Professional Documents

Culture Documents

Blade Arrangments 1

Uploaded by

Ravi MirzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blade Arrangments 1

Uploaded by

Ravi MirzaCopyright:

Available Formats

Special Issue - 2016 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

IC-QUEST - 2016 Conference Proceedings

Computer Aided Design and Force Analysis of

Rotor shaft of Rotavator

S. A. Mishra Prof. A. R. Sahu Prof. R. D. Thakre

Dept. of Mechanical Engineering Dept. of Mechanical Engineering Dept. of Mechanical Engineering

B.D.College Of Engineering, B.D.College Of Engineering B.D.College Of Engineering

Sevagram, Wardha, India Sevagram, Wardha, India Sevagram, Wardha, India

Abstract - The intent of this paper is to study the various forces

and stress acting on a rotor shaft of a standard rotavator which

is subjected to transient loading. The standard models of

rotavator, having a progressive cutting sequence was considered

for the study and analysis. The study was extended to various

available models having different cutting blade arrangement.

The study was carried on different papers and identifies the

various forces acting on a Rotor shaft of a rotavator. The

positions of the torque and forces applied are varied according

to the model considered. The response was obtained by Figure: CAD model of Rotar shaft of rotavator

considering the angle of twist and equivalent stress on the rotor

shaft. This paper presented a methodology for conducting III. MAIN PARTS OF ROTAVATOR

transient analysis of rotor shaft of a rotavator.

Keywords—Rotor shaft, Blades, Torsional stresses, flange

I. INTRODUCTION

Rotavator is agricultural machinery, used to perform

primary and the secondary tillage operations in farm. It is

used to agitate the soil as well as to produce a good seed bed

for crops. In the process it increases the Porosity and aeration

of the soil which enhances the germination and growth of the

crops. One of the added advantages of using rotavator is that

it provides some forward thrust there by reducing the traction Figure: Rotavator Parts

demand of the tractor [1]. When compared to conventional

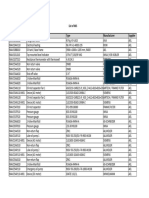

plough the total power requirement is lower. It is the most 1. Independent Top Mast: one end of shaft will be connected

efficient means of transmitting engine power directly to the to tractor P.T.O. and another end to rotavator.

soil when compared to conventional tillage operations [2]. In 2. Single / Multi Speed Gear Box: A gear box with bevel

comparison with that of the plough type rotavator, the rotary gears, main shaft, pinion shaft, heavy duty roller bearings

type consumes 25% less power [3]. Usually the power from combine form a unit to reduce standard P.T.O. rpm 540

the engine is given to the rotavator through the tractor PTO rpm to 204 rpm. It enables the rotor shaft to rotate in the

shaft. Rotary motion is then transferred to the rotor through direction of travel.

gearbox and transmission system. Flanges are mounted in the 3. Chain / Gear Cover Part Flange: A chain and gear cover

rotor on which cutting blades are attached. part flange is a supporting element on which chain and

gears are mounted.

II. PROBLEM IDENTIFICATION 4. Blades: The L shaped will be most common due to L

It has been observed that the rotavator assembly gets failed shape is usually superior to others in heavy trash.

during the operation if proper speed is not maintained. it is 5. Chain / Gear Cover Part: A chain and gear cover part is a

also observed that the rotor shaft is not designed or selected covering element in which chain and gears are safely

by the manufacturer by applying any scientific tools like protected from outside.

modeling & FEM analysis. Also they do not considered 6. Frame and Cover: By adjusting the position of rear cover;

working conditions under which rotavator is going to used. the degree of pulverization of soil will be controlled.

Therefore in this paper the author is trying to find out what 7. Adjustable depth skids: It is fixed on adjustable frame to

are the various critical parameters shell be considered for fix up a distance a gap between soil and Blade contact i.e.

proper designing of a rotavator so that it will not get failed depth skid.

during the operation.

