Professional Documents

Culture Documents

Rdso B-11753 5R1

Uploaded by

shibnath lahiriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rdso B-11753 5R1

Uploaded by

shibnath lahiriCopyright:

Available Formats

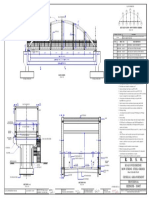

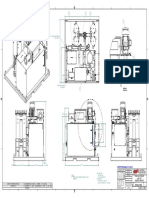

12 11 10 9 8 7 6 5 4 3 2 1

e lng e lat

verso verso

H LONGITUDINAL DIRECTION 287 287 8.3

H

90

16

3

180 180 8.2

89

8.1

16

60 125

12

300

20

6 358 6

360

370

B

1 3.2 ELEVATION

3

30 50

30 50

8

3

8

89

3.1 36

42

G G

42

ANCHOR BOLTS

(SCHEMATIC) 89

6.1 6.2 2 3.3 358

B 15 150 40

SECTION B-B

6

SCALE 1 : 5 138 287 287

SECTION A-A

SCALE 1 : 5

147 147 38

Along Traffic

287

75 75

955

38

50 770 85 50

650 Across Traffic

638

10

650

638

287

F F

50

150

287

650

290

370

150

152

650

A A

150

32

12

6

9x 15 THRU 147 147 32 12

M16x1.5 - TAPPED THRU

50

287

370

6x 39 THRU HOLES

4x 30 THRU 150 40 FOR M36 ANCHOR BOLTS

63 X 90° 6x 39 THRU ELASTOMERIC BEARING SIDE ELEVATION

300 PLAN

38

9x 18 THRU 100 650 15

E 40 18 E

50 30

DETAIL OF BOTTOM PLATE

DETAIL OF TOP PLATE ELEVATION PLAN

PLAN SCALE 1 : 5

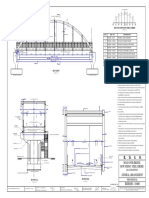

3

C 150

138 287 287 152

142 3

6

72 72

5.2 3

5.1 8

104

104

8

D D

42

C 8

50 770 85 50 8 2

955

DETAIL OF BOTTOM PLATE SECTION C-C

ELEVATION SCALE 1 : 5

C

C

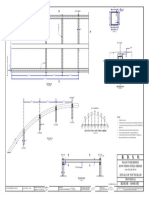

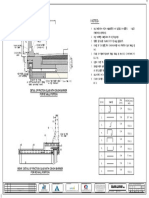

16 8.3 6 Hex Nut - M36 M36 ISO: 4035

15 8.2 6 Washer (300 HV)-36 D66/39X5 ISO:7089-hdg

1. ALL DIMENSIONS ARE IN MILLIMETER. 14 8.1 6 Anchor bolts M36x450 IS:2062/equv.

2. THE DESIGN IS BASED ON UIC CODE CODE-772-2R , "CODE FOR THE USE OF RUBBER BEARING FOR THE RAIL BRIDGES AND IRC-83 13 7.3 4 Hexagonal Nut M27 ISO: 4035

PART-II. 12 7.2 4 Plain Washer ISO:7089-hdg

3. ALLOWABLE COMPRESSIVE STRESS IN ELASTOMERIC BEARING INCLUDING CDA IS TAKEN AS 1.10 Kg/mm2/. WEIGHT OF ELASTOMERIC BEARINGS LOAD PER SPAN FOR DESIGN OF SUBSTRUCTURE D50/30X4

EXCLUDING WEIGHT OF ELASTOMERIC 11 7.1 4 CSK Screw M36 M27x110

B 4. THE STATIC SHEAR MODULUS FOR THE ELASTOMERIC PADS HAS BEEN ASSUMED AS 0.1 Kg/mm2/. LOAD (ƚ) FOR DESIGN 10 6.2 18 Plain Washer D30/18X3 ISO:7089-hdg B

5. MAX. DESIGN PRESSURE BELOW THE BEARING ASSEMBLY IS 0.758 Kg/mm2/. PAD PER SPAN ---------133 ƚ PER SPAN LOAD TYPE

6. THE ELASTOMERIC PADS SHALL BE OF IRHD-70 AND SHALL CONFORM TO THE SPECIFICATIONS LAID DOWN IN UIC 772-2R. 9 6.1 18 Hexagonal Screw M16X30 ISO:4017-10.9 hdg

DL SIDL LL EQ/WIND ( )

