Professional Documents

Culture Documents

By S. Narasimha Rao and Y. V. S. N. Prasad 2: J. Geotech. Engrg. 1993.119:352-357

Uploaded by

Mirza SakibOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

By S. Narasimha Rao and Y. V. S. N. Prasad 2: J. Geotech. Engrg. 1993.119:352-357

Uploaded by

Mirza SakibCopyright:

Available Formats

E S T I M A T I O N OF U P L I F T C A P A C I T Y OF H E L I C A L

A N C H O R S IN C L A Y S

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

By S. Narasimha Rao ~ and Y. V. S. N. Prasad 2

INTRODUCTION

Currently, helical anchors are being extensively used in the construction

of transmission tower foundations, pipelines, and braced excavations. Moo-

ney et al. (1985) were among the first few who suggested design criteria for

this type of anchor in clay and silt. In this paper, an attempt has been made

to arrive at the capacities of these anchors based on the measured shear

strength. It is assumed that there is a cylindrical failure surface between the

top and bottom helical plates. However, in this type of study, one should

consider the effect of spacing of helical plates on the uplift capacity and in

this present study, this aspect has been taken into account. In the estimation

of capacities of these anchors, the effect of the spacing of helical plates can

usefully be incorporated. With the help of an experimental program carried

out on model anchors, the predicted capacities are verified.

TESTING PROGRAM

Four model anchors were made of 13.8-mm-diameter mild steel shafts to

which mild steel plates of 33-mm diameter were welded at a pitch of 8.3

mm to form helical anchors. The number of helical plates and the spacing

of the plates varied. These anchors were designated as A~, A2, A3, and A 4.

Anchor At consisted of two helical plates spaced at 152 mm. The anchor

A2 consisted of three helical plates spaced at 76 ram. Similarly the anchors

A 3 and A 4 consisted of four and five helical plates spaced at 50 mm and 38

mm, respectively. However, the distance between top and bottom helical

plates was kept at 152 mm in all these anchors. The total length of all the

anchors was 513 mm. The helical plates were spaced conforming to pre-

determined spacing ratios (spacing ratio [SR] = spacing of helical plates/

diameter of helical plate). Thus the anchors At, A> A3, and A4 had helical

plates spaced at a SR of 4.6, 2.3, 1.5, and 1.1, respectively.

Pullout tests on these anchors were conducted in a cylindrical test tank

of diameter 350 mm and height 500 mm. The size of the tank was considered

sufficient to minimize the side effects according to Davie and Sutherland

(1978) and Mooney et a l . (1985), The clay used in this study was marine

clay from the coastal deposit in the east coast of India (liquid limit (LL) =

82%, plastic limit (PL) = 32%). Fully saturated soil was placed in layers

of 50-ram thickness. Each layer was made with hand packing in the first

instance and the same was pressed with a template so as to remove entrapped

air. As all the tests were conducted at soft consistency, Ic < 0.5 (Ic = LL

aprof., Ocean Engrg. Ctr. and Civ. Engrg. Dept., Indian Inst. of Tech., Madras

600 036 India.

2Res. Scholar, Ocean Engrg. Ctr., Indian Inst. of Tech., Madras 600 036 India.

Note. Discussion open until July 1, 1993. To extend the closing date one month,

a written request must be filed with the ASCE Manager of Journals. The manuscript

for this paper was submitted for review and possible publication on February 4, 1991.

This paper is part of the Journal of Geoteehnicai Engineering, Vol. 119, No. 2,

February, 1993. 9 ISSN 0733-9410/93/0002-0352/$1.00 + $. 15 per page. Paper

No. 1350.

352

J. Geotech. Engrg. 1993.119:352-357.

- water content/ILL - PL]), there was no difficulty in placing the soil and

achieving homogeneous fill. After the clay bed had been prepared, the

anchor was slowly screwed into the soil bed with enough downward force

until the top plate was so positioned such that it was level with the top

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

surface of the soil (embedment ratio, H/D = 0 where H = depth of embed-

ment of top helical plate and D = diameter of helical plate).

