Professional Documents

Culture Documents

Biosimilars - Scientific and Regulatory Considerations: Introduction To Biologics

Uploaded by

holiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Biosimilars - Scientific and Regulatory Considerations: Introduction To Biologics

Uploaded by

holiCopyright:

Available Formats

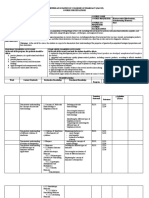

Program objectives

1. Review complexities of biologics and differences from chemical

drugs

Biosimilars—Scientific and 2. Introduce the US biosimilar regulatory framework

Regulatory Considerations

3. Learn about biosimilar development including design, analytical

studies, and clinical studies

Gustavo Grampp

4. Discuss post-approval considerations including

Regulatory Policy Director, Amgen pharmacovigilance, interchangeability, and substitution

Presented at Maryland Pharmacists Association meeting January 31, 2016

Grampp, Biosimilars—Scientific and Regulatory Considerations. 2

MPhA Meeting January 31, 2016

What is a biologic?

• Biologics are large protein-based therapeutics

– Biologics can include antibodies, recombinant proteins, or

fusion proteins

INTRODUCTION TO

BIOLOGICS

Monoclonal antibody

Neiderwieser D et al. Eur J Haematol 2011;86:277-288.

3 Grampp, Biosimilars—Scientific and Regulatory Considerations. 4

MPhA Meeting January 31, 2016

Amgen Corporate Template 1

What is a biologic? What is a biologic?

• Biologics are more complex in structure and function • Biologics are more complex in structure and function

than chemical drugs than chemical drugs

Up to 1000×

larger1,2

Complex,

with post-translational

modifications1

Simple,2

well-defined3

Monoclonal antibody1 Acetylsalicylic acid2

~150 kDa ~0.18 kDa Monoclonal antibody Acetylsalicylic acid

1. Roger SD. Nephrology 2006;11:341-346. 2. Prugnaud JL. Br J Clin Pharmacol 2007;65:619-620. 3. Genazzani AA et al. Biodrugs 2007;21:351-356.

1. Lipman NS et al. ILAR J. 2005;46:258-268. 2. Aspirin prescribing information. Available at:

http://www.fda.gov/ohrms/dockets/ac/03/briefing/4012B1_03_Appd%201-Professional%20Labeling.pdf. Accessed September 2015.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 5 Grampp, Biosimilars—Scientific and Regulatory Considerations. 6

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Biologics are made by living cells

through well-controlled processes So what is a biosimilar?

A typical biotechnology manufacturing process includes multiple stages • According to the US FDA, a biosimilar is a biological

product that is highly similar to the reference product

Transfection of

• There are no clinically meaningful differences in terms

Patient

DNA into host cell1 treatment2

of:

Cell line

selection and Refrigeration,2 – Safety

development1 storage,2 and

transport1 – Purity

– Potency

Manufacturer establishes a

unique master cell bank1 Formulation,1 fill,2

and finish2

In other words:

Differences between biosimilars and reference biologics

Cell culture Characterization

and expansion1 and stability2 are expected, but must not be clinically meaningful

FDA, Food and Drug Administration.

Isolation2 and purification1 US Food and Drug Administration. Available at: http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm291128.pdf. Accessed

September 2015.

1. Kresse GB. Eur J Pharm Biopharm. 2009;72:479-486. 2. Sharma BG. EJHP Practice. 2007;13:54-56.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 7 Grampp, Biosimilars—Scientific and Regulatory Considerations. 8

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Amgen Corporate Template 2

Each biosimilar is unique because of Biosimilars are fundamentally different

differences in manufacturing from generics

Biosimilars Generics Biosimilars Generics

Monoclonal Acetylsalicylic acid1 Monoclonal Acetylsalicylic acid1

Known DNA sequence Unique manufacturing Unique biosimilar antibody antibody

SIZE STRUCTURE

Complex with many

Large2 Small2 options for post- Simple5 and

MW = ~150,000 Da3 MW = 180 Da1 translational well defined2

modification4

MANUFACTURING CHARACTERIZATIONS

Each manufactured in a Predictable chemical Difficult to

unique living cell line2 process characterize fully Easy to fully

Similar but not identical Identical copy can be owing to a mixture of characterize6

copy can be made2 made2 related molecules6

STABILITY IMMUNOGENICITY

Sensitive to storage

and handling Relatively stable2 Higher potential2 Lower potential2

conditions2

MW, molecular weight.

1. Aspirin comprehensive prescribing information. Available at: www.fda.gov/ohrms/dockets/ac/03/briefing/4012B1_03_Appd%201Professional%20Labeling.pdf.

1. Roger SD. Nephrology (Carlton) 2006;11:341-346. 2. Mellstedt H et al. Ann Oncol 2008;19:411-419. Accessed January 2013. 2. Genazzani AA et al. Biodrugs 2007;21:351-356. 3. Lipman NS et al. ILAR J 2005;46:258-268. 4. Roger SD. Nephrology 2006;11:341-346.

