Professional Documents

Culture Documents

Design criteria and loads for civil structures

Uploaded by

myoaung28296Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design criteria and loads for civil structures

Uploaded by

myoaung28296Copyright:

Available Formats

DESIGN CRITERIA OF CIVIL AND BUILDING STRUCTURES

1. GENERAL

In this report, design criteria to be used in analysis and design for civil and building structures

will be discussed.

There are two types of structures included in the scope of project concerned with structural

design of civil structures.

▪ Building structures

o Reinforced Concrete Structure

o Structural Steel Structure

▪ Electrical Structures

o Super Structure

o Sub-Structure

▪ Earth Retaining Structure

2. ANALYSIS AND DESIGN

For analysis and design of building structures, computer program that based on finite element

method such as Etabs Integrated Building Design Software will be used.

For super structure of electrical structures, computer aided program will be used for analysis.

But analysis of electrical structure foundation (Sub-Structure), safer and conservative

analytical method will be used.

For bearing capacity checking and pile capacity checking based on geotechnical properties,

reaction values calculated based on Allowable Stress Method will be used.

For external stability checking for earth retaining structure (such as sliding, overturning),

Allowable Stress Method will be used. That means ASD load combinations will be used in

stability checking for earth retaining structure.

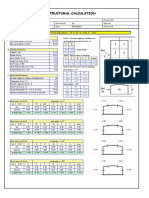

For design of reinforced concrete members, the design code to be followed is as below.

Type of R.C Member Design Code

Column, Beam, Wall, Slab ACI 318-08

Composite Beam ACI 360-08

Pile Capacity (Material Strength) ACI 543-08

For design of structural steel members, the design code to be followed is as below.

Type of Structural Steel Member Design Code

Column, Beam AISC LRFD 93, AISC ASD 89

3. DESIGN LOADS

The following design loads shall be taken into account for structural calculation of

foundations, columns, girders & beams of the civil and building structures.

3.1 Dead Loads

Dead or gravity loads are loads produced by the self-weight of the building with construction

materials and fixed equipment and machineries such as plumbing fixtures, electrical

equipment, and ventilation and air conditioning fans and machineries.

Unit weight of major construction materials are as follows.

Material Unit Weight Unit

Reinforced Concrete 24.0 kN/m3

Plain Concrete 23.0 kN/m3

Structural Steel 78.5 kN/m3

Brick Wall (150mm thick) 3.0 kN/m2

Ceramic Tile 1.1 kN/m2

Finishing Boards 0.3 kN/m2

Natural Soil 18.0 kN/m3

3.2 Live Loads

Live loads on the substation building are defined as loads due to occupancy use, and

loads produced by maintenance workers, equipment, machinery, and appliances.

Design live loads for the substation are shown on the following Table.

Design Live Load for Substation Building

Design Load (N/m2)

Rooms Girder, Column and

Slab and Beam Earthquake

Foundation

- Control room

- Protection and Relay room 4900 2400 1300

- Telecommunication room

Battery charger room 4900 2400 1300

Battery Room 3900 2400 1600

Office, Meeting room 2900 1800 800

Toilet, Kitchen 1800 1300 600

Employer’s Project Office

(Gust House)

- Living room 1800 1300 600

-Dining room

- Bed room

3.3 Equipment Loads

Equipment loads shall be calculated based upon the actual weight and size of the equipment

and parts to be placed on the floors during dismantling. The design loads shall comply with the

minimum of the manufactory specified load requirements. Equipment loading data shall be

attached in each detail design.

3.4 Construction and Maintenance Loads

All construction loads and anticipated maintenance loads shall be estimated for structural

design of building structure based on the construction method and the way of maintenance

including machinery and devices.

3.5 Wind Loads

Wind loads shall be estimated in accordance with the provisions of ASCE 07-10 Chapter 26

Wind load and/ or MNBC PART3 Structural Design-Section 3.3 Wind Design Criteria. The

table below is extracted from MNBC PART3 as a reference for basic wind speed to be used in

analysis and design of all civil structures.

