Professional Documents

Culture Documents

Cis37 - Handling Heavy Building Blocks

Uploaded by

Darko ZovkoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cis37 - Handling Heavy Building Blocks

Uploaded by

Darko ZovkoCopyright:

Available Formats

HSE information sheet

Handling heavy building blocks

Construction Industry Advisory Committee Construction Sheet No 37

properly planned. This guidance contains practical

advice on these matters and should help designers and

specifiers, those managing work on site and those who

handle blocks.

Risk assessment

1 To minimise the risk of injury:

(a) all the hazards involved need to be identified;

(b) the significant risks estimated; and

(c) suitable precautions to avoid or reduce these risks

incorporated into a safe system of work.

2 The main hazards are:

(a) heavy loads and poor posture: excessive stress

and strain causing injury to muscles and tendons,

particularly where handling involves bending,

twisting or other difficult postures;

(b) slips, trips and falls: including damage caused by

‘dropped blocks’;

(c) sharp edges: cuts and abrasions to the skin;

(d) skin hazards: dermatitis, burns and similar

conditions caused by contact with mortar (see HSE

construction information sheet No 26 Cement).

3 With block handling, the risk of injury is largely

determined by the weight of the block - the heavier the

block, the higher the risk of injury.

4 After taking account of expert opinion and the long

Introduction history of complaints over handling heavy blocks,

CONIAC has concluded that there is a high risk of

This guidance by the Construction Industry Advisory injury in the single-handed, repetitive manual

Committee (CONIAC) covers the safe handling of handling of blocks heavier than 20 kg (44 lbs).

building blocks, by which the committee means all

masonry units and blocks including those made of clay, 5 If single person handling is needed, either blocks of

concrete, reconstituted stone, or any similar man-made 20 kg or lighter should be specified and used or other

or natural material. precautions should be taken to reduce the risk by, for

example, the provision of mechanical handling. This

Handling of heavy building blocks can give rise to a wide would contribute to the risk assessment required under

range of injuries, including serious injuries where the the Manual Handling Operations Regulations 1992.

damage is gradual and progressive over a substantial

period of time. 6 With blocks weighing less than 20 kg, manual

handling risks are still significant and suitable

To reduce the risk of injury the blockwork design, site precautions should be taken to minimise these risks as

conditions and the way the work is organised should be much as possible.

Precautions The working environment

7 Designers and specifiers should take the weight Prepare roads and hard standing first and before blocks

guideline into account at the design and specification are on site. In areas where blocks are carried or

stage of the project. Where it is not reasonably handled, keep the site clear of obstacles or tripping

practicable to avoid specifying blocks heavier than 20 hazards, such as discarded block wrappings or stack

kg, provision should be made for mechanical handling or ties. Uneven, slippery or unstable ground conditions

for handling and laying by two people. increase the risk of injury. Blocks should be protected

from the weather to avoid them getting wet and

8 Project planners and contractors should follow increasing in weight.

the weight guideline and ensure that the precautions

Training

listed below are taken into account when planning the

work and when devising safe systems of work.

Workers should be given information and training on the

Contractors should also give instruction and exercise

systems of work and procedures to be used on that site

supervision to ensure that workers follow these plans to ensure safe manual handling of blocks. Suitable

and systems of work. training will also be necessary for designers, specifiers

and those managing contracts.

The task

Personal protective equipment

Handle and lay building blocks in accordance with the

following: When handling blocks the normal protective equipment

needed for use on building sites should be provided by

● Plan to stack blocks close to where they will be employers and worn by individual workers: in particular,

used safety helmets, safety footwear with protective toe caps

and suitable gloves.

● Stack on a level, firm base and wherever possible

without double stacking of block packs Wall ties

● Keep man-handling of blocks to a minimum and Serious injuries have occurred during blockwork when

use mechanical lifting and handling aids as much building double skin walls due to contact with the sharp

as possible, such as cranes, fork-lift trucks with ends and edges of some types of wall ties. The exposed

pallets, trolleys and telescopic handlers sharp edges should be covered or safer wall ties used.

