Professional Documents

Culture Documents

Aprilia Shop Manual PDF

Aprilia Shop Manual PDF

Uploaded by

Cao Đào Nam0 ratings0% found this document useful (0 votes)

42 views168 pagesOriginal Title

Aprilia Shop Manual.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

42 views168 pagesAprilia Shop Manual PDF

Aprilia Shop Manual PDF

Uploaded by

Cao Đào NamCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 168

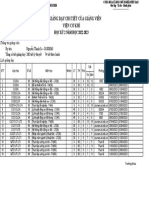

LIST OF SECTIONS

Introduetion

Baoan eaten ery

‘repair and service the vehicle in detail ”

This puicaton is intend er us by aprila dealers

and ht tained, experercod mechanic

‘The devaripons of many sarvice andres opera

tons nave been intently onstage sumed

thatthe woos ols manual nave baie mecharia

tring and basi knowledge othe prococuros Je

for etor ves epalt aswell as sfey Fes reoes

fo ensure the ally and that othe pubic wile

Fapating mato vetcies

Theta ts imerave that you o notte

pater aiy mantenanee or eae procedure wth

Sich you aro ra oughly ama sn ay aes

{Spariom, Such an ate can result n delecive

Tepats, which car be dange’eus both o you, toe

‘nme or use ofthe vent, andthe pola

sinera,

The lnoumation anita hs mara re

Qinent a of te manuals aa of seu,

She apila sp.a coninualy mpsoves is proaas,

‘hore mey become ctforoneastatweon tna veh cle

you se servicing and tho stations and netusions

‘von h big manual youhave ary questions

tout splat of ary eric recone

oes ACS)AG:S Tocmiod Counselors wiloe

‘5b 19 asi you wih any problams you magn ace

£5 wol's providing you wih lomaton or any

Update and ternal changes othe vole You 2

‘sorvcing.

‘ay changa made to tecrncal pactiations and

‘chide saving procedures wil be documented and

‘touted aprila dealers a ove the world. These

Shanes we srr ner conse Pe

prila spa. eserves height t madly spseoa

tions and characorstes of ary otis mosate at sry

_apriia makes ro representation that this manual

overs avy such changes

Fst tion: May 2001

Petco ana pinta

Varb. Alger, 37/A- 500%2 Fornacete [)

‘a s38 Oar 23600

Facea er a z801

Ernai deat

‘Spala Sa

eee

General information H

Routine maintenance

operations

Engine

Fuel system

Cooling system

[ cectiaiysen

Electrical system

Cycle parts i

CONTENTS

Chapter 1

‘SAFETY WARNINGS.

PRECAUTIONS AND GENERAL INFORRATION

REFITTING COMPONENTS

USING THE MANUAL.

POSITION OF SERIAL NUMBERS

‘SAFETY WARNINGS FOR FUEL, LUBRICANTS SOOLANT AND

OTHER COMPONENTS.

RUNNING.IN RULES

POSITION OF THE WARNING ADHESIVE LABELS

‘CALIFORNIA EVAPORATIVE EMISSION SYSTEM.

‘SPARE PARTS.

TECHNICAL DAA

RECOMMENDED LUBRICANT.

TOOLKIT

GENERAL SPECIFICATIONS FOR TORGUE WAENGH SETTINGS

ABBREVIATIONS / SYMBOLS /INTIALS

Chapter 2

ROUTINE MAINTENANCE PLAN

‘SERVICING SCHEDULE

LUBRICATION POINTS.

ABRANGEMENT OF Teie WGTRUMENTS / COMTBOLS

INSTRUMENTS AND INDICATORS

BATTERY.

SPARK PLUG

IDLE ADJUSTMENT

ADJUSTING THE THROTTLE CONTROL

‘AIR CLEANER

CHECKING THE ENGINE GIL LEVEL AND TOPPING ib

CHANGING THE ENGINE OIL AND THE ENGINE OIL FILTEa

CHECKING THE TRANSMISSION OIL LEVEL. .

CHANGING THE TRANSMISSION OIL,

DISC BRAKES.

FRONT BRAKE’

REAR BRAKE

CHECKING THE BRAKE Pad WEA

BLEEDING THE BRAKES:

COOLANT,

(CHANGING THE GOLAN.

CHECKING THE STEERING.

CHECKING THE SWINGING Aid PIVOT

INSPECTING THE FRONT SUSPENSION

INSPECTING THE REAR SUSPENSION

WheELS,

TORQUE WENCH SETTINGS TALE:

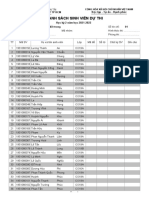

Chapter 3

ENGINE COMPONENTS THAT CAN BE REMOVED WITHOUT REMOVING THE ENGINE

REMOVING THE ENGINE FROM THE FRAME

Chapter 4

MAINTENANCE

DRAINING THE FUL TANK,

REMOVING THE FUEL PUMP

REMOVING THE FUEL LEVEL SENSOR

CARBURETOR,

2001.05

Eadae

42

42

43

4

45

Scarabeo 150

Chapter 5

DESCRIPTION, . 52

REMOVING THE RADIATOR : vn 38

REMOVING THE ELECTRIC COOLING Fad 33

REMOVING THE COOLANT 38

THERMAL SWITCH 54

REMOVING THE COOLANT THEANISTOA 55.

REMOVING THE EXPANSION TANK

THERMOSTAT VALVE.

COOLANT PUMP

Chapter 6

BuLas.

CHANGING THE FRONT AND REAR

DIRECTION INDICATOR BULBS.

CHANGING THE HEADLIGHT BULES

(CHANGING THE REAR LIGHT BULBS

(CHANGING THE DASHBOARD BULBS

CHANGING FUSES

WIRING DIAGRAW.

CHECKING THE RECHARGE SVSTEN 12

IGNITION SYSTEM

(COOLANT TEMPERATURE

GAUGE

ELECTRIC COOLING FAN

FUELLEVEL CIRCUIT

CHECKING THE AUTOMATIC CHOKE (GOLB SiAR}

SWITCHES

CARBURETOR HEATER.

CHECKING THE THERMAL SWi7GH..

