Professional Documents

Culture Documents

Zte Osian F8208401en

Uploaded by

Mamadou djibril BaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zte Osian F8208401en

Uploaded by

Mamadou djibril BaCopyright:

Available Formats

Washer-Extractors

Operation/Maintenance

Cabinet Hardmount

Refer to Page 6 for Model Identification

CHM1772C

CHM1772C

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

Part No. F8208401R2

www.comlaundry.com March 2009

Table of Safety Information..............................................................................

Explanation of Safety Messages...........................................................

2

2

Important Safety Instructions ............................................................... 2

Contents Safety Decals ........................................................................................ 4

Operator Safety..................................................................................... 5

Introduction......................................................................................... 6

Model Identification ............................................................................. 6

Nameplate Location.............................................................................. 8

Replacement Parts ................................................................................ 8

Customer Service.................................................................................. 8

Operation............................................................................................. 10

Operating Instructions, Vend Models Only.......................................... 10

Operating Instructions, OPL Models Only........................................... 12

Maintenance ........................................................................................ 14

Daily ..................................................................................................... 14

Beginning of Day ............................................................................. 14

End of Day ....................................................................................... 14

Weekly.................................................................................................. 15

Monthly................................................................................................. 15

Quarterly ............................................................................................... 17

Care of Stainless Steel .......................................................................... 18

© Copyright 2009, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 1

Safety Information

Explanation of Safety Messages Important Safety Instructions

Precautionary statements (“DANGER,” “WARNING”

and “CAUTION”), followed by specific instructions, WARNING

are found in this manual and on machine decals. These

To reduce the risk of fire, electric shock,

precautions are intended for the personal safety of the

serious injury or death to persons when

operator, user, servicer and those maintaining the

using your washer, follow these basic

machine.

precautions:

W023

DANGER 1. Read all instructions before using the washer.

DANGER indicates the presence of a 2. Refer to the GROUNDING INSTRUCTIONS in

hazard that will cause severe personal the INSTALLATION manual for the proper

injury, death, or substantial property grounding of the washer.

damage if the danger is ignored.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, dry-

WARNING cleaning solvents, or other flammable or

explosive substances as they give off vapors that

WARNING indicates the presence of a could ignite or explode.

hazard that can cause severe personal

4. Do not add gasoline, dry-cleaning solvents, or

injury, death, or substantial property

other flammable or explosive substances to the

damage if the warning is ignored.

wash water. These substances give off vapors that

could ignite or explode.

5. Under certain conditions, hydrogen gas may be

CAUTION produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

CAUTION indicates the presence of a IS EXPLOSIVE. If the hot water system has not

hazard that will or can cause minor been used for such a period, before using a

personal injury or property damage if the washing machine or combination washer-dryer,

caution is ignored. turn on all hot water faucets and let the water

flow from each for several minutes. This will

Additional precautionary statements (“IMPORTANT” release any accumulated hydrogen gas. The gas

and “NOTE”) are followed by specific instructions. is flammable; do not smoke or use an open flame

during this time.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where 6. Do not allow children to play on or in the washer.

minor machine damage will occur if the procedure Close supervision of children is necessary when

is not followed. the washer is used near children. This is a safety

rule for all appliances.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing 7. Before the washer is removed from service or

information that is important but not hazard discarded, remove the door to the washing

related. compartment.

8. Do not reach into the washer if the wash drum is

moving.

2 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Safety Information

9. Do not install or store the washer where it will be 20. If the supply cord is damaged, it must be replaced

exposed to water and/or weather. by a special cord or assembly, available from the

manufacturer or its service agent.

10. Do not tamper with the controls.

21. Be sure water connections have a shut-off valve

11. Do not repair or replace any part of the washer, or

and that fill hose connections are tight. CLOSE

attempt any servicing unless specifically

the shut-off valves at the end of each wash day.

recommended in the user-maintenance

instructions or in published user-repair 22. Loading door MUST BE CLOSED any time the

instructions that the user understands and has the washer is to fill, tumble or spin. DO NOT

skills to carry out. bypass the loading door switch by permitting the

washer to operate with the loading door open.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to 23. Always read and follow manufacturer’s

connect the washer to the electrical power instructions on packages of laundry and cleaning

source. aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

13. Use washer only for its intended purpose,

them out of the reach of children at all times

washing textiles.

(preferably in a locked cabinet).

14. Never wash machine parts or automotive parts in

24. Always follow the fabric care instructions

the machine. This could result in serious damage

supplied by the textile manufacturer.

to the basket.

25. Never operate the washer with any guards

15. ALWAYS disconnect the washer from electrical

and/or panels removed.

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord. 26. DO NOT operate the washer with missing or

broken parts.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All 27. DO NOT bypass any safety devices.

connections for water, drain, electrical power and

28. Failure to install, maintain, and/or operate this

grounding must comply with local codes and be

washer according to the manufacturer’s

made by licensed personnel when required.

instructions may result in conditions which can

17. To reduce the risk of fire, textiles which have produce bodily injury and/or property damage.

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil, NOTE: The WARNINGS and IMPORTANT

flammable chemicals, thinner, etc. or anything SAFETY INSTRUCTIONS appearing in this

containing wax or chemicals such as in mops and manual are not meant to cover all possible

cleaning cloths, must not be put into the washer. conditions and situations that may occur. Common

These flammable substances may cause the sense, caution and care must be exercised when

fabric to catch on fire by itself. installing, maintaining, or operating the washer.

18. Do not use fabric softeners or products to Any problems or conditions not understood should be

eliminate static unless recommended by the reported to the dealer, distributor, service agent or the

manufacturer of the fabric softener or product. manufacturer.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 3

Safety Information

WARNING CAUTION

This machine must be installed, adjusted, Be careful around the open door,

and serviced by qualified electrical particularly when loading from a level

maintenance personnel familiar with the below the door. Impact with door edges

construction and operation of this type of can cause personal injury.

machinery. They must also be familiar SW025

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment WARNING

damage, and may void the warranty.