For loading, cast iron weights were continuously placed on the weight

hanger until the anchors were pulled out. The load at which the anchor

came out with high upward movement was considered as gross ultimate

uplift capacity (Pg). The schematic diagram of experimental setup is shown

in Fig. 1. In this setup, a load cell of capacity of 250 N and an inductive

displacement transducer with a travel length of _+20 mm for measuring load

and movement of anchor, respectively, were used. An arrangement was

II o, o

IJ

I I I II-o--~-tk I. II

I I I I+l+~ ~

I I HULTICH~'N~EL'CA'RRIER

FREQUENCY A~MP.LIFIER

I l ll lJ_lll

I I"~'1 L_-II II---J I I I I ACQmmTtON

I ~)

DATA

~6

FIG. 1. Schematic Diagram of Experimental Setup

80

70|I-- I I I I I I

60 Ic Cu -

( k PQ)

SO o.45 4.4 -

u

~_ 40

0.40 3.8

0.36 3.5 -

o. 30 V o.28 3.0

| [] - A I ~ 0.17 2.2

Z0 I - 9 - AZ

JZ~ -A3

10 I - o -A4

0 /--~CALC~LATE[~ CAP~CITY I j

0 1 2 3 4 S 6 7

SPACING RATIO (SR)

FIG. 2. Variation of P of Anchors with SR at Different I~ Values

353

J. Geotech. Engrg. 1993.119:352-357.

1.1

I I I I I I

oooo~

,.1.0

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

n.

2p .0 . 8

~

z 0-7

FOR 3.5~<SR~<4.6 " N

"

ffl0 . 6

0.s I I T I I I

0 1 Z 3 t, S 6 7

SPACING RATIO (SR)

FIG. 3. Variation of Sr with SR

made to eliminate the suction below the bottom helical plate (as shown in

the Fig. 1). The tests were conducted at five different consistency indices

(Ic) of soil and the shear strength of the soil bed (C,) was measured using

the in situ vane shear test.

RESULTS AND ANALYSIS

The net ultimate uplift capacity (P) of an anchor can be obtained by

subtracting the weight of the anchor (W) from the gross ultimate uplift

capacity (P~) and is given by

P = Pg - W ............................................... (1)

The variation of P of the anchors with SR at different Ic values are presented

in Fig. 2. From the figure, it can be observed that as the Ic increases, there

is a considerable increase in P for the same anchor and it is because of the

increase in the C, of the soil. It can be further seen that as the spacing of

the helical plates is reduced, anchor capacities are increased and the opti-

mum capacities are found to be at a SR of around 1.5. According to Mooney

et al. (1985), the capacity of a helical anchor is given by (when H/D = 0),

P = (~DL)C. .............................................. (2)

where L = distance between top and bottom helical plates and C, =

measured shear strength of clay. The calculated capacities using (2) are

shown in Fig. 2 with dotted lines. From this, it can be seen that both

experimental and computed capacities are in good agreement for the an-

chors, with SR less than or equal to 1.5, and the assumption of cylindrical

failure surface seems to be valid for such cases. With the increase in spacing

of helical plates, the cylindrical failure surface may be incomplete and the

capacities are reduced. After the testing, the pulled-out anchors surfaces

354

J. Geotech. Engrg. 1993.119:352-357.

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

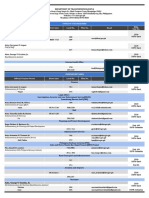

TABLE 1. Comparison of Lab and Field Test Results with Calculated Values

Total

length of

anchor (P~)

Diameter Spacing of embedded computed

of helical in soil, (p,) (P,)

Serial Helical helical plates, plates L H Lr=.L +H C. measured computed (P~)

number Reference plates D (mm) (mm) SR (ram) (ram) (mm) H/D Ic (kPa) (kN) (kN) measured

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10 (11) (12) (13) (14) (15)

1 Adams and Klym 4 2-280, 2-254 3-736.6 2.6, 2.8, 2.9 2,210 38,640 40,850 138 -- 47.9 218.700 220.200 ~ 1.00

(1972)

2 Adams and Klym 8 5-381,343, 7-736.6 4-1.9, 2, 2.4, 5,156 37,820 42,976 86 -- 24.0, 291.600 300.000 ~ 1.03

ol (1972) 286, 254 2.8 47.9

ol 3 Mooney et al. 3 72.0, 63.5, 2-228.6 3.4, 4.0 457 15 472 0.2 0.21 6.9 0.576 0.576 b 1,00

