steel, aluminum, or brass for separable socket; of length to suit

installation.

0.3 DIRECT-MOUNTING, FILLED-SYSTEM DIAL THERMOMETERS

A. Description: Vapor-actuated, universal-angle dial type.

B. Case: Drawn steel or cast aluminum, with 115 mm diameter, glass lens.

C. Adjustable Joint: Finish to match case, 180-degree adjustment in vertical plane, 360-degree

adjustment in horizontal plane, with locking device.

D. Thermal Bulb: Copper with phosphor-bronze Bourdon tube pressure gage.

E. Movement: Brass, precision geared.

METERS AND GAGES 15122 - Page 2/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

F. Scale: Progressive, satin-faced nonreflective aluminum with permanently etched markings.

G. Stem: Copper-plated steel, aluminum, or brass for separable socket; of length to suit

installation.

0.4 REMOTE-READING, FILLED-SYSTEM DIAL THERMOMETERS

A. Description: Vapor-actuated, remote-reading dial type.

B. Case: Drawn steel or cast aluminum, with 115 mm diameter, glass lens.

C. Movement: Brass, precision geared.

D. Scale: Progressive, satin-faced nonreflective aluminum with permanently etched markings.

E. Tubing: Bronze, double-braided, armor-over-copper capillary; of length to suit installation.

F. Bulb: Copper with separable socket for liquids; averaging element for air.

0.5 BIMETAL DIAL THERMOMETERS

A. Description: ASME B40.3; direct-mounting, universal-angle dial type.

B. Case: Stainless-steel with 125 mm diameter, glass lens.

C. Adjustable Joint: Finish to match case, 180-degree adjustment in vertical plane, 360-degree

adjustment in horizontal plane, with locking device.

D. Element: Bimetal coil.

E. Scale: Satin-faced nonreflective aluminum with permanently etched markings.

F. Stem: Stainless-steel for separable socket, of length to suit installation.

0.6 INSERTION DIAL THERMOMETERS

A. Description: ASME B40.3, bimetal type.

B. Dial: 25 mm diameter.

C. Case: Stainless-steel.

D. Stem: Dustproof and leakproof 3 mm diameter, tapered-end stem with nominal length of

125 mm.

0.7 SEPARABLE SOCKETS

A. Description: Fitting with protective socket for installation in threaded pipe fitting to hold

fixed thermometer stem.

1. Material: Brass, for use in copper piping.

2. Material: Stainless-steel, for use in steel piping.

METERS AND GAGES 15122 - Page 3/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

3. Extension-Neck Length: Nominal thickness of 50 mm, but not less than thickness of

insulation. Omit extension neck for sockets for piping not insulated.

4. Insertion Length: To extend to center of pipe.

5. Cap: Threaded, with chain permanently fastened to socket.

6. Heat-Transfer Fluid: Oil or graphite.

0.8 THERMOMETER WELLS

A. Description: Fitting with protective well for installation in threaded pipe fitting to hold test

thermometer.

1. Material: Brass, for use in copper piping.

2. Material: Stainless-steel, for use in steel piping.

3. Extension-Neck Length: Nominal thickness of 50 mm, but not less than thickness of

insulation. Omit extension neck for wells for piping not insulated.

4. Insertion Length: To extend to center of pipe.

5. Cap: Threaded, with chain permanently fastened to socket.

6. Heat-Transfer Fluid: Oil or graphite.

B. All thermometer wells are not to restrict the flow or service flow and are not to be installed

with sections outside the service being monitored.

0.9 DUCT THERMOMETER SUPPORT FLANGES

A. Description: Flanged-fitting bracket for mounting in hole of duct, with threaded end for

attaching thermometer.

1. Extension-Neck Length: Nominal thickness of 50 mm, but not less than thickness of

exterior insulation.

2. Insertion-Neck Length: Nominal thickness of 50 mm, but not less than thickness of

insulation lining.

0.10 PRESSURE GAGES

A. Description: ASME B40.1, phosphor-bronze Bourdon tube type with bottom connection;

dry type, for all purpose use. Liquid-filled-case type, for booster sets and pumps.