(CHECKING THE PRESSURE SENSOR

STARTER CIRCUIT

TURN SIGNAL CIRCLiT

HORN clacurT

WIRING DIAGRA

BRAKING LIGHTS GIAGUT

UigHr ciRCUT

UGHT CIRCUMT ex o>

Chapter 7

ANTHTHEFT HOOK,

UNLOCKING LOCKING THE SABOLE

‘SAFETY HELMET.

REMOVING THE CENTRAL WNSBECTION COVER

REMOVING THE SADDLE

REMOVING THE GRASH HELMET CASE,

REMOVING THE PARCEL GRID SUPPORT

REMOVING THE FUEL TANK COVER (SADDLE COMPARTMENT)

REMOVING THE REAR FAIRING.

REMOVING THE REAR ARCH

GLOVE COMPARTMENT.

REMOVING THE INNER FRONT SHieiD

REMOVING THE FRONT INSPECTION COVER

REMOVING THE FRONT COVER

REMOVING THE FRONT SHIELD

REMOVING THE FOOTREST we

REMOVING THE REAR FOOTAESTS

REMOVING THE FLOOR PANEL LOWER GUARD

REMOVING THE REAR-VIEW MIRRORS

SRSRS SSRRRSRE

eloase 00 2001-05,

Scarabeo 150

REMOVING THE FRONT FAIRING. 79

REMOVING THE HEADLIGHT. 73

REMOVING THE TURN SIGNALS 743

REMOVING THE REAR LIGHT... : 714

REMOVING THE DASHBOARD PANEL . Ta

REMOVING THE HEADLIGHT SUPPORT. 745

REMOVING THE HANDLEBAR COVER 75

REMOVING THE DASHBOARD. 76

REMOVING THE LEFT HANDLEBAR 7346

ELECTRICAL CONTROLS 7348

REMOVING THE EEE HANDLEBAR... @:5i:2““HasiieSar Tar

ELECTRICAL CONTROLS. 77

REMOVING THE HANDLEBAR, 747

REMOVING THE FUEL TANK re

REMOVING THE SADDLE LOCK 720

REMOVING THE IGNITION 720

SWITCHSTEERING LOCK 720

REMOVING THE AIR BOX 721

REMOVING THE EXHAUST BIDE : 721

REMOVING THE EXHAUST PIPE SUBBORT 722

REMOVING THE CENTER STAND. 722

FENOVING THE ENGINE CONNECTING OD oo soon 7-28

REMOVING THE FRONT MUDGUARD rea

FRONT WHEEL. 728

REMOVING THE FRONT WHEEL ay

CHANGING THE BEARINGS 728

REFITTING THE FRONT WHEEL oo 730

REAR WHEEL ts 731

REMOVING THE REAR WHEEL. 732

FRONT BRAKE. ents 738

(CHANGING THE BRAKE PADS 735

CHECKING THE BRAKE DISC. 738

REMOVING THE BRAKE DISC. 738

REAR BRAKE 737

STEERING... ee 738

INSPECTION OF THE BEARINGS ne 7.33

FEONT FORK : ral

REMOVING THE FORK TUBES 742

DISASSEMBLING THE FORK 742

REFITTING THE FORK. 748

REAR SUSPENSION. 748

REMOVING THE REAR SUSPENSION : 749

2001.05,

General information

Beleace 09 2001.05

General information Scarabeo 150

‘SAFETY WARNINGS

‘Te ollowing precatlonary wamlags are used thoughout hs manu i dare convey the allowing message:

Sefety warning. When you tind this symbol or the vehicle on the manual, be careful othe potontial

‘isk of personal injury. Non-compliance with te Inaatons given inthe messoges preceded by this

symbol may recut in grave risks for Your and ather people's safely and for tho vehicle!

Aware

Inleates a potemal hazard which may reult in serous injury or even death

AcautION

Inaleates « potemtal hazard which may result in pesonalnjury or damage to the vehicle or other property.

NOTE Tho word NOTE"in his manual prcedes imgorant infomation o Instutlons

PRECAUTIONS AND GENERAL INFORMATION

Keep strict tothe folowing instuctions when repaing, cisassmbing or eassenbing the motorcycle

Awaroone

Never use a naked flame for any operation whatsoever.

Betore starting any servicing oF inspection Job onthe motorcycle, stop the engine, remove tho key, walt

‘ntl the engine and exhaust have cooled down ard, It possible, raise up tho motoreyete using the correct

‘equipment standing on a sold lovl floor. Be especialy careful about the parts ofthe engine and exhaust

thatare stil hot, to avoid burs.

Motoreyeto parts are not eae; donot bite, suck, chew or swallow any ofthe motorcycle parts fr any

reason whatsoover

Unless expressly stated othenise,fllow the dsacsembly steps in reverse order when reassembling

‘The overlapping of operations in references to other chapters must be Interpreted ina logical way, to avoid

{he unnoceesary removal of components

Never use the fuel as a solvent tack

nthe motoreyote

Disconnect the battery negative lod) If eloctic welding has tobe performed,

‘Aways be careful about the safety of the others when two or more people are working atthe same time.

BEFORE DISASSEMBLY

Remove alli, mud, dust and foin bodies trom the motocyce before removing ary companans

When specied, use fe servic ook specaly designed forts marcy,

DISASSEMBLY OF COMPONENTS

Never ison andor tga ruts and bts wit lors cr other snr tools bays use a proper wrench

Marthe posions of al unions and connections (hoses, wes, et) before aconnecing tm wth clearly sn

guinabie mans.

Each component most be coal markod 90 that teanbe identi or oting

(lean and wash each emtoved component wi re pret solver

aed components must be kpt together, 3s they become "matched" ator norms wear. Some paired components

‘must etherbe used togeter or bot paced.

Felense 00 2001.05

REFITTING COMPONENTS

‘Acaurion

Never use crip twice. When a circip is removed, I must be replaced with a new one. When assembiing

‘2 now circin, be careful not o stretch ts ends more than strictly necessary to pace ton the shat: Alter

installing aeircip, make sure that itis completly and firmly ingorie in ts seat.

NOTE bearings must un ely wih no sein ane neee, Replace bearings thal show any roughness when |

the inner aces turned.

Use any Origin! apria Spare Pans fo replacement.

Use ony the recommended ibreants and sealing agent

Lubricate all metal parts before refting ten

Pay parulr ation to lbsicaeintral eng parts suchas piston ngs, valves,

Uso propriotryassomoly bears whon appropiate.