(1985) 50.8

4 Mooney et al. 3 72.0, 63.5, 2-228.6 3.4, 4.0 457 288 745 4.0 0.21 6.9 0.846 0.873 b 1.03

(1985) 50.8

5 Mooney et al. 3 72.0, 63.5, 2-228.6 3.4, 4.0 457 576 1,033 8.0 0.21 6.9 0.864 0.925 b 1.07

(1985) 50.8

6 Mooney et al. 3 290, 250, 200 2-914.4 3.4, 4.0 1,829 2,320 4,149 8.0 0.30 24.1 51.220 49,000 ~ 0.96

J. Geotech. Engrg. 1993.119:352-357.

(1985)

7 Mooney et al. 3 290, 250, 200 2-914.4 3.4, 4.0 1,829 2,900 4,728 10,0 0.30 24.1 48.830 50.200" 1.02

(1985)

8 Mooney et al. 3 290, 250, 200 2-914.4 3.4, 4.0 1,829 3,480 5,308 12.0 0.30 24.1 48,600 51,380" 1.06

(1985)

~5% of computed value is added to account for weight of anchor and suction below bottom helical plate.

b3% of computed value is added to account for weight of anchor and measured suction below bottom helical plate was used.

are observed and these observations confirmed the aforementioned state-

ments. Similar type of behavior was reported by Bassett (1977) for under-

reamed anchors in clays. This work concentrated on the effect of underreams

spacing on pullout capacity. This work showed that up to a spacing of 2D

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

to 3D, cylindrical or pluglike failure takes place and beyond that it changes

to end bearing failure on the top of underreams. Because of the inability

to find out actual failure surface for anchors with helical plates spaced at

high SR, it is suggested that a nondimensional spacing ratio factor, SF, can

be introduced to estimate the capacities. The SF is given by

(P) experimental

SF = (p) computed using (2) .................................. (3)

Fig. 3 represents the variation of SF with SR. In this figure, the results of

Narasimha Rao et al. (1991) on relatively big size model anchors with D

= 75 ram, 100 mm, and 150 mm and SR of 0.8, 1.0, 1.3, 1.5, 2.3, 3.1, 4.0,

and 4.6 are also used. A best curve is fitted and for the purpose of con-

venience, it is divided into three segments as shown in Fig. 3, and the

relationship between Sr and SR is given by

Sr = 1.0 for SR -- 1.5(Zone I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (4a)

Sv = 0.863 + 0.069(3.5 - SR) for 1.5 - SR -< 3.5(Zone II) . . . . . (4b)

Sr = 0.700 + 0.148(4.6 - SR) for 3.5 --- SR -< 4.6(Zone III) . . . . (4c)

By knowing the Sv from the aforementioned equations, actual capacity of

an anchor can be obtained by multiplying (P) computed using (2) with Sv.

In the case of anchors with varying size of helical plates, the SR value

between any two plates can be calculated as the ratio between spacing of

helical plates to average diameter of two helical plates.

If any field test results obtained from tests carried out on large-size an-

chors are available, they can be used to verify the formulations suggested.

The reported results of Adams and Klym (1972) and Mooney et al. (1985)

are made use in this paper. These capacities are compared with the computed

values and are summarized in Table 1. The contribution from top helical

plate and shaft friction above top plate are calculated as suggested by Moo-

hey et al. (1985). As can be seen from the table, there seems to be good

agreement and the agreement ratio varies between 0.96 to 1.07.

CONCLUSIONS

The load-carrying capacities of the helical anchors in clays are controlled

by the spacing of the helical plates. For spacing ratios beyond 1.5, the failure

surfaces are not cylindrical and for such cases also, formulations to predict

the capacities as suggested in this paper can be made. These formulations

are verified with the reported laboratory and field test results.

APPENDIX. REFERENCES

Adams, J. I., and Klym, T. W. (1972). "A study of anchors for transmission tower

foundation." Can. Geotech. J., 9(1), 89-104.

Bassett, R. H. (1977). "Underrearned ground anchors." Proc. 9th lnt. Conf. on

SMFE, International Society of Soil Mechanics and Foundation Engineering, 11-

17.

356

J. Geotech. Engrg. 1993.119:352-357.

Davie, J. R., and Sutherland, H. B. (1978). "Modelling of clay uplift resistance."