SW004

Never touch internal or external steam

pipes, connections, or components.

IMPORTANT: Ensure that the recommended These surfaces can be extremely hot and

clearances for inspection and maintenance will cause severe burns. The steam must

are provided. Never allow the inspection and be turned off and the pipe, connections,

maintenance space to be blocked. and components allowed to cool before

the pipe can be touched.

SW014

WARNING

Install the machine on a level floor of Safety Decals

sufficient strength. Failure to do so may

Safety decals appear at crucial locations on the

result in conditions which can produce

machine. Failure to maintain legible safety decals

serious injury, death and/or property

could result in injury to the operator or service

damage.

W703 technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Safety Information

Operator Safety Do not bypass any safety devices in the machine.

WARNING WARNING

NEVER insert hands or objects into Operating the machine with severe out-of-

basket until it has completely stopped. balance loads could result in personal

Doing so could result in serious injury. injury and serious equipment damage.

SW012 W728

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door and start the machine. The

machine should not start with the door

unlocked. Attempt to open the door while the

cycle is in progress. The door should not

open.

If the door lock and interlock are not functioning

properly, disconnect power and call a service

technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 5

Introduction

Model Identification

Information in this manual is applicable to these models:

Model

HCD020LD2 HCN020KCV SCN020GC2 SCN020KNF SCU020GD2 SCU020JXV

HCN020GC2 HCN020KY2 SCN020GD2 SCN020LC2 SCU020GE2 SCU020KN2

HCN020GD2 HCN020KYF SCN020GE2 SCN020LCF SCU020GL2 SCU020KNF

HCN020GE2 HCN020KYV SCN020GN2 SCN020LCV SCU020GN2 SCU020WEV

HCN020GN2 HCU020GC2 SCN020GX2 SCN020LD2 SCU020GX2 UCN020GN2

HCN020GX2 HCU020GD2 SCN020GY2 SCN020LY2 SCU020GY2 UCN020HN2

20 POUND

HCN020GY2 HCU020GE2 SCN020HN2 SCN020LYF SCU020HN2 UCN020HNF

HCN020HC2 HCU020GL2 SCN020HNF SCN020LYV SCU020HNF UCN020KN2

HCN020HCF HCU020GN2 SCN020JC2 SCN020WC2 SCU020JC2 UCU020GN2

HCN020HN2 HCU020GX2 SCN020JCF SCN020WCF SCU020JCF UCU020HN2

HCN020HNF HCU020GY2 SCN020JCV SCN020WCV SCU020JCV UCU020HNF

HCN020HY2 HCU020HC2 SCN020JY2 SCN020WY2 SCU020JEV UCU020KN2

HCN020HYF HCU020HN2 SCN020JYF SCN020WYF SCU020JL2

HCN020KC2 HCU020HNF SCN020JYV SCN020WYV SCU020JX2

HCN020KCF HCU020HX2 SCN020KN2 SCU020GC2 SCU020JXF

HCD030LD2 HCN030KCV SCL030LEV SCN030KN2 SCU030GC2 SCU030KN2

HCN030GC2 HCN030KY2 SCN030GC2 SCN030KNF SCU030GD2 SCU030KNF

HCN030GD2 HCN030KYF SCN030GD2 SCN030LC2 SCU030GE2 SCU030WCV

HCN030GE2 HCN030KYV SCN030GE2 SCN030LCF SCU030GL2 SCU030WE2

HCN030GN2 HCU030GC2 SCN030GN2 SCN030LCV SCU030GN2 UCN030GN2

HCN030GX2 HCU030GD2 SCN030GX2 SCN030LD2 SCU030GX2 UCN030HN2

30 POUND

HCN030GY2 HCU030GE2 SCN030GY2 SCN030LY2 SCU030GY2 UCN030HNF

HCN030HC2 HCU030GL2 SCN030HN2 SCN030LYF SCU030HN2 UCN030KN2

HCN030HCF HCU030GN2 SCN030HNF SCN030LYV SCU030HNF UCU030GN2

HCN030HN2 HCU030GX2 SCN030JC2 SCN030WC2 SCU030JC2 UCU030HN2

HCN030HNF HCU030GY2 SCN030JCF SCN030WCF SCU030JCF UCU030HNF

HCN030HY2 HCU030HC2 SCN030JCV SCN030WCV SCU030JCV UCU030KN2

HCN030HYF HCU030HN2 SCN030JY2 SCN030WY2 SCU030JX2 VCU030GN2

HCN030KC2 HCU030HNF SCN030JYF SCN030WYF SCU030JXF

HCN030KCF HCU030HX2 SCN030JYV SCN030WYV SCU030JXV

HCD040LD2 HCN040KY2 SCN040GE2 SCN040LCF SCU040GN2 UCN040GN2

HCN040GC2 HCN040KYF SCN040GN2 SCN040LCV SCU040GX2 UCN040HN2

HCN040GD2 HCN040KYV SCN040GX2 SCN040LD2 SCU040GY2 UCN040HNF

HCN040GE2 HCU040GC2 SCN040GY2 SCN040LY2 SCU040HN2 UCN040KN2

HCN040GN2 HCU040GD2 SCN040HN2 SCN040LYF SCU040HNF UCN040KNV

HCN040GX2 HCU040GE2 SCN040HNF SCN040LYV SCU040JC2 UCU040GN2

40 POUND

HCN040GY2 HCU040GL2 SCN040JC2 SCN040WC2 SCU040JCF UCU040HN2

HCN040HC2 HCU040GN2 SCN040JCF SCN040WCF SCU040JCV UCU040HNF

HCN040HCF HCU040GX2 SCN040JCV SCN040WCV SCU040JL2 UCU040KN2

HCN040HN2 HCU040GY2 SCN040JY2 SCN040WY2 SCU040JX2 UCU040KNV

HCN040HNF HCU040HC2 SCN040JYF SCN040WYF SCU040JXF VCU040GN2

HCN040HY2 HCU040HN2 SCN040JYV SCN040WYV SCU040JXV

HCN040HYF HCU040HNF SCN040KN2 SCU040GC2 SCU040KN2

HCN040KC2 HCU040HX2 SCN040KNF SCU040GD2 SCU040KNF

HCN040KCF SCN040GC2 SCN040KNV SCU040GE2 SCU040KNV

HCN040KCV SCN040GD2 SCN040LC2 SCU040GL2 SCU040WEV

(Continued)