7. BOTTOM SURFACE OF THICK TOP LAMINATE AND TOP SURFACE OF THICK BOTTOM LAMINATE SHALL BE VULCANISED TO $ *& 8 5.2 1 Support Cover Plate 142x152x6 IS:2062 E350BR

VERTICAL 115.71 122.22 331.13 41.48 / 97.56

ELASTOMERIC PAD. PASTING / GLUING OF RUBBER TO STEEL IS NOT ALLOWED. 7 5.1 2 ISMC 150 ISMC150x5.4x104 IS:2062 E350BR

LONGITUDINAL 0 0 74.97 62.63

8. COUNTERSUNK BOLTS SHOULD NOT PROJECT BEYOND MACHINED SURFACES. 6 3.3 1 Bottom Internal Plate 638X358X16 IS:2062 E250BR

9. WHEN REPLACING THE BEARINGS IN EXICTING GIRDERS, ALL BEARINGS IN ONE LINE OF SUPPORT SHALL BE REPLACED TOGETHER. LATERAL 0 0 31.14 42.63 5 3.2 1 Top Internal Plate 638X358X16 IS:2062 E250BR

10. IN CASE OF GIRDERS ON STRAIGHT ALIGNMENT, BEARINGS MUST BE PLACED BETWEEN TRUE HORIZONTAL SURFACE ( MAX. 4 3.1 3 Reinforcement Steel Plate 638X358X3 IS:2062/IS:1079

TOLERANCE 0.2% PERPENDICULAR TO LOAD) AND AT TRUE PLAN POSITION OF THIER CONTROL LINES MARKED ON RECEIVING * THIS LOAD IS SHARED BY TWO BEARINGS. ALL OTHER LOADS ARE SHARED BY FOUR BEARINGS

3 3 1 Elastomer 650x370x89 HDRB

SURFACES (±3 mm). PROVISIONS OF PARA 920 OF IRC 83 PART II SHALL BE FOLLOWED FOR INSTALLATION OF BEARINGS. DRAINAGE $ THIS LOAD IS FOR DESIGN OF SUB-STRUCTURE. 2 2 1 Bottom Plate 955x390x42 IS:2062 E350BR

SHALL BE ENSURED BY PROVIDING SLOPE AWAY FROM BEARING IN ALL DIRECTIONS. (BEARING SHALL REST ON FLAT HORIZONTAL

& THIS LOAD IS FOR DESIGN OF LOCAL ELEMENTS UNDER BEARINGS. 1 1 1 Top Plate 650x370x30 IS:2062 E350BR

SURFACE).

11. IN CASE OF GIRDERS ON CURVED ALIGNMENT, THE PEDESTALS SHALL BE CAST AT SLOPE WITH DIFFERENT HEIGHT TO PROVIDE THE SL. NO. Pos. Qty. DESCRIPTION DIMENSION MATERIAL

00 03-08-2020 For Approval S Roy L Mridha S.Lahiri

GIRDER AT SLOPE CORRESPONDING TO THE CANT REQUIRED IN CURVED TRACK. REV. DATE DESCRIPTION DRAWN CHECKED APPROVED

12. IT IS PREFERABLE THAT BEARING SHALL BE INSTALLED AT NEARLY MEAN TEMPERATURE. 45, JHOWTALA ROAD DRAWING UID : 19958000

13. ALL STRUCTURAL STEEL EXCEPT THINNER LAMINATES (MILD STEEL SHEETS) SHALL CONFORM TO MILD STEEL IS : 2062 Gr.B0 AND Kolkata-700019, West Bengal, India

TEL+91-33-2290 0250 - 53 / Fax +91-33-2290 0254

info@mageba.in - www.mageba.in

General tolerance according to: A

3mm THICK MILD STEEL SHEETS SHALL BE OF IS :1079 / IS 2062 E250BR. CIN-U45208WB2007PTC118511 IRC:83 PART IV

14. ALL MACHINED SURFACES ARE SHOWN THUS ...f. R. D. S. O.

15. FOR NEW WORKS, RCC BED BLOCK SHALL BE MIN. M25. FOR EXISTING WORKS, RCC BED BLOCK CONCRETE SHOULD NOT BE LESS 25T LOADING - 2008

18.3 M SPAN COMPOSITE WELDED GIRDER

THAN M20. (UPTO 4 CURVE)

DETAILS OF ELASTOMERIC BEARING

16. THE ANCHOR BOLTS AND THEIR NUTS SHALL BE HOT DIP GALVANISED 100 MICRON THICK, AS PER IS : 4759. PROVISIONAL DATE - 18.05.2015

