Professional Documents

Culture Documents

Technical Specification Sheet of Conveyor

Uploaded by

Ronak PanchalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification Sheet of Conveyor

Uploaded by

Ronak PanchalCopyright:

Available Formats

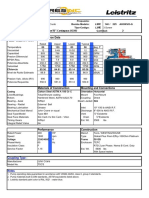

PROJECT.

DOC No

TECHNICAL SPECIFICATION SHEET OF CONVEYOR

DATE

REV

Eq. Name Eq.Tag No. 1001 CV 1003 Location

Recycle conveyor to high speed mixture

Quantity 01 Nos Duty Continuous Service

Mfr. Name ** Model No. ** Curve No.

Mfr. Std Performence ** Electricals

** Std

OPERATING PARAMETERS

A APPLICATION DDGS Product Conveying

B PROPERTIES

1 Material DDGS Product

2 Bulk Density 360 kg/mᵌ

3 Flow -ability Average

4 Solids 90% w/w

5 Discharge Capacity 10000 kg/hr

6 Operating Temp. 85⁰C

B PARAMETERS UNITS DISCRIPTION

1 Type of conveyor Horizontal Screw Conveyor

2 Size of conveyor mm 800

3 Length of Conveyor mm 10000

4 Inlet.Nozzle size mm 600

5 Outlet.Nozzle size mm 600

6 Non Flameproof Gear Motor KW/RPM mm ***/ 48

7 Screw shaft Pipe- DIA mm ***

8 Trough thk & MOC mm 5 min X SS304

9 End Plate Thkness mm 12 X SS304

10 End sealing for shaft - Stuffing Box With Teflon Gland Packing

Hager Bearing Hanger bearing or busher mounder on olid shaft to be provided at the Interval

11 - of 5.0 m of each conveyor

12 Area of classification - Flameproof

13 Bearing Make /No - *** SKF/Fag

14 Power Supply - 415 V , 3 Phase , 50 Hz

15 Zero Speed Switch - To be provided

16 Finishing & Painting Mat finish 160 Grt,

All MS part should be 2 coats of red oxide primer, finish paint-2 synthetic

- enamel pant shade

C PERFORMANCE

1 Capacity kg/hr 10000 REMARKS :

2 Temp ⁰C 85⁰C

3 Efficiency % ***

4 Rated Speed RPM **

5 Duty Point Power KW **

6 Recommended Motor KW/RPM **

NOTES :

¾ For design capacity, 30% filling should be considered.

¾ For power calculation, 100% filling is to be considered.

¾ Bottom cleaning nozzle should be provided with quick cleaning clamp.

¾ All SS304 Parts are Matt Finish internally & externally

¾ Screw conveyor will operate in Clockwise direction.

¾ Inlet Outlet openings to be adequately capped or plugged.

¾ Supplier to quote the necessary items required for proper functioning of the screw conveyor.

¾ Any deviation to be separately highlighted.

¾ Supplier have to suggest support needed for screw conveyor

6/15/2018

0

Indoor

**

415V,50Hz,3Phase

d Packing

under on olid shaft to be provided at the Interval

of red oxide primer, finish paint-2 synthetic

You might also like

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalNo ratings yet

- Electronics – From Theory Into Practice: Applied Electricity and Electronics DivisionFrom EverandElectronics – From Theory Into Practice: Applied Electricity and Electronics DivisionRating: 5 out of 5 stars5/5 (1)

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalNo ratings yet

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalNo ratings yet

- Technical Specification Sheet of ConveyorDocument4 pagesTechnical Specification Sheet of ConveyorRonak PanchalNo ratings yet

- Vibrating Screen ManualDocument36 pagesVibrating Screen ManualJUNIOR ANDERSON TINOCO FALERONo ratings yet

- Bag Filter Himenviro - O&m - Cement MillDocument51 pagesBag Filter Himenviro - O&m - Cement Millsambhu0% (1)

- Welding Machine Specifications PDFDocument4 pagesWelding Machine Specifications PDFrahmankhan8230% (1)

- S753 E-32 6e2838105 TransformerDocument27 pagesS753 E-32 6e2838105 TransformerJosip ZohilNo ratings yet

- OM MILL (Coal Pulveriser)Document7 pagesOM MILL (Coal Pulveriser)Nhật TuấnNo ratings yet

- Carpeta Tecnica Equipamiento Flush byDocument655 pagesCarpeta Tecnica Equipamiento Flush byFederico MoranNo ratings yet

- J0231 HV TR - FINAL变压器1Document23 pagesJ0231 HV TR - FINAL变压器1SerhiiNo ratings yet

- Catalogue Technical Specs 3.0tr Slim PackDocument3 pagesCatalogue Technical Specs 3.0tr Slim Packcalvin.bloodaxe4478No ratings yet