Volume 4, Issue 30 Published by, www.ijert.org 1

Special Issue - 2016 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

IC-QUEST - 2016 Conference Proceedings

8. Offset adjustable frame: There is fixed rigid support to the working hours of the blades and by using different

side parts mounted on rotary blade mounted shaft. materials increase the wear resistance of the blades.

5. J. V. Perumpral et.al, (1983) prepare A mathematical

IV. LITERATURE REVIEW: model based on limit equilibrium analysis which is

Literature review is carried out to find out what are useful for predicting the behaviour of slow moving

the earlier work has carried out related with design of narrow-tillage tools in cohesional-frictional soils. They

Rotavator predict the draft and vertical forces on a slow moving

1. Vignesh. M, et. al, (2015) has studied the torsional narrow tillage tool in soil and it can be effectively used

response of a rotor shaft of a standard rotavator which for parametric studies to better understand the soil-tool

is subjected to transient loading by considering the interaction.

angle of twist and equivalent stress on the rotor shaft 6. Sirisak Chertkiattipol & Tanya Niyamapa (2010) has

and they found that due to the shear stress and angle of studied the torque characteristics and the specific

twist , cyclic variation occurs . The cutting sequence tilling energies of three commonly used rotary blades

does have an influence in the tensional response of the (Japanese C-shaped blade, the European C-shaped

rotor. The cutting sequences have little effect on the blade and the European L-shaped blade) were studied

equivalent stress. The cutting blade arrangement of the to develop a suitable rotary blade for seedbed

standard rotavator considered is not arranged preparation. They did the experiments in a laboratory

according to an optimum sequence and the angle of soil bin at forward speed and the results in these

twist can be reduced by the proper selection of cutting experiments showed that the torque characteristics of

sequence. The torsional rigidity of the shaft can be the Japanese C-shaped blade, the European L-shaped

increased by proper selection of cutting sequence. blade and the European C-shaped blade during tilling

2. Mr. Prasad D. Tupkari, et. al, (2014) has studied about were different; the varying torque was related to the

‘Rotavator Blade’ and they found that Computer Aided blade tip positions of each rotary blade. The shape of

Design (CAD) is an effective tool for the design and the rotary blade influenced its torque characteristic.

development of rotavator blade. They also suggest that The specific tilling energies of all blades increased

that L-shaped blades are better than C or J type blades with the rotational speed. When the depth and the soil

in trashy conditions and at the forward rotation of the specific weight increased, the specific tilling energy

rotary tiller shaft, the tillage power consumption is also increased. The specific tilling energy decreased

decreased upto 10-15 % as compared to shaft reverse when the forward speed increased.

rotation because With the rotor blades cutting

upwards, the tilled soil was scattered out of the seeding

furrow and a seedbed was not formed.

V. DESIGN CALCULATION

3. C. Manivelprabhu, et.al (2015) investigated the Design

of rotavator blade and design modifications are done

by introducing one more cutting edge in other side of

the blade. The main outcome of their study was after 100m 1

introducing one more cutting edge in same blade with

slight modification, the new blade will withstand the 60m

same soil resistance without structural failure and same

time the blade life is increased to double the times by 1.75m 60 60m

introducing inter-changeability concept. They

improved the life of blades by carrying out the design

and modifications on the blade structure and this 100m

design and modifications are carried out by using

CATIA R20 and HYPER MESH 12 software to

simulate the stress distribution in the existing and new

blades.

4. Jeevarathinam A. et.al has performs a finite Element

Analysis for the investigation of Stress experienced by A Rotavator process 0.6 hector land area in 1 hour.

the blade and they found that the deformations and For processing of 0.6 hector land by using a 1.75 m Rotavator

stresses are minimum for the developed L-type blade, it takes 1 hour.

they also observed that the stress in material has been The width of Rotavator = 1.75 m

reduced by applying the design change and changing Therefore the time required for 0.6 hector land =1hr= 60 min.

the materials. The standard material used for blade is And

cast iron and it is producing high stress, different The forces acting = Pulling Force + Soil Resistance

material compositions and dimensions are taken for on a Rotavator

analysis and the load condition is applied for existing No. of turns required for a medium size Rotavator to process

and modified design blades. The best combination of a land with a width of 1.75 m is = 60/1.75= 34.28 = 35 turns

materials and dimensions is then suggested. By Now the distance traveled in one turn = 100 m.

changing the design of rotavator blade they increase Therefore the total distance traveled = 35 x 100m = 3500 m.

