Professional Documents

Culture Documents

MOLYKOTE 1000 Solid Lubricant 71-0218G-01

Uploaded by

Budi HandokoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOLYKOTE 1000 Solid Lubricant 71-0218G-01

Uploaded by

Budi HandokoCopyright:

Available Formats

Transportation & Advanced Polymers

MOLYKOTE® 1000

Solid Lubricant Paste

Solid lubricant paste for bolted metal joints; contains no lead or nickel

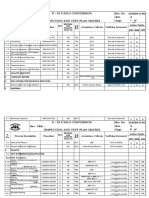

Features & benefits Typical properties

Specification writers: These values are not intended for use in

• Can be used over a wide range of temperatures (-30°C/-22°F to

preparing specifications. Please contact your local MOLYKOTE®

+650°C/1,202°F)

sales representative prior to writing specifications on this product.

• High load-carrying capacity

• Enables nondestructive dismantling, even after long use at high Standard(1) Test Unit Result

temperatures Color Brown

• Coefficient of friction unchanged in the area of oiled bolts, even

Penetration, density

after several bolt retightening and loosening processes

• Good corrosion protection ISO 2137 Unworked penetration mm/10 280-310

ISO 2811 Density at 20°C (68°F) g/ml 1.26

Composition Temperature

• Solid lubricants Service temperature °C -30 to 650

• Mineral oil range(2) °F -22 to 1,202

• Thickener Load-carrying capacity, wear protection, service life

• Powdered metal

Four-ball tester

DIN 51 350 Weld load N 4,800

Applications pt.4

Suitable for bolted joints that are subjected to high temperatures DIN 51 350 Wear scar under 400 N mm 0.65

up to 650°C (1,202°F) and to corrosive effects – and that after pt.5 load

assembling and the initial operation, have to be retightened or Almen-Wieland

disconnected. In order to ensure constant pre-stressing forces, machine

uniform and steady coefficients of friction of the lubricant are OK load N 20,000

necessary. Used successfully for cylinder head bolts, nozzle head Frictional force N 2,600

screws of plastic injection molding machines, bolted joints in the

Coefficient of friction

chemical industry, and also for the tension rings of centrifuges.

Screw test - µ thread(3) 0.13

Screw test - µ head 0.08

Description

Initial break-away Nm 135

MOLYKOTE® 1000 Solid Lubricant Paste is a lead- and nickel- torque(4)

free anti-seize paste used to reduce wear and optimize friction of

DIN 51 802 SKF-Emcor method 1

threaded fasteners, or other metal-to-metal joints, enabling (1)

ISO: International Standardization Organization. DIN: Deutsche

nondestructive dismantling, even after long exposure to high Industrie Norm.

temperatures. It offers good corrosion protection, under high (2)

Temperature resistance of solid lubricants.

loads, over a wide temperature range. (3)

Coefficient of friction in bolted connection, M12, 8.8, on blackened

surface.

(4)

M 12, with starting torque Ma = 62 Nm and heat treatment at 540°C

(1,004°F), 21 hr, bolt material: no. 1.7709.

How to use

If possible, clean the thread and the bolt with a wire brush.

Spread an adequate amount of the paste on the thread, right up

to its root to obtain a good seal. In order not to alter the

properties, the paste must not be mixed with grease or oils.

To enable this product to be applied more quickly and cleanly to

larger areas, it is advisable to use the spray can.

Handling precautions

PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE

USE IS NOT INCLUDED IN THIS DOCUMENT. BEFORE

HANDLING, READ SAFETY DATA SHEETS AND CONTAINER

LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD

INFORMATION.

Usable life and storage

When stored at or below 20°C (68°F) in the original unopened

containers, MOLYKOTE® 1000 Solid Lubricant Paste has a

usable life of 60 months from the date of production.

Packaging

This product is available in different standard container sizes.

Detailed container size information should be obtained from your

nearest MOLYKOTE® sales office or MOLYKOTE® distributor.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de Nemours, Inc.

unless otherwise noted.

© 1997-2019 DuPont.

The information set forth herein is furnished free of charge and is based on technical data that DuPont believes to be reliable and falls within the normal

range of properties. It is intended for use by persons having technical skill, at their own discretion and risk. This data should not be used to establish

specification limits nor used alone as the basis of design. Handling precaution information is given with the understanding that those using it will satisfy

themselves that their particular conditions of use present no health or safety hazards. Since conditions of product use and disposal are outside our

control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. As with any product,

evaluation under end use conditions prior to specification is essential. Nothing herein is to be taken as a license to operate or a recommendation to

infringe on patents.