‘When itoring ate and ble, start wih the lager slater or inet ones ane proseed in agonal ede

Tighten em a gradual steps belore applying the al geting torque

-Aays replace al gaskets, ctcips, snap ngs and O-ings. Replace sellocking ns I the feger torque allows the

‘ute be run ont ts matching Bo more han ore hal tur. Feplace the pis, stows andbots they are nicked,

Crack, or rei any sign of tread darage.

‘Thoroughly clean al mating surlaoes blore reassemby.

‘ply atv fim of Khium-basee rosso ool sel rime

‘ways replace ol eal Upon reasomely, app fun fln of itum-basos grease te the seaing tip of aol sea

before ta assembled overs mating sha

(Chock to make sure that each component hasbeen fied proper

‘te cayng out pals or reutine sevicng, ge ough te ro-iecheckt thoroughly beer ing the motor:

‘le or allowing its be rdcen, Take ara un a parking oto other low vat area belore returning the moter

ete to ts owner

USING THE MANUAL

HOW To CONSULT THE MANUAL

This manuals vided inte chapters. Each chaser based on a catego of man comparens

Fferto the MAIN CONTENTS" te

Uniocs expres stated otter, flow the dsassemby step in reverse order when reassembling uns

‘Tha tora "ight and taro ntended ae to cers rh and let when sing inthe noma cing poston.

CConesit he “USE AND MAINTENANCE handbook forinlematon onthe nema Use and serch ote motor

eye

| eciia | a Belongs 00__2001-05 2]

General information Scarabeo 160

POSITION OF SERIAL NUMBERS

‘Thase rumbars are que for vehicle registration

NOTE The aeration of he identi nue is

‘anofanes, punishabe wih eeminal and admit

fe canst Ir pareuar, he aleaion ofthe ame

umber wt result inmate invalgabon ofthe

waranty

VEHICLE IDENTIFICATION NUMBER (VAN)

(FRAME NUMBER)

Every vehicle produced by aprila receives vehis

leorfcstion umber (V1.8)

‘onthe steering head fhe rama

above

‘on the denis plate (B) which is cate onthe

ont porn nea the staeing head fhe ta

INFORMATION CONTAINED IN THE VEHICLE

IDENTIFICATION NUMBER

Deserpton ofthe vehicle identification number (V1

inion donseatengae ¥

Beloase 00 2101-05 cht

(CARBURETOR

ose EENORE

lente as jaan corel 250 D3)

[FUEL SUPE

Hes Tae pa

cy Tas eiy oad gacins win am acon ara

Bae ot

To GT a, TST

—

(SSRSOS.

Fen aL pare SRS AE

Sroka Tom (3a

Fest TIS a aa hk saa WH OER IATL

Whos =o osm (a

(oRARES

Fen “Se i OP (0. wi ya actin

Fear bale 022) re (OBB Nin Nurase eUAtOT

(EECA

ry Tara

Fen BsO LTC

TRE.

ripe baer

Fen TO 1

sar ODE BI

I NFUATION PRESSURE FOR SOLO RIDER.

ont oo. OaTaT Spa

[rear SOW 15027 5 pe

[ont owe OTA

ear Zeoa 22 eat Spe

(eNO

hs CI Tadao

gran ig EEF blo 126 aR

‘CONTINUED >

Release 00 2007.05

‘Searabeo 160

(SPARK PLUG

[Sandan TOK CREE=NOXOREE VE

[Se pus 06-0. en(OLE- DOTA

(eLEcTaIG eveTEN

uses B15: 734

[cena st magoat 20 i00W

[rt para ih 12: 3W

restr vow

[ues i ih c

[Dae w2V-12W

[aan

Tighsar

RECOMMENDED LUBRICANT

Engine ol (ecommondod) EX SUPERBIKE 4, SAE EW. 40,

‘Asan aterabve ote recommenced os posse 0 use bigh- qual ofs wih characters In compliance

‘wih er suporer te be A® L Se. specications,

‘Transmission oll recommended): BFC, SAE 750 - 80.

Azan atematva she rooammened o,f poste o Use igh- qual ots wth chaectersts in compianoe

‘sivorsuperor tobe AB SL# speciation

Fork ol (recommended): FA. 5W or BF. A. 20W/or ol

You'd an awh exerci charactenciesmcanparaon wih the BF. A, SW anc DF. A.20W or FORK

Wane FORK EOW, these can be mixed as indicated blow:

SAE 10W = IHF. A. SW 67% of the volume + IEF A. 20W 3994 of the volume

SAE 15W= EEF A. SW 33% f the volume + ZF A Z0W 67% of he volume

‘Bearings and other ubrication points (recommended) 2 BINOL GRASE 451

‘As an atematve fo the reconmensed produ, use high-quality grease fr roling beating, working tompraturo

tage SOc. HO (2a eae) dpi pam a0". 2° GOR. 4), igh poecon apa

‘rosin, good relstarcs to walor and Sudaton

Protection ofthe battery poles: neta grease oF vase,

‘Spray grease for chains (recommended): CHAINSPRAY.

Brake fluid (recommended): {2 FF, DOT (Conpatbe DOT 4).

“AWARWING

Use new brake id ont. Use of used or contaminated brake fli can lead to brake fllure with subse-

‘quent acelden, serious injury. or even death

Avannnic

Use only antifreeze and anicorrosive witout nite, ensuring protection at least 26°C (31°F),

Engine coolant (recommended): 32 ECOBLU - 40° 40°) or AGIP COOL.

Fale to use aperomral attvoez, rived whats walor ae colar, can lado saious damage othe

‘motrevelescaoing stom, whlch can eause engine slave, and subsequent Upeel wth serous Inury or even

lease 00 2001-05 ont | (EES

General information,

‘Scarabeo 150

TooL KIT

The look (1) socatod in its own compartment

under he sacle area.

“To gain access tthe too:

Lite sadce, see UNLOCKING / LOCKING THE

‘SADDLE,

“The toot (1) cds:

+ 844mm (02n) Aen wrench 2);

4 18mm (06ir spre plug socket wrench 2)

“a 3ockot roach hand (2:

“an 8mm (0.3) and 10mm (04) combinaton

ccketwrenen (5),

- Scombinaton Pips / sloted sexensiver (8):

+ shock asusing spanner wrench 7);

special socket wrench (8);

+ al pouch (3).