(Note: ensure that the landing area of scaffolding is References and reading list

adequate for the temporary loading of blocks)

Manual Handling Operations Regulations 1992

Guidance on Regulations L23 (Second edition)

● Always use mechanical lifting and handling or

HSE Books 1998 ISBN 0 7176 2415 3

operate a two-person system for blocks weighing

more than 20 kg BS 6073: 1981 Specification for pre-cast concrete

masonry units. British Standards Institution (BSI)

● Arrange work so that blocks can be handled close

to the body. Access around all sides of the block BS 5628: 1985 Code of practice for use of masonry. BSI

stack enables the closest blocks to be selected

Contemporary Ergonomics 1989: Block laying in the

● Arrange work to avoid over-reaching or twisting construction industry Tracy M F and Gray M I

when handling blocks Proceedings of the Ergonomics Society ’s 1989 Annual

Conference: Ergonomics- designing progress Megaw,

● Ensure good grip and secure foot placement in the E D, Taylor and Francis 1989 ISBN 085 066 484 5

working area when handling blocks

This leaflet contains notes on good practice which are

Arrange the work so that blocks only need to be handled not compulsory but which you may find helpful in

up to shoulder height. Go higher by using staging, for considering what you need to do.

instance. (Note: further protection against falls may be

necessary if the effective height of guard rails is © Crown copyright This publication may be freely

reduced.) Particular care and attention is needed for reproduced, except for advertising, endorsement or sale

higher risk block laying such as when head room is purposes. First published 6/93. Please acknowledge the

restricted, under soffits, or below working platform level. source as HSE.

Printed and published by the Health and Safety Executive Reprinted 6/03 CIS37 C50

You might also like

- Understanding Employment Relations 1st Edition 1e by by Keith Abbott Paul FalloDocument507 pagesUnderstanding Employment Relations 1st Edition 1e by by Keith Abbott Paul FalloZhicongNo ratings yet

- Method Statement For Erection of PanelDocument13 pagesMethod Statement For Erection of PanelNadeem Afzal100% (1)

- HR Job Description &job SpecificationDocument4 pagesHR Job Description &job Specificationemmanuel Johny100% (4)

- MOM Formwork Design Circular - 31jan2013Document9 pagesMOM Formwork Design Circular - 31jan2013Tey Chin WeiNo ratings yet

- Commissioning ManualDocument224 pagesCommissioning ManualAmit Balot100% (1)

- Learner'S Packet No. 5 Quarter 1: Identify Hazards and RisksDocument5 pagesLearner'S Packet No. 5 Quarter 1: Identify Hazards and RisksSalgie Masculino100% (2)

- Contractor Safety ManagementDocument18 pagesContractor Safety ManagementTim Yap100% (2)

- Ethical Analysis of Dominos Limited Pizza Delivery Policy Working VersionDocument11 pagesEthical Analysis of Dominos Limited Pizza Delivery Policy Working Versionapi-502151650No ratings yet

- Case Study 1 (ENGINEERING OF SOSITY)Document22 pagesCase Study 1 (ENGINEERING OF SOSITY)mohd irfanNo ratings yet

- Musculoskeletal Disorders (MSDS) Handling Kerbs: Reducing The Risks ofDocument4 pagesMusculoskeletal Disorders (MSDS) Handling Kerbs: Reducing The Risks ofJericFuentesNo ratings yet

- Risk Assessment and Safety in FormworkDocument9 pagesRisk Assessment and Safety in Formworkvasanth pugazhendhi0% (1)

- Construction Site Issues - Hazards and ControlDocument12 pagesConstruction Site Issues - Hazards and ControlDeva DNo ratings yet

- Demolition Guidence CDM RegsDocument2 pagesDemolition Guidence CDM RegsDockDiverNo ratings yet

- Construction Design Guidelines For Working Within and or Near Occupied BuildingsDocument7 pagesConstruction Design Guidelines For Working Within and or Near Occupied BuildingsAthirahNo ratings yet

- 20130131-55 Safety Requirements For Formwork Structures PDFDocument9 pages20130131-55 Safety Requirements For Formwork Structures PDFsawwahwahNo ratings yet

- Bsee 3b-Bosh Job Hazard Analysis Exam (Priela, Allen Kyle D.)Document6 pagesBsee 3b-Bosh Job Hazard Analysis Exam (Priela, Allen Kyle D.)Allen Kyle PrielaNo ratings yet

