Professional Documents

Culture Documents

Malleable Iron Flanges, Pipe Fittings, and Valve Parts For Railroad, Marine, and Other Heavy Duty Service at Temperatures Up To 650°F (345°C)

Uploaded by

william_m08Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Malleable Iron Flanges, Pipe Fittings, and Valve Parts For Railroad, Marine, and Other Heavy Duty Service at Temperatures Up To 650°F (345°C)

Uploaded by

william_m08Copyright:

Available Formats

Designation: A 338 – 84 (Reapproved 1998)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Malleable Iron Flanges, Pipe Fittings, and Valve Parts for

Railroad, Marine, and Other Heavy Duty Service at

Temperatures Up to 650°F (345°C)1

This standard is issued under the fixed designation A 338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Materials and Manufacture

1.1 This specification covers malleable iron flanges, pipe 4.1 The sizes, shapes, and dimensions of the fittings, cov-

fittings, and valve parts, including parts to be assembled for use ered by ANSI B16.3 shall conform to the requirements therein

in railroad, marine, and other heavy duty service applications specified.

where fittings furnished in accordance with American National 4.2 Screwed pipe fittings, unions, union fittings, and globe

Standard for Malleable Iron Threaded Fittings, Class 150 and and angle valves that are covered by the various standards and

300 (ANSI B16.3) are not considered adequate. recommended practices as issued by the Association of Ameri-

1.2 Service shall include up to 650°F (345°C).2 can Railroads shall conform to the requirements therein speci-

fied.

2. Referenced Documents 4.3 All pipe threads, unless otherwise specified, shall be in

2.1 ASTM Standards: accordance with ANSI B2.1. (Standards for pipe threads are

A 47 Specification for Ferritic Malleable Iron Castings3 also available in Section VI of Screw-Thread Standards for

A 153 Specification for Zinc Coating (Hot-Dip) on Iron and Federal Services.)

Steel Hardware4 4.4 Zinc coatings on fittings which are required to be

2.2 American National Standards: galvanized by the hot-dip process shall conform to the require-

B 2.1 Pipe Threads5 ments for Class A castings as prescribed in Specification A 153,

B 16.3 Malleable Iron Threaded Fittings, Class 150 and except on surfaces where it is the practice to machine after

3005 galvanizing.

2.3 Other Standards:

Hand Book H28, Section VI, Screw-Thread Standards for 5. Manufacture Control and Records

Federal Services, 19446 5.1 The iron shall be produced under constant control of

SP-25-1936 Standard Marking System for Valves, Fittings, chemical composition and physical properties. Records of the

Flanges, and Unions7 chemical composition of the iron and of the physical properties

of the test specimens shall be systematically made and main-

3. Process tained.

3.1 The castings shall be made in accordance with Specifi-

cation A 47. 6. Tests

6.1 Tests shall be made when required by the specifications

listed herein.

1

This specification is under the jurisdiction of ASTM Committee A-4 on Iron

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable Iron 7. Certification

Castings. 7.1 The manufacturer shall be prepared to certify, upon

Current edition approved March 8, 1984. Published May 1984. Originally

published as A 338 – 54. Last previous edition A 338 – 61 (1977).

request of the purchaser, that his product conforms to the

2

Based on Lauriston C. Marshall and George F. Sommer, “Stress Rupture requirements of this specification.

Properties of Malleable Iron at Elevated Temperatures,” Proceedings, Am. Soc.

Testing Mats., Vol 58, 1958, p. 733. 8. Product Marking

3

Annual Book of ASTM Standards, Vol 01.02.

4

Annual Book of ASTM Standards, Vol 01.06.

8.1 The castings shall be marked with the manufacturer’s

5

Available from American National Standards Institute, 11 West 42nd St., 13th name or trademark.

Floor, New York, NY 10036. 8.2 Malleable iron products conforming to the standards of

6

Available from National Institute of Standards and Technology, U.S. Depart- the Manufacturers Standardization Society of the Valve and

ment of Commerce, Washington, DC 20234.