Volume 4, Issue 30 Published by, www.ijert.org 2

Special Issue - 2016 International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

IC-QUEST - 2016 Conference Proceedings

Therefore the velocity of Rotavator = 3500 / 3600 = 0.972m/s VII. REFERENCES:

Now for the operation of 1.75 m width Rotavator it requires [1] ‘Study Of Torsional Response on the Rotor shaft of a Rotavator

45 Hp Tractor. Under Transient Load Conditions’ by VigneshM

Therefore, ,Dr.Muruganandhan.R , Dasairi. N, Nagarjun. M, IJIRSET volume4,

special Issue, 4April2015.

The power produced by tractor = 45 x 746 [2] ‘Computer Aided Design And Analysis Of RotavatorBalade’ by

= 33570 W Prasad D. Tupkari, Dr.P.K. Sharma, Prof. Amit Singh, IJATES

= 33.57 Kw. Volume 2, Issue No.05, May2014.

Now, in a standard 1.75 m width Rotavator there are total 42 [3] ‘Design Modification and Structural Analysis of Rotavator Blade

by Using HyperWorks 12.0’ by C. Manivelprabhu, Dr. N.

nos of blades are used. These blades are mounted on 8 Sangeetha, T .Ramganesh, 2015 India Altair Conference.

flanges. The flange are equidistant to each other in between [4] ‘Design Modification and Analysis of Rotavator Blade’ by

two end bearings of rotor shaft. Jeevarathinam.A, Velmurugan.C , IOSR Journal of Mechanical and

The pulling force required to a tractor = Power / Velocity Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320-

334X PP 43-50

= 33570 /0.972 [5] ‘A Soil-Tool Model Based on Limit Equilibrium Analysis’ by J. V.

= 36213.59 N Perumpral, R. D. Grisso, C. S. Desai, TRANSACTIONS of the

ASAE—1983 P. No. 991-995

Now pulling force acting on each flange = 36213.59 / 8 [6] ’ Variations of torque and specific tilling energy for different rotary

blades’ by SirisakChertkiattipol, Tanya Niyamapa, International

= 4526.59 N. Agricultural Engineering Journal Vol. 19, No. 3, December, 2010

The total force acting = Pulling Force + Soil Resistive Force

The Soil Resistive Pressure = 0.56 kg/ cm2.

Now

Pressure = Force / Area

Soil Resistive Pressure = 0.56 kg/cm2

We know that

Pressure = Force / Area

Therefore, Force = Pressure x Area

The area of blade which is in contact with soil = 144 cm2

Therefore resistive force of Soil = Pressure x Area

= 0.56 x 144

= 80.64 N

The total force acting = Puling force on + Soil resistive

on the shaft each Flange Force

= 4526.59 + 80.64

= 4607.23 N

VI. CONCLUSION:

After conducting detail literature review it is observed

that so many authors were studied the rotavator for optimal

designing of it. they had considered the effect of depth of

cut, rotational speed, forward speed and width of cut on the

torque requirement, arrangement of blades etc. but lest

consideration is given to torsional response& The various

forces acting on the rotor shaft of rotavator under transient

load conditions. The study of torsional vibration and forces is

of at most importance because it can result in gear wear, gear

tooth failure, shrink fit slippage and can even leads to the

failure of the rotor shaft in several cases. Therefore this paper

will be of great use to the designers and also for design

optimization.