MODIFICATION DATE - 11.01.2019

17. ALL BOLTS, NUTS ETC SHALL CONFORM TO PROVISIONS OF IS : 3640.

18. PEDESTALS, BED BLOCKS, SHALL PROJECT MINIMUM 150 MM BEYOND THE BOTTOM PLATE. RDSO/B-11753 / 5R1 (MODIFIED)

12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- 36m BowString PDFDocument1 page36m BowString PDFgoutammand67% (3)

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- RDSO B 11754 4R1 (Mod)Document1 pageRDSO B 11754 4R1 (Mod)shibnath lahiriNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- 60 M.bow String Girder 10411 1 RDocument1 page60 M.bow String Girder 10411 1 RkesharinareshNo ratings yet

- 60 M.bow String Girder-10411-RDocument1 page60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- 54 M.bow String Girder-10410-9Document1 page54 M.bow String Girder-10410-9SANJEEV VERMANo ratings yet

- Key elevation of bow string girderDocument1 pageKey elevation of bow string girdergoutammand100% (2)

- Rdso Guide Lines FR BridgesDocument76 pagesRdso Guide Lines FR BridgesUtpal KantNo ratings yet

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- IRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFDocument4 pagesIRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFJayantNo ratings yet

- ISO-Certified HDPE Pipe ManufacturerDocument4 pagesISO-Certified HDPE Pipe Manufacturerdhopat kalpeshNo ratings yet

- IRC 24-2010 Ammendment (Nov-17)Document3 pagesIRC 24-2010 Ammendment (Nov-17)avisek_basuNo ratings yet

- 42 M Bow String Girder-10408-R PDFDocument1 page42 M Bow String Girder-10408-R PDFPhanindra MajetiNo ratings yet

- 60 M.bow String Girder 10411 3 RDocument1 page60 M.bow String Girder 10411 3 RkesharinareshNo ratings yet

- RDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDDocument1 pageRDSO/B-10423/10 R0: Walls & Bridges (India) Pvt. LTDSrikanth Patel DspNo ratings yet

- Bow-String Girder - Design & Construction AspectsDocument12 pagesBow-String Girder - Design & Construction Aspectsepcepcepc100% (1)

- Amendment To IRC 24 - 2010Document6 pagesAmendment To IRC 24 - 2010mrraee4729100% (1)

- 60 M.bow String Girder-10411-4-RDocument1 page60 M.bow String Girder-10411-4-RkesharinareshNo ratings yet

- Rdso Bow String Girder-10411-9Document1 pageRdso Bow String Girder-10411-9a Rawat100% (1)

- 60 M.bow String Girder 10411 2 RDocument1 page60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- 42m BowStringDocument1 page42m BowStringsorowareNo ratings yet

- Construction of Road Over Bridge in Manduadih yardDocument21 pagesConstruction of Road Over Bridge in Manduadih yardkesharinaresh100% (1)

- Design of PSC Cross Girder As Per IRC 112Document2 pagesDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- 60 M.bow String Girder-10411-5-RDocument1 page60 M.bow String Girder-10411-5-RkesharinareshNo ratings yet

- 42 M Bow String Girder-10408-3-R PDFDocument1 page42 M Bow String Girder-10408-3-R PDFPhanindra MajetiNo ratings yet

- Guidelines on Well Foundation for Indian Railway BridgesDocument42 pagesGuidelines on Well Foundation for Indian Railway BridgesRavi VarmaNo ratings yet

- Uncoated Stress Relieved Low Relaxation Seven-Wire (Ply) Strand For Prestressed Concrete - SpecificationDocument16 pagesUncoated Stress Relieved Low Relaxation Seven-Wire (Ply) Strand For Prestressed Concrete - Specificationnikesh dubeyNo ratings yet

- 42 M Bow String Girder-10408-8-R1 PDFDocument1 page42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiNo ratings yet

- Proposed Arch Bridge On Lower Lake of Bhopal: A Case StudyDocument3 pagesProposed Arch Bridge On Lower Lake of Bhopal: A Case StudyInnovative Research PublicationsNo ratings yet

- Typical Detail of Friction Slab With Crash Barrier (1) - LayoutDocument1 pageTypical Detail of Friction Slab With Crash Barrier (1) - LayoutAditya ChauhanNo ratings yet

- Apr June14Document132 pagesApr June14Sony JsdNo ratings yet

- Dynamic Test Report 12T15 - DSIDocument9 pagesDynamic Test Report 12T15 - DSIManukantShrotriyaNo ratings yet