Form No. 71-0218G-01 (07/19) AGP16093

You might also like

- MOLYKOTE 1000 Paste 71-0218H-01Document2 pagesMOLYKOTE 1000 Paste 71-0218H-01Victor PomboNo ratings yet

- Molykote 1000 Paste PDFDocument2 pagesMolykote 1000 Paste PDFGyanaranjan NayakNo ratings yet

- MOLYKOTE HSC Plus Paste 71-0212H-01Document2 pagesMOLYKOTE HSC Plus Paste 71-0212H-01Vendy KurniawanNo ratings yet

- MOLYKOTE P-74 Assembly Paste 10-929B-01Document2 pagesMOLYKOTE P-74 Assembly Paste 10-929B-01ko htetNo ratings yet

- 517hoja-tecnica-MOLYKOTE® Longterm W 2Document2 pages517hoja-tecnica-MOLYKOTE® Longterm W 2Sophia RoseNo ratings yet

- MOLYKOTE Longterm 2 Plus Grease 71-0076F-01Document2 pagesMOLYKOTE Longterm 2 Plus Grease 71-0076F-01Dicky PratamaNo ratings yet

- MOLYKOTE Longterm 00 Fluid Grease 2019Document2 pagesMOLYKOTE Longterm 00 Fluid Grease 2019ANo ratings yet

- MOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Document2 pagesMOLYKOTE - P 3700 - Anti Seize - Paste - 03 1106 01 AGP1022Ramesh-NairNo ratings yet

- 528hoja-tecnica-MOLYKOTE® TP-42Document2 pages528hoja-tecnica-MOLYKOTE® TP-42Diego MarroneNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- Molykote BR-2 Plus High Performance GreaseDocument2 pagesMolykote BR-2 Plus High Performance GreaseRamonNo ratings yet

- MOLYKOTE BR-2 Plus High Performance Grease 71-0241D-01Document2 pagesMOLYKOTE BR-2 Plus High Performance Grease 71-0241D-01Syed Noman AhmedNo ratings yet

- MOLYKOTE 44 - MediumDocument2 pagesMOLYKOTE 44 - MediumCesar AlejandroNo ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- Moylkote DX Paste Technical Data SheetDocument2 pagesMoylkote DX Paste Technical Data SheetMihai AlexNo ratings yet

- Molykote 7348Document2 pagesMolykote 7348Luz Angela GuerreroNo ratings yet

- MOLYKOTE® G-Rapid Plus Solid Lubricant PasteDocument2 pagesMOLYKOTE® G-Rapid Plus Solid Lubricant PasteBart AertsNo ratings yet

- Folheto Tecnico - Molykote 7514 Synthetic Grease 80-3142A-01Document2 pagesFolheto Tecnico - Molykote 7514 Synthetic Grease 80-3142A-01marcosNo ratings yet

- OKS 252 - Product Information: White High Temperature Paste For The Food IndustryDocument2 pagesOKS 252 - Product Information: White High Temperature Paste For The Food IndustryIván ChávezNo ratings yet

- MOLYKOTE BR2 Plus Grease 80-3104A-01Document2 pagesMOLYKOTE BR2 Plus Grease 80-3104A-01Sophia RoseNo ratings yet

- Molykote 55 O-Ring Grease 71-0274h-01Document2 pagesMolykote 55 O-Ring Grease 71-0274h-01RicardoNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- MOLYKOTE P-1900 FM Anti-Seize Paste 80-3219D-01Document2 pagesMOLYKOTE P-1900 FM Anti-Seize Paste 80-3219D-01Reda GduiraNo ratings yet

- Molykote® P-37 Datasheet Eng PDFDocument2 pagesMolykote® P-37 Datasheet Eng PDFBib GmzNo ratings yet

- Moly KoteDocument2 pagesMoly KoteNagaraju PanguluriNo ratings yet

- MOLYKOTE CO220 Oil IDocument2 pagesMOLYKOTE CO220 Oil ILuz Angela GuerreroNo ratings yet

