Professional Documents

Culture Documents

HVAC Systems 9

Uploaded by

rohit0 ratings0% found this document useful (0 votes)

14 views2 pagesDiagrama de GIVONI

Original Title

1 (31)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDiagrama de GIVONI

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesHVAC Systems 9

Uploaded by

rohitDiagrama de GIVONI

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

HVAC Systems 9

Chilled Water Pump, CHWP

Chilled Water Supply, CHWS

Chilled Water Return, CHWR

Chilled Water Coil (Cooling Coil), CC

Heating Water Coil (Hot Water Coil, Heating Coil), HC

Heating Water Supply, HWS or HHWS

Heating Water Return, HWR or HHWR

Heating Water Pump, HWP

Boiler, B

Supply Air Fan, SAF, SF

Supply Air Duct, SA

Manual Volume Damper, MVD

Flex Duct, Flex

Ceiling Diffuser, CD

Return Air Inlet, RA

Return Air Duct, RA

Return Air Fan, RAF

Return Air Dampers, RA, ATC Damper (Automatic Temperature

Control Damper)

Exhaust Air (Dampers), EA, ATCD

Outside Air (Dampers) OA, ATCD

Filters, F

Water Valves, 3-way or 2-way ATC Valve(Automatic Temperature

Control Valve). MBV (Manual Balancing Valve) or Self-regu-

lating Balancing Valve

This AHU is located on the roof and is therefore designated

as a “roof top unit” (RTU).

HOW AN HVAC SYSTEM WORKS

An HVAC system is designed to provide conditioned air to

the occupied space, also called the “conditioned” space, to main-

tain the desired level of comfort. To begin to explain how an

HVAC system works let’s set some design conditions. First, we

10 HVAC Fundamentals

will need to determine the ventilation requirements. We know that

in the respiratory process the contaminate carbon dioxide is ex-

haled. In buildings with a large number of people, carbon dioxide

and other contaminants such as smoke from cigarettes and odors

from machinery must be continuously removed or unhealthy con-

ditions will result. The process of supplying “fresh” air (now most

often called outside air) to buildings in the proper amount to offset

the contaminants produced by people and equipment is known as

“ventilation”. Not only does the outside air that is introduced into

the conditioned space offset the contaminants in the air but be-

cause of its larger ion content, outside air has a “fresh air” smell in

contrast to the “stale” or “dead air” smell noticed in overcrowded

rooms that do not have proper ventilation. In many instances, lo-

cal building codes stipulate the amount of ventilation required for

buildings and work environments.

Let’s say that an HVAC system supplies air to a suite in an

office complex and the code requirement is for 20 cubic feet per

minute (abbreviated cfm) of outside air for each building occu-

pant. If the suite is designed for 10 people then the total outside

air requirement for the people in the suite is 200 cfm. An addi-

tional amount of outside ventilation air may be required if there

are exhaust hoods such as laboratory fume hoods, kitchen hoods,

and spray hoods or there are other areas where the air needs to

be exhausted or vented to the outside such as bathrooms and

restrooms. This ventilation air is called make-up air.

If more air is brought into a room (conditioned space) than

is taken out of a room the room becomes positively pressurized.

If more air is taken out of a room than is brought into a room the

room becomes negatively pressurized. These air pressures,

whether positive or negative are measured in inches of water

gage (in wg) or inches of water column (in wc).

Commercial office buildings are typically positively pressur-

ized to about 0.03 inches of water pressure. This is done to keep

outside air from “infiltrating” into the conditioned space through

openings in or around doorways, windows, etc. Other areas that

need positive pressurization are hospital operating rooms and

You might also like

- Project Report of HvacDocument56 pagesProject Report of HvacPrince Syed83% (59)

- Advantix FinalDocument55 pagesAdvantix FinalEric WebbNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Reciprocating Compressors:: Operation and MaintenanceFrom EverandReciprocating Compressors:: Operation and MaintenanceRating: 4 out of 5 stars4/5 (7)

- Industrial VentilationDocument70 pagesIndustrial VentilationAnkur Sharma86% (7)