5. Prugnaud JL. Br J Clin Pharmacol 2007;65:619-620. 6. Gottlieb S. Am J Health Syst Pharm 2008;65(Suppl 6):S2-S8.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 9 Grampp, Biosimilars—Scientific and Regulatory Considerations. 10

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Summary

Biologics are large, complex medicines

developed in living systems

Biosimilars are highly similar, but not

identical to the innovator biologic

Biosimilars differ from generics in REGULATORY FRAMEWORKS

complexity, manufacturing and sensitivity

Grampp, Biosimilars—Scientific and Regulatory Considerations. 11 12

MPhA Meeting January 31, 2016

Amgen Corporate Template 3

The US biosimilars pathway was signed In contrast to the regulatory framework for

into law along with the Affordable Care Act generics…

Generics Biosimilars

“Same (Identity)” = “Identical (Identity)”

Establish same active ingredient, Extensive structural and functional

strength, dosage form, route of characterization

administration, and condition of

use Pharmaceutical Therapeutic

Bioequivalence

Consider need for animal data to Equivalence Equivalence

assess toxicity

Demonstration of bioequivalence

Clinical studies to compare clinical Same active Same rate & Interchangeability

immunogenicity and PK/PD ingredients, extent of Rating

dosage form, absorbance &

Sufficient to demonstrate that the product is

“highly similar” to the reference product and administration availability at

safe, pure, and potent for one or more route & strength site (80-125%)

approved conditions of use PE = Pharmaceutical Equivalence

BE = Bioequivalence

FDA has discretion to determine that certain

studies not required

TE = Therapeutic Equivalence

“Same” Structure = “Same” Function

Food and Drug Administration. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf.

Accessed 24 January 2013. Steven Kozlowski, M.D. Director Office of Biotechnology Products/OPS/CDER. Available at http://www.biosimilarstoday.com/Kozlowski.pdf

Grampp, Biosimilars—Scientific and Regulatory Considerations. 13 Grampp, Biosimilars—Scientific and Regulatory Considerations. 14

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016 14

FDA recommends a “Totality of Evidence” and a Demonstration of biosimilarity is the first step -

stepwise approach for biosimilar development interchangeability has additional requirements

Safety, Efficacy, and • The FDA will consider the totality of evidence

Clinical Immunogenicity provided3 Approved as an

studies1 One study to inform Approved as a biosimilar

immunogenicity and will – Comparative assessment of the structure interchangeable biologic

likely need at least one and function

clinical study in a

Clinical sensitive population to – Nonclinical evaluation

confirm safety

Pharm. and efficacy2 – Human PK/PD

(PK/PD) – Clinical immunogenicity Additional evidence is needed to demonstrate interchangeability1

– Clinical safety and efficacy, as needed Can be expected to produce the same clinical result as the reference

product in any given patient

Nonclinical

• The purpose of the biosimilar development AND

program is to demonstrate that the biosimilar For a product that is administered more than once, there is no additional

is highly similar to the reference product and risk in terms of safety or diminished efficacy as a result of switching

Analytical not to independently establish its safety and between the biosimilar and the reference product compared with using

Characterization effectiveness3 the reference product alone

(Structure & Function

• The type and extent of analyses and testing

Assessment)

that are needed to demonstrate biosimilarity

will be determined on a case-by-case basis3 • The United States is the only country with a specific definition for an interchangeable biologic2

FDA, Food and Drug Administration; PD, pharmacodynamics; PK, pharmacokinetics.

• Studies needed to obtain the interchangeability designation are not yet determined by the FDA2

1. Kozlowski S. Presented at: Biotechnology Technology Summit; June 13, 2014; Rockville, MD.

https://www.ibbr.umd.edu/sites/default/files/public_page/Kozlowski%20-%20Biomanufacturing%20Summit.pdf. Accessed February 5, 2015. FDA, Food and Drug Administration.

2. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2015. 1. Patient Protection and Affordable Care Act. 2009. http://www.gpo.gov/fdsys/pkg/BILLS-111hr3590pp/pdf/BILLS-111hr3590pp.pdf. Accessed April 30, 2015.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed April 30, 2015.

2. Camacho L, et al. Cancer Med. 2014;3:889-899.

3. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

15 Grampp, Biosimilars—Scientific and Regulatory Considerations. 16

MPhA Meeting January 31, 2016

Amgen Corporate Template 4

Summary

The US pathway for approval of biosimilars was

signed into law along with the Patient Protection

and Affordable Care Act

A totality of evidence will be considered when

evaluating a biosimilar product for approval

Determination of interchangeability requires DEVELOPMENT OF

additional evidence BIOSIMILARS

Grampp, Biosimilars—Scientific and Regulatory Considerations. 17 Grampp, Biosimilars—Scientific and Regulatory Considerations. 18

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Biosimilar manufacturers start with no Biosimilar development requires reverse engineering,

knowledge of the reference product starting with reference product characterization

