Professional Documents

Culture Documents

Fine Atomization: in The 25-400 Micron Range Ideal For Dust Suppression

Uploaded by

salcedopozasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fine Atomization: in The 25-400 Micron Range Ideal For Dust Suppression

Uploaded by

salcedopozasCopyright:

Available Formats

P

Fine Atomization

DESIGN FEATURES SPRAY CHARACTERISTICS

• High energy efficiency • Finest fog of any direct pressure nozzle

• One-piece construction • Produces high percentage of droplets

• No whirl vanes or internal parts in the 25-400 micron range; ideal for

• Highly efficient laminar jet impinges on dust suppression

target pin generating fine fog Spray pattern: Cone-shaped Fog

• Male connection Spray angle: 90°. For best 90° pattern

operate nozzle at or above 60 psi Metal

Flow rates: 0.034 to 7.68 gpm

MISTING

Fog Male Fog Pattern

Dimensions are approximate. Check with BETE for critical dimension applications.

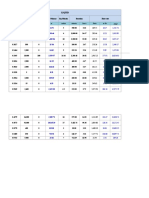

P Flow Rates and Dimensions

Cone-Shaped Fog, 90° Spray Angle, 1/4" Pipe Size

Approx. Approx.

GALLONS PER MINUTE @ PSI Approx. Coverage Spray Approx. Wt.

Male

Pipe Nozzle K 10 20 30 40 50 60 70 80 90 100 200 400 Orifice (inches) Height Dim. (in.) (oz.)

Size Number Factor PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI PSI Dia. (in.) D H (in.) A B Metal

P20 0.0106 0.034 0.047 0.058 0.067 0.075 0.082 0.089 0.095 0.10 0.11 0.15 0.21 0.020 12.0 6

TO ORDER: specify pipe size, connection type,

P24 0.0158 0.050 0.071 0.087 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.22 0.32 0.024 16.0 8

nozzle number, spray angle, and material.

P28 0.0206 0.065 0.09 0.11 0.13 0.15 0.16 0.17 0.18 0.20 0.21 0.29 0.41 0.028 18.0 9

P32 0.0285 0.090 0.13 0.16 0.18 0.20 0.22 0.24 0.25 0.27 0.28 0.40 0.57 0.032 22.0 11

1/4 P40 0.0443 0.14 0.20 0.24 0.28 0.31 0.34 0.37 0.40 0.42 0.44 0.63 0.89 0.042 24.0 12 1.83 0.63 2

P48 0.0633 0.20 0.28 0.35 0.40 0.45 0.49 0.53 0.57 0.60 0.63 0.89 1.26 0.047 28.0 14

P54 0.0838 0.27 0.37 0.46 0.53 0.59 0.65 0.70 0.75 0.80 0.84 1.19 1.68 0.054 30.0 15

P66 0.119 0.38 0.53 0.65 0.75 0.84 0.92 0.99 1.06 1.13 1.19 1.68 2.37 0.065 36.0 18

P80 0.171 0.54 0.76 0.94 1.08 1.21 1.32 1.43 1.53 1.62 1.71 2.41 3.42 0.085 48.0 24

P120 0.384 1.22 1.72 2.10 2.43 2.72 2.98 3.21 3.44 3.65 3.84 5.43 7.68 0.130 60.0 30

Flow Rate (GPM) = K √

⎯⎯⎯⎯

PSI

Standard Materials: Brass, 303 Stainless Steel and 316 Stainless Steel.

Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

68 www.BETE.com

You might also like

- PJ fine atomization nozzle designDocument1 pagePJ fine atomization nozzle designhidrastar123No ratings yet

- BETE_NDocument1 pageBETE_NDenaibeliNo ratings yet

- Bete NDocument1 pageBete NRaúl PalomoNo ratings yet

- Smallest Physical Size: Screen Screen Operate Nozzle at or Above 4 BarDocument1 pageSmallest Physical Size: Screen Screen Operate Nozzle at or Above 4 BarVictor MurciaNo ratings yet

- MW Microwhirl Misting NozzleDocument1 pageMW Microwhirl Misting NozzleblondtumbalaNo ratings yet

- Bete - MaxiPassDocument2 pagesBete - MaxiPassdrewtwitchNo ratings yet

- Astm Standard Dimensions: Schedule 80 CPVC FittingsDocument56 pagesAstm Standard Dimensions: Schedule 80 CPVC Fittingsvhench0127No ratings yet

- Threads and ChangegearsDocument36 pagesThreads and ChangegearsRC VilledaNo ratings yet

- ExtractPage14 PDFDocument2 pagesExtractPage14 PDFDries VandezandeNo ratings yet

- Cutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Document2 pagesCutting Nozzles: Propane Nozzle Mix - PNM and PNM-E (Extended)Dries VandezandeNo ratings yet

- Cutting and Welding Nozzles GuideDocument4 pagesCutting and Welding Nozzles GuideDries VandezandeNo ratings yet

- ESAB ExtractPage15-16cDocument9 pagesESAB ExtractPage15-16cDries VandezandeNo ratings yet

- ExtractPage14 15 PDFDocument2 pagesExtractPage14 15 PDFDries VandezandeNo ratings yet

- Process Nozzles: Propane Super HeatingDocument5 pagesProcess Nozzles: Propane Super HeatingDries VandezandeNo ratings yet

- Order Propane Super Heating NozzlesDocument9 pagesOrder Propane Super Heating NozzlesDries VandezandeNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- Spira X Sarco Fig 14Document2 pagesSpira X Sarco Fig 14Jacobus CalvelageNo ratings yet

- Mechanical fastener dimensions and specificationsDocument7 pagesMechanical fastener dimensions and specificationsLorena PessanhaNo ratings yet

- Standard Specifications Roll and Cut Groove For Steel Pipe and Other IPS Pipe Technical Data General DescriptionDocument6 pagesStandard Specifications Roll and Cut Groove For Steel Pipe and Other IPS Pipe Technical Data General DescriptionShaik's PeerNo ratings yet

- MetroDocument1 pageMetrotariqananNo ratings yet

- Lightweight Welding Nozzles Ordering GuideDocument10 pagesLightweight Welding Nozzles Ordering GuideDries VandezandeNo ratings yet

- Swaged and Lightweight Welding NozzlesDocument5 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Process Nozzles: Propane Super HeatingDocument3 pagesProcess Nozzles: Propane Super HeatingDries VandezandeNo ratings yet

- Cotter pin specificationsDocument1 pageCotter pin specificationsD_D_76No ratings yet

- Swaged and Lightweight Welding NozzlesDocument2 pagesSwaged and Lightweight Welding NozzlesDries VandezandeNo ratings yet

- Maximum Free Passage: Wide Angle MetalDocument1 pageMaximum Free Passage: Wide Angle MetalAlfonso BlancoNo ratings yet

- MicroWhirl PDFDocument1 pageMicroWhirl PDFDaniel Muñoz HernándezNo ratings yet

- Low Flow Full Cone NozzlesDocument1 pageLow Flow Full Cone NozzlesDaniel RestrepoNo ratings yet

- Extended Life Hollow Cone NozzlesDocument2 pagesExtended Life Hollow Cone NozzlesAlfian JunaidiNo ratings yet

- bORED pILES 1Document1 pagebORED pILES 1AqilahNasihahNo ratings yet

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-04 Date: July 17, 2017 Pin - Cot.SsDocument1 pageCotter Pin, Stainless Steel: Page 1 of 1 REV-04 Date: July 17, 2017 Pin - Cot.SsRolandoNo ratings yet

- Setup Plan Technical Center: Mold +Document4 pagesSetup Plan Technical Center: Mold +Victor MorenNo ratings yet

- En Pulsor170assemblyDocument2 pagesEn Pulsor170assemblysoorajssNo ratings yet

- Waterpipe v1Document19 pagesWaterpipe v1NghiaNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- En ChemiklerepdmDocument2 pagesEn Chemiklerepdmeloy marroquinNo ratings yet