J. Geotech. Engrg., ASCE, 104(6), 755-760.

Mooney, J. M., Adamczak, S., and Clemence, S.P. (1985). "Uplift capacity of helical

anchor in clay and silt: uplift behaviour of anchor foundations in soil. Proc., ASCE,

Downloaded from ascelibrary.org by The University of Queensland Library on 09/06/13. Copyright ASCE. For personal use only; all rights reserved.

48--72.

Narasimha Rao, S., Prasad, Y. V. S. N., and Shetty, M. D. (1991). "The behaviour

of model screw piles in cohesive soils." Soils Found., 31(2), 35-50.

357

J. Geotech. Engrg. 1993.119:352-357.

You might also like

- Redlands' 2015 California Public Records RequestsDocument26 pagesRedlands' 2015 California Public Records RequestsBeau Yarbrough100% (1)

- Understanding Blow Molding: Norman C. LeeDocument11 pagesUnderstanding Blow Molding: Norman C. LeeKiran ModakNo ratings yet

- Analysis and Design of Ballastless Track SlabDocument8 pagesAnalysis and Design of Ballastless Track SlabSuhas_vroom8546No ratings yet

- Behavior and Strength of Slab-Edge Beam-Column Connections Under Shear Force and MomentDocument6 pagesBehavior and Strength of Slab-Edge Beam-Column Connections Under Shear Force and MomentMahmoudSofanNo ratings yet

- Asce Discussion 2Document1 pageAsce Discussion 2rajgopalNo ratings yet

- Closure by Amin Ghali, Fellow,! ASCE, and Gamil Tadros, 6 Member, ASCEDocument2 pagesClosure by Amin Ghali, Fellow,! ASCE, and Gamil Tadros, 6 Member, ASCEDimvoulg CivilNo ratings yet

- FulopDocument9 pagesFulopma.shaheNo ratings yet

- Uplift Behavior of Screw Anchors in Sand. I. Dry SandDocument21 pagesUplift Behavior of Screw Anchors in Sand. I. Dry Sandahmed sallamNo ratings yet

- Yeh Sun RimrottDocument10 pagesYeh Sun RimrottMohd Shahrom IsmailNo ratings yet

- Cable-Stayed Bridge - Parametric StudyDocument10 pagesCable-Stayed Bridge - Parametric StudyTuan PnNo ratings yet

- Comparative Study Confinement Models PDFDocument11 pagesComparative Study Confinement Models PDFMaqMaikNo ratings yet

- Optimization of Stiffened Laminated-Composite Circular-Cylindrical Shells For BucklingDocument8 pagesOptimization of Stiffened Laminated-Composite Circular-Cylindrical Shells For Bucklinginame11No ratings yet

- Flexural-Torsional Buckling of Arches: January 1987Document19 pagesFlexural-Torsional Buckling of Arches: January 1987manupriyaNo ratings yet

- A Review of The Effect of Corner LoadsDocument4 pagesA Review of The Effect of Corner LoadsATSNo ratings yet

- 1972 - 129 - Load Carrying Capacity of Two Hinged Steel ArchesDocument12 pages1972 - 129 - Load Carrying Capacity of Two Hinged Steel ArchesArkarNo ratings yet

- Column Capacity With Site Imperfection Splice WeldDocument8 pagesColumn Capacity With Site Imperfection Splice WeldRaja GopalNo ratings yet

- 2000 Shear Lag of Thin-Walled Curved Box Girder BridgesDocument4 pages2000 Shear Lag of Thin-Walled Curved Box Girder BridgesPreeti AgarwalNo ratings yet

- Zhang 2018Document12 pagesZhang 2018Elvis Phala CopacatiNo ratings yet

- Buckling of Spherical Shells Subjected To External PressureDocument7 pagesBuckling of Spherical Shells Subjected To External PressureSUBHASH100% (1)

- 1998 - Polyzois and Raftoyiannis - Lateral-Torsional Stability of Steel Web-Tapered I-BeamsDocument9 pages1998 - Polyzois and Raftoyiannis - Lateral-Torsional Stability of Steel Web-Tapered I-BeamsJosé Ferreira FilhoNo ratings yet

- Shervin Maleki - Seismic Modeling of Skewed Bridges With Elastomeric Bearings and Side RetainersDocument8 pagesShervin Maleki - Seismic Modeling of Skewed Bridges With Elastomeric Bearings and Side RetainersSaeedNo ratings yet