Basic Wind Speed (3 sec Gust Wind Speed)

Basic Wind Speed

Sr. City

(mph)

1 Bago 80

2 Bhamo 70

3 Bogalay 100

4 Chauk 70

5 Dawei 90

6 Falam 70

7 Hakha 90

8 Henzada 90

9 Homalin 50

10 Hpa-An 70

11 Kale 70

12 Kawthaung 90

13 Kengtung 70

14 Kyaukpyu 130

15 Lashio 70

16 Loikaw 70

17 Magwe 70

18 Mandalay 80

19 Mawlamyine 90

20 Meiktila 70

21 Monywa 70

22 Muse 70

23 Myeik 90

24 Myitkyina 70

25 Nansam 70

26 Naypyitaw 70

27 Pakokku 70

28 Pathein 100

29 Putao 70

30 Pyay 70

31 Sittwe 130

32 Taungyi 70

33 Thandwe 130

34 Yangon 100

35 Ye 90

36 Yenangyaung 70

According to MNBC basic wind speed table, basic wind speed for two site locations can be

predicted as table below.

Site Basic Wind Speed

Phayargyi site (Bago) 80mph

Hlaingtharyar site (Kaba-Aye) 100mph

The basic design wind speed predicted in the table above is identical with wind speed suggested

in section 13.1.4.

3.6 Seismic Loads

Seismic Loads for building structures shall be estimated in accordance with the provisions of

ASCE 07-10 Chapter 11– Seismic loads and/or MNBC PART3 Structural Design-Section3.4

Seismic Design Criteria and Design.

According to MNBC which follow ASCE 7-10 for seismic load, Seicmic Zone is classified

based on the values of 0.2 second spectral response acceleration and 2 second spectral response

acceleration as shown in figures below.

Figure 3.4.1.1: Maximum Considered Earthquake Ground Motion for 1 Sec Spectral Response Acceleration at

2% Probability in 50 Years with 5% Critical Damping, Site Class B

Figure 3.4.1.3: Maximum Considered Earthquake Ground Motion for 0.2 Sec Spectral Response Acceleration

at 2% Probability in 50 Years with 5% Critical Damping, Site Class B

Seismic acceleration classified in above two figures can be predicted as a table form below.

Table 3.4.1- 0.2s (Ss) AND 1.0s (S1) SPECTRAL RESPONSE ACCELERATIONS

Sr. City/ Town Ss S1

1 Bagan 1.55 0.62

2 Bago (Pegu) 1.07 0.43

3 Bhamo 0.66 0.26

4 Coco Islands (Great Coco Island) 1.18 0.47

5 Dawei (Tavoy) 0.25 0.10

6 Hakha 1.87 0.75

7 Hpa-An (Pa-An) 0.74 0.30

8 Kengtung 1.32 0.52

9 Kyaukpyu (Kyaukphyu) 0.84 0.33

10 Labutta 0.64 0.26

11 Lashio 0.48 0.19

12 Loikaw 1.41 0.56

13 Magwe 1.45 0.58

14 Mandalay 2.01 0.80

15 Mawlamyine (Mawlamyaing) 0.74 0.30

16 Meiktila 2.07 0.83

17 Monywa 1.72 0.69

18 Myitkyina 1.70 0.68

19 Naypyitaw 1.32 0.53

20 Pakokku 1.54 0.61

21 Pathein (Bassein) 0.87 0.35

22 Putao 2.05 0.82

23 Pyay (prome) 0.80 0.32

24 Pyinmana 1.32 0.53

25 Sagaing 2.12 0.85

26 Shwebo 2.25 0.90

27 Sittwe (Akyab) 1.26 0.50

28 Taungoo 1.20 0.48

29 Taunggyi 1.69 0.68

30 Thandwe (Sandoway) 0.88 0.35

31 Yangon (Rangoon) 0.77 0.31

Note: Long-period transition period TL is to be taken as 6 sec.

According to MNBC Spectral Response Acceleration Table, spectral accelerations Ss and S1

for two site locations can be predicted as table below.

Spectrial Response Acceleration

Site

Ss (for0.2 sec) S1 (for 1 sec)

Phayargyi site (Bago) 1.55g 0.62g

Hlaingtharyar site (Yangon) 0.77g 0.31g

3.7 LOAD COMBINATIONS

Allowable Stress Design load combinations will be used for soil bearing capacity checking and

pile capacity based on geotechnical properties checking.

ASD load combinations according to MNBC are as fillow:

3.7.1 Load Combination for Allowable Stress Design Method

Loads listed herein shall be considered to act in the following combinations; whichever

produces the most unfavorable effect in the building, foundation, or structural member being

considered. Effects of one or more loads not acting shall be considered.