B. Case: Drawn steel, brass, or aluminum with 115 mm diameter, glass lens.

C. Connector: Brass, DN8.

D. Scale: White-coated aluminum with permanently etched markings.

E. Accuracy: Grade A, plus or minus 1 percent of middle 50 percent of scale.

F. Range: Comply with the following:

1. Vacuum: 100 kPa of vacuum to 103 kPa of pressure.

2. Fluids under Pressure: Two times the operating pressure.

0.11 PRESSURE-GAGE FITTINGS

METERS AND GAGES 15122 - Page 4/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

A. Valves: DN8 brass or stainless-steel needle type.

B. Syphons: DN8 coil of brass tubing with threaded ends.

C. Snubbers: ASME B40.5, DN8 brass bushing with corrosion-resistant porous-metal disc of

material suitable for system fluid and working pressure.

0.12 TEST PLUGS

A. Description: Nickel-plated, brass-body test plug in DN15 fitting.

B. Body: Length as required to extend beyond insulation.

C. Pressure Rating: 3450 kPa minimum.

D. Core Insert: Self-sealing valve, suitable for inserting 3 mm OD probe from dial-type

thermometer or pressure gage.

E. Core Material for Air, Water, Oil, and Gas: Minus 7 to plus 93 deg. C, chlorosulfonated

polyethylene synthetic rubber.

F. Core Material for Air and Water: Minus 35 to plus 136 deg. C, ethylene-propylene-diene

terpolymer rubber.

G. Test-Plug Cap: Gasketed and threaded cap, with retention chain or strap.

H. Test Kit: Pressure gage and adapter with probe, two bimetal dial thermometers, and

carrying case.

1. Pressure Gage and Thermometer Ranges: Approximately two times the system's

operating conditions.

0.13 FLOW-MEASURING SYSTEMS

A. System includes calibrated flow element, separate meter, hoses or tubing, valves, fittings,

and conversion chart compatible with flow element, meter, and system fluid.

1. Flow range of flow-measuring element and meter covers operating range of

equipment or system where used.

2. Display: Visual instantaneous rate of flow.

3. Display: Visual instantaneous rate of flow, with register to indicate total volume in

liters.

B. Permanent Meters: Suitable for wall or bracket mounting. Include 150 mm diameter, or

equivalent, dial with fittings and copper tubing for connecting to flow element.

1. Scale: Liters per second.

2. Accuracy: Plus or minus 1 percent of center 60 percent of range.

C. Include complete operating instructions with each meter.

D. Venturi Flow Elements: Differential-pressure-design, flow-element fitting made for

installation in piping.

METERS AND GAGES 15122 - Page 5/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

1. Construction: Bronze, brass, or factory-primed steel; with brass fittings and attached

tag with flow conversion data. Include ends threaded for DN50 and smaller elements

and flanged or welded for DN65 and larger elements.

2. Pressure Rating: 1725 kPa.

3. Temperature Rating: 121 deg. C.

E. Pitot-Tube Flow Elements: Differential-pressure design with probe made for insertion into

piping.

1. Construction: Stainless-steel probe of length to span inside of pipe, with brass

fittings and attached tag with flow conversion data.

2. Pressure Rating: 1035 kPa.

3. Temperature Rating: 121 deg. C.

0.14 TURBINE FLOWMETERS

A. Description: Insertion type; measures flow directly in liters per second.

1. Construction: Bronze or stainless-steel body and plastic turbine or impeller, with

integral direct-reading scale.

2. Pressure Rating: 1035 kPa minimum.

3. Temperature Rating: 82 deg. C minimum.

4. Display: Visual instantaneous rate of flow.

5. Display: Visual instantaneous rate of flow, with register to indicate total volume in

liters.

6. Accuracy: Plus or minus 2-1/2 percent.

0.15 VORTEX-SHEDDING FLOWMETERS

A. In-Line Vortex-Shedding Flowmeter: Made for installation between pipe flanges; measures

flow directly in liters per second.

1. Construction: Stainless-steel body, with integral transmitter and direct-reading scale.

2. Pressure Rating: 6900 kPa minimum.

3. Temperature Rating: 260 deg. C minimum.

4. Display: Visual instantaneous rate of flow.

5. Display: Visual instantaneous rate of flow, with register to indicate total volume in

liters.

