Professional Documents

Culture Documents

Consol Spectramate™ 25: A Thick-Film Trivalent Conversion Coating For Zinc

Uploaded by

Amandeep SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Consol Spectramate™ 25: A Thick-Film Trivalent Conversion Coating For Zinc

Uploaded by

Amandeep SinghCopyright:

Available Formats

TECHNICAL DATA

CONSOL SpectraMATE™ 25

A Thick-Film Trivalent Conversion Coating For Zinc

Brought to India in association with Columbia Chemical Corpn., - U.S.A., World Leaders in Zinc Plating Technologies.

TDS: 070504

CONSOL SpectraMATE™ 25…

• A high performance, thick-film trivalent conversion coating for electroplated zinc.

• Produces a slightly iridescent, multicolour finish (hues of yellow, green, purple and pink) which is

unique among high corrosion trivalent corrosion trivalent chromate processes.

• Provides a finish that consistently exceeds 250 hours of neutral salt spray to white corrosion products

without top coats, when applied properly.

• An easy to use one part system that does not require multiple starter, adjuster, and replenisher type

additives.

• Operates at a wider, and more user-friendly pH range (pH = 1.4 ~ 3.4) than conventional trivalent

chromates.

• Operates at low-to-ambient temperatures, thus eliminating the added cost and inconvenience of

heating as with conventional thick-film trivalent technologies.

• Is chelator-free, making it waste treatment friendly.

• Exhibits “true self-healing” properties similar to that of hexavalent conversion coatings.

• Provides over 500 hours to white corrosion when top coated with Zinc-Chro-Shield or Zinc-Chro-

Pellent.

• Ideal for both rack and barrel installations utilizing cyanide, alkaline cyanide-free or acid-chloride

zinc plating electrolytes.

OPERATING INSTRUCTIONS

CONSOL SpectraMATE™ 25 20 ~ 100 ml/l (Opt. 100 ml/l)

Temperature 10 ~ 42o C (Opt. 20 ~ 30o C)

pH 1.4 ~ 3.4 (Opt. 2.0 ~ 2.5)

Dip Time 45 ~ 120 Seconds

(Dip time can vary depending upon the concentration and age of the Chromate)

Typical Cycle: Plate >> Rinse >> Nitric Acid Pre-dip (0.5% by Vol) >> Rinse >> CONSOL

SpectraMATE™ 25 >> Cold water rinse >> Hot water rinse >> Dry.

Maintenance: Periodic titration is required to control the usage concentration. If the analysis shows the

proper amount of CONSOL SpectraMATE™ 25 is present, and the pH is high, small additions of 50% by

volume of Nitric acid can be made to adjust the pH.

Analysis Procedure: Pipette a 10ml chromate samples into 100 ml volumetric flask. Dilute to 100 ml with

distilled water and mix well. Pipette 10 ml of the above diluted solution into a 250 ml Erlenmeyer flask and

dilute to 100 ml with distilled water. Add 5 ml 20% Sodium Hydroxide and 1 ml 35% Hydrogen Peroxide.

Boil solution approximately 5 minutes. Add 1 ml 10% Nickel Chloride Solution and continue boiling for an

additional 2 minutes. Cool solution to room temperature. With mixing, add 10ml Concentrated

Hydrochloric Acid, 1 g Ammonium Bifluoride, 10 ml 10% Potassium Iodide and 2 ml Starch Indicator

solution. Titrate the solution to a clear / green endpoint using 0.010 N Sodium Thiosulfate.

Calculation: % by Volume CONSOL SpectraMATE™ 25 = ml 0.010 N Sodium Thiosulphate x 0.332

CONSOL SpectraMATE™ 25:060808 : Page 2/2

Iron Contamination: Iron contamination is a problem for all of the high-end/high performance trivalent

passivation technologies. Iron can cause yellowing, staining, discoloration and reduced corrosion

protection.

Extreme care should be used to keep iron from entering the working Consol SpectraMATE™ 25

chromate solution. The process tank should be cleaned at least once or twice per 8 hour shift to eliminate

the potential for dissolving fallen parts. Adequate rinsing should always be maintained and nitric pre-dips

prior to choromating should be dumped frequently to reduce drag-in of iron. Also, tubular parts should be

allowed to completely drain before entering the chromate solution.

CONSOLTri-Iron Control can be used as a treatment for iron contamination. (TDS available on request)

Ion Exchange Resin Filtration can also be used to remove iron. Contact a CMF Technical Service

Representative for further information.