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- R. D. S. O.: Rdso/b - 10408/6Document1 pageR. D. S. O.: Rdso/b - 10408/6MUTHU PANDINo ratings yet

- BS 114 VER 2 IR RSI Ver 2 FinalDocument57 pagesBS 114 VER 2 IR RSI Ver 2 Finalselvam chidambaram100% (1)

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- Fabrication Inspection of Bow String GirdersDocument46 pagesFabrication Inspection of Bow String GirdersHabib Ur Rahman100% (1)

- Ultimate Limit State of Induced Deformation - Sec. 11 of IRC 112 J IRC Vo. 76 - 3Document18 pagesUltimate Limit State of Induced Deformation - Sec. 11 of IRC 112 J IRC Vo. 76 - 3Zakee MohamedNo ratings yet

- RDSO Drawing ListDocument42 pagesRDSO Drawing Listkaushik96040% (5)

- Compendium For ROB by Indian RailwayDocument184 pagesCompendium For ROB by Indian RailwayDPJAIN INFRASTRUCTURENo ratings yet

- 36m BowString PDFDocument1 page36m BowString PDFD SRINIVAS100% (1)

- Guidelines For Inspection & Maintenance of Bridge Bearings: BS-102 For Official Use OnlyDocument11 pagesGuidelines For Inspection & Maintenance of Bridge Bearings: BS-102 For Official Use OnlyAnirbanNo ratings yet

- RDSO Substructure Code PDFDocument71 pagesRDSO Substructure Code PDFTarun Sai100% (1)

- Image PDFDocument44 pagesImage PDFAkshay Kumar SahooNo ratings yet

- 42 M Bow String Girder-10408-2-R PDFDocument1 page42 M Bow String Girder-10408-2-R PDFPhanindra MajetiNo ratings yet

- Oil supply and return flange dimensionsDocument1 pageOil supply and return flange dimensionsFrancisco VeraNo ratings yet

- Fortificación TolvaDocument1 pageFortificación TolvadiegoNo ratings yet

- T17m202-02300-205mi-00002 (Im8-65519-4)Document1 pageT17m202-02300-205mi-00002 (Im8-65519-4)Rodrigo RaddatzNo ratings yet

- Plan Cheie - PC - 00 - Dumesti - A2Document1 pagePlan Cheie - PC - 00 - Dumesti - A2tebreanlNo ratings yet

- (Calatayud) Danza Espanola (Sheet)Document2 pages(Calatayud) Danza Espanola (Sheet)Long Nguyen NgocNo ratings yet

- Dawn Winery (Night)Document3 pagesDawn Winery (Night)lNo ratings yet

- Dawn Winery (Night)Document3 pagesDawn Winery (Night)GuitarDMoeNo ratings yet

- Dawn Winery (Night)Document3 pagesDawn Winery (Night)Iusefh Kodoku OkamiNo ratings yet

- Dawn Winery Genshin Impact Guitar CoverDocument3 pagesDawn Winery Genshin Impact Guitar CoverRoastedKornzNo ratings yet

- Lincoln4 ModelDocument1 pageLincoln4 ModelAndrea Mena ObleaNo ratings yet

- 3/380 V, 60Hz 3/440 V, 60Hz 3/400 V, 50Hz: Technical SpecificationDocument1 page3/380 V, 60Hz 3/440 V, 60Hz 3/400 V, 50Hz: Technical SpecificationcristianNo ratings yet

- 01 B276e5 MaaDocument1 page01 B276e5 MaaRenxio KahuaNo ratings yet

- General Piping and Instrumentation NotesDocument25 pagesGeneral Piping and Instrumentation NotesItz GyyyNo ratings yet

- Tower of Power Maybe Itll Rub OffDocument3 pagesTower of Power Maybe Itll Rub OfflegrosNo ratings yet

- Rdso B-11753 5R1Document1 pageRdso B-11753 5R1shibnath lahiri100% (1)

- Rdso B 11754 4RDocument1 pageRdso B 11754 4Rshibnath lahiriNo ratings yet

- 25T 30.5m RR Bearing B-17164Document1 page25T 30.5m RR Bearing B-17164shibnath lahiriNo ratings yet

- 3Document1 page3shibnath lahiriNo ratings yet

- 17044Document1 page17044shibnath lahiriNo ratings yet

- Detailed elevation design for 700x50x900 bottom plateDocument1 pageDetailed elevation design for 700x50x900 bottom plateshibnath lahiri0% (1)

- RDSO B 11773 9 DWGDocument4 pagesRDSO B 11773 9 DWGshibnath lahiriNo ratings yet