- MOLYKOTE G-Rapid Plus Paste 71-0084F-01Document2 pagesMOLYKOTE G-Rapid Plus Paste 71-0084F-01sungkarsNo ratings yet

- Molykote Longterm W GreasesDocument2 pagesMolykote Longterm W GreasesDung Dung PretNo ratings yet

- MOLYKOTE EM-30L Grease 80-3106C-01Document2 pagesMOLYKOTE EM-30L Grease 80-3106C-01madkatteNo ratings yet

- Molykote® Longterm 2 Plus Datasheet EngDocument2 pagesMolykote® Longterm 2 Plus Datasheet EngAlaa HassanNo ratings yet

- Folheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01Document2 pagesFolheto Tecnico - Molykote 7400 Anti-Friction Coating 71-0073E-01marcosNo ratings yet

- Specialty Lubricants: Molykote® P 37Document2 pagesSpecialty Lubricants: Molykote® P 37Ahmed BeaetNo ratings yet

- MOLYKOTE Multilub Synthetic High Performance Grease 01-1050A-01Document2 pagesMOLYKOTE Multilub Synthetic High Performance Grease 01-1050A-01pmf engineering limitedNo ratings yet

- MOLYKOTE 41 Extreme High Temperature Bearing Grease 80-3096B-01Document2 pagesMOLYKOTE 41 Extreme High Temperature Bearing Grease 80-3096B-01Hemant RasamNo ratings yet

- 4.4.molykote TP 42 Grease Paste Data SheetDocument2 pages4.4.molykote TP 42 Grease Paste Data SheetAhmed Hamdy WorkNo ratings yet

- Molykote® P-1900FM Datasheet EngDocument2 pagesMolykote® P-1900FM Datasheet EngnavaronefraNo ratings yet

- Molykote Multilub TDSDocument2 pagesMolykote Multilub TDSDicky PratamaNo ratings yet

- High Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseDocument2 pagesHigh Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseRildo CarvalhoNo ratings yet

- Molykote 41 Grease 80-3096a-01Document2 pagesMolykote 41 Grease 80-3096a-01Dicky PratamaNo ratings yet

- Molylub GoldTex T 32 KnittingDocument1 pageMolylub GoldTex T 32 KnittingismoyoNo ratings yet

- MOLYKOTE G-1057 Grease 80-3706A-01Document2 pagesMOLYKOTE G-1057 Grease 80-3706A-01If ChenNo ratings yet

- MOLYKOTE D-6024 Anti-Friction Coating 001-20511-AGP1120Document2 pagesMOLYKOTE D-6024 Anti-Friction Coating 001-20511-AGP1120Yoga RahadianNo ratings yet

- Molylub GoldTex T 46 KnittingDocument1 pageMolylub GoldTex T 46 KnittingismoyoNo ratings yet

- MOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01Document2 pagesMOLYKOTE 33 Light Extreme Low Temperature Grease 80-3098E-01pmf engineering limitedNo ratings yet

- Molykote Grease PDFDocument2 pagesMolykote Grease PDFTeguh JayaNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- Molylub GoldTex T 22 KnittingDocument1 pageMolylub GoldTex T 22 KnittingismoyoNo ratings yet

- MOLYKOTE G-N Metal Asembly Paste and Spray 10-731F-01Document2 pagesMOLYKOTE G-N Metal Asembly Paste and Spray 10-731F-01Ronald Mario Quiroz SerrateNo ratings yet

- CALTEX GreaseDocument3 pagesCALTEX GreasePangky AbasoloNo ratings yet

- Unirex N Series PDFDocument3 pagesUnirex N Series PDFAbdulSattarNo ratings yet

- High Performance Lubricants Molykote: 55 O-Ring GreaseDocument2 pagesHigh Performance Lubricants Molykote: 55 O-Ring Greasesatheez3251No ratings yet

- Specialty Lubricants: Molykote® G-Rapid PlusDocument2 pagesSpecialty Lubricants: Molykote® G-Rapid PlusD CNo ratings yet

- MOLYKOTE L-0501 LubricantDocument2 pagesMOLYKOTE L-0501 LubricantLuz Angela GuerreroNo ratings yet

- 高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01Document2 pages高溫油脂MOLYKOTE D-321 R Anti-Friction 71-0219G-01If ChenNo ratings yet