1. D+F

2. D+H+F+L+T

3. D + H + F + (Lr or R)

4. D + H + F + 0.75(L + T) + 0.75 (Lr or R)

5. D + H + F + (W or 0.7E)

6. D + H + F + 0.75(W or 0.7E) + 0.75L + 0.75 (Lr or R)

7. 0.6D + W + H

8. 0.6D + 0.7E + H

3.7.2 Load Combination for Ultimate Strength Design Method

Load Combinations Load combination shall be in accordance with the provisions of ASCE 7 and /or

MNBC PART3 Structural Design-Section3.2 Load Combination and Loads. Load combinations using

strength design or load and resistance factor design (MNBC) are as follows.

1. 1.4 (D + F)

2. 1.2(D+F + T) + 1.6(L + H) + 0.5 (Lr or R)

3. 1.2D + 1.6(Lr or R) + (L or 0.8W)

4. 1.2D + 1.6W + L + 0.5(Lr or R)

5. 1.2D + 1.0E + L

6. 0.9D + 1.6W + 1.6H

7. 0.9D + 1.0E + 1.6H

EXCEPTIONS:

1. The load factor on L in combinations (3), (4), and (5) is equal to 0.5 for all occupancies in which L0 in

Table 3.2.2 is less than or equal to 100psf, with the exception of garages or areas occupied as places

of public assembly.

Where:

- D: Dead load

- F: Load due to fluids with well-defined pressure and maximum heights,

- T: Self-straining force arising from contraction or expansion resulting from temperature change,

moisture change

- H: Load due to lateral earth pressure, ground water pressure or pressure of bulk materials

- E: earthquake load

- L: live load - Lr: roof live load

- R: rain load

- W: wind load

4. STRENGTH OF MATERIALS

4.1 Concrete Compressive Strength

The listed below properties will be used for building structures.

Cube Strength Cylinder Strength Structure/ Member

Usage of Concrete

(Fcu) (f'c)

Lean Concrete 15MPa 12.5MPa All structure

30MPa 25MPa For Buildings

Structural Concrete

35MPa 28MPa For Electrical Sub Structure

4.2 Steel Bars for reinforced concrete

Reinforcing bar of HRB400 (400MPa) equivalent to fy = 58ksi will be used in all reinforced

concrete members. For safety, in design reinforcing bar will be regarded as fy = 50ksi. In local

market, ASTM A615 (equivalent to fy = 60ksi) is sometime not available.

Chemical composition and physical properties of HBR400 reinforcing bars are predicted in

table below.

Technical data of the original chemical composition (%)

Grade

C Mn Si S P V

≤0.25 ≤1.60 ≤0.80 ≤0.045 ≤0.045 0.04-0.12

Physics capability

HRB400

Yield Strength(N/cm2) Tensile Strength(N/cm2) Elongation (%)

≥400 ≥570 ≥14

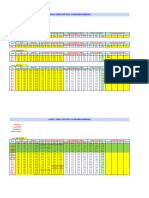

Reinforcing Bar Data

Theoretical Weight of 12M No of 12m Length

Diameter Cross Sectional Area

Weight Length Bar Bar in 1 ton

(mm) (mm2) (kg/m) (KG) Nos

6 28.27 0.222 2.664 375.38

8 50.27 0.395 4.74 210.97

10 78.54 0.617 7.404 135.06

12 113.10 0.888 10.656 93.84

14 153.90 1.21 14.52 68.87

16 201.10 1.58 18.96 52.74

18 254.50 2.00 24.00 41.67

20 314.20 2.47 29.64 33.74

22 380.10 2.98 35.76 27.96

25 490.90 3.85 46.2 21.65

28 615.80 4.83 57.96 17.25

32 804.20 6.31 75.72 13.21

36 1018.00 7.99 98.88 10.43

40 1257.00 9.87 118.44 8.44

4.3 Structural steel for Civil and Building structure

Local available steel members are JIS G3101 SS400 steel members.

JIS G3101 SS400 Steel

SS400 steel is the most commonly used hot-rolled structural steel (formerly known as SS41) in Japan,

and is called general structural rolled steel in JIS G3101. SS400 material is cheap and versatile, and

plays an important role in construction, bridges, civil engineering and mechanical equipment

structures. Its appearance includes round steel, flat steel (flat steel), steel plates, steel strips and

profiles.