- RDSO B 16014 3R DWGDocument1 pageRDSO B 16014 3R DWGshibnath lahiriNo ratings yet

- Integral HumanismDocument55 pagesIntegral HumanismBalaganapathi DevarakondaNo ratings yet

- Esre E03200Document1 pageEsre E03200shibnath lahiriNo ratings yet

- Hindi Book - Hindutva - Vinayak Damodar Savarkar PDFDocument167 pagesHindi Book - Hindutva - Vinayak Damodar Savarkar PDFshibnath lahiriNo ratings yet

- EthicsDocument10 pagesEthicsEssi Chan100% (4)

- Pecet 2016 Colleges ListDocument7 pagesPecet 2016 Colleges Listandhramirchi50% (2)

- Marantz sr4200 Service PDFDocument29 pagesMarantz sr4200 Service PDFAnonymous KSedwANo ratings yet

- Rationale Paper Standards 1-2Document7 pagesRationale Paper Standards 1-2danielmatthewsNo ratings yet

- 2.3 Stabilized MaterialDocument11 pages2.3 Stabilized MaterialMamush LetaNo ratings yet

- Tugas B.INGGRIS ALANDocument4 pagesTugas B.INGGRIS ALANAlan GunawanNo ratings yet

- 9331 DCCBDocument5 pages9331 DCCBgopimodalavalasaNo ratings yet

- Milking MachineDocument10 pagesMilking Machineuniversaldairy100% (2)

- Kinjal AttachedDocument1 pageKinjal AttachedNilay JethavaNo ratings yet

- Midea R410A T3 50Hz Split Type Top-Dishcharge Series Technical Manual - V201707Document157 pagesMidea R410A T3 50Hz Split Type Top-Dishcharge Series Technical Manual - V201707kaleabNo ratings yet

- Food Safety Culture Webinar SLIDESDocument46 pagesFood Safety Culture Webinar SLIDESAto Kwamena PaintsilNo ratings yet

- Case AnalysisDocument4 pagesCase AnalysisAirel Eve CanoyNo ratings yet

- Human Rights DefinitionDocument2 pagesHuman Rights DefinitionFathiah MhNo ratings yet

- Question 1 - Adjusting EntriesDocument10 pagesQuestion 1 - Adjusting EntriesVyish VyishuNo ratings yet

- CFLM-1 Chapter 5Document17 pagesCFLM-1 Chapter 5Rico T. MusongNo ratings yet

- Density Functional Theory Investigations of Bismuth VanadateDocument7 pagesDensity Functional Theory Investigations of Bismuth VanadateNurSalahuddinNo ratings yet

- Integrated BMSDocument14 pagesIntegrated BMSjim.walton100% (5)

- 01.shurangama Mantra - 1st VerseDocument1 page01.shurangama Mantra - 1st Versetrung tranNo ratings yet

- Wind LoadsDocument5 pagesWind LoadsMGNo ratings yet

- Liban AnalyseDocument12 pagesLiban AnalyseSatish ReddyNo ratings yet

- Thời gian làm bài: 90 phút (không kể thời gian giao đề)Document8 pagesThời gian làm bài: 90 phút (không kể thời gian giao đề)Nguyễn KiênNo ratings yet

- 2009 Bar Exam Criminal Law QuestionsDocument25 pages2009 Bar Exam Criminal Law QuestionsJonny Duppses100% (2)

- NCP For Ineffective Airway ClearanceDocument3 pagesNCP For Ineffective Airway ClearanceJennelyn BayleNo ratings yet

- Members From The Vietnam Food AssociationDocument19 pagesMembers From The Vietnam Food AssociationMaiquynh DoNo ratings yet

- Importance of Education: March 2015Document4 pagesImportance of Education: March 2015AswiniieNo ratings yet

- Korsakoff's SyndromeDocument5 pagesKorsakoff's SyndromeburnnotetestNo ratings yet

- Grade 9: International Junior Math OlympiadDocument13 pagesGrade 9: International Junior Math OlympiadLong Văn Trần100% (1)

- African Journalof Auditing Accountingand FinanceDocument13 pagesAfrican Journalof Auditing Accountingand FinanceTryl TsNo ratings yet

- The Irish Light 10Document28 pagesThe Irish Light 10Twinomugisha Ndinyenka RobertNo ratings yet

- 07 - Toshkov (2016) Theory in The Research ProcessDocument29 pages07 - Toshkov (2016) Theory in The Research ProcessFerlanda LunaNo ratings yet