6. Integral Transformer: For low-voltage power operation.

7. Accuracy: Plus or minus 7-10 percent for liquids and 1-1/4 percent for gases.

B. Insertion Vortex-Shedding Flowmeter: Made for installation in pipe; measures flow directly

in liters per second.

1. Construction: Stainless-steel probe, with integral transmitter and direct-reading scale.

2. Pressure Rating: 6900 kPa minimum.

3. Temperature Rating: 260 deg. C minimum.

4. Display: Visual instantaneous rate of flow.

5. Display: Visual instantaneous rate of flow, with register to indicate total volume in

liters.

6. Integral Transformer: For low-voltage power connection.

7. Accuracy: Plus or minus 1 percent for liquids and 1-1/2 percent for gases.

METERS AND GAGES 15122 - Page 6/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

0.16 FLOW INDICATORS

A. Description: Instrument for visual verification of flow; made for installation in piping

systems.

1. Construction: Bronze or stainless-steel body, with sight glass and plastic pelton-

wheel indicator.

2. Pressure Rating: 860 kPa.

3. Temperature Rating: 93 deg. C.

0.17 THERMAL-ENERGY FLOWMETERS

A. Instruments include turbine-wheel flowmeter, two temperature sensors, transmitter, solid-

state calculator with integral battery pack, integral stop valves, strainer, and magnetic trap.

B. Instruments include turbine-wheel or flow-sensor element and meter, two temperature

sensors, transmitter, solid-state calculator with integral battery pack, integral stop valves,

strainer, and magnetic trap.

1. Construction: Bronze body.

2. Pressure Rating: 860 kPa.

3. Temperature Range: 0 to 121 deg. C.

4. Data Output: Six-digit electromechanical counter with readout in kilowatt hours or

joules.

5. Accuracy: Plus or minus 1 percent.

6. Battery Pack: Five-year lithium battery.

0.18 WATER METERS

A. Description: AWWA C700, displacement type, bronze case. Registers flow in liters or

cubic meters as required by utility.

B. Description: AWWA C701, turbine type. Registers flow in liters or cubic meters as

required by utility.

C. Description: AWWA C702, compound type, bronze case. Registers flow in liters or

cubic meters as required by utility.

D. Description: AWWA C703, UL-listed, FM-approved, main-line, proportional, detector

type; 1035 kPa working pressure; with meter on bypass. Registers flow in liters or

cubic meters as required by utility.

1. Bypass Meter: AWWA C702, compound type, bronze case; size not less than one-

half nominal size of main-line meter.

2. Bypass Meter: AWWA C701, turbine type, bronze case; size not less than one-half

nominal size of main-line meter.

E. Description: AWWA C703, UL-listed, FM-approved, main-line-turbine, detector type;

1200 kPa working pressure; with strainer and with meter on bypass. Registers flow in liters

or cubic meters as required by utility.

1. Bypass Meter: AWWA C701, turbine type, bronze case; not less than DN50.

METERS AND GAGES 15122 - Page 7/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

F. Remote Registration System: Utility's standard; direct-reading type complying with

AWWA C706; modified with signal transmitting assembly, low-voltage connecting wiring,

and remote register assembly.

G. Remote Registration System: Utility's standard; encoder-type complying with

AWWA C707; modified with signal transmitting assembly, low-voltage connecting wiring,

and remote register assembly.

1. Data-Acquisition Units: Comply with utility's requirements for type and quantity.

2. Visible Display Units: Comply with utility's requirements for type and quantity.

PART 3 - EXECUTION

0.1 METER AND GAGE INSTALLATION, GENERAL

A. Install meters, gages, and accessories according to manufacturer's written instructions for

applications where used.

0.2 THERMOMETER INSTALLATION

A. Install thermometers and adjust vertical and tilted positions.

B. Install in the following locations:

1. Inlet and outlet of each hydronic and chiller.

2. Inlet and outlet of each hydronic coil in air-handling units and built-up central

systems.