- ADPL718 Catalog Page 25 - Yellow B AckDocument1 pageADPL718 Catalog Page 25 - Yellow B AckSugeng DarmintoNo ratings yet

- DPS Calculation SheetDocument133 pagesDPS Calculation SheetKraiwan AranyawatNo ratings yet

- Project: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataDocument1 pageProject: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataSajidNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Bar Diameter 10 MM 12 MM: Volume of Concrete Area of FormworksDocument7 pagesBar Diameter 10 MM 12 MM: Volume of Concrete Area of FormworksRey Ivan M. DeinlaNo ratings yet

- OringDocument1 pageOringIdehen KelvinNo ratings yet

- Metric Fastener Dimensions and SpecificationsDocument1 pageMetric Fastener Dimensions and SpecificationsDerekNo ratings yet

- Section 2 - Thread - BasicsDocument27 pagesSection 2 - Thread - BasicsChris MedeirosNo ratings yet

- Spherical Bearings 140107045033 Phpapp02 PDFDocument3 pagesSpherical Bearings 140107045033 Phpapp02 PDFRaja Sekaran SajjaNo ratings yet

- BETE MaxiPass LDocument1 pageBETE MaxiPass LHector CabezasNo ratings yet

- F 959 Washer TensionindicatingDocument2 pagesF 959 Washer Tensionindicatingdjelenko1No ratings yet

- Duct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor WestDocument12 pagesDuct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor Westwado11No ratings yet

- Two - Phase Line Sizing GelamDocument5 pagesTwo - Phase Line Sizing GelamElias EliasNo ratings yet

- Bete WTXDocument2 pagesBete WTXPraditia DanisNo ratings yet

- Sr. No Parameter Damper Size Blade Size Frame Side Frame Top & Bottom Angle Width 40 MM Partition W 166 MMDocument1 pageSr. No Parameter Damper Size Blade Size Frame Side Frame Top & Bottom Angle Width 40 MM Partition W 166 MMsabir hussainNo ratings yet

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- Dimensionamento_Roscas_Stub-AcmeDocument13 pagesDimensionamento_Roscas_Stub-AcmeVítor CarvalhoNo ratings yet

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Ultimist: Misting NozzlesDocument1 pageUltimist: Misting NozzlesDaniel RestrepoNo ratings yet

- En Abra10Document2 pagesEn Abra10Filipe SantosNo ratings yet

- Metric Socket Set ScrewsDocument2 pagesMetric Socket Set ScrewsvvvvvvNo ratings yet

- TFP1898 02 2015Document4 pagesTFP1898 02 2015Jun AntonioNo ratings yet

- Despresurizacion en Recipientes (FW)Document3 pagesDespresurizacion en Recipientes (FW)salcedopozasNo ratings yet

- 09 Plume Temperature CalculationsDocument6 pages09 Plume Temperature CalculationssalcedopozasNo ratings yet

- 04 Flame Height CalculationsDocument22 pages04 Flame Height CalculationssalcedopozasNo ratings yet

- Radiation and Dispersion Calculations: Vol% Vol%Document9 pagesRadiation and Dispersion Calculations: Vol% Vol%Maria Gabriela González CedeñoNo ratings yet

- Estimating Radiant Heat Flux from FiresDocument24 pagesEstimating Radiant Heat Flux from FiressalcedopozasNo ratings yet

- Estimating Burning Characteristics of Liquid Pool FiresDocument2 pagesEstimating Burning Characteristics of Liquid Pool FiressalcedopozasNo ratings yet

- Excel Fundamentals ManualDocument60 pagesExcel Fundamentals ManualAMIT AMBRENo ratings yet

- Aspen Hysys Surge Analysis Compressor DynamicsDocument4 pagesAspen Hysys Surge Analysis Compressor DynamicssalcedopozasNo ratings yet

- 05.1 Heat Flux Calculations Wind FreeDocument9 pages05.1 Heat Flux Calculations Wind FreesalcedopozasNo ratings yet

- Aspen Modelos AliviosDocument10 pagesAspen Modelos AliviossalcedopozasNo ratings yet