Volume 4, Issue 30 Published by, www.ijert.org 3

You might also like

- Review On Problem Identification in Rotor Pipe (Shaft) 5-Feet Raj RotavatorDocument8 pagesReview On Problem Identification in Rotor Pipe (Shaft) 5-Feet Raj RotavatorIJRASETPublicationsNo ratings yet

- Blade ArrangmentsDocument6 pagesBlade ArrangmentsRavi MirzaNo ratings yet

- International Engineering Journal For Research & DevelopmentDocument13 pagesInternational Engineering Journal For Research & Developmentdinosaur x-drakeNo ratings yet

- Modelling and Analysis of Excavator Arm: B. Raghu, B. Rajesh, CH. Swathi, D. Rishikesh, G. Abdul KadirDocument21 pagesModelling and Analysis of Excavator Arm: B. Raghu, B. Rajesh, CH. Swathi, D. Rishikesh, G. Abdul KadirShiee ShieeNo ratings yet

- 1 s2.0 S0307904X1300379X MainDocument10 pages1 s2.0 S0307904X1300379X MainPradita FirmansyahNo ratings yet

- Design & Fabrication of 360° Flexible Drilling MachineDocument4 pagesDesign & Fabrication of 360° Flexible Drilling MachineSumit ShuklaNo ratings yet

- File ServeDocument9 pagesFile ServeDadi DahalNo ratings yet

- 8 Ab 9Document4 pages8 Ab 9FMnPA CoEFMNo ratings yet

- Design and Modelling of Shaft of Two Furrow Reversible PloughDocument4 pagesDesign and Modelling of Shaft of Two Furrow Reversible PloughAnonymous PufNjgNo ratings yet

- 821.study of EffeDocument6 pages821.study of EffeVashishth KushwahaNo ratings yet

- Design Analysis of Rotary Tillage Tool Components by CAD-tool: RotavatorDocument6 pagesDesign Analysis of Rotary Tillage Tool Components by CAD-tool: RotavatorVishal NarNo ratings yet

- Design & Fabrication of 360° Flexible Drilling Machine: ArticleDocument5 pagesDesign & Fabrication of 360° Flexible Drilling Machine: ArticleDeep PatelNo ratings yet

- 5Document22 pages5xhtan0001No ratings yet

- Calculation of The Power Requirement For Soil Cutting by Rotary Tool BladeDocument8 pagesCalculation of The Power Requirement For Soil Cutting by Rotary Tool BladeVIJAY MOURYANo ratings yet

- JETIRreviewDocument6 pagesJETIRreviewDevadutta HatiNo ratings yet

- Design and Analysis of Drum Lathe For Manufacturing Large-Scale Optical Microstructured Surface and Load Characteristics of Aerostatic SpindleDocument6 pagesDesign and Analysis of Drum Lathe For Manufacturing Large-Scale Optical Microstructured Surface and Load Characteristics of Aerostatic SpindleN. P. JAGANNo ratings yet

- On The Performance Analysis of Savonius Rotor With Twisted BladesDocument13 pagesOn The Performance Analysis of Savonius Rotor With Twisted BladesSatya PrakashNo ratings yet

- Vibrational Analysis of Flexible Coupling by Considering UnbalanceDocument11 pagesVibrational Analysis of Flexible Coupling by Considering UnbalanceMuhammad TabishNo ratings yet

- Fabrication of Automatic Drilling & Tapping MachineDocument5 pagesFabrication of Automatic Drilling & Tapping MachineIJRASETPublicationsNo ratings yet

- Conveyor Pulley Failure Analysis PDFDocument3 pagesConveyor Pulley Failure Analysis PDFriysallNo ratings yet

- Gear BoxDocument7 pagesGear BoxshivamNo ratings yet

- Torque Draft Force Requirement Rotary TillerDocument13 pagesTorque Draft Force Requirement Rotary Tillerbalasubramani krishnamurthiNo ratings yet

- Design and Manufacturing of Hydro Pulper - 1604658130Document7 pagesDesign and Manufacturing of Hydro Pulper - 1604658130vanhuuduc102031No ratings yet

- Final Year ProjectDocument23 pagesFinal Year ProjectKarthik SubramaniNo ratings yet