GENERAL SPECIFICATIONS FOR

TORQUE WRENCH SETTINGS

“Te stands txque wench setings for sens and

nls wits ISO me vena ar ven nthe able bol.

The rue wrench etn

strowor | wrenen | 7

or Ree) [Kae

ra wa | sa) 0

we [sin | a8

Mo ve soe) [a0

we a _[sswos) [58

ae [ase | as

we | worse) | ie

Forte spocio slings fhe unions and courage

fone moteeyele im quston, soe FASTENERS

Unless otnervse specie, tho torque wrench stings

‘aero dean, cy toads a arbien emparaise.

NOTE To avo detoming tie components, oF

{ayia aleating nthe ho screws ard bot ae

Fre screw nal te fasteners by han, Segond, ug

fection o approaches ol he apa

{erque seting wareng nthe Gageral pat ae

‘Stn, (0) ah (O-ring eo tener

‘prolt spocioseeuo, wating nthe sara oie

[NOTE whon this procedures flowed the can

‘essure exerted byte fasteners wi be union)

‘Seinbted oer to srace of ojo

cht Release 00

2001-05

val Information

ABBREVIATIONS / SYMBOLS / INITIALS

al

tp

Wax,

bor

tan

PH

ua

Noam.

NORM.

Rema

« = ees than

> greater han

: ‘qual oor ess than

> = ‘equal rarest than

: appeosinatly

= Finny

So degrees Centirade

sf 1 degrees Fatrennet

: = plus or minus

ac, = erating arent

x Drnpore

an Dmpere hour

APL Armerican Polen iatte

AT hightorsion i)

bar uot pressure (1 bar= 100 kPa}

Pet Internal state pressure

ce, 7 dec curent (de)

om cube centimeters

co trmon manos

oN Deuce ngustie Norm

de. = area ouron

rimin > Fevoutors por mine (pm)

Ho tnburntryrocatoane

1SC > lle speed contol

ig Rlogaams

gm = blogyams por meter (1 kgm

km homeo

« = tion

koa hioPasoal (1 KPa ~ 0.01 bar}

kW 1 haha

, Mere

Foloase 09 2001.05

galons

Tat eniting dose

tetera second

witoar

ties pe nour

mogaoh

Motor mahod cctane ang

1 sResesc method ectane atra

average of research ane mater octane

‘ang meved

Nesom: (1 N=

foot paunds

foot

cable ches

inches

ohm

pec

botlom dead cantar (200)

{op deas contr (TDC)

‘evottons per minute

‘agnostic check

fer soc crew

‘ted head eerew

ma)

psi down forks

vot

Wie

cht |

Routine maintenance operations Scarabeo 150

Routine maintenance

operations

ch.2 Release 00 2001.05

Routi

‘Scarabeo 150

This socion doses the routine marserance proce

gine em

Dotaleraa nd ceoeerate the engine afew times

make ure, when he trite returns tl, hat he

longine ide speed i sil cored.

‘awarnn

After you have adjusted the il, rotate the handle-

bars fll eft and fl ight

Chock o ensure that he

bys. Algo check that he ttle smoothiyand

{ly closes when released.

ch.2 Belease 00 2001-05,

‘Searabeo 150

ADJUSTING

‘THE THROTTLE CONTROL,

Read carefully MAINTENANCE,

Thi voile equipped with vo tote cbs.

‘The folowing rigematon may ero stone vote

Awannne

"the throtte sticks open, it may cause a colision

wth anothor vob

the throttle sticks, kl the engine with the engine

stop switch located on the right handlebar.

Do not attempt to restart the engine unt the

throttle has been repaired and works perfectly

Fallur to obey this warning can leadto a runeway

with seriously injuries or even death.

Wany fastener inthe trot system becomes

os, ikewise you wil lose contol ofthis ve-

fete.

Ether situation can lead to an upset o colision

with subsequent serious Injury or death

“This vehicles equipped wih a double cable thot

ne cable epons tte uote when you tao te

thot grip toward you: he cnr clases te tote

vwhon yu rota he gp away rom yous essen

{al wien you lace te tote rp tht & automat

tly etn to th ile poston

‘Ti couse eat arrangement enhances safely by

rowing fa pete closing othe tate

“AWARNNG

In the event ofa throttle sticking emergency,

tlvays kl he engine using ths engine stop

‘ule located near the tote grip on the ight

handlebor Never use this vehicle If the throttle,

ses a atemetiay ta aun oh

ian when the tvatle gp ls released

Fue to heed this waming can led to serious

celdent and subsequent injury or even death.

AcauTION

Perform these maintonance operations at one-

half ofthe spectiod interval, this veh

‘ten Used in rainy orvery dusty conatons, on

‘unpaved roads.

‘Cheek the tree cables ater the first 100 km

(00 mi) and tereater every 6,000 kn (750 Mi.

‘The play ofthe tote cable must be between 2-3

sem (0.06 - 0.12, measured athe eage oft ap

500 the itaton above.

Beleass 00 2001-05

en? (EE

Routine maintenance operations

To agustthe cable:

Place the vehicle on ho center sta, (oe PLACING

THE VEHICLE ON THE STAND}.

Pull bac the rubber bet (1),

Loosen the ck nut

Fotato the adjustr (3) so aso provide to proper

‘Searanoe

‘Mor the adusimect,ghton the lock rut (2) and

‘heck he pay agai

Replace the ter boot (1)

peat he adustmant forthe second cable

Awanunis

Exhaust gases contain carbon monoxide, which is

‘extremely poisonous inhaled.

Bo not start the engin in closed or badlyvert-

(ed rooms.

Fallure i observe this warning may cause loss of

‘consciousness o even load to death.

Aware

‘Alter you have adjusted the throttle, rotate the

‘handtebars fl left end ful ight with he enghe

atfocted by this.

‘Also check tat the trotle smoothly and uly

loses when released.

AIR CLEANER,

Fadl carefully MAINTENANCE,

“Aware

Use only tre-prot solvent or mide detergest 0

‘wash thea cloner.

Awannoe

esr rubber or ltex gloves whon servic

Ing tho alr cloaner.Fallure to observe this waning

‘ca lead fo heath problems,

Acaution

Perform these maintenance operations at one-

half ofthe spectegIntorvas, this vehicle

‘often used in rainy or very city condone, en

tinpaved roads.