6 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Introduction

(Continued)

Model

HCD060LD2 HCN060KY2 SCN060GD2 SCN060LC2 SCU060GL2 UCN060GN2

HCN060GC2 HCN060KYF SCN060GE2 SCN060LCF SCU060GN2 UCN060HN2

HCN060GD2 HCN060KYV SCN060GN2 SCN060LCV SCU060GX2 UCN060HNF

HCN060GE2 HCU060GC2 SCN060GX2 SCN060LD2 SCU060GY2 UCN060KN2

HCN060GN2 HCU060GD2 SCN060GY2 SCN060LY2 SCU060HN2 UCN060KNV

HCN060GX2 HCU060GE2 SCN060HN2 SCN060LYF SCU060HNF UCU060GN2

60 POUND

HCN060GY2 HCU060GL2 SCN060HNF SCN060LYV SCU060JC2 UCU060HN2

HCN060HC2 HCU060GN2 SCN060JC2 SCN060WC2 SCU060JCF UCU060HNF

HCN060HCF HCU060GX2 SCN060JCF SCN060WCF SCU060JCV UCU060KN2

HCN060HN2 HCU060GY2 SCN060JCV SCN060WCV SCU060JX2 UCU060KNV

HCN060HNF HCU060HC2 SCN060JY2 SCN060WY2 SCU060JXF VCU060GN2

HCN060HY2 HCU060HN2 SCN060JYF SCN060WYF SCU060JXV

HCN060HYF HCU060HNF SCN060JYV SCN060WYV SCU060KN2

HCN060KC2 HCU060HX2 SCN060KN2 SCU060GC2 SCU060KNF

HCN060KCF HCU060KEV SCN060KNF SCU060GD2 SCU060KNV

HCN060KCV SCN060GC2 SCN060KNV SCU060GE2 SCU060WEV

HCD080LDV HCN080HYV HCU080GYF SCN080JCV SCU080GLF UCN080HNV

HCN080GCF HCN080KCF HCU080HCF SCN080JYV SCU080GNF UCN080KNV

HCN080GDF HCN080KCV HCU080HNF SCN080KNV SCU080GXF UCU080GNF

HCN080GEF HCN080KYF HCU080HXF SCN080LCV SCU080GYF UCU080HNV

80 POUND

HCN080GNF HCN080KYV SCN080GCF SCN080LDV SCU080HNF UCU080KNV

HCN080GXF HCU080GCF SCN080GDF SCN080LYV SCU080JCF VCU080GNF

HCN080GYF HCU080GDF SCN080GEF SCN080WCV SCU080JCV

HCN080HCF HCU080GEF SCN080GNF SCN080WYV SCU080JXF

HCN080HCV HCU080GLF SCN080GXF SCU080GCF SCU080JXV

HCN080HNF HCU080GNF SCN080GYF SCU080GDF SCU080KNV

HCN080HYF HCU080GXF SCN080HNF SCU080GEF UCN080GNF

SCN125KNV

125 POUND

SCU125KNV

UCU125KNV

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 7

Introduction

Nameplate Location Replacement Parts

The nameplate is located at the rear of the machine and If literature or replacement parts are required, contact

inside door. Always provide the machine’s serial the source from whom the machine was purchased or

number and model number when ordering parts or contact Alliance Laundry Systems at (920) 748-3950

when seeking technical assistance. for the name and address of the nearest authorized

parts distributor.

1

Customer Service

For technical assistance, call: (920) 748-3121 Ripon,

Wisconsin.

CHM2233N

1 Nameplate

Figure 1

8 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Introduction

Model Number Familiarization Guide

Sample Model Number: *CN030GC2OU1001

*C Product Family

N Agency Approval

030 Washer-Extractor Capacity (pounds dry weight of laundry)

G Type of Control

C Actuation (C = Coin drop)

2 Washer-Extractor Speed Capability (2 = 2 speed)

O Electrical Characteristics

U Panel Type

1 Design Series

0 Heat Feature (0 = Standard No Heat)

00 Option Identification (varies from machine to machine)

* Denotes Brand

Model No. *CN030GCUOU001

Serial No. 00000000000

Voltage 208 – 240 Hz 60 Phase 3

Number of wires : 3 FLA : amps

Circuit Breaker Size : 3 amps

Max. Load : 40 LB 18.2 KG

Schematic :

Supply Water: 30 - 85 psi, 2 - 5.7 BAR

EXAMPLE OF NAMEPLATE CHM2234N

CHM2234N

Figure 2

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9

Operation

Operating Instructions, Vend 4. Close door and turn handle counter clockwise.

Refer to Figure 5.

Models Only

1. Turn on main power source (circuit breaker).

2. Turn handle clockwise to open. Refer to

Figure 3.

CHM2244N

Figure 5

5. The default wash cycle will display.

CHM2243N

CHM2243N

WARNING

Figure 3

To prevent personal injury, avoid contact

3. Load to capacity whenever possible. DO NOT with inlet water temperatures higher than

OVERLOAD. Refer to Figure 4. 125° Fahrenheit (51° Celsius) and hot

surfaces.

NOTE: Underloading can cause out-of-balance W748

conditions that can shorten machine life.