Material SS400 Meaning

SS400 Steel meaning: SS is the abbreviation of Steel Structure, 400 means that the tensile strength is

≥ 400 MPa (≈ 58,000psi). 50ksi

SS41 Meaning: 41 means that the tensile strength is 41kgf/mm2 or higher.

Thus, it could be concluded that JIS G3101 SS400 steel is equivalent to ASTM A572 Grade 50 steel.

Limited shapes and sizes of structural members are available at local market. The table below shows

the available I-shaped and H-shaped steel members at local market.

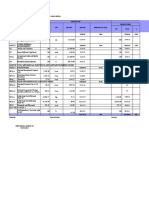

Local Available Steel Members

Section kg/m lb/ft H B Tf Tw r Remark

400 x 400 172.00 kg/m 115.6 lb/ft 400 400 21 13.0 22 Japan-H-Shape-RECNO-41

400 x 200 66.00 kg/m 44.4 lb/ft 400 200 13 8.0 16 Japan-H-Shape-RECNO-35

350 x 350 137.00 kg/m 92.1 lb/ft 350 350 19 12.0 20 Japan-H-Shape-RECNO-30

350 x 175 49.60 kg/m 33.3 lb/ft 350 175 11 7.0 14 Japan-H-Shape-RECNO-29

300 x 300 94.00 kg/m 63.2 lb/ft 300 300 15 10.0 18 Japan-H-Shape-RECNO-24

300 x 150 36.70 kg/m 24.7 lb/ft 300 150 9 6.5 13 Japan-H-Shape-RECNO-23

250 x 250 72.40 kg/m 48.7 lb/ft 250 250 14 9.0 16 Japan-H-Shape-RECNO-18

250 x 125 29.60 kg/m 19.9 lb/ft 250 125 9 6.0 12 Japan-H-Shape-RECNO-17

200 x 200 49.90 kg/m 33.5 lb/ft 200 200 12 8.0 13 Japan-H-Shape-RECNO-13

200 x 100 21.30 kg/m 14.3 lb/ft 200 100 8 5.5 11 Japan-H-Shape-RECNO-12

150 x 150 31.50 kg/m 21.2 lb/ft 150 150 10 7.0 11 Japan-H-Shape-RECNO-7

150 x 75 14.00 kg/m 9.4 lb/ft 150 75 7 5.0 8 Japan-H-Shape-RECNO-6

You might also like

- Assessment 2 Thermo Fluid SystemDocument23 pagesAssessment 2 Thermo Fluid Systemlong100% (2)

- ECP201 2008 Earthquake Lateral Forces - 2015 Feb 07 - Rev1.2Document27 pagesECP201 2008 Earthquake Lateral Forces - 2015 Feb 07 - Rev1.2hesham33usNo ratings yet

- Program of WorkDocument40 pagesProgram of WorkLorraine Jane D. Barber100% (2)

- បេតុង (Concrete Material Price List)Document4 pagesបេតុង (Concrete Material Price List)semitsu67% (9)

- Design Calculation Report - Pipe Rack - and FoundationDocument128 pagesDesign Calculation Report - Pipe Rack - and FoundationMUTHUKKUMARAM100% (2)

- Rev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEDocument37 pagesRev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEsalman alfarisyNo ratings yet

- Back Up ComputationDocument12 pagesBack Up ComputationAbigail Mae DizonNo ratings yet

- Biodiesel Reactor Optimization using CFD-Taguchi MethodDocument26 pagesBiodiesel Reactor Optimization using CFD-Taguchi Methodnabadeyemi9761No ratings yet

- GF - SST 62M NL - 02 Februari 2021 - Rev01Document151 pagesGF - SST 62M NL - 02 Februari 2021 - Rev01galang setiawanNo ratings yet

- Dpipe: Calculation Sample and Recommended Sequence For Entering Input DataDocument14 pagesDpipe: Calculation Sample and Recommended Sequence For Entering Input DataAbhinav OjhaNo ratings yet

- Helix Calculation Stage-1 CV 42 (R2) Approved - 230524 - 222556Document26 pagesHelix Calculation Stage-1 CV 42 (R2) Approved - 230524 - 222556Karthikeyan MallikaNo ratings yet

- 8.1.1 Design For Bearing On Concrete: ReferencesDocument10 pages8.1.1 Design For Bearing On Concrete: Referencessyed muhammad azeemNo ratings yet

- Flat Slab Equivalent Frame MethodDocument3 pagesFlat Slab Equivalent Frame MethodNp Pw100% (1)