Irspect hear leaner avery 6.000 km (3:70 or

"iments of ue, to engure that & hae not become

aged.

‘Tho a Gleaner must be inspect more Kequenty,

loaned # necessary aod replaced moe equa

tho vice cused on dusty or wot oad.

More roquentoearing afte a eaneis sug

fgoste, especialy your be is Used under very

Susty concen.

Evry 6.000 km (3,750 mi

Femove the cena iain, (se8 REMOVING THE

(CENTRAL FAIRING) ana crock seo ther ei.

‘or eartaminaton nthe Tower pat of te ra tue (1).

Awa

‘Scarabeo 150

ch.2 Belease 00

Routine maintenance 9}

‘Scarabeo 150

any contamination or i coming rom he ier

‘af tound lean the tbe a floes

{aoson te stew

‘Wiha the cain ube () from te clamp (3).

efor leaing, remove the alr leaner,

NOVING THE AIR CLEANER),

Witz the dain tube (1) from te lamp 3).

Ferme the pug (8

Empty te oto Some kind of eons, ard

bot nal and at trough hose (7)

‘he thermal switch (8) oe rate energizes anc

‘ches on the elaine fan (9) the coolant tempera.

{ute exceeds 95°C (202

‘nen thea a over th actor bythe an rouoes

te oslant epernie ln B80 (Y04) the eva

‘wish ume te elect ano

“The incase in volume cased byte heating ofthe ls

's compensated forint expansin tank 10). The racer

brouher te (1) comect the aaron an

iS

fn

Cooling system [Scarabeo 150

REMOVING THE RADIATOR

esd carefully COOLANT and PRECAUTIONS AND

GENERAL INFORMATION,

Dain ofthe coor compitely (sea CHANGING

‘THe COOLANT,

Femove te inne tot shied (s8e REMOVING “HE

INNER FRONT SHIELD).

Fmeve he tloer pare! ower guard (REMOVING

‘THEFLOOA PANEL LOWER GUARD)

Fmeve the octets (REMOVING THE FOOT:

Resn

Fomove the tune

{REMOVING THE TUNNEL)

Disconnect he mo elactical connectors (1) and (2)

trom he tetra sc (3

NOTE obtain new soenciversype hose camps to

replace tho ol carpe epoca cross type),

(Cathe camps (4) ana)

NOTE Aways use new clamps (f) an (5) wher

rating.

Disconnect the wo hoses (6) and (7) from the raior

Cut tha head of he hose clam

NOTE Use a now clamp (6) wren iting

scannect the brea D0 (9) om fs connect on

ncrow and remove he tre serows (10) (There

a wo lateral screws, one on each).

Lite radiator up out fs mounting pn holes.

“caution.

Proceed with care.

Do not damage the radatr fins.

Fereve the radiator (1) ina downward ection,

REMOVING THE

ELECTRIC COOLING FAN

ead carefully COOLANT and PRECAUTIONS AND

(GENERAL INFORMATION

Remove the inne ont held (668 REMOVING THE

INNER FRONT SHIELD),

Remove the foavests (REMOVING THE FOOT:

REST

Remove the tunnel (REMOVING THE TUNNEL},

Disconnect ne seca connection 1) one fan

Boloase 00 2001.05

Looeen and remove the to bots (2) (ne fom the

cer side), Keeping the ruts.

Lower the elect fan (3) of ts support.

Remove te elec lan na dowmvard oxon,

oaing rom te op 9.

NOTE win refting the fan tt tthe top pin ist

‘and hen to te suppor plate tthe bottom.

REMOVING THE COOLANT

THERMAL SWITCH

Resd carefully COOLANT and PRECAUTIONS AND

(GENERAL INFORMATION,

Postion he motorjco on be care tan

“Awannons.

‘Stop the engine and wait unl the radator cools

‘coun,

Femave the inner ont sil see REMOVING THE

INNER FRONT SHIELD),

Disconnetthe to elactcal

inal (1) 2° (2).

Avan

DO.NOT DISPOSE OF COOLANT IN THE ENVI-

RONMENT.

‘hen you unscrew and remove the thermal switch

{@)a certain amount of coolant wil come out of ts

‘mounting hoe

Puta container of approximate capacity 1 erin

postion to catch the coolant as iteomes out.

Peation an absorbent cioth atthe bottom ofthe

radiator to eateh any coolant that spills out

LUncrew and remove the thera aie (2), ang

wth he seal washer.

‘AcauTION

When reiting, apply LOCTITE © to the thermal

‘switch thread (3)

2001.05,

Cooling system ‘Scarabeo 150

REMOVING

‘THE COOLANT THERMISTOR

‘ead carfully COOLANT and PRECAUTIONS AND

(GENERAL INFORMATION.

Drain ofthe coolant completely (S00 CHANGING

THE COOLANT

Remove he comer inspection cover (se REMOVING

THE CENTRAL INSPECTION COVER)

Disconnect ne slsctren connector ()

UUnecem and remove the themisor (2

‘Thermistr tightening torque

158m (1.5 ge) (11.1 Fes

AcauTion

‘When refting, apply LOCTITE © to tho thrmstor

threads (2)

REMOVING THE EXPANSION TANK

‘Read carefully COOLANT and PRECAUTIONS AND

GENERAL INFORMATION.

Poation ie motreyete on the canter sana

Remove the inna font hil 06 REMOVING

‘THE INNER FRONT SHIELD),

“awarnine

DISPOSE OF COOLANT PROPERLY. DO NOT

DISPOSE OF ITIN THE ENVIRONMENT.

USE A SYRINGE AND TUBE TO SUCK THE FLUID

(OUT OF THE EXPANSION TANK,

When the hose (tis disconnected, the cootant

contained inthe expansion tank (2) il ru

Puta container of approximate capecty 1 it

position to catch the ud as it comes out

Place an absorbent cloth under the expansion

tank to cateh any coolant that spils out

NOTE obtain scrowctivertype tose clamps to

‘eplace the agin special screws yp.

ch. 5 Bolease 00 2001.05

Cooling system, Scarabeo 150_|

at the clam (ot.

Disconreet the hos (4) tom ts comnactor onthe

fxpangion tank, Cut the head othe clap (3).

‘isconnoct the hodo (1) om hs caret an he

‘Gicky place the container under the exparsion ark

‘Beatch he coolant

“Awannin

Coolants harmful

Keop the container ina safe plac.