- HVAC System in 5 Star HotelsDocument56 pagesHVAC System in 5 Star Hotelsvnitce100% (2)

- HVAC Services in Buildings: Ar. Antara Nandy Assistant Professor Rani Rashmoni College of Architecture, Durgapur (W.B)Document18 pagesHVAC Services in Buildings: Ar. Antara Nandy Assistant Professor Rani Rashmoni College of Architecture, Durgapur (W.B)Archi PinuNo ratings yet

- Samuel C. Sugarman - HVAC Fundamentals-Fairmont Press - Distributed by Marcell Dekker - CRC Press (2005) - 3Document2 pagesSamuel C. Sugarman - HVAC Fundamentals-Fairmont Press - Distributed by Marcell Dekker - CRC Press (2005) - 3rohitNo ratings yet

- (Clivet-1803-5C1712) Water Cooled Screw Chiller (Flooded Type)Document18 pages(Clivet-1803-5C1712) Water Cooled Screw Chiller (Flooded Type)d.gitaNo ratings yet

- HVAC Design For CleanroomsDocument4 pagesHVAC Design For CleanroomsEdgar Alejandro Barajas RuizNo ratings yet

- Offshore Hvac DesignDocument6 pagesOffshore Hvac DesignAndrew AlexNo ratings yet

- 2 Mep Hvac RevDocument49 pages2 Mep Hvac Revsardarmkhan100% (4)

- 5-TB - Ventilation Air For Indoor PoolsDocument4 pages5-TB - Ventilation Air For Indoor Poolsakhlaq_hssainkotaNo ratings yet

- Docm (AutoRecovered)Document13 pagesDocm (AutoRecovered)Anonymous AFFiZnNo ratings yet

- Ventilation of Poultry Slaughtering and Processing Plants: Uilding EntilationDocument4 pagesVentilation of Poultry Slaughtering and Processing Plants: Uilding Entilationtroscian7No ratings yet

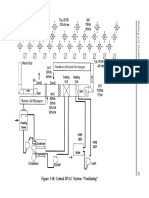

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Hvac Prelim Finalspsychrometric PalangDocument62 pagesHvac Prelim Finalspsychrometric PalangCHRISTED ALJO BARROGANo ratings yet

- I-Mall Antipolo Supermarket Hvac DesignDocument36 pagesI-Mall Antipolo Supermarket Hvac DesignCHRISTED ALJO BARROGANo ratings yet

- Hvac (H V & A C) : Eating Entilation IR OnditioningDocument50 pagesHvac (H V & A C) : Eating Entilation IR OnditioningTushal100No ratings yet

- An Air Handling UnitDocument4 pagesAn Air Handling UnitDono WayNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0186050 A1Document4 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0186050 A1avalosheNo ratings yet

- What Is An HVACDocument3 pagesWhat Is An HVACAbnetastroNo ratings yet

- HVAC & Water SystemDocument153 pagesHVAC & Water SystemSujan Bose100% (1)

- Fundamentals of HVAC ControlsDocument68 pagesFundamentals of HVAC Controlsbenson100% (2)

- VentilationDocument18 pagesVentilationTao Ma100% (1)

- I-Mall Antipolo Supermarket Hvac DesignDocument32 pagesI-Mall Antipolo Supermarket Hvac DesignCHRISTED ALJO BARROGANo ratings yet

- Hvac AssignmentDocument27 pagesHvac AssignmentChethan. M.D.100% (1)

- A33 Si - Kitchen VentilationDocument1 pageA33 Si - Kitchen VentilationAhmed NabilNo ratings yet

- Course Content: Fundamentals of HVAC ControlsDocument39 pagesCourse Content: Fundamentals of HVAC ControlsMuhammad AfzalNo ratings yet

- Hvac TermsDocument65 pagesHvac Termszebidians100% (1)

- Variable Air Volume 143: VAV OperationDocument2 pagesVariable Air Volume 143: VAV OperationRohit ShresthaNo ratings yet

- Air Duct CleaningDocument15 pagesAir Duct CleaningMohd Shafiq100% (1)