Attributes related to the amino acid

sequence and all post-translational Biological and functional

modifications, including glycans activities, including receptor binding

Primary and immunochemical properties

structure

Integrity of the secondary,

• Purchase and analyze reference product tertiary, and quaternary

? • Determine amino acid sequence

structure Higher

order

structure

Biological

function

Product-related Degradation

• Characterize product, including glycosylation substances and profiles denoting

impurities stability

• Understand structure–function Quantitative levels of

product variants and Stability Receptor

• Determine critical quality attributes their identities General

properties

binding and

immuno- Kinetics and thermodynamics

and

chemical

excipients properties of binding, related to functional

activity

Process-

Properties of the finished related

drug product, including strength

impurities

Impurities from host cells

and formulation and downstream process

Kozlowski S. Presented at: Biotechnology Technology Summit; June 13, 2014; Rockville, MD. Available at:

US Food and Drug Administration. Available at: http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291134.pdf. Accessed

https://www.ibbr.umd.edu/sites/default/files/public_page/Kozlowski%20-%20Biomanufacturing%20Summit.pdf. Accessed February 2015.

September 2015.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 19 Grampp, Biosimilars—Scientific and Regulatory Considerations. 20

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Amgen Corporate Template 5

Biosimilar manufacturers create a unique cell A stepwise development program follows

line and a unique manufacturing process after reverse engineering

Known1 Unknown2 Analytics

Biosimilar?

Cell line Originator BLA Biosimilar

Growth media Cross

Method of cell expansion reference

Bioreactor conditions Clinical 3. Clinical

Protein recovery conditions studies Biosimilar?

Compare Cross

DNA Purification conditions structure and reference

sequence Formulation methods function Nonclinical 2. Non-Clinical

Reagents

Reference standards

Analytical Biosimilar? 1. Quality

Characterization Cross reference –

(Structure & Function Prior findings of safety and Integrated Biosimilarity Exercise –

Quality, Safety and Efficacy

To reverse engineer a reference product, each Assessment) efficacy

biosimilar developer must create a manufacturing

process for that biologic de novo2

Food and Drug Administration. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf.

Accessed 24 January 2013.

1. Mellstedt H et al. Ann Oncol 2008;19:411-419. 2. Roger SD. Nephrology (Carlton) 2006;11:341-346.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 21 Grampp, Biosimilars—Scientific and Regulatory Considerations. 22

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Stepwise assessment begins with extensive Comparisons assess alignment of many

structural and functional comparisons attributes, with emphasis on critical attribute

General properties1 Sample exercise: Biosimilar attributes

compared with reference product1

Primary structure2

• Foundational for biosimilar Biosimilar Biosimilar

vs US vs EU

development program High-order structure2 reference reference

• Involves structural and functional product product

characterization of reference Biological2

Attributes

product 91 93

matched

Product-related substances and impurities2

• Involves the determination of

Attributes not

differences in relevant critical Process-related impurities2 matched, but 4 2

attributes between biosimilar and not critical

Analytical reference product using Particles and aggregates1 Attributes not

Characterization appropriate analytical matched and 0 0

(Structure & Function Product degradation2 critical

methodology

Assessment)

Adapted from Foraker S, provided October 28, 2014, as part of an oral presentation and is qualified by such, containing forward-looking statements, and actual

results may vary materially; Amgen disclaims any duty to update.

ABP, Amgen biosimilar product; EU, European Union; US, United States.

1. Adapted from Foraker S. http://investors.amgen.com/phoenix.zhtml?c=61656&p=irol-presentations. Accessed March 5, 2015. 2. FDA. Guidance for Industry: Quality

Considerations in Demonstrating Biosimilarity to a Reference Protein Product. 2012.

FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291134.pdf. Accessed February 6, 2015.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 23 Grampp, Biosimilars—Scientific and Regulatory Considerations. 24

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Amgen Corporate Template 6

Toxicity assessments based on data Clinical pharmacology studies are a

from animal studies are useful critical part of demonstrating biosimilarity

• Comparative human PK and PD studies are fundamental

components in demonstrating there no clinically meaningful

differences between reference and biosimilar1

• PK studies should demonstrate similar exposure over time and

• Animal toxicity data are useful when PD studies should demonstrate similar effect on clinically

uncertainties remain about safety of relevant PD measure(s) related to efficacy or safety concerns1

biosimilar after extensive structural Clinical

• Important PK parameters that are commonly studied include

and functional characterization Pharm. AUC and Cmax2

(PK/PD)

Nonclinical • Not warranted if biosimilar has been Example of PK of biosimilar that is highly

demonstrated to be highly similar to similar to that of the reference3

reference through analytical

concentration, µg/mL

Mean (±SD) serum

characterization

Biosimilar

Reference

Figure reproduced from Park W, et al. Ann Rheum Dis. 2013;72:1605-1612. With permission from BMJ Publishing Group Ltd.

FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

AUC, area under the concentration-time curve; Cmax , maximum concentration; PD, pharmacodynamics; PK, pharmacokinetics; SD, standard deviation. aBiosimilar N=113.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

1. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015. 2. FDA. Guidance for Industry: Clinical Pharmacology Data to Support a

Grampp, Biosimilars—Scientific and Regulatory Considerations. 25 Demonstration of Biosimilarity to a Reference Product. 2014. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM397017.pdf.

26 3. Park W, et al. Ann Rheum Dis.

MPhA Meeting January 31, 2016 2013;72:1605-1612.

Immunogenicity studies are critical for Comparative clinical safety and efficacy

establishing biosimilarity assessments may address residual uncertainties

Safety, Efficacy, and

Immunogenicity Clinical Studies

One clinical study in Factors that affect the type and

Clinical a sensitive population (Safety,

extent of clinical efficacy and safety

Studies

to inform

immunogenicity1 • The goal of immunogenicity studies is Efficacy)1 studies needed2

to establish that there are no clinically

meaningful differences in incidence and • Nature and complexity of the

Clinical

severity of human immune response

Clinical reference

Pharm.

between the biosimilar and reference Pharm. • Mechanism of action of reference and

PK/PD (PK/PD) disease pathology

product2

• Extent of clinical experience with the

reference and its therapeutic class

Nonclinical • Extent to which differences in

• Immunogenicity can be tested during structure and function studies predict

clinical safety and efficacy studies, differences in clinical outcomes

including PK/PD studies1 Analytical • Extent to which PK and PD studies

• Studies should be conducted in sensitive Characterization predict clinical outcomes (eg, are

population2 (Structure & Function sensitive PD markers available)

• Studies should include assessment of Assessment)

binding and neutralizing antibodies2

PD, pharmacodynamics; PK, pharmacokinetics.

PD, pharmacodynamics; PK, pharmacokinetics.

1. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2015. 1. Kozlowski S. Presented at: Biotechnology Technology Summit; June 13, 2014; Rockville, MD.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015. https://www.ibbr.umd.edu/sites/default/files/public_page/Kozlowski%20-%20Biomanufacturing%20Summit.pdf. Accessed February 5, 2015.

2. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012. 2. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

27 28

Amgen Corporate Template 7

Indication extrapolation is important to

Clinical confirmation: safety and efficacy biosimilar development

• A proposed biosimilar product may be licensed in one or

Clinical

Studies

(Safety, • The goal is to demonstrate that the biosimilar has neither

Efficacy)

decreased nor increased activity compared with the

more additional conditions of use for which the reference

reference product and has similar immunogenicity product is licensed, without additional clinical trials, if

appropriate scientific justification is provided

Study design • Two-sided test to demonstrate equivalence; with an appropriate equivalence • Extrapolation is not automatic

margin

– A one-sided noninferiority design more appropriate in certain Reference product studies Biosimilar studies

circumstances

Endpoints and • Clinically relevant and sensitive in detecting clinically meaningful differences

study population • Selected by considering comorbidities and effect on disease state (eg,

immunosuppressed)

RA AS RA + PsO

+ +

Important • Clinical trial should allow PsO + CD

considerations – Sufficient exposure

– Detection of relevant safety signals + + Extrapolated indications

– Detection of clinically meaningful differences in effectiveness and safety PsA UC

FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

PsA + AS + CD + UC

AS, ankylosing spondylitis; CD, Crohn’s disease; PsA, psoriatic arthritis; PsO, psoriasis; RA, rheumatoid arthritis; UC, ulcerative colitis.

US Food and Drug Administration. Available at:

Grampp, Biosimilars—Scientific and Regulatory Considerations. 29 30

http://www.fda.gov/downloads/drugs/guidancecomplianceregulatoryinformation/guidances/ucm291128.pdf. Accessed September 2015.

MPhA Meeting January 31, 2016

FDA recommendations address Summary:

considerations related to extrapolation Pillars of Biosimilar Development

Considerations1 FDA recommendations2

• Extrapolation is considered on case-by-case basis Biosimilar development starts with reverse engineering of the reference product quality

• When MOA is not fully understood, separate attributes

clinical trials in each indication are likely

Potential for distinct MOA in each Physiochemical and functional characterization of both the reference and the biosimilar

necessary

therapeutic indication • Biological data covering all functional aspects of is foundational to stepwise development

agent, demonstrating high similarity to reference,

is required Comparative human PK and PD studies demonstrating absence of clinically meaningful

differences between reference and biosimilar are critical to establishing biosimilarity

Variable optimal doses for efficacy • Data are produced using patient population and Immunogenicity testing demonstrating no clinically meaningful differences in incidence

or safety profiles in different clinical endpoint most sensitive to detect clinically and severity is required

patient groups meaningful differences in efficacy and safety

It is likely that at least one clinical study in a sensitive population is needed to confirm

safety and efficacy and inform immunogenicity

Influence of individual patient • Careful consideration must be given to

characteristics on treatment comorbidities/concomitant medications and Appropriate scientific justification is required to allow extrapolation of indications of use

response intersubject variability for which the reference is licensed

FDA, Food and Drug Administration; MOA, mechanism of action.