7

Available from the Manufacturers Standardization Society of the Valve and Fittings Industry shall be marked in accordance with the

Fittings Industry, 5203 Leesburg Pike, Suite 502, Falls Church, VA 22041. SP-25-1936 of that Society. Malleable iron products furnished

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

A 338

in accordance with the standards issued by the American 9. Keywords

Standards Association or by the Association of American

9.1 flanges; heavy duty service; malleable iron; marine

Railroads shall be marked as specified in the respective

service; pipe fittings; railroad service; valve parts

standards.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

You might also like

- Astm A484-A484m-00Document12 pagesAstm A484-A484m-00Razvan Andrei GiuscaNo ratings yet

- Astm A338-14 PDFDocument2 pagesAstm A338-14 PDFromerobernaNo ratings yet

- Astm 401Document4 pagesAstm 401JOSEPH REFUERZONo ratings yet

- Astm f1554 Grade 36Document9 pagesAstm f1554 Grade 36AngelicaNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Astm c172-99 Sampling Freshly Mix Concrete PDFDocument3 pagesAstm c172-99 Sampling Freshly Mix Concrete PDFVíctor M Fernández JiménezNo ratings yet

- Astm A328Document2 pagesAstm A328william_m08100% (1)

- SCO - GOLDBULLION - CIF HI Switz Thai 12% 9 3Document4 pagesSCO - GOLDBULLION - CIF HI Switz Thai 12% 9 3Luis Fernando Parra Zapata Medellín Líderes INo ratings yet

- Term Loan ProcedureDocument5 pagesTerm Loan ProcedureHardik Sharma100% (1)

- A338 Steel StandardDocument2 pagesA338 Steel StandardguilhermehsssNo ratings yet

- Steel Wire, Cold-Drawn For Mechanical SpringsDocument4 pagesSteel Wire, Cold-Drawn For Mechanical SpringsARAVIND PATILNo ratings yet

- ASTM A276-98bDocument7 pagesASTM A276-98bNadhiraNo ratings yet

- A231A231Document4 pagesA231A231MohamedNo ratings yet

- ASTM A 350 - A 350M - 04 LowCarbon ForgingsDocument8 pagesASTM A 350 - A 350M - 04 LowCarbon ForgingsSaravanan VaradarajanNo ratings yet

- A 108 - 03 - Qtewoa - PDFDocument7 pagesA 108 - 03 - Qtewoa - PDFHanifiantoNo ratings yet

- Wrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDocument5 pagesWrought Carbon Steel Sleeve-Type Pipe Couplings: Standard Specification ForDeen ew100% (1)

- Chromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForHoem ITNo ratings yet

- Astm 401 PDFDocument4 pagesAstm 401 PDFJOSEPH REFUERZONo ratings yet

- Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding FittingsDocument4 pagesSeamless and Welded Unalloyed Titanium and Titanium Alloy Welding FittingsGreg YeeNo ratings yet

- Astm A 227 A227m 2006Document4 pagesAstm A 227 A227m 2006Aadhya engineering ServicesNo ratings yet

- A31 PDFDocument5 pagesA31 PDFAravind BabuNo ratings yet

- Astm A350Document8 pagesAstm A350nse mcx100% (1)

- Steel Wire, Oil-Tempered Carbon Valve Spring Quality: Standard Specification ForDocument4 pagesSteel Wire, Oil-Tempered Carbon Valve Spring Quality: Standard Specification ForErick ERICKNo ratings yet

- Astm A264 03Document6 pagesAstm A264 03Muhammad Mehedi HasanNo ratings yet

- Astm A108-3Document8 pagesAstm A108-3Shahid RehmanNo ratings yet

- Steel Wire, Plain, For Concrete ReinforcementDocument4 pagesSteel Wire, Plain, For Concrete ReinforcementedwinbadajosNo ratings yet

- Astm A108Document4 pagesAstm A108Emir AkçayNo ratings yet

- Heat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint BarsDocument3 pagesHeat-Treated Carbon Steel Joint Bars, Microalloyed Joint Bars, and Forged Carbon Steel Compromise Joint BarsJuanNo ratings yet

- Standard ASTM A 470-01Document6 pagesStandard ASTM A 470-01Dumitru PascuNo ratings yet

- A 228 - A 228M - 00 Qtiyoc0wma - PDFDocument4 pagesA 228 - A 228M - 00 Qtiyoc0wma - PDFRafael GarciaNo ratings yet

- Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsDocument8 pagesCarbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing For Piping ComponentsMaxNo ratings yet

- Stainless Chromium-Nickel Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium-Nickel Steel-Clad Plate: Standard Specification ForErick ERICKNo ratings yet

- Astm A756 PDFDocument3 pagesAstm A756 PDFCristian OtivoNo ratings yet

- Electric Fusion Welded UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy PipeDocument5 pagesElectric Fusion Welded UNS N08020, UNS N08024, and UNS N08026 Nickel Alloy PipeChetan PawarNo ratings yet

- Astm A234-A234m-99Document8 pagesAstm A234-A234m-99NadhiraNo ratings yet

- Astm A47 47MDocument5 pagesAstm A47 47McherrerarNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification ForMaxNo ratings yet

- Steel Rivets and Bars For Rivets, Pressure VesselsDocument4 pagesSteel Rivets and Bars For Rivets, Pressure Vesselsrohit kumarNo ratings yet