- NT6222GK (MBP) - DatasheetDocument5 pagesNT6222GK (MBP) - Datasheetdesenvolvimento appNo ratings yet

- IPC Medium-Pressure Internal Gear Pumps: Technical Data SheetDocument20 pagesIPC Medium-Pressure Internal Gear Pumps: Technical Data SheetNutrición SaludableNo ratings yet

- Fiche Technique SK12 - enDocument14 pagesFiche Technique SK12 - enMuhamad zainiNo ratings yet

- KSB WKLN 65Document3 pagesKSB WKLN 65KelebogileChabalala100% (1)

- EMT6165GK DatasheetDocument4 pagesEMT6165GK Datasheetnilesh yedveNo ratings yet

- Model: T-8045: Installation & ServiceDocument28 pagesModel: T-8045: Installation & ServiceAlisson FelipeNo ratings yet

- Gear Pumps KF 0 Gear Pumps KF 0: With Magnetic CouplingDocument12 pagesGear Pumps KF 0 Gear Pumps KF 0: With Magnetic CouplingHany EdwardNo ratings yet

- Soldadora Vantage 500 I LINCONDocument6 pagesSoldadora Vantage 500 I LINCONDemian CruzNo ratings yet

- RCML15 Series EncodersDocument2 pagesRCML15 Series Encoderssandeep naikNo ratings yet

- Specifications:: 1. Traveling Block (YG-150)Document6 pagesSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisNo ratings yet

- Grundfosliterature - CRN, CRNE Chamber EnsambleDocument19 pagesGrundfosliterature - CRN, CRNE Chamber EnsambleRudo RockNo ratings yet

- Specification For Power Transformer:::: Document No. Description Item/Tag Imo NumberDocument30 pagesSpecification For Power Transformer:::: Document No. Description Item/Tag Imo NumberFILIN VLADIMIRNo ratings yet

- Cat C32 1000KVADocument10 pagesCat C32 1000KVAjohn BeltranNo ratings yet

- Method Statement For Coal Feeder ErectionDocument20 pagesMethod Statement For Coal Feeder ErectiontreyNo ratings yet

- Daikin DAR SpecsDocument8 pagesDaikin DAR SpecsGian Carlos Gonzales ChaconNo ratings yet

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- IVB KL CARB Repsol - Prices - Simulation - 27 - 7 - 2013 - 05.52.36Document68 pagesIVB KL CARB Repsol - Prices - Simulation - 27 - 7 - 2013 - 05.52.36Ricardo Hurtado HernándezNo ratings yet

- 38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KDocument20 pages38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KAamerNo ratings yet

- 38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KDocument20 pages38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KhgogoriyaNo ratings yet

- Axera 7260t Sandvik Mining and ConstructionDocument4 pagesAxera 7260t Sandvik Mining and ConstructiondaniloNo ratings yet

- Specification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Document32 pagesSpecification For HV Transformer (Hyundai Heavy Industries CO., LTD.)Oleksandr RakshaNo ratings yet

- (TDB) +VRF+DVM+S+Eco+HR+For+America Ver.1.5 201214 PDFDocument67 pages(TDB) +VRF+DVM+S+Eco+HR+For+America Ver.1.5 201214 PDFLuis Angulo CaroNo ratings yet

- DW115CNC Technical ParametersDocument11 pagesDW115CNC Technical ParametersProfCarlos GamaNo ratings yet

- C128.2.230210-Effwa InfraDocument13 pagesC128.2.230210-Effwa InfraMahesh MNo ratings yet

- m0-8 - v6701000 Final DRW & Instruction Manual For LatheDocument69 pagesm0-8 - v6701000 Final DRW & Instruction Manual For Lathewawet10014No ratings yet

- Data Sheet Tq-04 RLL Eppetroecuador Epn Rev CDocument10 pagesData Sheet Tq-04 RLL Eppetroecuador Epn Rev CFrancesco GuardiniNo ratings yet

- 750-2 KTA38-G2B Caracteristica Motor y AlternadorDocument4 pages750-2 KTA38-G2B Caracteristica Motor y AlternadorjosegqNo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- DataSheet L3HC 140-225 AHOKVO-GDocument1 pageDataSheet L3HC 140-225 AHOKVO-GJAC 91No ratings yet

- Design Data Sheet (ID Fan Motor 800 KW)Document4 pagesDesign Data Sheet (ID Fan Motor 800 KW)Swarup Nayak100% (1)

- Seaharvest 650 HP Workover Rig Technical Specs1Document20 pagesSeaharvest 650 HP Workover Rig Technical Specs1Ali mohammad100% (1)

- Boq For 160 KLD Arvindo Hospital, Jaitpura, Shibu Enterprises.Document10 pagesBoq For 160 KLD Arvindo Hospital, Jaitpura, Shibu Enterprises.Anshika RaiNo ratings yet