1. Dörner T, et al. Ann Rheum Dis. 2013;72:322-328. 2. FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. FDA, Food and Drug Administration; PD, pharmacodynamics; PK, pharmacokinetics.

2012. http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 31 Grampp, Biosimilars—Scientific and Regulatory Considerations. 32

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Amgen Corporate Template 8

Ongoing pharmacovigilance is important

for biologics and biosimilars

Robust post-marketing safety monitoring is important to

ensure similar safety and effectiveness between the biosimilar

and the reference drug

Safety monitoring should take into account the safety or

effectiveness concerns associated with reference product

Safety monitoring should have the ability to differentiate

POST-APPROVAL CONSIDERATIONS between adverse events associated with the proposed

biosimilar product vs those associated with the reference drug

or other biosimilars

FDA. Guidance for Industry: Scientific Considerations in Demonstrating Biosimilarity to a Reference Product. 2012.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM291128.pdf. Accessed February 7, 2015.

33 Grampp, Biosimilars—Scientific and Regulatory Considerations. 34

MPhA Meeting January 31, 2016

Why the practitioner needs to know Proximal agent is

not always the

what product a patient received casual agent! Class effect vs. product specific effect

“[C]ompanies will make manufacturing-related

changes to biologics periodically … and even Requires

small changes could affect safety or efficacy.”

– FDA1

Safety

• Sensitivity and Monitoring

complexity • Access to accurate and

• Manufacturing • Immune response complete medication

• Potential “drift” histories

changes

between products

Medical

Variability

Records

Justifies

Doctors CVS for

Refill #1

Office

Walgreens

Refill #2

Patient Record

Independent

1. Kozlowski S et al. N Engl J Med. 2011;365:385-388. pharmacy

Refill #3

Grampp, Biosimilars—Scientific and Regulatory Considerations. 35 Source: Casadevall Nicole, Immune-response and adverse reactions: PRCA case example. Presentation to EMA Nov, 36

2009. Available at

MPhA Meeting January 31, 2016 http://www.ema.europa.eu/docs/en_GB/document_library/Presentation/2009/11/WC500011064.pdf

Amgen Corporate Template 9

Interchangeability will require additional In the US, state regulations govern

evidence beyond approval as a biosimilar automatic substitution

Additional evidence is needed to

demonstrate interchangeability1

FDA approves a Automatic State pharmacy

Can be expected to produce the same substitution

clinical result as the reference product biologic as practice laws allow

of an

in any given patient interchangeable interchangeable for substitution of

AND Approved, with the reference biologic is an interchangeable

Approved For a product that is administered more interchangeable product1 allowed biologic2

biosimilar than once, there is no additional risk to biosimilar

safety or efficacy as a result of

switching between the biosimilar and

the reference product

The US is the only country with a specific definition

of an interchangeable biologic 1. US Food and Drug Administration.

http://www.fda.gov/Drugs/DevelopmentApprovalProcess/HowDrugsareDevelopedandApproved/ApprovalApplications/TherapeuticBiologicApplications/Biosimilars/ucm2

41718.htm. Accessed February 2015. 2. NCSL. State Laws and Legislation Related to Biologic Medications and Substitution of Biosimilars. 2014.

1. US Food and Drug Administration. Available at: http://www.ncsl.org/documents/health/Biologics_BiosimilarsNCSLReport_July_2014.pdf. Accessed April 4, 2015.

http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM444661.pdf. Accessed September 2015.

Grampp, Biosimilars—Scientific and Regulatory Considerations. 37 Grampp, Biosimilars—Scientific and Regulatory Considerations. 38

MPhA Meeting January 31, 2016 MPhA Meeting January 31, 2016

Summary

Ongoing safety monitoring is critical to ensuring patient safety.

FDA has proposed a system of distinguishable nonproprietary names to help

facilitate accurate and timely adverse event reporting.

FDA determines interchangeability and states determine the terms of

pharmacy substitution of biologics

THANKS!

Grampp, Biosimilars—Scientific and Regulatory Considerations. 39 40

MPhA Meeting January 31, 2016

Amgen Corporate Template 10

You might also like

- Computational Approaches To Predict Drug Metabolism: ReviewDocument13 pagesComputational Approaches To Predict Drug Metabolism: ReviewEduardo Damasceno CostaNo ratings yet

- Week 2 PCOL211 Review of Pharmacodynamics - Evaluation of DrugsDocument15 pagesWeek 2 PCOL211 Review of Pharmacodynamics - Evaluation of DrugsTrixie SalcedoNo ratings yet

- Biosimilars ClarifiedDocument37 pagesBiosimilars ClarifiedkotakmeghaNo ratings yet

- WEEK 3 Drug Discovery and Drug Product DevelopmentDocument12 pagesWEEK 3 Drug Discovery and Drug Product DevelopmentSheng OsabelNo ratings yet

- Drug Interaction in Clinical PracticeDocument10 pagesDrug Interaction in Clinical PracticeSathish SizzyNo ratings yet