KEEP OUT OF REACH OF CHILDREN

Unscrew an remove ho sore (6).

Rerrove the expansion ak 2).

‘THERMOSTAT VALVE

Frinton onthe thermestat valve, sae ENGINE

WORKSHOP MANUAL 91000 (-0), 1001 (LUISA)

snd 1002 (FE),

COOLANT PUMP.

Forinfomation on he coolant pump, see ENGINE

WORKSHOP WANUAL 91096 (-D},n°1001(LUSA)

fans n1002 (F),

Foloase 00 2£01-05 ch.5.

Electrical system [ Scarabeo 150

Electrical system

Bolaase 09 2001.05

lectrical systom

BULBS

ead carefully MAINTENANCE,

Avanwne

‘The vehicle must not be used ifthe ight ae not

functioning properly.

‘Thevehice must not be used if the heaclight is

adjusted incorrectly. This could temporarily bing

‘oncoming car, and also reduce the ier's ality

te see any obstacto along the road while riding at

ight.

Wis always advisable o reduce speed when riaing

‘during the night, such a way ato have the me

‘necessary to avold any obstacle and to adapt to

the poorer visibly that inevitably results trom

‘arineas, Failure fo observe this warning can lod

{oacolision with another objec, with consequent

tsk of serious Injury or even death

Awannnia

Fisk offre

Keop fel and other flammable substances away

{rom the lecvical components.

Before changing a bulb, tum the ignition switch

(A) tothe "2" (OFF) poston and walt a Tow min

‘es co that the bulb cools down.

‘Change the bull wearing clean gloves or using @

clean and dry cloth

Do not eave fingerprints onthe bulb, since these

‘may cause ts overheating and consequent break:

‘You touch the bulb with your bare fingers, re

‘move any fingorprints with alcohol in order to

veld any damage.

‘TAKE CARE TO AVOID DAMAGING THE ELECTRIC

CABLES,

NOTE betore changing a bul, chock th uses,

‘CHANGING FUSES),

‘CHANGING THE FRONT AND REAR

DIRECTION INDICATOR BULBS

Read carefully BULBS.

NOTE Betore changing a bulb, check th uses, (s88

‘CHANGING FUSES).

“To change the bulb

NOTE Tho fotowing intormation retest one rec

tion ineeator only, tis val ral of hem

Piaceth vehi on tha cant eand, ose PLACING

THE VEHICLE ON THE STAND),

Unsere an emove the sere (1),

lease 00 2601-05

‘Scarabeo 160

STOP

and

WAIT!

ical sys ‘Scarabeo 150

Acaumion

‘Upon reassembly tighten the serew () moderately

and with eae to aveld damaging the lens ane the

Colored sereen.

NOTE wie removing tr lens, use exra caro be

sure that you do ot oreak te kay.

Fomve tho los (2).

NOTE Upon reassemaly place ho ons cect in

Femove the colored screen (2)

NOTE Upon reassembly place the colored serean

cont nits sot

sh the Bub (i ight and eat Wt counterdook

Eract he Eb from i st

NOTE Ince the bubin the bub socket. careuly

aligning the te bub pin wit thir gues inthe

‘Cente ital a now bub ofthe same ype.

NOTE Upon reassombi tthe bul coke 5) has

fain out fs seat, replace iteorecy, ensuring that

the stint reflector ais wi the Stew hon

the body of te wn signal amp,

CHANGING THE HEADLIGHT BULBS.

Read carefully BULBS.

NOTE fefore changing abub, check he uses (see

(CHANGING FUSES)

‘he headlight contains

ne ah beara halogen bub 1) canal pon.

one pang ight bu (2) (cota lmer poston)

‘TO.GAIN ACCESS TO THE BULBS

Uso ane remove tho ere

NOTE Do rot mx screws. Upon reassamby,

take care nario invert the poston o he sew ()

ote sen (3).

Unscrew and remove the to sores (3).

move tha ame (5).

strat te reteto (8)

NOTE Upon reassory, instal rece (6)

sorry making he iaaron coats cane wih the

‘AcauTion

ctr (6), inorder to prevent

from aceldentaly ang down.

To change the bulbs:

orang, tom te conval rors pat of he vehi, and

‘operating onthe roar par of thereto (3),

Belease 00

‘Scarabeo 150

(CentRat Postion)

‘Acaurion

‘To extract the bulb electric connector, donot pall,

is electne wire.

Grasp the bulb elcrc connector (7), pul and

‘Seconeet trom the bu (+

Rotate bul sockot (8) counterclockwise ano

‘ara from terete

Femove he bu (1) tom the soa

NOTE 22 sure to maintain he same cranntion at

‘he od bu when you inal the new bub Do ty

to roe the bub, I wil go easly s propery

overtes.

Inset he new bu (1) let the eter, by aligning

‘he wo tabs (8 onthe bub wih the respecive gues

(10}in tne reflector:

Postion the bub socket (2) inthe refetor and rotate

‘locks

Connect te bu eletre connect (7)

Fepace the loca (8), 00 TO GAIN ACCESS TO

‘THE BULBS)

PARKING LIGHT BULB

(CENTRAL LOWER POSTON)

‘Acaumion

“nile removing a bulb cocket, donot pull on the

Grasp tne bu socket (1), pull and remove rom

Femove the parking ght bub (2) anc replace t with

eneentcaltae tet

NOTE Ensure that he bul is conectirseied in

the bulb socket

Inset the bu socket (11) in ts sat

pace the toca), soe TO GAIN ACOESS TO

CHANGING THE REAR LIGHT BULBS

Read caretlly (BULBS).

‘Awarnina

Do not ride this vehicle ithe tai ght and the

‘stoplight are not working propery

‘Tho stopight is parculaly important to prevent

ther vehicles from rearending you, Obviously,

{aire to comply with these instructions could

Tead to serious accident with subsequent injuries

‘or even death

NOTE Belore changing abut, check the tses, coe

(CHANGING FUSES), also check the operation ol ho

‘Stoplight suthes, 068 CHECKING THE SWITCHES)

Bolease 00 2001.05.

Electrical system

‘Scarabeo 150

Treo at conti:

he psig ight spit (1) onal exit)

“re eee pe ut ta on poste).

To Ga access To THE BULaS

Pace he wei one cert tar see PLACING

She VENGLE oN The STAN).