3. Inlet and outlet of each hydronic heat exchanger.

4. Inlet and outlet of each hydronic heat-recovery unit.

5. Inlet and outlet of each thermal storage tank.

6. Outside-air, supply air, return-air, and mixed-air ducts.

7. Each duct thermometer support flange.

C. Install remote-reading dial thermometers in control panels with tubing connecting panel and

thermometer bulb supported to prevent kinks. Use minimum tubing length.

D. Install separable sockets in vertical position in piping tees where fixed thermometers are

indicated.

1. Install with socket extending to center of pipe.

2. Fill sockets with oil or graphite and secure caps.

E. Install thermometer wells in vertical position in piping tees where test thermometers are

indicated.

1. Install with stem extending to center of pipe.

2. Fill wells with oil or graphite and secure caps.

F. Duct Thermometer Support Flanges: Install in wall of duct where duct thermometers are

indicated. Attach to duct with screws.

METERS AND GAGES 15122 - Page 8/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

0.3 PRESSURE-GAGE INSTALLATION

A. Install pressure gages in piping tees with pressure-gage valve located on pipe at most

readable position.

B. Install dry-type pressure gages in the following locations:

1. Discharge of each pressure-reducing valve.

2. Building water-service entrance.

3. Chilled-water and condenser-water inlets and outlets of chillers.

4. Inlet and Outlet of each hydronic coil in Air Handling Units.

C. Install liquid-filled-type pressure gages at suction and discharge of each pump, including

fire and booster pumps.

D. Install pressure-gage needle valve and snubber in piping to pressure gages.

0.4 FLOW-MEASURING SYSTEM INSTALLATION

A. Install flowmeters in accessible and most readable positions in piping systems.

B. Install flow-measuring elements and meters at discharge of each pump, at inlet of each

hydronic coil in built-up central systems, and elsewhere as indicated.

C. Install differential-pressure-type flow elements with minimum straight lengths of pipe

upstream and downstream from element as prescribed by manufacturer's written

instructions.

D. Install connection fittings for attachment to portable flowmeters in accessible locations.

E. Install permanently mounted meters for flow elements on walls or brackets in accessible

locations.

F. Install connections, tubing, and accessories between flow elements and meters as prescribed

by manufacturer's written instructions.

0.5 FLOWMETER INSTALLATION

A. Install flowmeters and components according to manufacturer's written instructions.

0.6 THERMAL-ENERGY FLOWMETER INSTALLATION

A. Install meters in hydronic supply piping. Install thermal well in return line for remote

sensor. Mount meter on wall if accessible; if not, provide bracket to support meter.

0.7 WATER METER INSTALLATION

A. Install water meters, piping, and specialties according to AWWA M6 and utility's

requirements.

METERS AND GAGES 15122 - Page 9/10

STD-SPC-DCA(A1)-ME-DCA REV A

<Project Title>

PROJECT STANDARD SPECIFICATION

1. Install displacement-type water meters with shutoff valve on water meter inlet.

Install valve on water meter outlet and valved bypass around meter, unless prohibited

by authorities having jurisdiction.

2. Install compound-type water meters with shutoff valves on water meter inlet and

outlet and on valved bypass around meter. Support meters, valves, and piping on

brick or concrete piers.

3. Install detector-type water meters with shutoff valves on water meter inlet and outlet

and on full-size valved bypass around meter. Support meter, valves, and piping on

brick or concrete piers.

0.8 ROUGHING-IN FOR WATER METERS

A. Install roughing-in piping and specialties for water meter installation according to utility's

instructions and requirements.

0.9 CONNECTIONS

A. Piping installation requirements are specified in other Division 15 Sections. Drawings

indicate general arrangement of piping and specialties. The following are specific

connection requirements:

1. Install meters and gages adjacent to machines and equipment to allow service and

maintenance.

2. Connect flow-measuring-system elements to meters.

3. Connect flowmeter transmitters to meters.

4. Connect thermal-energy-flowmeter transmitters to meters.

B. Make electrical connections to power supply and electrically operated meters and devices.

C. Ground electrically operated meters.

1. Tighten electrical connectors and terminals according to manufacturer's published

torque-tightening values. If manufacturer's torque values are not indicated, use those

specified in UL 486A and UL 486B.