- Provisions For The Safe Use of Cranes On Construction SitesDocument2 pagesProvisions For The Safe Use of Cranes On Construction Siteskla_alkNo ratings yet

- Sécurité GCDocument12 pagesSécurité GCRahma JemaielNo ratings yet

- IJRET - Technical Paper 22.9.161Document12 pagesIJRET - Technical Paper 22.9.161Kaushiki RaskarNo ratings yet

- Barricading Awareness TrainingDocument67 pagesBarricading Awareness TrainingJohn Ervin AgenaNo ratings yet

- Method Statements For Construction of Masonry Lined Drains Rev 0Document13 pagesMethod Statements For Construction of Masonry Lined Drains Rev 0McDonald WesleyNo ratings yet

- ISBN Safe Work Method Statements 2018 11 PDFDocument6 pagesISBN Safe Work Method Statements 2018 11 PDFZeljkoNo ratings yet

- ISBN Safe Work Method Statements 2018 11Document6 pagesISBN Safe Work Method Statements 2018 11ZeljkoNo ratings yet

- Falsework-EngDocument21 pagesFalsework-Engdox4useNo ratings yet

- Construction Information Sheets Steel ErectionDocument4 pagesConstruction Information Sheets Steel ErectionRoni EnjelaniNo ratings yet

- W2 L2 Limit State DesignDocument28 pagesW2 L2 Limit State Design木辛耳总No ratings yet

- HS-18-Hazards-Structural SteelworkDocument1 pageHS-18-Hazards-Structural SteelworktresspasseeNo ratings yet

- Earthquake Tip: Why Quality Critical Earthquake Resistant Buildings?Document2 pagesEarthquake Tip: Why Quality Critical Earthquake Resistant Buildings?Ayushi MistryNo ratings yet

- Chapter 19 - Demolition: MG Latimer 19.1 ScopeDocument8 pagesChapter 19 - Demolition: MG Latimer 19.1 Scopeecks09No ratings yet

- HTCI - METHOD STATEMENT-Foundation & Erection Works of Steel PolesDocument9 pagesHTCI - METHOD STATEMENT-Foundation & Erection Works of Steel PolesFrancis GonzalesNo ratings yet

- Safety in Design ProcessDocument14 pagesSafety in Design ProcessHARENDRA SINGH BISHTNo ratings yet

- Formwork For Concrete: University of WashingtonDocument36 pagesFormwork For Concrete: University of Washingtonraahul_nNo ratings yet

- Demolition Hazards and Heirarchy of ControlDocument14 pagesDemolition Hazards and Heirarchy of ControlMel DowleyNo ratings yet

- Demolishen Work NoteDocument40 pagesDemolishen Work NoteTeacher IshaNo ratings yet

- False Work OshaDocument41 pagesFalse Work OshasuhaemiNo ratings yet

- Im-10 Construction Activities Hazard and Control NewDocument71 pagesIm-10 Construction Activities Hazard and Control NewElvira Lopez AndadiNo ratings yet

- 028 034 F1Rajen 0711ZDocument7 pages028 034 F1Rajen 0711ZAbhishek KudalNo ratings yet

- Department of Civil Engineering M.Tech Seminar Report 2021Document22 pagesDepartment of Civil Engineering M.Tech Seminar Report 2021Classic PrintersNo ratings yet

- Lecture 3 - CIE 531-EGM 501 - 2021Document43 pagesLecture 3 - CIE 531-EGM 501 - 2021Emmanuel MwabaNo ratings yet

- Demolition Works in BangladeshDocument6 pagesDemolition Works in BangladeshJithesh SukumaranNo ratings yet

- NSCP Chapter 2 Summary FinalDocument2 pagesNSCP Chapter 2 Summary FinalshienellajacildoNo ratings yet

- Attachment R (Draft Offshore Decommissioning Safety Requirement Guideline)Document10 pagesAttachment R (Draft Offshore Decommissioning Safety Requirement Guideline)mustaffa bakriNo ratings yet

- Study of Safety in Demolition of Buildin PDFDocument5 pagesStudy of Safety in Demolition of Buildin PDFprathamesh narkarNo ratings yet