- HVAC Design Principles: Written By: Harish Ashraf, Lijo JohnDocument78 pagesHVAC Design Principles: Written By: Harish Ashraf, Lijo JohnNalaka SiyanthaNo ratings yet

- HvacDocument5 pagesHvacCyra AndayaNo ratings yet

- Design Guide - Humidity ControlDocument2 pagesDesign Guide - Humidity Controldzul92100% (1)

- Articles About HVAC - Fresh Air and OccupancyDocument13 pagesArticles About HVAC - Fresh Air and OccupancyAnonymous DjWqKpZ1No ratings yet

- Ventilation (Architecture) : From Wikipedia, The Free EncyclopediaDocument8 pagesVentilation (Architecture) : From Wikipedia, The Free EncyclopediagnitinNo ratings yet

- Air-Distribution SystemsDocument18 pagesAir-Distribution SystemsHarjo Wiyono100% (1)

- AcousticsDocument5 pagesAcousticsarchi042No ratings yet

- Air Handling Unit: Temperature ControlDocument4 pagesAir Handling Unit: Temperature ControlNaveen Kumar VashistNo ratings yet

- Solving Kitchen Ventilation ProblemsDocument6 pagesSolving Kitchen Ventilation ProblemsJohn DiasNo ratings yet

- Ventilation Is The Intentional Movement Of: Air Hvac Water Heaters BoilersDocument15 pagesVentilation Is The Intentional Movement Of: Air Hvac Water Heaters Boilersvershasinha09No ratings yet

- What Is HVACDocument3 pagesWhat Is HVACAyingBabeNo ratings yet

- BU RESEARCH PDF Di Pa FinalDocument26 pagesBU RESEARCH PDF Di Pa FinalMichelle VillarandaNo ratings yet

- Review Report of Bule Hora Referral Hospital Mechanical Ventilation and HVAC System Design Drawings and BOQDocument4 pagesReview Report of Bule Hora Referral Hospital Mechanical Ventilation and HVAC System Design Drawings and BOQkali highNo ratings yet

- Commercial Kitchen VentilationDocument59 pagesCommercial Kitchen VentilationPrabhjot BediNo ratings yet

- Experiment Title:: Flow Through Orifices (Exp1)Document12 pagesExperiment Title:: Flow Through Orifices (Exp1)hahahaaNo ratings yet

- Energy Recovery VentilationDocument3 pagesEnergy Recovery VentilationPrabhat KumarNo ratings yet

- Duct Design Myth BustersDocument4 pagesDuct Design Myth BusterscphamfNo ratings yet

- Script:-.Air Condition ScriptDocument11 pagesScript:-.Air Condition Scriptaimri_cochinNo ratings yet

- Why Is Forced Mechanical Ventilation Necessary in A Confined BuildingDocument3 pagesWhy Is Forced Mechanical Ventilation Necessary in A Confined BuildingJade Putis100% (1)

- Components of HVAC Systems: Indoor Fan (Blower)Document17 pagesComponents of HVAC Systems: Indoor Fan (Blower)monoj5859No ratings yet

- Apco Air Valve GuideDocument12 pagesApco Air Valve Guideanon_711152122No ratings yet

- HEI Tech Sheet 110Document15 pagesHEI Tech Sheet 110Suganya LokeshNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Storage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionFrom EverandStorage Tanks Selection, Design, Testing, Inspection, and Maintenance: Emission Management and Environmental Protection: Emission Management and Environmental ProtectionNo ratings yet

- Figure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamDocument2 pagesFigure 3-3. Btu Change in One Pound of Ice To Water To Steam To Superheated SteamrohitNo ratings yet

- Heating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerDocument2 pagesHeating and Ventilating Systems 37: Figure 3-6. Combustion Chamber and Fire Tubes. Two-Pass BoilerrohitNo ratings yet

- Heating and Ventilating Systems 27Document2 pagesHeating and Ventilating Systems 27rohitNo ratings yet