- Graxa LMCG 1 para Acloplamento SKFDocument2 pagesGraxa LMCG 1 para Acloplamento SKFrobson robsonNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Is 14268 - 2022Document16 pagesIs 14268 - 2022Vijith Vijayan100% (1)

- Aluminum Experience in ApplicationDocument11 pagesAluminum Experience in ApplicationVelmohanaNo ratings yet

- Sunrise Cnc-CatalogDocument49 pagesSunrise Cnc-CatalogAdan Serrano CaroNo ratings yet

- UNIT-IV Question BankDocument3 pagesUNIT-IV Question BankParamasivam VeerappanNo ratings yet

- City Vendor Type Ready To Onboard On OMS Email Address Vendor Type1Document3 pagesCity Vendor Type Ready To Onboard On OMS Email Address Vendor Type1Biswajet RouthNo ratings yet

- SH 5107 Hoods 2021 Version 1Document127 pagesSH 5107 Hoods 2021 Version 1Shuyuan LuNo ratings yet

- FMD - RCD For (4.7uh Inductor) 74479887247ADocument2 pagesFMD - RCD For (4.7uh Inductor) 74479887247AAbhishek TiwariNo ratings yet

- Carbon Steel Tube Manufacturers in GCCDocument2 pagesCarbon Steel Tube Manufacturers in GCCAli MustafaNo ratings yet

- ATA Heet: LSS D2Document2 pagesATA Heet: LSS D2X800XLNo ratings yet

- IG 76 MESC 14d - 2021Document3 pagesIG 76 MESC 14d - 2021bmanojkumar16No ratings yet

- 630mm2 Data SheetDocument8 pages630mm2 Data SheetMohammed MadiNo ratings yet

- ITP For Piping WorksDocument44 pagesITP For Piping WorksSyafril Akbar100% (3)

- PQR ForDocument3 pagesPQR ForAkash Singh TomarNo ratings yet

- Galfan eDocument1 pageGalfan ePCX2491100% (1)

- Fire Pro Specifications - RDDocument5 pagesFire Pro Specifications - RDRaymundo DelfinNo ratings yet

- Rules of Thumb For Mechanical EngineersDocument1 pageRules of Thumb For Mechanical Engineerskinfe haileNo ratings yet

- Forming V1Document32 pagesForming V1Walid DamoniNo ratings yet

- BS en 13523-10-2010Document12 pagesBS en 13523-10-2010DanielVegaNeiraNo ratings yet

- Scientific and Sustainable Mining: R.K. Sharma Federation of Indian Mineral IndustriesDocument8 pagesScientific and Sustainable Mining: R.K. Sharma Federation of Indian Mineral IndustriesSteve CoinNo ratings yet

- Croning Shell MouldingDocument7 pagesCroning Shell MouldingIvan TalandaNo ratings yet

- Unit I. Bascis of Manufacturing ProcessesDocument30 pagesUnit I. Bascis of Manufacturing Processes070 ARITRITA BRAHMA ECENo ratings yet

- Power Actuated FastenersDocument8 pagesPower Actuated FastenersNicolaNo ratings yet

- 3M VHB Specialty Tapes TSDDocument9 pages3M VHB Specialty Tapes TSDKinNo ratings yet

- BSK 07-Svedski StandardDocument40 pagesBSK 07-Svedski Standardmerim1984No ratings yet

- Synthetic Slag Plant: (EIRI/EDPR/3705) J.C.: 1792XLDocument4 pagesSynthetic Slag Plant: (EIRI/EDPR/3705) J.C.: 1792XLEIRI Board of Consultants and PublishersNo ratings yet

- Reductores TORQTAPERDocument68 pagesReductores TORQTAPERjohn Gonzalez100% (1)

- 11kV 22kV AB Switch With Polymer Insulator 31.08.2020Document18 pages11kV 22kV AB Switch With Polymer Insulator 31.08.2020SunilkumarNo ratings yet

- BS 4504-Part 1Document104 pagesBS 4504-Part 1Simon LawNo ratings yet

- 2011 Coal Preparation Buyer's Guide: Products and Services Available For Coal ProcessingDocument31 pages2011 Coal Preparation Buyer's Guide: Products and Services Available For Coal ProcessingLLNo ratings yet

- NG2DW1500B Mechanical Level SwitchDocument1 pageNG2DW1500B Mechanical Level SwitchRafaelius Ary Surya SaputraNo ratings yet