- Parasismic ChapterDocument23 pagesParasismic ChapterHadi MoussaNo ratings yet

- Earthquake Lateral Forces According Egyptian Code of Loads (ECP201-2008)Document23 pagesEarthquake Lateral Forces According Egyptian Code of Loads (ECP201-2008)Ahmed ShakerNo ratings yet

- Contract Sum Analysis: Total Carried To Form of TenderDocument18 pagesContract Sum Analysis: Total Carried To Form of Tenderandre khooNo ratings yet

- Shoring Calculation Report 20211118Document37 pagesShoring Calculation Report 20211118Oshin RajapakshaNo ratings yet

- Civil Works Estimation Comparison for PST ConstructionDocument16 pagesCivil Works Estimation Comparison for PST Constructionjuliyet strucNo ratings yet

- Pf1 Res RevisedDocument4 pagesPf1 Res RevisedFed ValdezNo ratings yet

- TNG256 - Dukuh - Summary AnalysisDocument2 pagesTNG256 - Dukuh - Summary AnalysisSu SantiNo ratings yet

- Load Computations For Beams and Girders (Version 5)Document4 pagesLoad Computations For Beams and Girders (Version 5)Reuben James BangaoilNo ratings yet

- Working AccomplishmentDocument2 pagesWorking AccomplishmentOwen Francis Arles MaongatNo ratings yet

- J 619 CidcoDocument32 pagesJ 619 CidcoAJAY SHINDENo ratings yet

- Shear Design Provisions for RC BeamsDocument5 pagesShear Design Provisions for RC BeamsAKSNo ratings yet

- Final Horticulture Dept Office Building MadifyDocument101 pagesFinal Horticulture Dept Office Building Madifyparisjain1008No ratings yet

- Wind Load Example - CylinderDocument18 pagesWind Load Example - CylinderAnonymous f3uZJugqvNo ratings yet

- Behavior of SFRC Walls Without Conventional Shear ReinforcementDocument6 pagesBehavior of SFRC Walls Without Conventional Shear ReinforcementEden De GuzmanNo ratings yet

- Behaviour of RC Beams under TorsionDocument10 pagesBehaviour of RC Beams under TorsionKhimavathBharathNaikNo ratings yet

- Progress ReportDocument2 pagesProgress Reportjgawo2022No ratings yet

- Wind Loading With Cp3Document4 pagesWind Loading With Cp3Suhail AhamedNo ratings yet

- Project Accomplishment Report: Removal of Actual Structures/ ObstructionDocument2 pagesProject Accomplishment Report: Removal of Actual Structures/ ObstructionNiño De LeonNo ratings yet

- 5.0 Itemized Cost of RevisionDocument9 pages5.0 Itemized Cost of Revisiondexter guanzon serotNo ratings yet

- Load Calculation Report of Cold Box Main Body Column Base Anchor Bolt For Messer Vietnam ProjectDocument11 pagesLoad Calculation Report of Cold Box Main Body Column Base Anchor Bolt For Messer Vietnam ProjectTrung Trần BảoNo ratings yet

- China 2Document9 pagesChina 2Danniel Dizon LanggaNo ratings yet

- COLUMN DESIGN REPORTDocument13 pagesCOLUMN DESIGN REPORTdongshengNo ratings yet

- SorptionDocument19 pagesSorptionROMELIE GABALLO ALBIANo ratings yet

- Analysis and design of high-rise building using STAAD ProDocument3 pagesAnalysis and design of high-rise building using STAAD ProAnt PhweNo ratings yet

- Analysis and Design of High Rise BuildinDocument3 pagesAnalysis and Design of High Rise BuildinDepartment of Civil EngineeringNo ratings yet

- Analysis and Design of High Rise Building FramesDocument3 pagesAnalysis and Design of High Rise Building FramesRanvier Singh100% (1)

- Analysis and design of high-rise building using STAAD ProDocument3 pagesAnalysis and design of high-rise building using STAAD Prosanjay mishraNo ratings yet

- Analysis and Design of High Rise Building Frames PDFDocument3 pagesAnalysis and Design of High Rise Building Frames PDFMohammed Abdul RahmanNo ratings yet

- Analysis and Design of High Rise BuildinDocument3 pagesAnalysis and Design of High Rise BuildinDepartment of Civil EngineeringNo ratings yet