D. Install electrical connections for power and devices.

E. Electrical power, wiring, and connections are specified in Division 16 Sections.

0.10 ADJUSTING AND CLEANING

A. Calibrate meters according to manufacturer's written instructions, after installation.

B. Adjust faces of meters and gages to proper angle for best visibility.

C. Clean windows of meters and gages and clean factory-finished surfaces. Replace cracked

and broken windows, and repair scratched and marred surfaces with manufacturer's touchup

paint.

END OF SECTION 15122

METERS AND GAGES 15122 - Page 10/10

STD-SPC-DCA(A1)-ME-DCA REV A

You might also like

- Flooring MaterialsDocument57 pagesFlooring MaterialsMohammed FazilNo ratings yet

- John Wilson - Lost Solar System of The Ancient (Vol 2)Document522 pagesJohn Wilson - Lost Solar System of The Ancient (Vol 2)Rajat K Bose100% (2)

- Water SoftenersDocument11 pagesWater Softenersadel rihanaNo ratings yet

- SANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsDocument158 pagesSANYO ELEVATORS AND ESCALATORS CO.LTD USER GUIDE Warnings and CautionsAliRouyou64% (11)

- Metal Duct SpecificationDocument12 pagesMetal Duct Specificationadel rihanaNo ratings yet

- Refrigerant PipingDocument8 pagesRefrigerant PipingfaltuNo ratings yet

- Project Standard Specification: Refrigerant Piping 15530 - Page 1/9Document9 pagesProject Standard Specification: Refrigerant Piping 15530 - Page 1/9adel rihanaNo ratings yet

- SEO-Optimized Steam Piping TitleDocument7 pagesSEO-Optimized Steam Piping Title황철No ratings yet

- KeyboardingDocument56 pagesKeyboardingJed Tedor100% (5)

- 15-1-6 - Chilled Water Piping SystemDocument10 pages15-1-6 - Chilled Water Piping Systemfarshan296015No ratings yet

- Jet A1 Fuel Piping SpecificationDocument17 pagesJet A1 Fuel Piping Specificationadel rihana100% (1)

- HVAC Engineer Interview 70 Question Answers (Mechanical Engineer) PDFDocument11 pagesHVAC Engineer Interview 70 Question Answers (Mechanical Engineer) PDFChahbi Ramzi100% (1)

- List of welding processes guideDocument4 pagesList of welding processes guidespahicdaniloNo ratings yet

- Firefighting Engineer Interview 50 Questions & AnswersDocument7 pagesFirefighting Engineer Interview 50 Questions & AnswersSyed Abbu Hurerah75% (4)

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- Project Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12Document12 pagesProject Standard Specification: Potable-Water Storage Tanks 15450 - Page 1/12adel rihanaNo ratings yet

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- 2016OilSafeCatalog PDFDocument76 pages2016OilSafeCatalog PDFwilmerNo ratings yet

- 15182B Steam Condensate PipingDocument8 pages15182B Steam Condensate PipingAltaf ur RehmanNo ratings yet

- Mx0301-E (Pump) FlowserveDocument34 pagesMx0301-E (Pump) Flowservehasan099No ratings yet

- CZ-USA 2011 Product CatalogDocument60 pagesCZ-USA 2011 Product CatalogMario Lopez100% (1)

- Project Standard Specification: Hydronic Piping 15181 - Page 1/12Document12 pagesProject Standard Specification: Hydronic Piping 15181 - Page 1/12adel rihanaNo ratings yet

- Din en 12101 8 PDFDocument40 pagesDin en 12101 8 PDFadel rihana100% (1)

- IMS Protocol Reference GuideDocument31 pagesIMS Protocol Reference Guideparimipavan_794176No ratings yet

- Project Standard Specification: Water Distribution Piping 15411 - Page 1/10Document10 pagesProject Standard Specification: Water Distribution Piping 15411 - Page 1/10adel rihanaNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Renault Twingo (2000 - 2004) - Fuse Box DiagramDocument5 pagesRenault Twingo (2000 - 2004) - Fuse Box DiagramrafaelecNo ratings yet