Helpful Hints:

• A Nitric Acid pre-dip is recommended to increase the life of the chromate particularly when an

alkaline zinc electrolyte is utilized.

• Although the pH for a new solution make-up may be below the recommended operating range of

1.4 ~ 3.4, parts can be processed since the pH will climb after only a few hours.

• Sulphuric Acid or Nitric Acid can be used to adjust the pH down in a working Consol

SpectraMATE™ 25 solution.

Handling & Storage: Caution: CONSOL SpectraMATE™ 25 is corrosive and contains Chromium compounds and strong mineral acids.

Contact with the skin or eyes should be carefully avoided. Protective clothing, goggles and mask should be worn when handling CONSOL

SpectraMATE™ 25. In case of contact, flush with large amounts of water. Remove contaminated clothing. Consult doctor. Always store in a

cool dry area away from combustibles.

Non-Warranty: The data contained in this bulletin is believed by Consolidated Metal Finishing Pvt. Ltd. to be accurate, true and complete.

Since however, final methods of use of these products are in the hands of the customer and beyond our control, we cannot guarantee that the

customer will obtain the results described in this bulletin, nor can we assume any responsibility for the use of this product by the customer in any

process which may infringe the patent.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Iso 9001 2015Document1 pageIso 9001 2015Amandeep SinghNo ratings yet

- Magni-565-Product-Data-Sheet - COFDocument1 pageMagni-565-Product-Data-Sheet - COFAmandeep SinghNo ratings yet

- Vernier LifeDocument1 pageVernier LifeAmandeep SinghNo ratings yet

- RecordDocument2 pagesRecordAmandeep SinghNo ratings yet

- Magni-515-Product-Data-Sheet - COFDocument1 pageMagni-515-Product-Data-Sheet - COFAmandeep SinghNo ratings yet

- AISI304Document1 pageAISI304Amandeep SinghNo ratings yet

- POKAYOKE Competition Presentation FormatDocument18 pagesPOKAYOKE Competition Presentation FormatAmandeep SinghNo ratings yet

- Automotive Tests & Standards Honda SAE Standards & Testing: Reference Specification TestDocument1 pageAutomotive Tests & Standards Honda SAE Standards & Testing: Reference Specification TestAmandeep SinghNo ratings yet

- Data AnalysisDocument9 pagesData AnalysisAmandeep SinghNo ratings yet

- Scope CC 2576 - 1Document25 pagesScope CC 2576 - 1Amandeep SinghNo ratings yet

- Kova Fasteners PVT - LTD: Heat Treatment Report Material DescriptionDocument3 pagesKova Fasteners PVT - LTD: Heat Treatment Report Material DescriptionAmandeep SinghNo ratings yet

- Zinc Plating Reports 02Document1 pageZinc Plating Reports 02Amandeep SinghNo ratings yet

- DPMO Z CPK, Yield ChartDocument3 pagesDPMO Z CPK, Yield ChartAmandeep SinghNo ratings yet

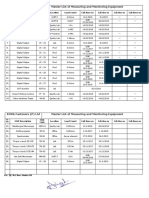

- Calibration Certificate-2020-21Document10 pagesCalibration Certificate-2020-21Amandeep Singh100% (1)

- Master List of InstrumentsDocument2 pagesMaster List of InstrumentsAmandeep SinghNo ratings yet

- SST Test FormatDocument6 pagesSST Test FormatAmandeep SinghNo ratings yet

- Cat 2 - 5S Kaizen Lean-5.2Document28 pagesCat 2 - 5S Kaizen Lean-5.2Amandeep SinghNo ratings yet

- Safety First Luck Afterwards Work Is Worship No Compromise On QualityDocument8 pagesSafety First Luck Afterwards Work Is Worship No Compromise On QualityAmandeep SinghNo ratings yet

- Zinc Plating Reports 01Document2 pagesZinc Plating Reports 01Amandeep Singh100% (1)

- Before After: CommentsDocument2 pagesBefore After: CommentsAmandeep SinghNo ratings yet

- Enquiry Conrtol Register OkDocument1 pageEnquiry Conrtol Register OkAmandeep SinghNo ratings yet

- Kova Fasteners Zinc Plating Inprocess Reports Qfm/Qc/33Document1 pageKova Fasteners Zinc Plating Inprocess Reports Qfm/Qc/33Amandeep SinghNo ratings yet