- Confinement of Columns and Wall Boundary Elements Using Headed BarsDocument9 pagesConfinement of Columns and Wall Boundary Elements Using Headed BarsJuaNNo ratings yet

- Experimental Investigation On The Effect of Geometric ImperfectionsDocument11 pagesExperimental Investigation On The Effect of Geometric ImperfectionsSUBHASHNo ratings yet

- Behavior of Corrugated Web I-Girders Under In-Plane LoadsDocument9 pagesBehavior of Corrugated Web I-Girders Under In-Plane LoadsAsr FlowerNo ratings yet

- Energy Losses in Cross JunctionsDocument6 pagesEnergy Losses in Cross JunctionsVikasNo ratings yet

- 1971 - 109 - Out-Of-Plane Buckling of Solid Rib Arches Braced With Transverse BarsDocument8 pages1971 - 109 - Out-Of-Plane Buckling of Solid Rib Arches Braced With Transverse BarsArkarNo ratings yet

- Tapered, Circular TubesDocument11 pagesTapered, Circular TubesifadacitraNo ratings yet

- Paper 29Document10 pagesPaper 29Rieza Zulfahmi TaftazaniNo ratings yet

- Influence of Stirrup Distribution and SupportDocument11 pagesInfluence of Stirrup Distribution and SupportRayan MahgoubNo ratings yet

- Cable Bolt Anchors Performance PDFDocument8 pagesCable Bolt Anchors Performance PDFwilmerlanceNo ratings yet

- 1984 - Sheetpile Interlock TensionDocument13 pages1984 - Sheetpile Interlock TensionafuhcivNo ratings yet

- 10 1 1 875 5824 PDFDocument33 pages10 1 1 875 5824 PDFحمودي معزNo ratings yet

- Effect of Joint Hoops On Seismic Behavior of Wide Beam-Column JointsDocument12 pagesEffect of Joint Hoops On Seismic Behavior of Wide Beam-Column JointsklheirosNo ratings yet

- OKANEDocument5 pagesOKANEDHANASRI MOTAPARTHYNo ratings yet

- Zhengyang Guo and Lijun Deng - 2018Document11 pagesZhengyang Guo and Lijun Deng - 2018Felipe DornellesNo ratings yet

- Deepbeamsachan Main PDFDocument8 pagesDeepbeamsachan Main PDFAnil SachanNo ratings yet

- Elastic Stress Parameters in Simply Supported Skew Plates in FlexureDocument9 pagesElastic Stress Parameters in Simply Supported Skew Plates in Flexureluna luneraNo ratings yet

- 11 - Stability of Built-Up ColumnsDocument15 pages11 - Stability of Built-Up Columnsخوێندن لە ئەوروپاNo ratings yet

- 3 - Laterally Loaded Helical Piles in SandDocument7 pages3 - Laterally Loaded Helical Piles in SandAhmed RamadanNo ratings yet

- Experimental Behaviour of Thin-Walled Cylindrical Shells Subjected To External PressureDocument17 pagesExperimental Behaviour of Thin-Walled Cylindrical Shells Subjected To External PressureGustavo TeixeiraNo ratings yet

- (1996) Tubular Members. I Stability Analysis and Preliminary ResultsDocument8 pages(1996) Tubular Members. I Stability Analysis and Preliminary ResultsMohammad AshrafyNo ratings yet

- Ahmed and Rajaratnam1998Document13 pagesAhmed and Rajaratnam1998Ahmad HelmiNo ratings yet

- Experimental Model For Predicting The Semi-Rigid Connections' Behaviour With Angles and StiffenersDocument12 pagesExperimental Model For Predicting The Semi-Rigid Connections' Behaviour With Angles and StiffenersMerve MerveNo ratings yet

- 19-0011 Calvi SO20Document13 pages19-0011 Calvi SO20silroy d'saNo ratings yet

- Analysis of Beams Prestressed With Unbonded Internal or External Tendons 1Document21 pagesAnalysis of Beams Prestressed With Unbonded Internal or External Tendons 1Amin ZuraiqiNo ratings yet

- Engineering Structures: Yong-Lin Pi, Mark Andrew BradfordDocument12 pagesEngineering Structures: Yong-Lin Pi, Mark Andrew BradfordluisalvesqueirozNo ratings yet

- Assessment of Cross Sections For Cantilevered ImplantDocument8 pagesAssessment of Cross Sections For Cantilevered ImplantDental Del NorteNo ratings yet