- Buried Pipe Heat Loss 20090816Document2 pagesBuried Pipe Heat Loss 20090816salcedopozasNo ratings yet

- 15 Explosion CalculationsDocument6 pages15 Explosion CalculationssalcedopozasNo ratings yet

- Iron & Manganese Removal: Advanced Water Treatment SolutionsDocument2 pagesIron & Manganese Removal: Advanced Water Treatment SolutionssalcedopozasNo ratings yet

- Oil & Gas Process Data CalculationsDocument185 pagesOil & Gas Process Data CalculationssalcedopozasNo ratings yet

- Drilling Note BookDocument100 pagesDrilling Note Booksalcedopozas100% (2)

- Cost Estimating Manual For Projects: December 2020Document72 pagesCost Estimating Manual For Projects: December 2020M Al HattanNo ratings yet

- Maximize Fired Heater Efficiency With Combustion CalculationsDocument24 pagesMaximize Fired Heater Efficiency With Combustion CalculationssalcedopozasNo ratings yet

- Fluoride: Removal SystemsDocument2 pagesFluoride: Removal SystemssalcedopozasNo ratings yet

- Isolux: A Division of Magnesium Elektron, IncDocument1 pageIsolux: A Division of Magnesium Elektron, IncsalcedopozasNo ratings yet

- Hydrogen Sulfide Control and RemovalDocument3 pagesHydrogen Sulfide Control and RemovalsalcedopozasNo ratings yet

- Liqui-Flux® B 22 Beverage Filtration Product Data Sheet: Membrane CharacteristicsDocument2 pagesLiqui-Flux® B 22 Beverage Filtration Product Data Sheet: Membrane CharacteristicssalcedopozasNo ratings yet

- Improve Power Plant Efficiency Using Design Documents and Five Basic ParametersDocument20 pagesImprove Power Plant Efficiency Using Design Documents and Five Basic ParameterssalcedopozasNo ratings yet

- Fine Atomization: in The 25-400 Micron Range Ideal For Dust SuppressionDocument1 pageFine Atomization: in The 25-400 Micron Range Ideal For Dust SuppressionsalcedopozasNo ratings yet

- Technology Sheet Degassing of Liqids Using Membrane TechnologyDocument6 pagesTechnology Sheet Degassing of Liqids Using Membrane TechnologysalcedopozasNo ratings yet

- Technical Publication: Take Care of Your Pumps and They'll Take Care of YouDocument4 pagesTechnical Publication: Take Care of Your Pumps and They'll Take Care of YousalcedopozasNo ratings yet

- Crude Oil Transport Pumps: Higher Productivity. Better Reliability. Lower Cost of OwnershipDocument13 pagesCrude Oil Transport Pumps: Higher Productivity. Better Reliability. Lower Cost of OwnershipsalcedopozasNo ratings yet

- Caida de Presión 2 Fases HorizDocument10 pagesCaida de Presión 2 Fases HorizsalcedopozasNo ratings yet

- Desert Water Emergency: City of Yuma, AZ: Case StudyDocument3 pagesDesert Water Emergency: City of Yuma, AZ: Case StudysalcedopozasNo ratings yet

- 5 Steps Towards An Actionable Risk Appetite 1630506330Document20 pages5 Steps Towards An Actionable Risk Appetite 1630506330XDeepbleu100% (1)

- GCSE AQA Chemistry 8642 Paper 1Document28 pagesGCSE AQA Chemistry 8642 Paper 1walidabdulrahman96No ratings yet

- Microwave Treatment For High Lipid Production in Scenedesmus ObliquusDocument6 pagesMicrowave Treatment For High Lipid Production in Scenedesmus ObliquusIJAR JOURNALNo ratings yet

- Classic ExperimentsDocument53 pagesClassic ExperimentsAbhay Kumar100% (1)

- B.Tech Food Technology Sugar Properties and ReactionsDocument17 pagesB.Tech Food Technology Sugar Properties and ReactionsPoonkodi Tp100% (1)