- Deep Excavations - A Practical Manual (PDFDrive)Document568 pagesDeep Excavations - A Practical Manual (PDFDrive)Malik RizwanNo ratings yet

- Chapter 2 UltmiteDocument4 pagesChapter 2 UltmiteUsama Moh GANo ratings yet

- Bab 3 Keselamatan Konstruksi Dan PermesinanDocument68 pagesBab 3 Keselamatan Konstruksi Dan PermesinandindaNo ratings yet

- ZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngDocument5 pagesZTV-InG, Part 1-10 ARS 13 - 2012 Status - 2012 - 03.PDF EngSahiduj Jaman SajuNo ratings yet

- Https Rdso - Indianrailways.gov - in Uploads Files GE-G-0016Document38 pagesHttps Rdso - Indianrailways.gov - in Uploads Files GE-G-0016vinodshukla25No ratings yet

- Unit 2 - Construction Technology - WWW - Rgpvnotes.inDocument14 pagesUnit 2 - Construction Technology - WWW - Rgpvnotes.inmadhavi likhar100% (1)

- Math Terms 2 RefresherDocument3 pagesMath Terms 2 Refreshercat buenafeNo ratings yet

- ScaffoldingDocument21 pagesScaffoldingKrm ChariNo ratings yet

- Temp Structures - Lesson1 To 7 (Washington University)Document121 pagesTemp Structures - Lesson1 To 7 (Washington University)tony fungNo ratings yet

- Sandwich Panel SafetyDocument38 pagesSandwich Panel Safetykhalid mohamedNo ratings yet

- Oil Industry Safety Directorate (Oisd) Guidelines-192 & 207Document74 pagesOil Industry Safety Directorate (Oisd) Guidelines-192 & 207S Sinha Ray100% (1)

- Design of Residential Buildings in High-Wind Coastal AreasDocument164 pagesDesign of Residential Buildings in High-Wind Coastal AreasRochelle FernandoNo ratings yet

- Ghana Building Code - Part 11Document72 pagesGhana Building Code - Part 11vasvuk100% (2)

- Health and Safety in ConstructionDocument11 pagesHealth and Safety in Constructionkarl facturan100% (1)

- Guidelines For Safety in Tunnels During ConstructionDocument40 pagesGuidelines For Safety in Tunnels During ConstructionPrasanta ParidaNo ratings yet

- To Falsework: GuideDocument3 pagesTo Falsework: GuideVictor OmotoriogunNo ratings yet

- 5B High Rise Building Summary of FindingsDocument3 pages5B High Rise Building Summary of FindingsJholo LopezNo ratings yet

- Demolition Techniques - Case StudyDocument18 pagesDemolition Techniques - Case Studybasanth_71298296% (23)

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Circulation Unit - Flexi - 98140943 - GB - DE - RU - IT - FR - SE - PL - Utgd - LRDocument32 pagesCirculation Unit - Flexi - 98140943 - GB - DE - RU - IT - FR - SE - PL - Utgd - LRDarko ZovkoNo ratings yet

- Mazda 2016 01.10.Document54 pagesMazda 2016 01.10.Darko ZovkoNo ratings yet

- Indg290 - A Simple Guide To LOLERDocument8 pagesIndg290 - A Simple Guide To LOLERDarko ZovkoNo ratings yet

- Noise PDFDocument20 pagesNoise PDFDarko ZovkoNo ratings yet

- Cis51 - Construction Fire SafetyDocument2 pagesCis51 - Construction Fire SafetyDarko ZovkoNo ratings yet

- Workers: The Construction (Design and Management) Regulations 2007 Industry Guidance ForDocument11 pagesWorkers: The Construction (Design and Management) Regulations 2007 Industry Guidance ForDarko ZovkoNo ratings yet

- Asbestos Managing The RisksDocument6 pagesAsbestos Managing The RisksDarko ZovkoNo ratings yet

- CDM Co-OrdinatorsDocument30 pagesCDM Co-OrdinatorsDarko ZovkoNo ratings yet

- Principal Contractors: The Construction (Design and Management) Regulations 2007 Industry Guidance ForDocument17 pagesPrincipal Contractors: The Construction (Design and Management) Regulations 2007 Industry Guidance ForDarko ZovkoNo ratings yet