Unsce andremore he wo sre

omovies)

[NOTE Upon eascony, make su that holes

Seats prepay.

‘Acaunon

‘pon reassemaly, dona overghen the wo

Gower) Overtahering wil eek he one

‘To change the but:

PARKING LIGHTSTOPLIGHT BULB

{CENTRAL POSITION)

eo remove the parking lgrstopligt bub (1), push the

‘ub sight fond snd otatet countrlocse

Pultton ts seat

‘Corey intl a naw but of te same ype

NOTE censure tat he orontaon of you: ropa:

‘net bulb sre otal ote rg a. Do

rot oto fore he bub, wl easy is propery

Stetes.

Replace the lens (4, (60 TO GAIN ACCESS TO THE

BULBS)

LICENSE PLATE BULB.

(CENTRAL LOWER POSITION)

Remove the esse pat bulb (2) an replace it with

an nial but,

NOTE Ensure thatthe bub is comecy inserted its

‘Replace the lens), (s¢@ TO GAIN ACCESS TO THE

BULBS),

apriia

Electrical system, ‘Scarabeo 150

CHANGING THE DASHBOARD BULBS

ead caretlly CHANGING BULBS,

Cn the eashboud hae ar

‘he warring light, the dashboard ights andthe dock

Dbatory (CHANGING THE CLOOK BATTERY}

follows:

Femavethe headlight support (se REMOVING THE

HEADLIGHT SUPPORT),

the bulbs and battery, proceed as

Wrsing ight bulbs

Femave be bl let forthe bu that neds tbe change

oT ven 1

Liste [aan Tag geo

Fave te bu and loo th abub ote same

te

Dashboard it

Remove the bulb oir corespenng

tothe pooty lurinated part othe dastboard

Pos. Tina one

Femove the bub and replace it wth a bub ofthe

same Np.

(CHANGING THE CLOCK BATTERY

Remove the headlight support (see REMOVING 2 4

‘THE HEADLIGHT SUPPORT). Se

Fre te clock suport (ton the back othe ds a eae

board by releasing he eatch (2).

“ake out the cock and change te baton.

‘Scarabeo 150

Electrical system.

ADJUSTING THE HEADLIGHT BEAM VERTICALLY

warn

'Do not use the vehicle te lights are not ure-

tioning property.

Do nat Use the whic the healigh is adjusted

Incorrectly. This eould temporary Bnd oneaming

iz reduoe the ier’ ability to see any

ng the road wile riding 3 ight.

itis always advisable to reduce speed when ding

‘during the night, m sucha way a5 fo have tha ime

hocoseary to avald any obstacle and to adaptto

{the poorer visibly that inevitably results rom

‘arlinoss. Failure to observe this warning car

‘use you o coli with anothor objec, with

‘consequent risk of serious injury or even death,

NOTE the prosecure described hare iin com-

‘ce withthe allan candard tat exabiahos the

maximum height of te heacigt bean.

For vonies used is thor counties, you must cen

format tne eel reguations

somes)

‘To qui check he core adjustment of he bean,

Bice nie on ft pour, 10m 2 ay

‘Tu on the lw beam, ston the vehicle and make

Sure athe beam projected on he wal sgt

Ur the horzrral ts othe headlight abot 2100

ofthe total hag

‘To adjust he heslight beam vertically:

‘AcauTion

Do not force the serew beyond its limits.

‘Adjust th srow (1) wits abont box wrench (2).

Turn the scrw clockwise o adjust the beam niger

(epwaras)

‘Trmthe sorew countrlockwie o aust the beam

lowoe(downears)

Awanwna

‘Make sure thatthe vertical adjustment ofthe

‘ealight beam is coro

awannona:

Hake sure that the horizontal adjustment of he

adlight beam fs correct, (soe ADJUSTING THE

HEADLIGHT BEAN HORIZONTALLY).

Boleace 00 2001-05

Electrical system Sei

ADJUSTING THE HEADLIGHT BEAM HORIZONTALLY

AA WARMING

Do not use the vehicle the lights are not functon-

propery Bo nat ue the velco tthe headlight

Gjustod incorect. This could temporary bine

‘oncoming care, and ago redies the riders ait) >

Seo any obstacie along he oad while ring at,

Fight Ie always advitable fo reduce spoed when

Fang curing the night, n such s way auto nave the

time necessary to avoid any obstacle and to adapt

to tho poorer silly that mewtaby reulls trom

Sorkness. Failure to obervo thi warming can eaus>

outa colide with another abject with consequent

Fisk serious Injury or even death.

NOTE The terms ght" andi ao otonedto the

"ier seated on he vere nthe nema riing postion

Fig poste to alt the horzora positon bah 1 he

ight a tothe et

‘To aust the headlight beam orzontally:

“A.caUTION

‘Do not completely unscrew nor remove the serews

(0) ana

Looson he serews (1) and 2)

‘Once screws (1) anc (2) ae oso, you may agust

tho beam tothe let and ras you wis, Proceed ver)

eta as foto

‘AcauTION

Do not force the sides of headlights beyond thelr

Tits

‘To asust ine beam tothe right, apply force as

‘own in igure

Push onthe ight oof the headlight 2) and pln

‘hele ae a he head

‘To adust the beam tothe et, apply force as

shown igure 8

Push on he let side of tha heaaoh (5) and pl on

‘he ight seo! he alight).

Winer you are sailed wh he oust, hen

‘he sews snugly. Donat overightan.

AccauTiON

Tighten the screws (1) and (2) with cae.

Awarnns

ake sure thatthe horizontal adjustment ofthe

headlight beam ls correct.

Aware

‘Mako sure that the vertical adjustment ofthe

headlight beam ls correct, (eve ADJUSTING THE

HEADLIGHT BEAM VERTICALLY).

2001-05

Electrical system Scarabeo 150

CHANGING FUSES

Fac carefully MAINTENANCE.

“AWaRNING

Fisk offre. Keep fue and other flammable b=

ince nay om ns cca componente

repair faulty tases, Use ony recommended fx

AcauToN

Using uses of an improper capacity can cause

{damage to the sleotrcalsyotom ora slecrcl re,

‘onion sould result in total Gestructon of his vonicle

se wal asin yo,

Haute blow requenty tere probed ea short

‘eur or an oaroad int ocica speen an scene

‘component Ses net werk or wots regu of Fe

‘ec also star, tis necosary to chock th es

‘TO GAIN ACCESS TO THE FUSES:

Remove te front over, (6@ REMOVING THE

FRONT COVER},

Fuse ciRcuT

‘This vehicle's equipped wah tre fuses:

78 Afuse (1.

From tigation ete ogriton

oats

From the ignition switch ol igh ads a hon.