- General Instructions: Pie Matlab Assessment For Chemical EngineersDocument6 pagesGeneral Instructions: Pie Matlab Assessment For Chemical EngineersJulia RodriguezNo ratings yet

- SDS - Barrier 90 - Comp. A - Marine - Protective - English (Uk) - Australia - 2528 - 30.10.2012Document8 pagesSDS - Barrier 90 - Comp. A - Marine - Protective - English (Uk) - Australia - 2528 - 30.10.2012DonNo ratings yet

- Clobazam EP 11.0Document2 pagesClobazam EP 11.0Alejandro RestrepoNo ratings yet

- Atoms Bonding GuideDocument729 pagesAtoms Bonding Guide1553No ratings yet

- Innovative New Facade Material UsedDocument2 pagesInnovative New Facade Material UsedRafia GulzarNo ratings yet

- MSDS Report From SS Agrotech - Guar Gum ManufacturerDocument5 pagesMSDS Report From SS Agrotech - Guar Gum ManufacturerSSAgrotech Pvt.Ltd.No ratings yet

- 12 - Chemistry QP (Set-Ii)Document6 pages12 - Chemistry QP (Set-Ii)Shravan ZoneNo ratings yet

- E 355Document3 pagesE 355Mogos PaulNo ratings yet

- Tutorial 4 Solution (Updated)Document7 pagesTutorial 4 Solution (Updated)Jayden Chan33% (3)

- Methods of Chemical Analysis of FluorsparDocument23 pagesMethods of Chemical Analysis of Fluorsparevalencia100% (1)

- Ozone Solutions MSDS Ozone PDFDocument4 pagesOzone Solutions MSDS Ozone PDFJunaid AhmadNo ratings yet

- Industrial Hazards and Safety Management in Pharmaceutical IndustryDocument7 pagesIndustrial Hazards and Safety Management in Pharmaceutical IndustryShmmon AhmadNo ratings yet

- PE Health 11 Ist Semester Module 2 Energy System Version 3Document21 pagesPE Health 11 Ist Semester Module 2 Energy System Version 3Leary John TambagahanNo ratings yet

- Permanent Plate Magnets: Series SD, SD Xtreme, Brutepower and SuperbruteDocument4 pagesPermanent Plate Magnets: Series SD, SD Xtreme, Brutepower and SuperbruteIngmar José Bellott AlandiaNo ratings yet

- Division Achievement Test in Science 9Document5 pagesDivision Achievement Test in Science 9Rosalyn Angcay Quintinita100% (1)

- Bresle Test - Chloride Test Kit: Product DescriptionDocument3 pagesBresle Test - Chloride Test Kit: Product DescriptionHarikesh PandeyNo ratings yet

- Ayurvedic Dosage FormsDocument9 pagesAyurvedic Dosage FormsDeepak BasyalNo ratings yet

- Comparative Performance Analysis of Different Twisted Tape Inserts in The Absorber Tube of Parabolic Trough CollectorDocument14 pagesComparative Performance Analysis of Different Twisted Tape Inserts in The Absorber Tube of Parabolic Trough CollectorTJPRC PublicationsNo ratings yet

- Ultra C6 fabric provides advanced flame resistanceDocument1 pageUltra C6 fabric provides advanced flame resistancedaniel garcia cortesNo ratings yet

- Liquid Penetrant Inspection 50 Question QuizDocument10 pagesLiquid Penetrant Inspection 50 Question QuizAnonymous gFcnQ4go100% (6)

- Astm 2017-F2059Document5 pagesAstm 2017-F2059laythNo ratings yet

- Vapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForDocument9 pagesVapor Pressure of Petroleum Products (Mini Method) : Standard Test Method ForahmedNo ratings yet

- Gupta (2010)Document42 pagesGupta (2010)x raysNo ratings yet

- ATEXGuidelines LowDocument1 pageATEXGuidelines LowalphieNo ratings yet

- Hydraulics MCQDocument228 pagesHydraulics MCQShrajit GuptaNo ratings yet

- Projet PHD FonkouDocument6 pagesProjet PHD FonkouSylvain KamdemNo ratings yet