- Annex I: Summary of Duty HoldersDocument9 pagesAnnex I: Summary of Duty HoldersDarko ZovkoNo ratings yet

- Dispatcher Ilwu Jack Hall Is DeadDocument8 pagesDispatcher Ilwu Jack Hall Is DeadjerrymonacoNo ratings yet

- Fall Protection ProcedureDocument50 pagesFall Protection Proceduretnsv22No ratings yet

- Sec 19 (3) Employer AppointmentDocument2 pagesSec 19 (3) Employer Appointmentridhwaan singhNo ratings yet

- Chapter 1 IntroductionDocument8 pagesChapter 1 IntroductionSachin MohalNo ratings yet

- Tex 20psDocument268 pagesTex 20psMantenimiento AtocongoNo ratings yet

- PIDAC Cleaning Disinfection and Sterilization 2013Document117 pagesPIDAC Cleaning Disinfection and Sterilization 2013sami1218No ratings yet

- Managing Major Accident Hazards Through Sce Management ProcessDocument4 pagesManaging Major Accident Hazards Through Sce Management ProcessLi QiNo ratings yet

- 06 She Sop Consultation and Participation of WorkersDocument7 pages06 She Sop Consultation and Participation of WorkersHADWAN YUSOFNo ratings yet

- Ceiling WorkDocument10 pagesCeiling WorkNisanth ThulasidasNo ratings yet

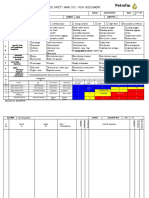

- Petrofac: Job Safety Analysis / Risk AssessmentDocument4 pagesPetrofac: Job Safety Analysis / Risk Assessmentazer Azer0% (1)

- 32 Oct-Dec52 PDFDocument56 pages32 Oct-Dec52 PDFAhmad Jukliv Pandu YoedhawanNo ratings yet

- SITXWHS007 Student Assessment Tasks (6504)Document34 pagesSITXWHS007 Student Assessment Tasks (6504)helpdeskarea001No ratings yet

- Supervise EditononDocument37 pagesSupervise EditononDALISAY GINGCO67% (3)

- Construction Risk Assessment Sample Form PDFDocument4 pagesConstruction Risk Assessment Sample Form PDFZaka Ur RehmanNo ratings yet

- MSDS Enerpac Hydraulic OilDocument4 pagesMSDS Enerpac Hydraulic Oiljusman sadorraNo ratings yet

- CHN Prefinals: Occupational Health Strategies: Assessment and Control of Hazards in The WorkplaceDocument2 pagesCHN Prefinals: Occupational Health Strategies: Assessment and Control of Hazards in The WorkplaceRosemarie MendezNo ratings yet

- Slips and Trips Mapping Tool: An Aid For Safety RepresentativesDocument4 pagesSlips and Trips Mapping Tool: An Aid For Safety RepresentativesIoana UrsanNo ratings yet

- 2. job Safety Analysis Excavation 挖土工作安全分析Document6 pages2. job Safety Analysis Excavation 挖土工作安全分析ADEN LIUNo ratings yet

- Tower Crane HirarcDocument3 pagesTower Crane HirarcNethiyaaRajendran88% (16)

- Pnle CHNDocument25 pagesPnle CHNLrak Eed0% (1)

- OVID 19: Districtwise List of Manufacturers / Suppliers of Essential Items in Tamil NaduDocument77 pagesOVID 19: Districtwise List of Manufacturers / Suppliers of Essential Items in Tamil NaduTibu ThomasNo ratings yet

- Lecture 8.1&2 Process Safety Management Ilearn PDFDocument32 pagesLecture 8.1&2 Process Safety Management Ilearn PDFMuhammad AshmanNo ratings yet

- 555-1QT 2U CA EN safetyDataSheet Sds 8799831064580 0 1Document12 pages555-1QT 2U CA EN safetyDataSheet Sds 8799831064580 0 1compras.lairtechNo ratings yet

- 2020 Sustainable Agriculture Standard - Farm Requirements - Rainforest Alliance PDFDocument83 pages2020 Sustainable Agriculture Standard - Farm Requirements - Rainforest Alliance PDFLuis LanzasNo ratings yet