- Design of Fiber Reinforced Composite PreDocument13 pagesDesign of Fiber Reinforced Composite Premirza_munir_baig995No ratings yet

- Data Reduction & Dynamic P-Y Paper 1Document13 pagesData Reduction & Dynamic P-Y Paper 1Moustafa El-SawyNo ratings yet

- Incidence-Deviation Angle For Compressor MeeDocument10 pagesIncidence-Deviation Angle For Compressor MeescNo ratings yet

- International Conference On "Structural Engineering & Construction Management" SECM-2016Document8 pagesInternational Conference On "Structural Engineering & Construction Management" SECM-2016VishwanadhNo ratings yet

- Zirakian, 2005Document9 pagesZirakian, 2005carlosNo ratings yet

- Undrained Stability of Ring Foundations: Axisymmetry, Anisotropy, and NonhomogeneityDocument10 pagesUndrained Stability of Ring Foundations: Axisymmetry, Anisotropy, and Nonhomogeneityزوزو جيجيNo ratings yet

- Department of Civil Engineering: Guide:Prof. Vishal SapateDocument21 pagesDepartment of Civil Engineering: Guide:Prof. Vishal SapateshrikantharleNo ratings yet

- @@CITE - IDES Hay@@ A Crushing Analysis and Multi-Objective Optimization of Thin-Walled Five-Cell StructuresDocument18 pages@@CITE - IDES Hay@@ A Crushing Analysis and Multi-Objective Optimization of Thin-Walled Five-Cell StructuresNhanNo ratings yet

- Development of Analytical Model of Bending Force During 3-Roller Conical Bending Process and Its Experimental VerificationDocument9 pagesDevelopment of Analytical Model of Bending Force During 3-Roller Conical Bending Process and Its Experimental VerificationAchref Ben MabroukNo ratings yet

- Behaviour of Cold Formed Lipped Angles in Transmission Line TowersDocument15 pagesBehaviour of Cold Formed Lipped Angles in Transmission Line TowersFrancisco Javier Torres AlvaradoNo ratings yet

- Buckling of Thin Shells, Recent Advances and TrendsDocument12 pagesBuckling of Thin Shells, Recent Advances and Trendschuckhsu1248No ratings yet

- Maximum Reduction in Strip Rolling: by (Eng.), Phd. (Eng.)Document20 pagesMaximum Reduction in Strip Rolling: by (Eng.), Phd. (Eng.)L V SatyavathiNo ratings yet

- Experimental and Numerical Investigation of Dynamic Plastic Behavior ofDocument11 pagesExperimental and Numerical Investigation of Dynamic Plastic Behavior ofRaees MazharNo ratings yet

- Hydrostatically Loaded Structures: The Structural Mechanics, Analysis and Design of Powered SubmersiblesFrom EverandHydrostatically Loaded Structures: The Structural Mechanics, Analysis and Design of Powered SubmersiblesNo ratings yet

- Algebraic Geometry and Commutative Algebra: In Honor of Masayoshi NagataFrom EverandAlgebraic Geometry and Commutative Algebra: In Honor of Masayoshi NagataHiroaki HijikataNo ratings yet

- Effects of Helical Anchor Geometry On Long-Term Performance of Small Wind Tower Foundations Subject To Dynamic LoadsDocument13 pagesEffects of Helical Anchor Geometry On Long-Term Performance of Small Wind Tower Foundations Subject To Dynamic LoadsMirza SakibNo ratings yet

- Anchors in Sand Bed: Delineation of Rupture Surface: K. Ilamparuthi, K. MuthukrishnaiahDocument25 pagesAnchors in Sand Bed: Delineation of Rupture Surface: K. Ilamparuthi, K. MuthukrishnaiahMirza SakibNo ratings yet

- Ultimate Uplift Capacity of Multiplate Helical Type Anchors in ClayDocument14 pagesUltimate Uplift Capacity of Multiplate Helical Type Anchors in ClayMirza SakibNo ratings yet

- A2 PDFDocument16 pagesA2 PDFMirza SakibNo ratings yet

- Effects of Long-Term Dynamic Loading and Fluctuating Water Table On Helical Anchor Performance For Small Wind Tower FoundationsDocument11 pagesEffects of Long-Term Dynamic Loading and Fluctuating Water Table On Helical Anchor Performance For Small Wind Tower FoundationsMirza SakibNo ratings yet