6. Select the desired soil setting (select models

only), cycle setting (select models only) and

cycle/temperature. The LED indicator(s) for that

cycle will light.

U003I

Figure 4

10 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Operation

7. Add liquid and/or powder supplies to supply b. Bleach:

dispenser. Refer to Figure 6.

• Liquid - Compartment 3

a. Detergent:

• Powder - Compartment 2

• Liquid - Compartment 1 (prewash) +

c. Softener:

Compartment 3

• Liquid - Compartment 4

• Powder - Compartment 1 (prewash) +

Compartment 2

a. DETERGENT

Liquid Powder

CHM2228N CHM2227N

b. BLEACH

Liquid Powder

CHM2230N

CHM2229N

c. SOFTENER

CHM2231N

Figure 6

8. Insert coin(s) or card as necessary. 9. Press the START keypad.

• If the machine is a coin operated unit, add coins. 10. During first fill, the desired wash cycle can be

As each coin is added, the vend counts down to changed. After first fill has ended, the wash cycle

the amount remaining. active at that moment remains the chosen wash

• If the machine is a card operated unit, insert and cycle.

remove card per card system instructions. 11. When cycle is complete, display shows “00”.

• If the unit is interfaced to a central/remote pay

system, go to the central/remote pay console,

make payment and select the machine and follow

central/remote pay system instructions.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 11

Operation

Operating Instructions, OPL Models 4. Close door and turn handle counter clockwise.

Refer to Figure 8.

Only

1. Turn on main power source (circuit breaker). NOTE: For 125 models, close door and turn handle

clockwise.

2. Turn door handle clockwise to open.

NOTE: For 125 models, press the Unlock/Stop

keypad. Turn door handle counter clockwise to

open.

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 7.

NOTE: Underloading can cause out-of-balance

conditions that can shorten machine life.

CHM2244N

Figure 8

5. The default wash cycle will display.

WARNING

To prevent personal injury, avoid contact

with inlet water temperatures higher than

U003I 125° Fahrenheit (51° Celsius) and hot

surfaces.

Figure 7 W748

6. If desired, select a different wash cycle

temperature (select models only) or a different

wash cycle number. The LED indicator for that

cycle will light or the display will indicate the

current cycle.

12 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Operation

7. Add liquid and/or powder supplies to supply b. Bleach:

dispenser. Refer to Figure 9.

• Liquid - Compartment 3

a. Detergent:

• Powder - Compartment 2

• Liquid - Compartment 1 (prewash) +

c. Softener:

Compartment 3

• Liquid - Compartment 4

• Powder - Compartment 1 (prewash) +

Compartment 2

a. DETERGENT

Liquid Powder

CHM2228N CHM2227N

b. BLEACH

Liquid Powder

CHM2230N

CHM2229N

c. SOFTENER

CHM2231N

Figure 9

8. Press the START keypad. 10. When cycle is complete, display shows “00”.

9. During first fill, the desired wash cycle can be

changed on some models. After first fill has

ended, the wash cycle active at that moment

remains the chosen wash cycle.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 13

Maintenance

3. Check door interlock before starting operation:

WARNING a. Attempt to start the machine with the door

open. The machine should not start with the

Sharp edges can cause personal injury.

door open.

Wear safety glasses and gloves, use

proper tools and provide lighting when b. Close the door and start the machine. The

handling sheet metal parts. machine should not start with the door

W366R1

unlocked. Attempt to open the door while the

cycle is in progress. The door should not

IMPORTANT: Replace all panels that are removed open.

to perform service and maintenance procedures.

Do not operate the machine with missing guards or If the door lock and interlock are not functioning

with broken or missing parts. Do not bypass any properly, disconnect power and call a service

safety devices. technician.

End of Day

Daily

1. Clean the door gasket of residual detergent and

IMPORTANT: Door lock should be checked daily all foreign matter.

to ensure proper operation. Also check that all

safety and instruction stickers are on the machine. 2. Clean the door glass with a damp cloth.

Any missing or illegible safety instructions stickers 3. Clean automatic supply dispenser lid and general

should be replaced immediately. area.

Beginning of Day 4. Clean the machine’s top, front and side panels

with mild detergent. Rinse with clean water.

1. Inspect water inlet valve hose connections on the

back of the machine for leaks. 5. Leave loading door open at the end of each day to

allow moisture to evaporate.

2. Inspect steam hose connections for leaks (where

applicable). NOTE: Unload the machine promptly after each

completed cycle to prevent moisture buildup. Leave

loading door open after each completed cycle to

allow moisture to evaporate.

14 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Maintenance

Weekly Monthly

1. Check the machine for leaks. NOTE: Disconnect power to the machine at its

a. Start an unloaded cycle to fill the machine. source before performing the monthly maintenance

procedures.

b. Verify that door and door gasket do not leak.

1. Use the following procedures to determine if

c. Verify that the drain valve is operating and

V-belt(s) require replacement or adjustment. Call

that the drain system is free from obstruction.

a qualified service technician in either case.

If water does not leak out during the first

wash segment, the drain valve is closed and a. Check V-belt(s) for uneven wear and frayed

functioning properly. edges.

For 125 models only, clean the AC drive box filter(s) b. For groove-pulley drive systems, verify

weekly or more frequently as needed: alignment by placing a straightedge across

both pulley faces. The straightedge should

1. Wash the filter with warm water and allow filter

make contact with the pulleys in four places.

to air dry. As an alternative, the filter may be

Refer to Figure 10.

vacuumed clean.

IMPORTANT: The control module cover and fan

filter must be in place for the fan to properly cool 1

the AC inverter drive. Failure to observe this

warning will void the warranty and could lead to

expensive AC inverter drive repair.