- PharmacodynamicsDocument28 pagesPharmacodynamicsAbdishakur AdanNo ratings yet

- Progress in Biopharmaceutical DevelopmentDocument18 pagesProgress in Biopharmaceutical DevelopmentAlexandra BulboacăNo ratings yet

- 4.1 BiopharmaceuticsDocument8 pages4.1 BiopharmaceuticsAzech Yam Ü100% (1)

- BiopharmaceuticalsDocument6 pagesBiopharmaceuticalsNikko Nabasca GorneNo ratings yet

- WEEK 2 Pharmaceutical ChemistryDocument7 pagesWEEK 2 Pharmaceutical ChemistrySheng OsabelNo ratings yet

- 1 PCOL Introduction Review of KineticsDocument18 pages1 PCOL Introduction Review of Kineticsnica velanoNo ratings yet

- GVO 06 Pharmacology enDocument88 pagesGVO 06 Pharmacology enAlexandre FunciaNo ratings yet

- Ambient Mass Spectrometry in MetabolomicsDocument17 pagesAmbient Mass Spectrometry in MetabolomicsAlisnonNo ratings yet

- VILLARIAZA - New Drug Discovery FinalDocument46 pagesVILLARIAZA - New Drug Discovery FinalMary Angelique BanogonNo ratings yet

- Biopharmaceutics & PharmacokineticsDocument10 pagesBiopharmaceutics & PharmacokineticsEstelle Janica FusterNo ratings yet

- Pharmacology 1Document53 pagesPharmacology 1Dawn WRein LegaspiNo ratings yet

- Introduction To Biopharmaceutics and PharmacokineticsDocument4 pagesIntroduction To Biopharmaceutics and PharmacokineticsJM MatiasNo ratings yet

- Biosimilar Development - An Overview: Correspondence ToDocument8 pagesBiosimilar Development - An Overview: Correspondence ToAjay IyerNo ratings yet

- Electrochemical Biosensors in Pharmaceutical AnalyDocument17 pagesElectrochemical Biosensors in Pharmaceutical AnalyRimaNo ratings yet

- New Insights On Bio-Based Micro-And Nanosystems in FoodDocument7 pagesNew Insights On Bio-Based Micro-And Nanosystems in FoodAnne Sophie ArcigaNo ratings yet

- Attention! Info On Term Projects: BiomaterialsDocument6 pagesAttention! Info On Term Projects: BiomaterialsC NNo ratings yet

- Developing Safe Medicines L3 - Small MoleculesDocument16 pagesDeveloping Safe Medicines L3 - Small Moleculesshaumiya ketheesNo ratings yet

- Modul PANUM FarmakoDocument15 pagesModul PANUM FarmakoShifa TifarinNo ratings yet

- Beta-Sitosterol PresentationDocument20 pagesBeta-Sitosterol PresentationAishleen SinghNo ratings yet

- Overview of The Research ProcessDocument30 pagesOverview of The Research ProcessLouisa CabañogNo ratings yet

- Developments in Phytochemistry: Moronkola Dorcas OlufunkeDocument13 pagesDevelopments in Phytochemistry: Moronkola Dorcas Olufunkeေအာင္ ေက်ာ္ စြာNo ratings yet

- 3rd Year MBBS CurriculumDocument41 pages3rd Year MBBS Curriculumhamidmirza737No ratings yet

- Axiology PhilosophyDocument22 pagesAxiology PhilosophyXindy Imey PratiwiNo ratings yet

- (PHA6118 Lec) Introduction To PharmacologyDocument5 pages(PHA6118 Lec) Introduction To Pharmacologychristian redotaNo ratings yet

- CM - Consumer Chemistry - 2022-2023Document4 pagesCM - Consumer Chemistry - 2022-2023Apar DizonNo ratings yet

- 2-Principles of PharmacodynamicsDocument6 pages2-Principles of Pharmacodynamicss.palao.annfrencislouiseNo ratings yet

- BASIC PRINCIPLES OF PHARMACOLOGY For DENTISTRYDocument142 pagesBASIC PRINCIPLES OF PHARMACOLOGY For DENTISTRYKuya RnJNo ratings yet

- Plenary 05 - Biotherapeutics - What S Right For Patients Moving Forward by Ms. Karen M. Hauda1Document62 pagesPlenary 05 - Biotherapeutics - What S Right For Patients Moving Forward by Ms. Karen M. Hauda1ARUN NTNo ratings yet

- Epp4 Idm Winter 2021 FinalDocument11 pagesEpp4 Idm Winter 2021 Finalapi-552486649No ratings yet

- CH 13Document1 pageCH 13Amany SalamaNo ratings yet

- Bio Pharmaceutical Classification SystemDocument7 pagesBio Pharmaceutical Classification SystemRafi Arif 7189No ratings yet

- 20 Quimica Organica Facts Every Student Should KnowDocument13 pages20 Quimica Organica Facts Every Student Should KnowIvan Dario Alfonso BetancourtNo ratings yet