- Analysis and Design of High Rise BuildinDocument3 pagesAnalysis and Design of High Rise BuildinDepartment of Civil EngineeringNo ratings yet

- Conveyor Design Summary: Helix Technologies Pty LTDDocument23 pagesConveyor Design Summary: Helix Technologies Pty LTDmamatsulsNo ratings yet

- Beam warping and shear calculationsDocument1 pageBeam warping and shear calculationsTruong Phuoc TriNo ratings yet

- CSC (Columns) Estimate Annavaram..Document48 pagesCSC (Columns) Estimate Annavaram..mahaboobbasha9949No ratings yet

- Four-Storey Apartment Project Cost AnalysisDocument109 pagesFour-Storey Apartment Project Cost AnalysisKiesha SantosNo ratings yet

- Assignment 5 - AirportDocument2 pagesAssignment 5 - AirportSaroj AcharyaNo ratings yet

- XX/XX 06/20: Almeida O, Miranda FC, Ferreira Neto O, Saad FGDocument2 pagesXX/XX 06/20: Almeida O, Miranda FC, Ferreira Neto O, Saad FGDang Tien PhucNo ratings yet

- GPT Nadu NeduDocument222 pagesGPT Nadu NeduSwarna LathaNo ratings yet

- STRUCTURAL ANALYSIS AND DESIGN DRAWING FOR A 62M SELF-SUPPORTING TOWERDocument47 pagesSTRUCTURAL ANALYSIS AND DESIGN DRAWING FOR A 62M SELF-SUPPORTING TOWERdavinci codeNo ratings yet

- Alfonso Ramirez Final Draft Deprec CarDocument7 pagesAlfonso Ramirez Final Draft Deprec Carhoneyjn.manlaNo ratings yet

- 1 Deck + Abutment 15.88+load Combo 15.88Document45 pages1 Deck + Abutment 15.88+load Combo 15.88sudipNo ratings yet

- Analysis, Stability Checking and Design of The Structure 3.1. Model InformationDocument29 pagesAnalysis, Stability Checking and Design of The Structure 3.1. Model InformationWai Yann ZawNo ratings yet

- N Ojt ReportDocument28 pagesN Ojt ReportSamarpan PokhrelNo ratings yet

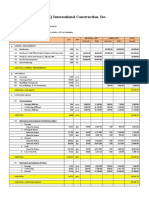

- JQ International Construction, IncDocument2 pagesJQ International Construction, Incyael rodriguez100% (1)

- Dumalon W.S. Ground Tank - FinalDocument226 pagesDumalon W.S. Ground Tank - FinaljungzkiNo ratings yet

- Statical Calculation for Steel Support Post Insulator StructureDocument31 pagesStatical Calculation for Steel Support Post Insulator StructureJonathan NapitupuluNo ratings yet

- Indore Stadium KavityDocument18 pagesIndore Stadium KavityD.V.Srinivasa RaoNo ratings yet

- Weekly Progress ReportDocument8 pagesWeekly Progress Reportjgawo2022No ratings yet

- Kuakata - CRS Building 3rd RA Bill (Samhee-1)Document4 pagesKuakata - CRS Building 3rd RA Bill (Samhee-1)Anower ShahadatNo ratings yet

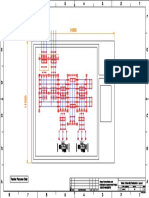

- 09) West University Substation LayoutDocument1 page09) West University Substation Layoutmyoaung28296No ratings yet

- Combinaciones Asce 113 Substation Structure Design Guide PDFDocument1 pageCombinaciones Asce 113 Substation Structure Design Guide PDFmyoaung28296No ratings yet

- Design of Gabon Retaining Wall Design ReportDocument14 pagesDesign of Gabon Retaining Wall Design Reportmyoaung28296No ratings yet

- Siemens Drawings (Proposal Stage) PDFDocument11 pagesSiemens Drawings (Proposal Stage) PDFmyoaung28296No ratings yet

- Design of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020Document52 pagesDesign of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020myoaung28296No ratings yet

- Design of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020Document52 pagesDesign of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020myoaung28296No ratings yet

- Design of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020Document52 pagesDesign of Underground R.C Chamber: Model File: Valve Chamber, Revision 0 5SEP2020myoaung28296No ratings yet

- Front/Back Elevation: DWG: Calves ShadeDocument1 pageFront/Back Elevation: DWG: Calves ShadeMwesigwa DanielNo ratings yet