- Heating and Ventilating Systems 29: Figure 3-2. Steam BoilerDocument2 pagesHeating and Ventilating Systems 29: Figure 3-2. Steam BoilerrohitNo ratings yet

- Heating and Ventilating Systems 35Document2 pagesHeating and Ventilating Systems 35rohitNo ratings yet

- 1 PDFDocument2 pages1 PDFrohitNo ratings yet

- Heating and Ventilating Systems 33Document2 pagesHeating and Ventilating Systems 33rohitNo ratings yet

- Heating and Ventilating Systems 25Document2 pagesHeating and Ventilating Systems 25rohitNo ratings yet

- Air Conditioning Systems 57Document2 pagesAir Conditioning Systems 57rohitNo ratings yet

- Figure 4-4. Air-to-Water AC SystemDocument2 pagesFigure 4-4. Air-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)Document2 pagesAir Conditioning Systems 63: Evaporators (Heat Picked Up From The Conditioned Space)rohitNo ratings yet

- Figure 4-.2 Air Conditioning System ExampleDocument2 pagesFigure 4-.2 Air Conditioning System ExamplerohitNo ratings yet

- Air Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemDocument2 pagesAir Conditioning Systems 59: Figure 4-3. Water-to-Water AC SystemrohitNo ratings yet

- Air Conditioning Systems 55Document2 pagesAir Conditioning Systems 55rohitNo ratings yet

- Heating and Ventilating Systems 41: Figure 3-8. Oil BurnerDocument2 pagesHeating and Ventilating Systems 41: Figure 3-8. Oil BurnerrohitNo ratings yet

- Btuh GPM ×: Heat Flow 23Document2 pagesBtuh GPM ×: Heat Flow 23rohitNo ratings yet

- Figure 3-10. Central HVAC System "Ventilating"Document2 pagesFigure 3-10. Central HVAC System "Ventilating"rohitNo ratings yet

- Air Conditioning Systems 47Document2 pagesAir Conditioning Systems 47rohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- Air Conditioning Systems 51Document2 pagesAir Conditioning Systems 51rohitNo ratings yet

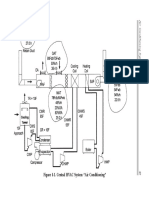

- Figure 4-1. Central HVAC System "Air Conditioning"Document2 pagesFigure 4-1. Central HVAC System "Air Conditioning"rohitNo ratings yet

- HVAC Systems 1Document2 pagesHVAC Systems 1rohitNo ratings yet

- Heating and Ventilating Systems 43: MAT (%OA ×Document2 pagesHeating and Ventilating Systems 43: MAT (%OA ×rohitNo ratings yet

- Latent HeatDocument2 pagesLatent HeatrohitNo ratings yet

- HVAC Systems 13: VentilatingDocument2 pagesHVAC Systems 13: VentilatingrohitNo ratings yet

- This Page Intentionally Left BlankDocument2 pagesThis Page Intentionally Left BlankrohitNo ratings yet

- Samuel C. Sugarman - HVAC Fundamentals-Fairmont Press - Distributed by Marcell Dekker - CRC Press (2005) - 4Document2 pagesSamuel C. Sugarman - HVAC Fundamentals-Fairmont Press - Distributed by Marcell Dekker - CRC Press (2005) - 4rohitNo ratings yet

- Heat Flow 19Document2 pagesHeat Flow 19rohitNo ratings yet

- Heat Flow 17: ConductionDocument2 pagesHeat Flow 17: ConductionrohitNo ratings yet

- Sample of Technical Description: RefrigeratorDocument1 pageSample of Technical Description: RefrigeratorHawaiiChongNo ratings yet

- TCH-V - 006-060 - PARTE1 ClimatemasterDocument33 pagesTCH-V - 006-060 - PARTE1 Climatemastercarlos albertoNo ratings yet

- High Side Tender AnalysisDocument33 pagesHigh Side Tender Analysissripriya01No ratings yet

- Design and Performance Evaluation of An Indirect Evaporative Air CoolerDocument5 pagesDesign and Performance Evaluation of An Indirect Evaporative Air CoolerIDES100% (1)