- Rotovator Blade DesignDocument7 pagesRotovator Blade DesignFrancis SalviejoNo ratings yet

- Computer Aided Design of Jaw CrusherDocument50 pagesComputer Aided Design of Jaw Crusherdinesh_ypkNo ratings yet

- Ravikumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 988 012043Document15 pagesRavikumar 2020 IOP Conf. Ser. Mater. Sci. Eng. 988 012043ko koNo ratings yet

- Analysis of Balancing of Unbalanced Rotors and Long Sfts Using GUI MATLAB - 46862Document31 pagesAnalysis of Balancing of Unbalanced Rotors and Long Sfts Using GUI MATLAB - 46862Gustavo da Silva100% (1)

- A Study On Wear Characteristics of ADI Rotavator BladesDocument7 pagesA Study On Wear Characteristics of ADI Rotavator Bladesrahul kumarNo ratings yet

- Mse 147 1 012009Document7 pagesMse 147 1 012009Irina BESLIUNo ratings yet

- Force Analysis of Metal Sheet in Bending Operation On Sheet Bending Machine IJERTV4IS010115 PDFDocument4 pagesForce Analysis of Metal Sheet in Bending Operation On Sheet Bending Machine IJERTV4IS010115 PDFAnnada Prasad MoharanaNo ratings yet

- Optimization of Savonius Rotor For Wind TurbineDocument6 pagesOptimization of Savonius Rotor For Wind Turbinejun005No ratings yet

- Design and Fabrication of Pneumatic Sheet Metal Cutting and Pneumatic Sheet Metal Bending MachineDocument6 pagesDesign and Fabrication of Pneumatic Sheet Metal Cutting and Pneumatic Sheet Metal Bending MachineAnonymous kw8Yrp0R5rNo ratings yet

- Design of Machine Tool SpindleDocument5 pagesDesign of Machine Tool SpindleKarthik Varma PNo ratings yet

- Design, Modeling and Analysis of Rotavator Blade: KeywordsDocument20 pagesDesign, Modeling and Analysis of Rotavator Blade: KeywordsAhsan JunaidNo ratings yet

- 43 Wang - 2017 - J. - Phys. - Conf. - Ser. - 916 - 012010Document8 pages43 Wang - 2017 - J. - Phys. - Conf. - Ser. - 916 - 012010PrashantNo ratings yet

- Design Modification of Cluster Gear Shaft of Synchromesh Gearbox in TractorDocument14 pagesDesign Modification of Cluster Gear Shaft of Synchromesh Gearbox in TractorIJRASETPublicationsNo ratings yet

- Modelling and Analysis of Gas Turbine BLDocument5 pagesModelling and Analysis of Gas Turbine BLHaneen Safwat ArabNo ratings yet

- Design & Analysis of Mono Composite Leaf Spring: Volume 2 Issue2 PP 103-107 May 2013Document5 pagesDesign & Analysis of Mono Composite Leaf Spring: Volume 2 Issue2 PP 103-107 May 2013Rajesh Kumar PNo ratings yet

- Wind Turbine Gearbox Technologies: April 2010Document19 pagesWind Turbine Gearbox Technologies: April 2010Adarsh ShindeNo ratings yet

- A Review Paper On Design, Optimization and Testing of Special Purpose Worm and Worm Wheel Gearbox For Butterfly Valve OperationDocument3 pagesA Review Paper On Design, Optimization and Testing of Special Purpose Worm and Worm Wheel Gearbox For Butterfly Valve Operationess_mnsNo ratings yet

- Rotary-Axial Spindles For Ultra-Precision MachiningDocument4 pagesRotary-Axial Spindles For Ultra-Precision MachiningphuongdxNo ratings yet

- Ijetr011305 PDFDocument4 pagesIjetr011305 PDFerpublicationNo ratings yet

- Design of Involute Spur Gears With Asymmetric Teeth & Direct Gear DesignDocument4 pagesDesign of Involute Spur Gears With Asymmetric Teeth & Direct Gear DesignPushparaj VigneshNo ratings yet