- Astm A490 1979Document10 pagesAstm A490 1979dharlanuctcomNo ratings yet

- A 350 Â " A 350M Â " 02 - QTM1MC0WMKEDocument8 pagesA 350 Â " A 350M Â " 02 - QTM1MC0WMKEhNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument11 pagesCarbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothMartuaHaojahanSaragihSidabutarNo ratings yet

- ASTM A227 A227M - 06 Steel Spring WireDocument4 pagesASTM A227 A227M - 06 Steel Spring WireLesley EsparzaNo ratings yet

- A500 PDFDocument5 pagesA500 PDFGuilherme SchenkelNo ratings yet

- Seamless Copper-Nickel Pipe and Tube: Standard Specification ForDocument6 pagesSeamless Copper-Nickel Pipe and Tube: Standard Specification ForGreg YeeNo ratings yet

- Carbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument12 pagesCarbon and Alloy Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothCarlos Raul Caballero LeonNo ratings yet

- Stainless Steel Bars and Shapes: Standard Specification ForDocument7 pagesStainless Steel Bars and Shapes: Standard Specification ForBenjamin OsccoNo ratings yet

- Astm A707 PDFDocument5 pagesAstm A707 PDFCristian OtivoNo ratings yet

- Astm A 502 - 03Document4 pagesAstm A 502 - 03Ahmad KhreisatNo ratings yet

- Astm A216Document8 pagesAstm A216Hamdan AtaminiNo ratings yet

- A 877 - A877mDocument4 pagesA 877 - A877mAon HemmatadNo ratings yet

- ASTM A 82 - Steel Wire, Plain, For Concrete Reinforcement1 PDFDocument4 pagesASTM A 82 - Steel Wire, Plain, For Concrete Reinforcement1 PDFjojeecaresNo ratings yet

- Astm B164 1998 PDFDocument9 pagesAstm B164 1998 PDFel_apache10No ratings yet

- Stainless Chromium Steel-Clad Plate: Standard Specification ForDocument5 pagesStainless Chromium Steel-Clad Plate: Standard Specification ForErick ERICKNo ratings yet

- A 395 - A 395M - 99 QTM5NS9BMZK1TQDocument8 pagesA 395 - A 395M - 99 QTM5NS9BMZK1TQserkandmNo ratings yet

- Copper-Brazed Steel Tubing: Standard Specification ForDocument4 pagesCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- A 53 - A 53m - 01 QtuzltaxDocument4 pagesA 53 - A 53m - 01 QtuzltaxRene HernandezNo ratings yet

- Hot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceDocument11 pagesHot Isostatically-Pressed Stainless Steel Flanges, Fittings, Valves, and Parts For High Temperature ServiceProduction DepartmentNo ratings yet

- Chromium-Vanadium Alloy Steel Spring Wire: Standard Specification ForDocument4 pagesChromium-Vanadium Alloy Steel Spring Wire: Standard Specification Foripkm123No ratings yet

- Astm A320Document8 pagesAstm A320RGanjvarNo ratings yet

- A485 PDFDocument4 pagesA485 PDFProduction DepartmentNo ratings yet

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification Forrohit kumarNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- C 0150Document7 pagesC 0150william_m08No ratings yet

- A336A336Document7 pagesA336A336Andres Camilo BenitezNo ratings yet

- Flat-Rolled Electrical Steels For Magnetic ApplicationsDocument4 pagesFlat-Rolled Electrical Steels For Magnetic Applicationswilliam_m08No ratings yet

- Seamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceDocument8 pagesSeamless Ferritic Alloy-Steel Pipe For High-Temperature ServiceSofiaJabadanEspulgarNo ratings yet

- MSS SP 83 01 Class 3000 Steel Pipe Unions Socket Welding and Threaded.Document12 pagesMSS SP 83 01 Class 3000 Steel Pipe Unions Socket Welding and Threaded.william_m08No ratings yet

- Astm ADocument32 pagesAstm AKhaled FatnassiNo ratings yet

- Astm A139Document6 pagesAstm A139william_m08100% (1)

- A 479 PDFDocument8 pagesA 479 PDFwilliam_m08No ratings yet

- A 447Document4 pagesA 447william_m08No ratings yet

- Teacher's Printable Activities for Top Notch ExtensionDocument3 pagesTeacher's Printable Activities for Top Notch ExtensionCristina SoaresNo ratings yet

- Asme B16.25Document22 pagesAsme B16.25william_m08No ratings yet

- Dear MarinaDocument1 pageDear Marinawilliam_m08No ratings yet

- Rotina ExplosaoDocument1 pageRotina Explosaowilliam_m08No ratings yet

- OPP-20 Rev 0 RMU For Housing SocietyDocument4 pagesOPP-20 Rev 0 RMU For Housing SocietyOmer Abdul RazzaqNo ratings yet