4

2

3

H040I

H040I

1 Motor

2 Motor Pulley

3 Straightedge

4 Basket Pulley

Figure 10

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 15

Maintenance

c. For flat-pulley drive systems, verify allowable

distance of belt from edge of pulley. Refer to

Table 1 below.

Flat-Pulley Alignment

Allowable

Model 1

Distance from Edge

20 .09 in. (2 mm)

2

30 .09 in. (2 mm)

40 .09 in. (2 mm)

60 .38 in. (10 mm)

Table 1 H039I

1 Deflection

d. For variable-speed models only, verify that

2 Span Length

V-belts are properly tensioned by applying a

set force to the belts and measuring the

deflection to determine the belt tension. Refer Figure 11

to Table 2 for the acceptable belt’s tension

ranges. Belt tension measurements should be

taken as close to the center of the belt span as

possible. Refer to Figure 11.

Belt Tension Testing for Variable-Speed Models

Force

Model Belt Belt Span Deflection Range

Min – Max

40 Motor-Basket 16.9 in. (428 mm) .31 – .34 in. (7.9 – 8.7 mm) 6.1 – 7.4 lbs. (27 – 33 N)

60 Motor-Basket 16.8 in. (426 mm) .28 – .31 in. (7.1 – 7.9 mm) 6.1 – 7.4 lbs. (27 – 33 N)

80 Motor-Basket 22.1 in. (561 mm) .22 – .25 in. (5.08 – 6.35 mm) 23 – 26 lbs. (102.3 – 115.6 N)

Banded Belt

Table 2

2. For 80 and 125 pound capacity models only, 3. Remove back panel and check overflow hose and

lubricate bearings and seals each month OR after drain hose for leaks.

every 200 hours of operation.

4. Unlock and remove the top cover and check the

a. Use a premium-grade lithium-based #2 supply dispenser hoses and hose connections.

grease. Never mix two types of grease, such

5. Clean inlet hose filter screens:

as petroleum and silicone.

a. Turn water off and allow valve to cool, if

b. Pump the grease gun slowly, permitting only

necessary.

the following number of strokes:

b. Unscrew inlet hose and remove filter screen.

• Bearing grease fitting, 2 strokes

c. Clean with soapy water and reinstall. Replace

• Seal grease fitting, 2 stroke

if worn or damaged.

NOTE: Do not pump the grease gun until grease 6. Tighten motor mounting bolt locknuts and

comes out of the bearing housing. This can result in bearing bolt locknuts. Check to see that the pin is

overlubrication, causing damage to bearings and in place.

seals.

16 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

Maintenance

7. Use compressed air to clean lint from motor.

8. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

9. Use compressed air to clean all electrical

components of moisture and dust.

10. Verify the insulation is intact on all external wires 1

and that all connections are secure. If bare wire is

evident, call a service technician.

11. For 125 models only, clean AC drive cooling fan 2

blades monthly (more often if required by the

condition of the air).

Quarterly

NOTE: Disconnect power to the machine at its

H042I

source before performing the quarterly

maintenance procedures. H042I

1 Cap

1. Tighten door hinges and fasteners, if necessary.

2 Filter Element

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and Figure 12

secure, if so equipped.

6. Check the bearing mounting bolts to make sure

4. Check all painted surfaces for exposed metal. they are torqued properly. Refer to Table 3 for

(Matching paint is available from the specifications.

manufacturer.)

• If bare metal is showing, paint with primer or Machine

Bearing Torque

Capacity

solvent-based paint.

• If rust appears, remove it with sandpaper or by 20 All 75 ft.-lbs.

chemical means and then paint with primer or 30-60 All 105 ft.-lbs.

solvent-based paint.

80 Front 200 ft.-lbs.

5. Clean customer-supplied steam filter, where

applicable. Refer to Figure 12. 80 Rear 97 ft.-lbs.

a. Turn off steam supply and allow time for the Table 3

valve to cool.

b. Unscrew Cap.

c. Remove Element and clean.

d. Replace Element and Cap.

F8208401 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 17

Maintenance

Care of Stainless Steel

• Remove dirt and grease with detergent and water. • Remove discoloration or heat tint from

Thoroughly rinse and dry after washing. overheating by scouring with a powder or by

employing special chemical solutions.

• Avoid contact with dissimilar metals to prevent

galvanic corrosion when salty or acidic solutions • Do not leave sterilizing solutions on stainless

are present. steel equipment for prolonged periods of time.

• Do not allow salty or acidic solutions to • When an external chemical supply is used,

evaporate and dry on stainless steel. Wipe clean ensure no siphoning of chemicals occurs when

of any residues. the washer-extractor is not in use. Highly

concentrated chemicals can cause severe damage

• Rub in the direction of the polish lines or “grain”

to stainless steel and other components within the

of the stainless steel to avoid scratch marks when

machine. Damage of this kind is not covered by

using abrasive cleaners. Use stainless steel wool

the manufacturer’s warranty. Locate the pump

or soft, non-metal bristle brushes. Do not use

and tubing below the washer-extractor’s injection

ordinary steel wool or steel brushes.

point to prevent siphoning of chemicals into the

• If the stainless steel appears to be rusting, the machine.

source of the rust may be an iron or steel part not

made of stainless steel, such as a nail or screw.

Tip: Paint all carbon steel parts with a heavy

protective coating. Stainless steel fasteners

should be used whenever possible.