- VCM-X Modular E-BUS Controller Technical Guide: Factory Packaged ControlsDocument88 pagesVCM-X Modular E-BUS Controller Technical Guide: Factory Packaged ControlsMichael PasayNo ratings yet

- I 0000035Document20 pagesI 0000035jose antonioNo ratings yet

- Ventilation and Air Distribution in Indoor Aquatic FacilitiesDocument14 pagesVentilation and Air Distribution in Indoor Aquatic FacilitiesPatrick ClarkeNo ratings yet

- 25-Ton Rental Air Conditioning Unit 60 HZ: SpecificationsDocument2 pages25-Ton Rental Air Conditioning Unit 60 HZ: SpecificationsGhulam MustafaNo ratings yet

- Flash Steam SystemDocument4 pagesFlash Steam SystemAnonymous CX51waINo ratings yet

- RAC Questions NewDocument2 pagesRAC Questions NewChary100% (1)

- Spiral Duct Manufacturers AssociationDocument8 pagesSpiral Duct Manufacturers AssociationEduardo GarcíaNo ratings yet

- TE 2008 Nov-Dec 2013Document182 pagesTE 2008 Nov-Dec 2013prateekg92No ratings yet

- BMS Sequence of OperationDocument2 pagesBMS Sequence of OperationRaja AntonyNo ratings yet

- Heating and Cooling: 9.1 Overview 2 9.2 Central Cooling Systems 3Document23 pagesHeating and Cooling: 9.1 Overview 2 9.2 Central Cooling Systems 3Giftson ImmanuelNo ratings yet

- Air ConditionDocument4 pagesAir ConditionTaller Energy EnergyNo ratings yet

- MIDEA UGRADJENO Air Cooled Chillers 50Hz 20131216 PDFDocument39 pagesMIDEA UGRADJENO Air Cooled Chillers 50Hz 20131216 PDFDragisa DjukicNo ratings yet

- HRV Guide For Houses - Compiled - WebDocument59 pagesHRV Guide For Houses - Compiled - WebIvan Jelic Beli100% (1)

- Cvhe - 1994 - 2025Document131 pagesCvhe - 1994 - 2025Umar Majeed100% (1)

- Tools For High Performance Building Designers: ASHRAE's HVAC Design: Level I Essentials (MENA)Document2 pagesTools For High Performance Building Designers: ASHRAE's HVAC Design: Level I Essentials (MENA)Lisma RantoNo ratings yet

- Refrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFDocument13 pagesRefrigeration Cycle, HVAC System Basics and Refrigerant Charging PDFMurillo MendesNo ratings yet

- Pengantar Teknik Kimia Sesi 1 Peralatan Proses: Ir. Abdul Wahid Surhim, MTDocument14 pagesPengantar Teknik Kimia Sesi 1 Peralatan Proses: Ir. Abdul Wahid Surhim, MTAinul NasihaNo ratings yet

- EVCIS-18K-J - EvvoliDocument5 pagesEVCIS-18K-J - EvvoliMohamed faisalNo ratings yet

- Liebert Intelecool 2: A Real Choice For Telecom Shelter Air ConditioningDocument4 pagesLiebert Intelecool 2: A Real Choice For Telecom Shelter Air Conditioningfawzy radwanNo ratings yet

- Rac QB Set WiseDocument3 pagesRac QB Set WiseSam SukumarNo ratings yet

- CfsdfsfwcereDocument28 pagesCfsdfsfwcerevinicius schwabNo ratings yet

- 1 Assignment Solution MEENG322 3BDocument5 pages1 Assignment Solution MEENG322 3BKing Cyruz PabloNo ratings yet

- Acson Catalogue Air Handling Unit (1201)Document12 pagesAcson Catalogue Air Handling Unit (1201)William Ball50% (4)

- Introduction To Chillers PDFDocument26 pagesIntroduction To Chillers PDFValar MorghulisNo ratings yet

- ARNU15GL2G4Document2 pagesARNU15GL2G4julioNo ratings yet