- Introduction To BiochemistryDocument2 pagesIntroduction To BiochemistryRichelle Glynisse Llarenas EstilongNo ratings yet

- Comparability Pathway For The Approval of Similar Biologics With Respect To Reference Biologics in Europe and BrazilDocument13 pagesComparability Pathway For The Approval of Similar Biologics With Respect To Reference Biologics in Europe and Brazil10 Adarsh GuptaNo ratings yet

- BiopharmaceuticalClassificationSystem PDFDocument7 pagesBiopharmaceuticalClassificationSystem PDFShahd Diefalla Ahmed DiefallaNo ratings yet

- Synthesis and Evaluation of Some Amino Acid Conjugates of NSAIDSDocument9 pagesSynthesis and Evaluation of Some Amino Acid Conjugates of NSAIDSSACHIN BHASKAR NARKHEDENo ratings yet

- Computer Aided Drug DesigningDocument19 pagesComputer Aided Drug DesigningPitchumaniangayarkanni S.No ratings yet

- Polymeric Based Drug Delivery System: Risa Ahdyani, M.Pharm - SciDocument26 pagesPolymeric Based Drug Delivery System: Risa Ahdyani, M.Pharm - SciRisa AhdyaniNo ratings yet

- Diazepam Understanding The Pharmacokinetics of Anxiolytic DrugsDocument19 pagesDiazepam Understanding The Pharmacokinetics of Anxiolytic DrugsFarros ibrahimNo ratings yet

- modMODULE II-D MUSCARINIC CHOLINORECEPTOR ANTAGONISTSDocument6 pagesmodMODULE II-D MUSCARINIC CHOLINORECEPTOR ANTAGONISTSKenneth NuñezNo ratings yet

- Polymers in Drug Delivery Technology Types of PolyDocument5 pagesPolymers in Drug Delivery Technology Types of Polyvijayambhore1906No ratings yet

- Syllabus Bioquímica 2021-II FG YACHAYDocument8 pagesSyllabus Bioquímica 2021-II FG YACHAYMathew Cedeño AvellanNo ratings yet

- Craik2012 Konformasi THDP AktivitasDocument12 pagesCraik2012 Konformasi THDP AktivitasHasna NoerNo ratings yet

- Biochemistry CoursepackDocument34 pagesBiochemistry Coursepackanonymous squash0% (1)

- RX PDFDocument8 pagesRX PDFshubham singhNo ratings yet

- Chemistry NotesDocument2 pagesChemistry NotesAngelo Kyle AdrianoNo ratings yet

- Inorganic - Organic Chemistry MergedDocument53 pagesInorganic - Organic Chemistry MergedisyandanNo ratings yet

- NCM 106 PHARMACOLOGY - PrelimsDocument26 pagesNCM 106 PHARMACOLOGY - PrelimsKelsey Macaraig100% (3)

- Developing Biosimilars The Process and Quality StandardsDocument9 pagesDeveloping Biosimilars The Process and Quality Standardssagar dhakalNo ratings yet

- Characters of PolymersDocument3 pagesCharacters of PolymerstariqjiyaNo ratings yet

- 01 - General Principles of Phamacology (Intro)Document11 pages01 - General Principles of Phamacology (Intro)janenaleighNo ratings yet

- Physiologically Based Pharmacokinetic PBPK Modeling and Simulations 2Nd Edition Sheila Annie Peters All ChapterDocument67 pagesPhysiologically Based Pharmacokinetic PBPK Modeling and Simulations 2Nd Edition Sheila Annie Peters All Chapterrobert.barker598100% (7)

- Review of Stimuli-Responsive Polymers in Drug Discovery Development and DeliveryDocument16 pagesReview of Stimuli-Responsive Polymers in Drug Discovery Development and DeliveryЕгор Летов100% (1)

- Learning Clinical ChemistryDocument69 pagesLearning Clinical Chemistryquimico clinico 2798% (46)

- Electromagnetic Elds and Radiation: What Are They?Document4 pagesElectromagnetic Elds and Radiation: What Are They?holiNo ratings yet

- Book Description: Epidemiology of Electromagnetic FieldsDocument4 pagesBook Description: Epidemiology of Electromagnetic FieldsholiNo ratings yet

- Electric & Magnetic Fields: COVID-19Document4 pagesElectric & Magnetic Fields: COVID-19holiNo ratings yet

- Electromagnetic Field: PhysicsDocument8 pagesElectromagnetic Field: PhysicsholiNo ratings yet

- Introduction To Matrix Algebra I: 1 Definition of Matrices and VectorsDocument15 pagesIntroduction To Matrix Algebra I: 1 Definition of Matrices and VectorsholiNo ratings yet

- High Frequency Words SCSDocument6 pagesHigh Frequency Words SCSholiNo ratings yet

- Magnetism: Magnissia, Grecia ApplicationsDocument5 pagesMagnetism: Magnissia, Grecia ApplicationsholiNo ratings yet