18 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F8208401

You might also like

- Uc40mn2 - O&mDocument20 pagesUc40mn2 - O&mVinoj RamakrishnanNo ratings yet

- Operation Supplement For Washer-ExtractorDocument28 pagesOperation Supplement For Washer-ExtractorWaleed AlqarafiNo ratings yet

- Washer-Extractors: Cabinet Freestanding Refer To Page 7 For Model IdentificationDocument19 pagesWasher-Extractors: Cabinet Freestanding Refer To Page 7 For Model IdentificationAntonio BarajasNo ratings yet

- Washer-Extractors: Pocket Hardmount Variable-SpeedDocument19 pagesWasher-Extractors: Pocket Hardmount Variable-SpeedHomeroPerezNo ratings yet

- IPSO Washer Manual PDFDocument36 pagesIPSO Washer Manual PDFsof009100% (1)

- Ade3trgs455lw01 Users GuideDocument22 pagesAde3trgs455lw01 Users GuideProject VJ GROUPNo ratings yet

- User's Guide: For Topload WashersDocument25 pagesUser's Guide: For Topload WasherspauloznarfNo ratings yet

- User's Guide: For Topload WashersDocument26 pagesUser's Guide: For Topload WashersHektor TinaheroNo ratings yet

- Manual ProheatDocument29 pagesManual ProheatAlejandro CortesNo ratings yet

- Technical Manual: Safety and EnvironmentDocument30 pagesTechnical Manual: Safety and EnvironmentRachid SmailiNo ratings yet

- UW35B2Document32 pagesUW35B2Fakhar IqbalNo ratings yet

- Matachana Type AutoclaveDocument72 pagesMatachana Type AutoclaveOscar OkantoNo ratings yet

- Dehumidifier: CD045IU-DF (ZG) N7 16120100000356Document11 pagesDehumidifier: CD045IU-DF (ZG) N7 16120100000356Hai Long ChenNo ratings yet

- Lina+MB+ENG+Rev03 1+User+ManualDocument76 pagesLina+MB+ENG+Rev03 1+User+Manualmedhat fathyNo ratings yet

- Carrier 58MXA-10SMDocument16 pagesCarrier 58MXA-10SMMichael MartinNo ratings yet

- Hydraulic Breakers: Service Manual For Models G10, G20, G30, G40, G50, & G60Document28 pagesHydraulic Breakers: Service Manual For Models G10, G20, G30, G40, G50, & G60kamel100% (1)

- Instruction Manual: R 5 OxygenDocument36 pagesInstruction Manual: R 5 OxygenAlexandru SavuNo ratings yet

- Workshop Manual: Husqvarna: Gardena: MccullochDocument48 pagesWorkshop Manual: Husqvarna: Gardena: Mccullochduchamp100% (1)

- Plate Type Fresh Water Generatoren-R7Document36 pagesPlate Type Fresh Water Generatoren-R7primoNo ratings yet

- Instruction Manual R5 RA 0025-0100 F - EN - enDocument36 pagesInstruction Manual R5 RA 0025-0100 F - EN - enllulius asNo ratings yet

- iMMR User ManualDocument163 pagesiMMR User ManualHARISH SHARMA100% (2)

- Eww14023 User Manual en My PDFDocument120 pagesEww14023 User Manual en My PDFkamsaniNo ratings yet

- EB 8394 EN: Translation of Original InstructionsDocument80 pagesEB 8394 EN: Translation of Original InstructionsLuis GallinaNo ratings yet

- Ewf12853 User Manual en SGDocument68 pagesEwf12853 User Manual en SGWhite TigerNo ratings yet

- 8 12 HADEF Manual Spur Gear HoistDocument15 pages8 12 HADEF Manual Spur Gear HoistAli Osman SarnıkNo ratings yet

- 2008 Evinrude E-Tech 200HP 225HP 250HP Service Repair Manual PDFDocument15 pages2008 Evinrude E-Tech 200HP 225HP 250HP Service Repair Manual PDFfjskedmmsme50% (2)

- Owner's Manual & Safety InstructionsDocument36 pagesOwner's Manual & Safety InstructionsZafar IqbalNo ratings yet

- PS 3.20 Manual de UsuarioDocument88 pagesPS 3.20 Manual de UsuariodiegoNo ratings yet

- Serv Ops Manua D722D902Document233 pagesServ Ops Manua D722D902Alejandro MartNo ratings yet

- Setup Guide: Read This FirstDocument56 pagesSetup Guide: Read This FirstChristophe DallemagneNo ratings yet

- D1403 D1703 V1903 V2203 PDFDocument38 pagesD1403 D1703 V1903 V2203 PDFGaurav AgarwalNo ratings yet

- Be General Owners ManualDocument68 pagesBe General Owners ManualMilburnDrysdaleNo ratings yet

- Installation, Operation, and Maintenance Manual: 8106.082/.181 MatadorDocument56 pagesInstallation, Operation, and Maintenance Manual: 8106.082/.181 MatadorJhon AyalaNo ratings yet

- Flender GearboxesDocument98 pagesFlender GearboxesRahul RoyNo ratings yet

- Manual de Mtto Bravo 400 PDFDocument56 pagesManual de Mtto Bravo 400 PDFCarlos Humberto RomeroNo ratings yet

- Troy Bilt 2550 Pressure Was HerDocument52 pagesTroy Bilt 2550 Pressure Was HerrobertmunseyNo ratings yet

- Manual de Utilizare ProSpray 3.20 Airless SpraypackDocument88 pagesManual de Utilizare ProSpray 3.20 Airless Spraypackjohnny angeles ñiquenNo ratings yet

- Stripping Machine S22: Operating InstructionsDocument21 pagesStripping Machine S22: Operating InstructionsJavierNo ratings yet

- HYMD500 ManualDocument40 pagesHYMD500 ManualCReamflourishNo ratings yet

- Operating Manual: Gas Fired Igniter Pa2 / Pda2Document56 pagesOperating Manual: Gas Fired Igniter Pa2 / Pda2Winston CitrickNo ratings yet

- Liodr r23014Document24 pagesLiodr r23014Julio De la RosaNo ratings yet

- Domina Plus BDocument40 pagesDomina Plus BAnastasiu MihaiNo ratings yet

- 0463 418 001 UsDocument44 pages0463 418 001 UsmiguelNo ratings yet

- Service and Maintenance 16L IndustryDocument90 pagesService and Maintenance 16L IndustryEdison CasallasNo ratings yet