- Bending MachineDocument4 pagesBending MachineRahul RathodNo ratings yet

- Parametric Analysis of Gear Hobbing Process by Using Tin and Alcrn Coated M 35 HobDocument7 pagesParametric Analysis of Gear Hobbing Process by Using Tin and Alcrn Coated M 35 HobpruthvirajNo ratings yet

- IADC/SPE 128458 Asymmetric Vibration Damping Tool - Small Scale Rig Testing and Full Scale Field TestingDocument29 pagesIADC/SPE 128458 Asymmetric Vibration Damping Tool - Small Scale Rig Testing and Full Scale Field TestingGhazi MhedhbiNo ratings yet

- Optimization of Planetary Gear Box For High Reduction RatioDocument12 pagesOptimization of Planetary Gear Box For High Reduction RatioNovriansyah BrianNo ratings yet

- Design and Analysis of 22 Ton Class Excavator Swing Braking SystemDocument6 pagesDesign and Analysis of 22 Ton Class Excavator Swing Braking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- GUI Matlab BalancingDocument31 pagesGUI Matlab BalancingSathish KumarNo ratings yet

- Design and Dynamic Analysis of Flywheel: December 2016Document7 pagesDesign and Dynamic Analysis of Flywheel: December 2016atiaNo ratings yet

- Fabrication of Multicrop CutterDocument6 pagesFabrication of Multicrop CutterSanthana Bharathi50% (2)

- Dobreva 2022 IOP Conf. Ser. Mater. Sci. Eng. 1220 012025Document6 pagesDobreva 2022 IOP Conf. Ser. Mater. Sci. Eng. 1220 012025King PipiNo ratings yet

- Development of Turn-Milling in Conventional Lathe Machine: Journal of Ocean, Mechanical and Aerospace, Vol.53Document8 pagesDevelopment of Turn-Milling in Conventional Lathe Machine: Journal of Ocean, Mechanical and Aerospace, Vol.53Anugerah Raya PratamaNo ratings yet

- Theoretical Analysis of Multi Way PowerDocument4 pagesTheoretical Analysis of Multi Way PowerTanjid Al TajimNo ratings yet

- A Review Paper On Design, Modelling and Analysis of Shaft of Two Furrow Reversible PloughDocument3 pagesA Review Paper On Design, Modelling and Analysis of Shaft of Two Furrow Reversible PloughfasikawNo ratings yet

- IJETR021761 LibreDocument3 pagesIJETR021761 LibreLindgrenNo ratings yet

- Bearings: A Tribology HandbookFrom EverandBearings: A Tribology HandbookM. J. NealeRating: 3 out of 5 stars3/5 (8)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Head of Engineering Generic JDDocument5 pagesHead of Engineering Generic JDrandombrandon111No ratings yet

- Mot Spur GearDocument8 pagesMot Spur GearRavi MirzaNo ratings yet

- T & D 1500T TXDocument1 pageT & D 1500T TXRavi MirzaNo ratings yet

- SAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsDocument5 pagesSAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsRavi MirzaNo ratings yet

- 5.seal Assembly MethodDocument1 page5.seal Assembly MethodRavi MirzaNo ratings yet

- Is.3342.1998 SHOVELDocument18 pagesIs.3342.1998 SHOVELRavi MirzaNo ratings yet

- 3.new GENRATION SAP SEALSDocument21 pages3.new GENRATION SAP SEALSRavi MirzaNo ratings yet

- 0.business Profile 2014Document4 pages0.business Profile 2014Ravi MirzaNo ratings yet

- TextDocument1 pageTextRavi MirzaNo ratings yet

- Spoken English Guru Ebook 1 PDFDocument400 pagesSpoken English Guru Ebook 1 PDFVince87% (182)

- Specification Agriculture ImplimentsDocument25 pagesSpecification Agriculture ImplimentsRavi MirzaNo ratings yet

- List of Distt. Sangrur NRI PDFDocument14 pagesList of Distt. Sangrur NRI PDFRavi MirzaNo ratings yet