- OT Outside Tolerance (X Is Set)Document6 pagesOT Outside Tolerance (X Is Set)carlos puertoNo ratings yet

- Jumbo Ficha TecnicaDocument4 pagesJumbo Ficha TecnicaRodrigo FooNo ratings yet

- Brochure VARIPURE 20160519 EN PDFDocument8 pagesBrochure VARIPURE 20160519 EN PDFMhs EngineerNo ratings yet

- TEK20141027023SPECDocument1 pageTEK20141027023SPECHary FadlyNo ratings yet

- Salient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800Document2 pagesSalient Features: 1-SDR0808-00-00-001 Smooth Double Roll Crusher 800X800patelchiragisNo ratings yet

- 7-6325-E (DL310-7) PDFDocument4 pages7-6325-E (DL310-7) PDFMax RojasNo ratings yet

- Kaltfräse W 200 Cold Milling Machine W 2000: Technische Daten Technical Specifi CationDocument8 pagesKaltfräse W 200 Cold Milling Machine W 2000: Technische Daten Technical Specifi Cationventas3No ratings yet

- Working Ranges Specifications: SK17SR-5Document4 pagesWorking Ranges Specifications: SK17SR-5Akhmad SebehNo ratings yet

- 38lha 40lha h15 1pd Rev2Document28 pages38lha 40lha h15 1pd Rev2nhatNo ratings yet

- Carrier 38LH D13 1PD UpdateDocument13 pagesCarrier 38LH D13 1PD Updatesunil kumarNo ratings yet

- ECPM4316T 4 InfoPacketDocument10 pagesECPM4316T 4 InfoPacketBenjamin BenzaquenNo ratings yet

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htikeNo ratings yet

- 513203001... E-FFU160HAX (L - MBP) - DatasheetDocument5 pages513203001... E-FFU160HAX (L - MBP) - Datasheetdesenvolvimento appNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- Processes 07 00654 PDFDocument21 pagesProcesses 07 00654 PDFRonak PanchalNo ratings yet

- Model-Ec 7 Map. For: Modified Atmosphere PackagingDocument1 pageModel-Ec 7 Map. For: Modified Atmosphere PackagingRonak PanchalNo ratings yet

- EnviroDocument14 pagesEnviroHardikNo ratings yet

- P 775 Aus 5 20 - 51 4870Document8 pagesP 775 Aus 5 20 - 51 4870Ronak PanchalNo ratings yet

- Air Separation by Carbon Molecular SievesDocument9 pagesAir Separation by Carbon Molecular SievesRonak PanchalNo ratings yet

- 3.3 Compressed Air SystemDocument9 pages3.3 Compressed Air SystemstephenNo ratings yet

- 312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionDocument6 pages312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionRonak PanchalNo ratings yet

- Silo CapDocument5 pagesSilo CapOliver SanvictoresNo ratings yet

- Processes 07 00654Document21 pagesProcesses 07 00654Ronak PanchalNo ratings yet

- Penwaybrochure PDFDocument12 pagesPenwaybrochure PDFRonak PanchalNo ratings yet

- Fabric Filter DesignDocument16 pagesFabric Filter DesignDragan GasicNo ratings yet

- PVAR Catalog PDFDocument16 pagesPVAR Catalog PDFrenebbNo ratings yet

- Projects in Excel Format Search Criteria Project Partner: Project Promoter: Keyword: Products/ServicesDocument242 pagesProjects in Excel Format Search Criteria Project Partner: Project Promoter: Keyword: Products/ServicesRonak PanchalNo ratings yet

- Detail of Damper Pipe Size 200 NBDocument2 pagesDetail of Damper Pipe Size 200 NBRonak PanchalNo ratings yet

- Data Sheet ShirasagiDocument1 pageData Sheet ShirasagiRonak PanchalNo ratings yet

- Desiccant Type Compressed Air Dryer PDFDocument4 pagesDesiccant Type Compressed Air Dryer PDFRonak PanchalNo ratings yet

- Name Last Name First Name CompanyDocument78 pagesName Last Name First Name CompanyRonak PanchalNo ratings yet

- OEM Dew Point Transmitter Down To - 60 °C TD: EE355 Technical DataDocument2 pagesOEM Dew Point Transmitter Down To - 60 °C TD: EE355 Technical DataRonak PanchalNo ratings yet

- NGA-SCE PGP Brochure Nov19 SCDocument2 pagesNGA-SCE PGP Brochure Nov19 SCSudhir ShastriNo ratings yet

- Kitchen SystemDocument12 pagesKitchen SystemmythygpbhuNo ratings yet

- Easidew Transmitters 97554 UK DatasheetDocument4 pagesEasidew Transmitters 97554 UK Datasheetrafik1995No ratings yet