- RTC Dismissal Upheld in Corporate Veil Piercing CaseDocument2 pagesRTC Dismissal Upheld in Corporate Veil Piercing CaseRaymond ChengNo ratings yet

- Mr. Mohamed Shabaaz PO 2297, KHOBAR 31952 31952 AL KHOBAR Saudi ArabienDocument5 pagesMr. Mohamed Shabaaz PO 2297, KHOBAR 31952 31952 AL KHOBAR Saudi ArabienMohammed Mukram AliNo ratings yet

- Entrance Exam Questions on Political ScienceDocument12 pagesEntrance Exam Questions on Political ScienceKanki RajeshNo ratings yet

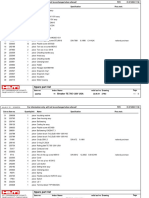

- Spare Part List: Breaker TE 705 120V USADocument7 pagesSpare Part List: Breaker TE 705 120V USAJoseLuisCarrilloMenaNo ratings yet

- (Labor 2 - Atty. Nolasco) : G.R. No. 196539 Perez, J. Digest By: IntiaDocument2 pages(Labor 2 - Atty. Nolasco) : G.R. No. 196539 Perez, J. Digest By: IntiaRaymund CallejaNo ratings yet

- Rivac V PeopleDocument17 pagesRivac V PeopleLoren yNo ratings yet

- Ngaf M5300Document2 pagesNgaf M5300sigit pamungkasNo ratings yet

- Mission 2 Contact List Telephone Numbers 20200331Document42 pagesMission 2 Contact List Telephone Numbers 20200331Dawood KhanNo ratings yet

- PK Kunju Sahib: The Beacon of Empowerment Through EducationDocument7 pagesPK Kunju Sahib: The Beacon of Empowerment Through EducationJisha CVNo ratings yet

- Court Martial Jurisdiction Over Police Officer RemainsDocument7 pagesCourt Martial Jurisdiction Over Police Officer RemainsLourd CellNo ratings yet

- About The Canon - Encyclopaedia Judaica (Vol. III)Document17 pagesAbout The Canon - Encyclopaedia Judaica (Vol. III)Arllington R. F. da CostaNo ratings yet

- Income Taxation and MCIT RulesDocument4 pagesIncome Taxation and MCIT RulesMJNo ratings yet

- Court Rules Arrest of Vessel a Covered RiskDocument3 pagesCourt Rules Arrest of Vessel a Covered Riskretep69phNo ratings yet

- Meralco Vs CIRDocument22 pagesMeralco Vs CIRmifajNo ratings yet

- Central Board of Direct Taxes, E-Filing Project: ITR 1 - Validation Rules For AY 2021-22Document15 pagesCentral Board of Direct Taxes, E-Filing Project: ITR 1 - Validation Rules For AY 2021-22MOHAMMED LayeeqNo ratings yet

- Virtual AEM 7.0.0.0 Installation GuideDocument17 pagesVirtual AEM 7.0.0.0 Installation GuideFrancis ArzapaloNo ratings yet

- TR 101968 T1V1Document128 pagesTR 101968 T1V1euric82No ratings yet

- LAWS1052 Legal Research NotesDocument17 pagesLAWS1052 Legal Research NotesBaar SheepNo ratings yet

- NA To SS en 1993-1!1!2010 - PreviewDocument8 pagesNA To SS en 1993-1!1!2010 - Previewiniyan 1998No ratings yet

- Meghans LawDocument4 pagesMeghans LawNick MuhohoNo ratings yet

- Verilink 8108 - 8508-Manual-revBDocument221 pagesVerilink 8108 - 8508-Manual-revBdpnswNo ratings yet

- Sonal Project (Transfer of Property Act)Document15 pagesSonal Project (Transfer of Property Act)Handcrafting BeautiesNo ratings yet

- Andres V. MajaduconDocument2 pagesAndres V. MajaduconLeidi Chua BayudanNo ratings yet

- Judicial AttitudeDocument4 pagesJudicial Attitudeanubhav_singh_26100% (1)

- RRL For Men and Women in The FamilyDocument12 pagesRRL For Men and Women in The FamilyIvan LuzuriagaNo ratings yet

- Shell Price Change and Comparision q1 2017Document3 pagesShell Price Change and Comparision q1 2017rishiNo ratings yet

- Ms Ram Kumar Agrawal Engineers PVT LTD V State of Odisha 04 March 2022 411261Document20 pagesMs Ram Kumar Agrawal Engineers PVT LTD V State of Odisha 04 March 2022 411261Ankita RathiNo ratings yet