- SRM-266/S Grass Trimmer / Brush CutterDocument40 pagesSRM-266/S Grass Trimmer / Brush CutternoeleberryNo ratings yet

- Instruction Manual DOLPHIN LX 0030-0055 B - LX 0110-0430 C - EN - enDocument36 pagesInstruction Manual DOLPHIN LX 0030-0055 B - LX 0110-0430 C - EN - enHocine AminiNo ratings yet

- Instruction Manual: Fusion SplicerDocument87 pagesInstruction Manual: Fusion SplicerFelipe SouzaNo ratings yet

- Sweety Quick 60Document43 pagesSweety Quick 60eng1knockerNo ratings yet

- 31ZB1615 PDFDocument55 pages31ZB1615 PDFThế Út PhanNo ratings yet

- 6379 BA Elmasolvex RM ENDocument42 pages6379 BA Elmasolvex RM ENstatisticssalesNo ratings yet

- PDFDocument144 pagesPDFanon_844391780100% (2)

- Memmert Un30 Oven User ManualDocument52 pagesMemmert Un30 Oven User ManualNadun KodikaraNo ratings yet

- Downloaded From Manuals Search EngineDocument38 pagesDownloaded From Manuals Search EngineSyed100% (1)

- DD311 40Document154 pagesDD311 40luis naupari100% (1)

- Evinrude E-Tech 200hp 225hp 250hp Service Repair Workshop Manual Download PDFDocument404 pagesEvinrude E-Tech 200hp 225hp 250hp Service Repair Workshop Manual Download PDFPavlos Michalios100% (2)

- 9852 1007 01j Maintenance Instructions COP 1840,1840EXDocument32 pages9852 1007 01j Maintenance Instructions COP 1840,1840EXrolandNo ratings yet

- Lina PRO13-003 WH Med ENG Rev06 User ManualDocument76 pagesLina PRO13-003 WH Med ENG Rev06 User Manualdanny caceresNo ratings yet

- Maintenance Instructions COP 1132Document26 pagesMaintenance Instructions COP 1132marcelo espinoza100% (1)

- Alliance Laundry System D1345enDocument36 pagesAlliance Laundry System D1345enbiomedicalNo ratings yet

- Error E34 - Technical Troubleshooting Discussion in Forkliftaction's ForumsDocument3 pagesError E34 - Technical Troubleshooting Discussion in Forkliftaction's ForumsguevbaNo ratings yet

- 840C IbnDocument1,154 pages840C IbnVarun BuddeNo ratings yet

- Siemens Simodrive 611 UniversalDocument1,006 pagesSiemens Simodrive 611 Universalchnandu100% (2)

- Service Service Manual Manual: Onan Generator Set For MarineDocument204 pagesService Service Manual Manual: Onan Generator Set For MarinenajeebabdulkadarNo ratings yet

- Analyse Article Dormant 3Document12 pagesAnalyse Article Dormant 3guevbaNo ratings yet

- No Spark - Technical Troubleshooting Discussion in Forkliftaction's ForumsDocument3 pagesNo Spark - Technical Troubleshooting Discussion in Forkliftaction's ForumsguevbaNo ratings yet

- F34 Error - Caterpillar - DP30NT - Design & Engineering Discussion in Forkliftaction's ForumsDocument2 pagesF34 Error - Caterpillar - DP30NT - Design & Engineering Discussion in Forkliftaction's ForumsguevbaNo ratings yet

- Siemens - Simodrive 611 Analog - DescriptionDocument52 pagesSiemens - Simodrive 611 Analog - DescriptionrichsalgadoNo ratings yet

- Quick Guide For Jestronic 500 JT95 Belt Scale: Standard DisplayDocument7 pagesQuick Guide For Jestronic 500 JT95 Belt Scale: Standard DisplayMamadou djibril BaNo ratings yet

- JT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Document9 pagesJT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Mamadou djibril BaNo ratings yet

- Passarge Siegfried, 2010, Adamawa. Rapp... Cameroun Au Cours Des Années 1893-1894Document7 pagesPassarge Siegfried, 2010, Adamawa. Rapp... Cameroun Au Cours Des Années 1893-1894Ba MamadouNo ratings yet

- Procedure For Preparing 840C Harddisk PDFDocument3 pagesProcedure For Preparing 840C Harddisk PDFMamadou djibril BaNo ratings yet

- JT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Document9 pagesJT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Mamadou djibril BaNo ratings yet

- Quick Guide For Jestronic 500 JT95 Belt Scale: Standard DisplayDocument7 pagesQuick Guide For Jestronic 500 JT95 Belt Scale: Standard DisplayMamadou djibril BaNo ratings yet

- JT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Document54 pagesJT95A JT95A JT95A JT95A: Jestronic 400 & Jestronic 500Mamadou djibril BaNo ratings yet

- Data Sheet 6EP1433-2BA20: Show Actual Product DetailsDocument4 pagesData Sheet 6EP1433-2BA20: Show Actual Product DetailsMamadou djibril BaNo ratings yet

- Hiperfet Power MosfetsDocument4 pagesHiperfet Power MosfetsMamadou djibril BaNo ratings yet

- Common Ways To Set Up A Base StationDocument4 pagesCommon Ways To Set Up A Base StationMamadou djibril BaNo ratings yet

- Mauritanie General Wiring-Rev1Document48 pagesMauritanie General Wiring-Rev1Mamadou djibril BaNo ratings yet

- Couplage de 2 Groupes Electrogènes - Forums de VOLTA-ElectricitéDocument4 pagesCouplage de 2 Groupes Electrogènes - Forums de VOLTA-ElectricitéMamadou djibril BaNo ratings yet

- Quote 5994Q - SNIM - TTX-REC-M6 Recording SystemDocument3 pagesQuote 5994Q - SNIM - TTX-REC-M6 Recording SystemMamadou djibril BaNo ratings yet