- Zapi FC2086 Codes PDFDocument8 pagesZapi FC2086 Codes PDFGabriel BravoNo ratings yet

- 04-68350A Manual CCN DM01-DI01 PDFDocument47 pages04-68350A Manual CCN DM01-DI01 PDFtaha50% (2)

- Equipment TP MAV AEL Oil Supply UnitDocument1,392 pagesEquipment TP MAV AEL Oil Supply UnitMuhammad Hasbi AsidiqiNo ratings yet

- Diagrama 444EDocument2 pagesDiagrama 444Echikoo499No ratings yet

- Millat Tractors Limited Report Group Ali Hamza Ali Asghar Usman AhmadDocument13 pagesMillat Tractors Limited Report Group Ali Hamza Ali Asghar Usman AhmadUSABAHNo ratings yet

- Donghwa Tanabe H SeriesDocument95 pagesDonghwa Tanabe H Seriesjohn smith0% (1)

- 2 PDFDocument40 pages2 PDFCerasela GeorgescuNo ratings yet

- Rth6360d 5 2 Programmable Thermostat ManualDocument40 pagesRth6360d 5 2 Programmable Thermostat ManualcgedmanNo ratings yet

- Man TGSDocument2 pagesMan TGSPaul CiobanuNo ratings yet

- Servo Motor - RushikeshDocument17 pagesServo Motor - RushikeshRushikesh wavare100% (2)

- Short Manual: Vision Sensor With Built-In Touch ScreenDocument65 pagesShort Manual: Vision Sensor With Built-In Touch ScreenJavier AyzaNo ratings yet

- Figure 1. Schematic - Ev-100Zx SCR Control For Traction MotorDocument43 pagesFigure 1. Schematic - Ev-100Zx SCR Control For Traction MotorMario AguirreNo ratings yet

- Summit X: With Expert PackageDocument2 pagesSummit X: With Expert PackagealexNo ratings yet

- Signal Line 256 Gray Level 3 Channel Constant Current LED Driver ICDocument8 pagesSignal Line 256 Gray Level 3 Channel Constant Current LED Driver ICsteven MelgarejoNo ratings yet

- Polaris 180 Repair ManualDocument40 pagesPolaris 180 Repair ManualPool Supply Sales100% (2)

- Helion Invictus 10 MT: Owner's ManualDocument36 pagesHelion Invictus 10 MT: Owner's ManualalexgkkNo ratings yet

- Bd9397efv e PDFDocument30 pagesBd9397efv e PDFshafiuddin7326No ratings yet

- G Drive Engines ABATODocument14 pagesG Drive Engines ABATObely nurdiansyahNo ratings yet

- VEG2000 - Manual - ENG - V4.6Document49 pagesVEG2000 - Manual - ENG - V4.6ahmed morsyNo ratings yet

- Connecting Push Buttons To MicrocontrollerDocument1 pageConnecting Push Buttons To MicrocontrollerSaritechNo ratings yet

- Engine Valve Lash - Inspect/Adjust: Controlli e RegistrazioniDocument4 pagesEngine Valve Lash - Inspect/Adjust: Controlli e RegistrazionijamcaNo ratings yet

- 0000003221Document3 pages0000003221Ael Ch100% (2)

- Cng-Booster: Lifetime Business PartnerDocument4 pagesCng-Booster: Lifetime Business PartnerKASIMNo ratings yet

- 2008 85 SX SW ChassisDocument28 pages2008 85 SX SW ChassischarlesNo ratings yet

- CX2032MM Rev1Document301 pagesCX2032MM Rev1totalofficesupportNo ratings yet

- Operation Tables: User ManualDocument19 pagesOperation Tables: User ManualМаксим Остапенко100% (1)

- OMM DozerDocument238 pagesOMM DozerAmir Bambang YudhoyonoNo ratings yet

- Filtro Carbon ActivoDocument1 pageFiltro Carbon ActivoZzmangostazZNo ratings yet

- ICO4SDocument12 pagesICO4SGopinath SekarNo ratings yet