- Split-System Air ConditioningDocument6 pagesSplit-System Air Conditioningadel rihanaNo ratings yet

- Project Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5Document5 pagesProject Standard Specification: Pipe Expansion Fittings and Loops 15121 - Page 1/5adel rihanaNo ratings yet

- Hvac-05 Air CoilsDocument3 pagesHvac-05 Air CoilsCosphiiiNo ratings yet

- Vents and StacksDocument5 pagesVents and Stacksadel rihanaNo ratings yet

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDocument16 pagesPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNo ratings yet

- Project Standard Specification: Valves Page 1/8Document8 pagesProject Standard Specification: Valves Page 1/8adel rihanaNo ratings yet

- SECTIONDocument14 pagesSECTIONadel rihanaNo ratings yet

- Project Standard Specification: Duct Accessories 15820 - Page 1/9Document9 pagesProject Standard Specification: Duct Accessories 15820 - Page 1/9adel rihanaNo ratings yet

- Steam, Domestic Storage Water HeaterDocument7 pagesSteam, Domestic Storage Water Heaterbandithaguru6338No ratings yet

- Fire Supperssion StandpipesDocument15 pagesFire Supperssion StandpipesMohammad Sadik0% (1)

- Project Standard Specification: Compressed-Air Piping 15481-Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Piping 15481-Page 1/9adel rihanaNo ratings yet

- Project Standard Specification: Valves 15100 - Page 1/7Document7 pagesProject Standard Specification: Valves 15100 - Page 1/7adel rihanaNo ratings yet

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- Section 221513 - General-Service Compressed-Air Piping.1Document9 pagesSection 221513 - General-Service Compressed-Air Piping.1jkhgvdj mnhsnjkhgNo ratings yet

- Packaged Cooling Towers Section 15640Document7 pagesPackaged Cooling Towers Section 15640Munir RasheedNo ratings yet

- Oib Technical Spec 21,22,23Document586 pagesOib Technical Spec 21,22,23kali highNo ratings yet

- Project Standard Specification: Heat Exchangers 15710 - Page 1/3Document3 pagesProject Standard Specification: Heat Exchangers 15710 - Page 1/3adel rihanaNo ratings yet

- Project Standard Specification: Air Coils 15761 - Page 1/5Document5 pagesProject Standard Specification: Air Coils 15761 - Page 1/5adel rihanaNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- Fuel Handling SystemDocument4 pagesFuel Handling SystemRoel FranciscoNo ratings yet

- 23 11 23 Facility Natural-Gas PipingDocument19 pages23 11 23 Facility Natural-Gas PipingKak SofiNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- SECTION 15120 Piping Specialties 1.1Document18 pagesSECTION 15120 Piping Specialties 1.1Munir RasheedNo ratings yet

- Bart Facilities StandardDocument8 pagesBart Facilities StandardBehnam AshouriNo ratings yet

- Project Standard Specification: Hangers and Supports Page 1/10Document10 pagesProject Standard Specification: Hangers and Supports Page 1/10adel rihanaNo ratings yet

- Section 15505 - Fire Protection System (Basic Materials and Methods)Document10 pagesSection 15505 - Fire Protection System (Basic Materials and Methods)Kurt Darryl SabelloNo ratings yet

- 220523-General-Duty Valves For Plumbing PipingDocument9 pages220523-General-Duty Valves For Plumbing PipingAttef BedaweNo ratings yet

- 15510Document13 pages15510uddinnadeemNo ratings yet

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonNo ratings yet

- 23 20 00 Hvac Piping SystemsDocument14 pages23 20 00 Hvac Piping Systemsamirshahi2019No ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- 23 21 13 Iei - Hvac PipingDocument10 pages23 21 13 Iei - Hvac PipingAiman AliNo ratings yet

- Steam and Steam Condensate PDocument14 pagesSteam and Steam Condensate PDanny BoysieNo ratings yet

- Valves and Related ComponentsDocument7 pagesValves and Related ComponentsSalim BakhshNo ratings yet