- Thank You For Your Order: Power & Signal Group PO BOX 856842 MINNEAPOLIS, MN 55485-6842Document1 pageThank You For Your Order: Power & Signal Group PO BOX 856842 MINNEAPOLIS, MN 55485-6842RuodNo ratings yet

- Radiation Physics and Chemistry: L.T. Hudson, J.F. SeelyDocument7 pagesRadiation Physics and Chemistry: L.T. Hudson, J.F. SeelyThư Phạm Nguyễn AnhNo ratings yet

- 1 Stack Testing Source Policy - RA 8749 Legal Oct 2019 Updates - Engr. Jundy Del SocorroDocument80 pages1 Stack Testing Source Policy - RA 8749 Legal Oct 2019 Updates - Engr. Jundy Del SocorroJayson ResultayNo ratings yet

- The Mind of A MnemonistDocument4 pagesThe Mind of A MnemonistboobeeaaaNo ratings yet

- A Novel Wastewater Derived BiodieselDocument13 pagesA Novel Wastewater Derived BiodieselYuri ClaroNo ratings yet

- Lighting Movements-The Fox On The FairwayDocument1 pageLighting Movements-The Fox On The FairwayabneypaigeNo ratings yet

- Catalogo EnduroDocument52 pagesCatalogo EnduroCarqtre Carqtre TegNo ratings yet

- Updated DOTr Directory As of 29 October 2021Document9 pagesUpdated DOTr Directory As of 29 October 2021Twinkle MiguelNo ratings yet

- Dr. M. Syed Jamil Asghar: Paper Published: 80Document6 pagesDr. M. Syed Jamil Asghar: Paper Published: 80Awaiz NoorNo ratings yet

- Fishery MachinesDocument9 pagesFishery Machinesirshad hussainNo ratings yet

- Herpes Simplex KeratitisDocument20 pagesHerpes Simplex KeratitisriskhapangestikaNo ratings yet

- Ste FannyDocument17 pagesSte FannyElmer DE LA CruzNo ratings yet

- Valores de Laboratorio Harriet LaneDocument14 pagesValores de Laboratorio Harriet LaneRonald MoralesNo ratings yet

- Of Love AnalysisDocument8 pagesOf Love AnalysisRica Jane Torres100% (1)

- Test Engleza Clasa A5a Modul 3Document3 pagesTest Engleza Clasa A5a Modul 3Adelina HasasNo ratings yet

- Grade 7-Advanced Science Environmental ScienceDocument8 pagesGrade 7-Advanced Science Environmental ScienceChrisel Luat LopezNo ratings yet

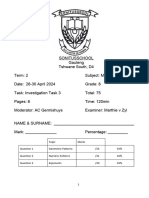

- Investigation Gr. 8Document6 pagesInvestigation Gr. 8Marthie van zylNo ratings yet

- Cause and Effect PowerpointDocument20 pagesCause and Effect PowerpointSherly V.LizardoNo ratings yet

- Mechanics of Solids - (Riveted and Welded Joints)Document37 pagesMechanics of Solids - (Riveted and Welded Joints)TusherNo ratings yet

- Piping - Fitings HandbookDocument240 pagesPiping - Fitings HandbookzohirNo ratings yet

- Basic SCBA: Self-Contained Breathing ApparatusDocument51 pagesBasic SCBA: Self-Contained Breathing ApparatusPaoloFregonaraNo ratings yet

- Alfa Laval Energy Balance Casestory enDocument2 pagesAlfa Laval Energy Balance Casestory enHélder FernandoNo ratings yet

- Hydrogen Codes and Standards Workshop: Naser ChowdhuryDocument24 pagesHydrogen Codes and Standards Workshop: Naser ChowdhuryDiana DhominicNo ratings yet

- Unit 2Document9 pagesUnit 2Quinn LilithNo ratings yet

- PDS Syncade RADocument6 pagesPDS Syncade RAKeith userNo ratings yet

- Lecture5 (4) Mech of SolidsDocument18 pagesLecture5 (4) Mech of Solids'jhony' Fauzan NurdinNo ratings yet

- Writing Good PI ObjectivesDocument42 pagesWriting Good PI Objectivesfrankiepaul06No ratings yet