- Ar09 BioconDocument153 pagesAr09 Bioconchandra12345678No ratings yet

- NBT 4305Document12 pagesNBT 4305RobsonNo ratings yet

- Pharmaceuticals 270111Document34 pagesPharmaceuticals 270111Sidd SinghNo ratings yet

- Iip Report of Pranjal YadavDocument54 pagesIip Report of Pranjal YadavHarsh parasher (PGDM 17-19)No ratings yet

- Guidance On Registration of Similar Biological Products in SingaporeDocument13 pagesGuidance On Registration of Similar Biological Products in SingaporeWilliam ChandraNo ratings yet

- Reuters To Make Documentary On Paras Biopharmaceuticals Finland Oy - Innovations in Biologics: Insights of A Leading ExpertDocument3 pagesReuters To Make Documentary On Paras Biopharmaceuticals Finland Oy - Innovations in Biologics: Insights of A Leading ExpertPR.comNo ratings yet

- Scms 6s 6-16 Hawaiisppl v9Document28 pagesScms 6s 6-16 Hawaiisppl v9Michele CarvalhoNo ratings yet

- CPGM 7345.848 - Inspection of Biological Drug ProductsDocument20 pagesCPGM 7345.848 - Inspection of Biological Drug ProductsKisho RamNo ratings yet

- Advanced Biopharmaceutical Manufacturing: An Evolution UnderwayDocument16 pagesAdvanced Biopharmaceutical Manufacturing: An Evolution UnderwayEE KMNo ratings yet

- Cphi Pharma Annual Ind Report 2018 Full Version PDFDocument83 pagesCphi Pharma Annual Ind Report 2018 Full Version PDFJorge Colin SanchezNo ratings yet

- Medicine Box NotesDocument7 pagesMedicine Box NotesNiruNo ratings yet

- Case 6-6Document9 pagesCase 6-6Chamuel Michael Joseph Santiago50% (2)

- Brand Name Pharmaceutical Manufacturing in The US Industry Report (Short)Document15 pagesBrand Name Pharmaceutical Manufacturing in The US Industry Report (Short)Rasika GodboleNo ratings yet

- Current Scenario of Biologics in IndiaDocument30 pagesCurrent Scenario of Biologics in IndiaShivang Shah100% (1)

- Clin Pharma and Therapeutics - 2020 - Barbier - The Efficacy Safety and Immunogenicity of Switching Between ReferenceDocument22 pagesClin Pharma and Therapeutics - 2020 - Barbier - The Efficacy Safety and Immunogenicity of Switching Between ReferenceBenedikt StefanssonNo ratings yet

- Extending Pharmaceutical Horizons: Generics and Biosimilars in Russia and CISDocument4 pagesExtending Pharmaceutical Horizons: Generics and Biosimilars in Russia and CISJagdish Chander0% (1)

- Intertek Pharmaceutical Services BrochureDocument12 pagesIntertek Pharmaceutical Services BrochureRubayetNo ratings yet

- As The CEO of Teva, Which Markets Would You Concentrate On Developing Going Forward?Document12 pagesAs The CEO of Teva, Which Markets Would You Concentrate On Developing Going Forward?mGD1993No ratings yet

- Sivasankaran Harishankar: ContactDocument3 pagesSivasankaran Harishankar: ContactPrasoon MishraNo ratings yet

- Plenary 05 - Biotherapeutics - What S Right For Patients Moving Forward by Ms. Karen M. Hauda1Document62 pagesPlenary 05 - Biotherapeutics - What S Right For Patients Moving Forward by Ms. Karen M. Hauda1ARUN NTNo ratings yet

- Coverage Initiation - BioconDocument32 pagesCoverage Initiation - BioconAjit AgrawalNo ratings yet

- Biocon 3R Feb28 - 2022Document7 pagesBiocon 3R Feb28 - 2022Ratan PalankiNo ratings yet

- Biosimilars JapanDocument2 pagesBiosimilars JapanVijay Nag ThotaNo ratings yet

- 2016 Healthcare OutlookDocument38 pages2016 Healthcare OutlookeliforuNo ratings yet

- Preclinical CRO ServicesDocument6 pagesPreclinical CRO ServicesGundoju sureshNo ratings yet

- Amcp Media List 8Document96 pagesAmcp Media List 8api-407904109No ratings yet

- Annex 2: Guidelines On Evaluation of Monoclonal Antibodies As Similar Biotherapeutic Products (SBPS)Document36 pagesAnnex 2: Guidelines On Evaluation of Monoclonal Antibodies As Similar Biotherapeutic Products (SBPS)sumaira zaibNo ratings yet

- 7.0 InterchangibilityDocument2 pages7.0 InterchangibilitySanket ChintawarNo ratings yet

- Ijpdt 8 (2) 2018 12-36Document25 pagesIjpdt 8 (2) 2018 12-36wlNo ratings yet

- Genentech 2019 Oncology Trend Report Digital VersionDocument110 pagesGenentech 2019 Oncology Trend Report Digital VersiontheoNo ratings yet