- FM HR 01 Works CommitteeDocument1 pageFM HR 01 Works CommitteeAmandeep SinghNo ratings yet

- Wire Drawing Inprocess ReportDocument2 pagesWire Drawing Inprocess ReportAmandeep SinghNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Specialty Plastics-Liquid Crystal PolymersDocument28 pagesSpecialty Plastics-Liquid Crystal PolymersAshutosh SachanNo ratings yet

- Rayyan - Brochure Final v2Document4 pagesRayyan - Brochure Final v2Ivica PrvanovićNo ratings yet

- Materials Science and Engineering A First Coursev RaghavanDocument53 pagesMaterials Science and Engineering A First Coursev RaghavanKILL 1No ratings yet

- Practical Guide To AdjuvantsDocument5 pagesPractical Guide To AdjuvantsDavid SilverNo ratings yet

- EMD Module 2Document37 pagesEMD Module 2Amirtha Abirami RajuNo ratings yet

- Flow Boiling ReviewDocument9 pagesFlow Boiling ReviewAbhijit PalNo ratings yet

- Chemicals Used For Treatment of Water Intended For Human Consumption - High-Calcium LimeDocument8 pagesChemicals Used For Treatment of Water Intended For Human Consumption - High-Calcium LimeSameera RanasingheNo ratings yet

- ACIDS AND BASES (Handouts)Document4 pagesACIDS AND BASES (Handouts)RyanKingjimDiezUyNo ratings yet

- Viscose Rayon NotesDocument11 pagesViscose Rayon NotesAnkur Vaidya100% (1)

- Omala S2 GX 150Document2 pagesOmala S2 GX 150Kieran MañalacNo ratings yet

- Chapter 10 PDFDocument18 pagesChapter 10 PDFJeong100% (1)

- 1 - Geochemistry (Minerals)Document9 pages1 - Geochemistry (Minerals)Nasukha RifaiNo ratings yet

- Brgy - Viejo PMNPDocument41 pagesBrgy - Viejo PMNPJim AquinoNo ratings yet

- 282MEDocument2 pages282MEdutt0784No ratings yet

- 12.3 PPTDocument22 pages12.3 PPTKingProNo ratings yet

- Weekly Report DraftDocument4 pagesWeekly Report DraftSidharth KizhakkiveettilNo ratings yet

- General Guidelines To Starting An Electric Motor Lube ProgramDocument2 pagesGeneral Guidelines To Starting An Electric Motor Lube ProgramHenrique Do PradoNo ratings yet

- Chapter 3 Composition of Substances and SolutionsDocument70 pagesChapter 3 Composition of Substances and SolutionsNatalie. H100% (1)

- Manufacturing Process of Veneer WoodDocument2 pagesManufacturing Process of Veneer WoodSachin HarriramNo ratings yet

- Actual Repeat Paper 2013Document10 pagesActual Repeat Paper 2013Jasmeet Kaur SandhuNo ratings yet

- Development of The Dry Sand/rubber Wheel Abrasion TestDocument9 pagesDevelopment of The Dry Sand/rubber Wheel Abrasion TestRodrigo PereaNo ratings yet

- Lecture 2 Process Engineering - 2016Document56 pagesLecture 2 Process Engineering - 2016Yazhou ZhouNo ratings yet

- Celesta BrochureDocument13 pagesCelesta BrochurePranavNo ratings yet

- Hardtop XPL AGDocument6 pagesHardtop XPL AGHung NGUYEN SYNo ratings yet

- Mist Elimination Liquid Liquid CoalescingDocument20 pagesMist Elimination Liquid Liquid Coalescingpippo2378793No ratings yet

- Disposable Cofee CupDocument27 pagesDisposable Cofee CupAndrea Fernández TéllezNo ratings yet

- WI 2403 5C6 Simulated Post Weld Heat TreatmentDocument2 pagesWI 2403 5C6 Simulated Post Weld Heat TreatmentzhiqianxuNo ratings yet

- CLS JEEAD-19-20 XI Che Target-4 Level-1 Chapter-11Document14 pagesCLS JEEAD-19-20 XI Che Target-4 Level-1 Chapter-11Vaibhav JaimanNo ratings yet

- Solver Vinnakota Cap 11 PDFDocument57 pagesSolver Vinnakota Cap 11 PDFJunior Tejada SanchezNo ratings yet

- C710-Electrodos Lincoln PDFDocument56 pagesC710-Electrodos Lincoln PDFCésar García TeruelNo ratings yet