- Cable TraysDocument4 pagesCable TraysMohammed Hussain OMNo ratings yet

- Project Standard Specification: Fuel Oil Piping 15191 - Page 1/6Document6 pagesProject Standard Specification: Fuel Oil Piping 15191 - Page 1/6adel rihanaNo ratings yet

- Project Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10Document10 pagesProject Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10adel rihanaNo ratings yet

- Refrigeration DX Piping and Specialties (Rev. 11-16Document5 pagesRefrigeration DX Piping and Specialties (Rev. 11-16T0 R3dNo ratings yet

- SF - Piped Utilities - Basic Materials and MethodsDocument11 pagesSF - Piped Utilities - Basic Materials and MethodsMuwafaq_mibNo ratings yet

- SEC 226200 Laboratory Vacuum SystemDocument8 pagesSEC 226200 Laboratory Vacuum SystemAkilaJosephNo ratings yet

- BMMM SectionDocument9 pagesBMMM SectionObaidAliKhanNo ratings yet

- Section 15183 - Refrigerant PipingDocument11 pagesSection 15183 - Refrigerant PipingJavier BarbosaNo ratings yet

- HVAC Pipe and Equipment Hanger GuideDocument10 pagesHVAC Pipe and Equipment Hanger GuideAmeen Mohamed Ali SanadNo ratings yet

- Dartmouth College Design January 3, 2012 & Construction GuidelinesDocument6 pagesDartmouth College Design January 3, 2012 & Construction GuidelinesSalman AkramNo ratings yet

- SECTION 15125 Piping Expansion Compensation: 50 Degrees F 210 Degrees F 140 Degrees FDocument5 pagesSECTION 15125 Piping Expansion Compensation: 50 Degrees F 210 Degrees F 140 Degrees FfatREVITNo ratings yet

- HVAC Ductwork and Casings GuideDocument10 pagesHVAC Ductwork and Casings GuidemanikantanNo ratings yet

- FL - Expansion Fittings and Loops For Plumbing Piping - BudDocument6 pagesFL - Expansion Fittings and Loops For Plumbing Piping - BudAntonius HarrisNo ratings yet

- Temperature .: Psig 200 Deg FDocument28 pagesTemperature .: Psig 200 Deg Fabdelazeem ElhajNo ratings yet

- 23 05 29 - HVAC Hangers and SupportsDocument9 pages23 05 29 - HVAC Hangers and SupportsperezismaelNo ratings yet

- Section 21 05 00Document6 pagesSection 21 05 00Ismail MohammadNo ratings yet

- Project Standard Specification: Sewage Pumps 15445 - Page 1/12Document12 pagesProject Standard Specification: Sewage Pumps 15445 - Page 1/12adel rihanaNo ratings yet

- Project Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10Document10 pagesProject Standard Specification: Electric, Domestic Water Heaters 15485 - Page 1/10adel rihanaNo ratings yet

- Project Standard Specification: Centrifugal Water Chillers 15625 - Page 1/18Document18 pagesProject Standard Specification: Centrifugal Water Chillers 15625 - Page 1/18adel rihanaNo ratings yet

- Rotary-Screw Chiller SpecificationDocument11 pagesRotary-Screw Chiller Specificationadel rihanaNo ratings yet

- Mechanical Vibration and Seismic Controls SpecificationDocument10 pagesMechanical Vibration and Seismic Controls Specificationadel rihanaNo ratings yet

- PLUMBING SPECIALTIES TITLEDocument19 pagesPLUMBING SPECIALTIES TITLEadel rihanaNo ratings yet

- Plumbing FixturesDocument30 pagesPlumbing Fixturesadel rihanaNo ratings yet

- Coatings and Corrosion ProtectionDocument13 pagesCoatings and Corrosion Protectionadel rihanaNo ratings yet

- SECTIONDocument14 pagesSECTIONadel rihanaNo ratings yet

- Project Standard Specification: Basic Mechanical Materials and Methods 15050 - Page 1/17Document17 pagesProject Standard Specification: Basic Mechanical Materials and Methods 15050 - Page 1/17adel rihanaNo ratings yet

- Duct Insulation Project SpecificationDocument11 pagesDuct Insulation Project Specificationadel rihanaNo ratings yet