- Data Sheet 6EP1333-2BA20: Show Actual Product DetailsDocument4 pagesData Sheet 6EP1333-2BA20: Show Actual Product DetailsMamadou djibril BaNo ratings yet

- Trimble R8 Radio Communication Issues - GPS ForumsDocument3 pagesTrimble R8 Radio Communication Issues - GPS ForumsMamadou djibril BaNo ratings yet

- Common Ways To Set Up A Base StationDocument4 pagesCommon Ways To Set Up A Base StationMamadou djibril BaNo ratings yet

- Trimble R7 & R8 T01 File Problem - Surveying & Geomatics - Land Surveying and Geomatics Community ForumsDocument5 pagesTrimble R7 & R8 T01 File Problem - Surveying & Geomatics - Land Surveying and Geomatics Community ForumsMamadou djibril BaNo ratings yet

- Trimble R8 Radio Communication Issues - GPS ForumsDocument3 pagesTrimble R8 Radio Communication Issues - GPS ForumsMamadou djibril BaNo ratings yet

- Digitair Model 6695-CC End-of-Train Sense & Brake Unit (SBU) Composite CaseDocument165 pagesDigitair Model 6695-CC End-of-Train Sense & Brake Unit (SBU) Composite CaseMamadou djibril BaNo ratings yet

- Base Station Operation GuidelinesDocument3 pagesBase Station Operation GuidelinesMamadou djibril BaNo ratings yet

- Resetting Trimble ReceiversDocument2 pagesResetting Trimble ReceiversDeanna ClineNo ratings yet

- 2jz Ecu TerminalsDocument4 pages2jz Ecu TerminalsJp Da Silva100% (1)

- University Physics With Modern Physics 12th Edition: Hugh D. Young Roger A. FreedmanDocument65 pagesUniversity Physics With Modern Physics 12th Edition: Hugh D. Young Roger A. FreedmanEmrehan GökçayNo ratings yet

- Physics 14 HWDocument2 pagesPhysics 14 HWMelody KimNo ratings yet

- Rigging GuideDocument142 pagesRigging GuideJB MadeleineNo ratings yet

- Question and Answer On Steam TurbinesDocument33 pagesQuestion and Answer On Steam TurbineschunkyNo ratings yet

- Column End Support Reaction For Footing Design Under Service ConditionDocument76 pagesColumn End Support Reaction For Footing Design Under Service ConditionINNOVATIVE ENGINEERNo ratings yet

- General Electric Systems Technology Manual Control Rod Drive SystemDocument37 pagesGeneral Electric Systems Technology Manual Control Rod Drive SystemEN IDNo ratings yet

- Maag Online Condition Monitoring System: Save Money by Investing in Condition Based Predictive MaintenanceDocument2 pagesMaag Online Condition Monitoring System: Save Money by Investing in Condition Based Predictive MaintenanceMuhammadNo ratings yet

- 5321 Elastomeric Bearing Design AASHTO For P18 & P19 ADocument10 pages5321 Elastomeric Bearing Design AASHTO For P18 & P19 AAshraf Mohamed YehiaNo ratings yet

- 6.M - Georgin F - IngDocument4 pages6.M - Georgin F - IngclauNo ratings yet

- Khan 2000Document18 pagesKhan 2000HIMANSHU YADAVNo ratings yet

- Pumps (Questions & Answers)Document14 pagesPumps (Questions & Answers)SriRaman Pathakgaru100% (4)

- Index 2015 Gas-TurbinesDocument20 pagesIndex 2015 Gas-TurbinesAbdo SyNo ratings yet

- ME6301-Engineering Thermodynamics 2013 RegulationDocument12 pagesME6301-Engineering Thermodynamics 2013 RegulationLogesh LoganNo ratings yet

- SV400 Shop Manual Section 1 2 3 and 5Document149 pagesSV400 Shop Manual Section 1 2 3 and 5EnzoManalang100% (1)

- Mechanics WorksheetDocument6 pagesMechanics WorksheetJessica GuyNo ratings yet

- Fluid MechanicsDocument31 pagesFluid MechanicsRameez Ali FaridiNo ratings yet

- Rotary Encoders For The Elevator Industry: Product OverviewDocument6 pagesRotary Encoders For The Elevator Industry: Product OverviewSarjeet Singh DagarNo ratings yet

- Boilers - ClassificationDocument77 pagesBoilers - Classificationkabbilaash kumarNo ratings yet

- Answer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationDocument3 pagesAnswer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationKrishna YadavNo ratings yet

- Honda Activa 125 Dealer PriceDocument2 pagesHonda Activa 125 Dealer PricevivekNo ratings yet

- UMC240 CamshaftDocument3 pagesUMC240 CamshaftBurik8No ratings yet

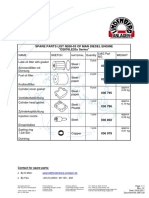

- Spare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Document1 pageSpare Parts List N200-03 of Man Diesel Engine "D2876LE20x Series"Jezrell JaravataNo ratings yet

- Abstract On Steam TurbineDocument2 pagesAbstract On Steam TurbineAsdfNo ratings yet

- Physic Lab 6Document10 pagesPhysic Lab 6api-463453187No ratings yet

- MIT Ising ModelDocument43 pagesMIT Ising ModelAritra LahiriNo ratings yet

- Maintaining Military VehiclesDocument2 pagesMaintaining Military VehiclesDUTY BOUNDNo ratings yet

- Ns Series Sub Mers DewateringDocument8 pagesNs Series Sub Mers DewateringPrateekNo ratings yet

- Cstps Modofied-131230103858Document66 pagesCstps Modofied-131230103858Santoshkumar GuptaNo ratings yet

- SM-6-2017 DefDocument6 pagesSM-6-2017 DefazizNo ratings yet