- Bill of Quantities & Price Schedule - Civil & Structure WorksDocument9 pagesBill of Quantities & Price Schedule - Civil & Structure Workssayali pardhiNo ratings yet

- Truss 2 122119009 Aniruddh Dnyanesh PansambalDocument3 pagesTruss 2 122119009 Aniruddh Dnyanesh PansambalAniruddh PansambalNo ratings yet

- Primary Clarifier Estimate (AutoRecovered)Document3 pagesPrimary Clarifier Estimate (AutoRecovered)epe civilNo ratings yet

- TST Pages From Nha-General-Specification-E-35-Volum-Ii PDFDocument7 pagesTST Pages From Nha-General-Specification-E-35-Volum-Ii PDFMuhammad Shahbaz KhokharNo ratings yet

- Transit NZ Bridge Manual 2nd EditionDocument254 pagesTransit NZ Bridge Manual 2nd EditionJohnnie StrydomNo ratings yet

- Cellular Beam L 10MDocument10 pagesCellular Beam L 10MAnh KyNo ratings yet

- First Class Brick Properties & Manufacturing ProcessDocument10 pagesFirst Class Brick Properties & Manufacturing ProcessSAURABH KUMAR SINGHNo ratings yet

- Architect Philippines - English - Tagalog Construction TermsDocument5 pagesArchitect Philippines - English - Tagalog Construction TermsDon PePeNo ratings yet

- Two-Storey Residential House Program of Work & QuantitiesDocument46 pagesTwo-Storey Residential House Program of Work & QuantitiesMark Allan RojoNo ratings yet

- QAHD Office Building 30 M Structural Plans-S102.0Document1 pageQAHD Office Building 30 M Structural Plans-S102.0Adrian PachecoNo ratings yet

- Plastering: Ashwin JoshiDocument15 pagesPlastering: Ashwin JoshiVarunNo ratings yet

- Dennis H. Mahan Memorial Bridge Project ID: 00018A-Iteration #3 (Thu, 15 Jun 2017, 15:28:10) Iteration #3 (Thu, 15 Jun 2017, 15:28:10)Document1 pageDennis H. Mahan Memorial Bridge Project ID: 00018A-Iteration #3 (Thu, 15 Jun 2017, 15:28:10) Iteration #3 (Thu, 15 Jun 2017, 15:28:10)Ghofar Kebumen CliquersNo ratings yet

- Everdure Waterstop - Page1Document1 pageEverdure Waterstop - Page1Jefferd AlicanNo ratings yet

- Essentials of Eurocode 3 PDFDocument61 pagesEssentials of Eurocode 3 PDFSRARNo ratings yet

- Deflection Check (Beams BS 8110)Document2 pagesDeflection Check (Beams BS 8110)dhanya1995No ratings yet

- RCD2 PROBLEM Set2Document2 pagesRCD2 PROBLEM Set2JAMES ALLEN DOMINGONo ratings yet

- Basic StructuralDocument11 pagesBasic Structuraljennifer FernanNo ratings yet

- Factors Affecting Choice of Structural SystemDocument4 pagesFactors Affecting Choice of Structural SystemBaguma Grace Gariyo100% (2)

- STRUCTURES INFLUENCE LINESDocument5 pagesSTRUCTURES INFLUENCE LINESChristian Paul RamosNo ratings yet

- RetainingWall SBC 150Document35 pagesRetainingWall SBC 150Elvis GrayNo ratings yet

- SeptictankDocument8 pagesSeptictankkejspmNo ratings yet

- 3 - Durability of Reinforced Concrete StructureDocument24 pages3 - Durability of Reinforced Concrete StructureyakaNo ratings yet

- The Post-Frame Advantage HandbookDocument61 pagesThe Post-Frame Advantage HandbookChuck Achberger100% (1)

- Structural Conceptualization (Pre Board)Document10 pagesStructural Conceptualization (Pre Board)Mavie PerieNo ratings yet

- Connection 2Document19 pagesConnection 2Der3'am Al m7armehNo ratings yet

- Two Way Slab Detailing and Design RecoommDocument4 pagesTwo Way Slab Detailing and Design RecoommJohn STCNo ratings yet

- Column Design As Per BS 8110-1:1997: PHK/JSNDocument16 pagesColumn Design As Per BS 8110-1:1997: PHK/JSNShabana ferozNo ratings yet