- Nitrogen Generation by PSADocument12 pagesNitrogen Generation by PSALakshmi Pathi Bojja100% (1)

- Unijet Vacuum Conveyor QuestionaireDocument1 pageUnijet Vacuum Conveyor QuestionaireRonak PanchalNo ratings yet

- Fabric Filter DesignDocument16 pagesFabric Filter DesignDragan GasicNo ratings yet

- Some Lower Bounds On The Reach of An Algebraic Variety: Chris La Valle Josué Tonelli-CuetoDocument9 pagesSome Lower Bounds On The Reach of An Algebraic Variety: Chris La Valle Josué Tonelli-CuetospanishramNo ratings yet

- Lab4 F15 Si DiodeDocument15 pagesLab4 F15 Si DiodeJohn MarkNo ratings yet

- Sample Theory With Ques. - Organometallic Compounds (NET CH UNIT-3) PDFDocument26 pagesSample Theory With Ques. - Organometallic Compounds (NET CH UNIT-3) PDFPriyanshi VermaNo ratings yet

- EEDI FormulaDocument67 pagesEEDI Formulawaleed yehiaNo ratings yet

- EarlyDocument59 pagesEarlyjrtlimNo ratings yet

- EmSAT Grammar Study GuideDocument74 pagesEmSAT Grammar Study GuideAbdullah AlmadiNo ratings yet

- 06 Story StiffnessDocument2 pages06 Story StiffnessDigvijay GiraseNo ratings yet

- Petroleum Products KolkataDocument3 pagesPetroleum Products KolkatabrijeshkynNo ratings yet

- 2001: A Space Odyssey - Film AnalysisDocument4 pages2001: A Space Odyssey - Film AnalysisSummerNo ratings yet

- Vo 1263 AaDocument8 pagesVo 1263 Aa801400No ratings yet

- 2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFDocument59 pages2.2 - NDEP-C1574-5-6-7-8 - Rev.0 NDE Procedures Book PDFGeorge JhonsonNo ratings yet

- Affiliated Institutions Anna University, Chennai Regulations - 2009 Curriculum Ii To Iv Semesters (Full Time) M.E. Applied ElectronicsDocument21 pagesAffiliated Institutions Anna University, Chennai Regulations - 2009 Curriculum Ii To Iv Semesters (Full Time) M.E. Applied ElectronicsRamya VNo ratings yet

- Harmony of The GospelsDocument11 pagesHarmony of The GospelsJesus LivesNo ratings yet

- RELI 280 NotesDocument7 pagesRELI 280 NotesFaith KentNo ratings yet

- Type VBPDF: Pilot Operated Check ValvesDocument3 pagesType VBPDF: Pilot Operated Check ValvesAslam ShaikhNo ratings yet

- LANCNC Display Mount Plate Installation v5Document10 pagesLANCNC Display Mount Plate Installation v5Maquina EspecialNo ratings yet

- Lower Motor Neuron LesionsDocument29 pagesLower Motor Neuron LesionsLoshi ChandrasekarNo ratings yet

- Critical Planning Issues in MTODocument2 pagesCritical Planning Issues in MTOAzhar QadriNo ratings yet

- Spek Dental Panoramic Rotograph EVODocument2 pagesSpek Dental Panoramic Rotograph EVOtekmed koesnadiNo ratings yet

- Analytical Text 1Document11 pagesAnalytical Text 1RijayyyNo ratings yet

- Manual Sony HCD-SH2000 (88 Páginas)Document2 pagesManual Sony HCD-SH2000 (88 Páginas)Alberto CaseroNo ratings yet

- What Is Aplastic Anemia?Document23 pagesWhat Is Aplastic Anemia?Ayi SuwarayiNo ratings yet

- SC3 User Manual - V1.06 PDFDocument196 pagesSC3 User Manual - V1.06 PDFJoeNo ratings yet

- (Ethics) AttitudeDocument46 pages(Ethics) AttitudeAbhishek SinghNo ratings yet

- Design and Assembly Analysis of Piston, Connecting Rod & CrankshaftDocument12 pagesDesign and Assembly Analysis of Piston, Connecting Rod & CrankshaftD MasthanNo ratings yet

- Detection of Food AdulterationDocument10 pagesDetection of Food AdulterationDavara Paresh R.No ratings yet

- 2004 Timbre To DissonanceDocument4 pages2004 Timbre To DissonancetgraubaenaNo ratings yet

- PSR-S700 S900 Lsi CDocument13 pagesPSR-S700 S900 Lsi CAdriano CamocardiNo ratings yet

- Serif Business LetterDocument18 pagesSerif Business LetterNeerajha RabindranathNo ratings yet

- Tutoria Radio MobileDocument11 pagesTutoria Radio MobileGanti Nama Aja LahNo ratings yet