- Project Standard Specification: Decorative Fountain 15495 - Page 1/7Document7 pagesProject Standard Specification: Decorative Fountain 15495 - Page 1/7adel rihanaNo ratings yet

- Project Standard Specification: Air Coils 15761 - Page 1/5Document5 pagesProject Standard Specification: Air Coils 15761 - Page 1/5adel rihanaNo ratings yet

- Project Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11Document11 pagesProject Standard Specification: Computer-Room Air-Conditioning Units 15783 - Page 1/11adel rihanaNo ratings yet

- Project Standard Specification: Pipe Insulation 15083 - Page 1/15Document15 pagesProject Standard Specification: Pipe Insulation 15083 - Page 1/15adel rihanaNo ratings yet

- Project Standard Specification: Compressed-Air Piping 15481-Page 1/9Document9 pagesProject Standard Specification: Compressed-Air Piping 15481-Page 1/9adel rihanaNo ratings yet

- 15785-Pca Air Handling UnitsDocument10 pages15785-Pca Air Handling Unitsadel rihanaNo ratings yet

- Project Standard Specification: Swimming Pool 15490 - Page 1/8Document8 pagesProject Standard Specification: Swimming Pool 15490 - Page 1/8adel rihanaNo ratings yet

- Kamstrup Multical 602 - Installation and User GuideDocument28 pagesKamstrup Multical 602 - Installation and User GuideMarco RamosNo ratings yet

- Understand ElectrostaticsDocument39 pagesUnderstand Electrostaticsanup vermaNo ratings yet

- PAX Planner: Your PAX Code: 8PNLS7 Total Price:dhs 4.580.00Document6 pagesPAX Planner: Your PAX Code: 8PNLS7 Total Price:dhs 4.580.00anwarNo ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- RC Datasheet ISCOM2600G 20160128 PDFDocument5 pagesRC Datasheet ISCOM2600G 20160128 PDFJhovanny PasaranNo ratings yet

- Tonepad OffboardwiringDocument0 pagesTonepad OffboardwiringJulio C. Ortiz MesiasNo ratings yet

- Concep PlusDocument1 pageConcep PlusgerzaelNo ratings yet

- New Aluminium FormworkDocument34 pagesNew Aluminium FormworkSandip Jagdale0% (1)

- Service Fujitsu Inverter r410Document80 pagesService Fujitsu Inverter r410Henrique MagalhaesNo ratings yet

- Hager Wiring Accessories Catalogue 1120Document64 pagesHager Wiring Accessories Catalogue 1120lizukyNo ratings yet

- Ascotel Aastra I5 - I7.7 Hardware Software Compatibility ListDocument22 pagesAscotel Aastra I5 - I7.7 Hardware Software Compatibility ListtapkepNo ratings yet

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocument2 pagesAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaNo ratings yet

- WAC Telecom StandardDocument116 pagesWAC Telecom StandardmdandersNo ratings yet

- Importance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresDocument5 pagesImportance of Reliable Geotechnical Investigation For Safe and Economical Foundation Design of Civil StructuresAshwini ShettyNo ratings yet

- Philips Az1500 Az1505 SMDocument33 pagesPhilips Az1500 Az1505 SMJuan Carlos PerdomoNo ratings yet

- CVEN90043 Sustainable Infrastructure EngineeringDocument2 pagesCVEN90043 Sustainable Infrastructure EngineeringApril IngramNo ratings yet

- Ammar Hafez Presentation SP2019Document66 pagesAmmar Hafez Presentation SP2019Sunita ChayalNo ratings yet

- 3.2.A UnitConversionDocument6 pages3.2.A UnitConversionevan martinezNo ratings yet

- Modernizing Your Active Directory Environment: Active Directory Modernization Is Critical. Here's How To Achieve ItDocument9 pagesModernizing Your Active Directory Environment: Active Directory Modernization Is Critical. Here's How To Achieve ItJorgeHoracioGallardoNo ratings yet

- Sae Technical Paper Series: J. Nazar, A. Ramesh and B. NagalingamDocument12 pagesSae Technical Paper Series: J. Nazar, A. Ramesh and B. NagalingamManpreet KaurNo ratings yet