20.Atuse

From eat toto atch, vtage rgutr

To CHECK THE FUSES

Tum he ignton swich (4 in the (OFF) poston

NOTE Thea fuses are spare ure.

‘AcauTION

Extract ho fuses one by one, sucha way as 0

voi replacing them icomecty during resasembly.

Remove, oe by one, he tse aedinspect te

mart (5) tl open th use must be roplaced,

place ho blown uso withthe appropriate spars

fuse or wth anew fase having the same amperage

rang

Awantens

you replace the fuse and it blows again immed

sy, there isa serious problem with the electrical

System ofthis vehicle: Do not atempt to contnue

sing this vehicle

[NOTE check he spare fuse hole. the appre

‘a spare tases are not here, epics ther

Bolease 00 2001.05

Elgctrical system ‘Searabeo 160

WIRING DIAGRAM

olease 00 2001-05

Electrical system ‘Scarabeo 150

WIRING DIAGRAM KEY

1) Gonsratoe

2 gation cat

5) Sarer motor

7) Staring lay

8) Beato light font witch

9) Beak ight oa sue

10) tar temperatura thermistor

11) Engel pressure sensor

12) Fig crectonnseatore warring ght

18) Fusl sensor

18) ear docton nator

15) Tag

46} Rear? erection indicator

7} Flasher

8 Ignition key sch

18} Fight hghow beam soictor

20) Lathighiow beam selector

21) Complete dashooara

22) Low beam wang ight

25) Dasnboaa ights

27) Water temperature gauge

28) High beam warig lt

) Let direson ndcators warning ght

30) Hom

231) Front ight rection inscator

£2) Lowhigh bear ihe

) Fron park ight

28) Front deeconincoator

£35) Engne all pressure warning ight

236) Mulile comocors

37) Spark pig

38) Automate tener

39) Head

40) Foo everest

41) Fan

42) CDloonrolunt

45) Thermo suten

48) Pokup

45) Usonse plate ight

48) Thermometic sch STARTER,

anere

‘WIRE COLORS

Br orange

Be ght oe

Bue

Bi white

@yelow

Gr gay

Moun

N Bloc

Ro res

v reen

ve bute

Fo pik

Belease 00 2001

Electrical system,

(CHECKING THE RECHARGE SYSTEM

Retr tothe folowing hey when consuting

ten estos

fe Lpetbiue

& bus

i

Bron

is

4B

(CHECKING THE RECHARGE VOLTAGE

‘check ne electron tovel(see CHECKING THE

(heck he battery volteg (00 F

BATTERY).

Psion ho motoryce on the center stand

‘State engine are tke 19 2000 rpm (hota

ental ened appreciate rene),

Sich tho ight woh fo ">" polvon ar

falecorto te “poston.

Using a ponabe tester chock the contruous votage

bench ata pone (9) endneate

Ihe tata reasng i ss than 19 V or greater han

15%,

Chak the funeson an contrty of the aerator

‘without ted, (CHECKING THE ALTERNATOR WITH

‘OUTLOAD) aed (CHECKING THE ALTERNATOR

CONTINUITY) and he votage regulator (908 VOLT:

GE REGULATOR}

Key to second figure

1) otage ragdater

2) atiery

5} lion switen

ruse

‘Standard charge voltage: 181015 a.) ot 3000

pm.

HARGING THE

ight

(CHECKING THE ALTERNATOR

\WiTHOUT LOAD

Remove te ton tik

Datanneet the regis wre connect: (1).

‘Stath engine ae take 10 S000 rpm (ote

onal umed spproxatay 16 of ange)

Fost the maforeyele on te conte ta,

Using a portable tse, et he vtoge

‘nt 0) betwoan nets yllon wires (,

The tstrreaing i oss than 4S V the aerator is

oletve

‘Standard voltage without load: greater than 5 V

{ae} a¢3000 rpm,

lease 00 2001.05

‘Scarabeo 160

Electrical system ‘Scarabeo 150

(CHECKING THE ALTERNATOR CONTINUITY .

‘wnt the engine of:

Remove the rot shies

Discennec the regu: wires connector (1).

Using & prio tester, ost the contnuy between the

yolw vires (6) of th star.

‘iso, chook ne soon a the stator surge

‘Standard resiatance: 01-10

‘Slandardreslstance between wires and sta

‘supports Git

VOLTAGE REGULATOR

Remve the toot shi.

Disconnect the connector (2,

‘Unscraw ad remove the screws (2) and dsconrset

the terminal of wire () and ie (5)

Acaumon,

nen reassembling, reconnect bth wires) ane (6)

{Using vai tio fraieE0) fat ea e

Fegulto ia) tha reicance betwen the wires

Indes inte tabla ben

Ih restance reosing is incorrect, change the

regulator.

Taso postive emainal

e[a[e[ale lav

ite [-[-[-[- =

Elwl-[-|-|-|l=

NOTE This inssecton method onl apraxia

possible, subsite avokage repute st you

ow won, lo check the caging cu

ch.6 Release 00 2007.05

‘Scarabeo 150

IGNITION SYSTEM

WIRING blaGRaM

1) Baty

2) CDI. contotunt

3) Pickup

4) Heat

5) To susan services

8) Sparkpiug cap

2). Votage regulator

‘erator

Spake pig

£0) Igrton swe

5) Stopistant

12) Engine stop switch

13) To cabureoe heater system

CHECKING THE HT CoML

Remove tel sdeinspacton cover (s88 REMOV:

ING THE LEFT INSPECTION COVER),

Disconnect the termina ().

Disconneat the spark ug cao rom the lead.

Take readings (A) and (B) shown in the igure, using a

potable ester.

2101.05

trical system

Koy to figure

Ay Measurement 1

Bi), Measurement 2

12) Tabs

13) Bosstance te

18) Black HT eas

15) How

Standard readings:

Moasutomen 1705 +25

Measurement 2! 135k # 20%

‘Scarabeo 150

“AccauTion

‘The measurement method ie only sppraximat. It

you gan, sett co that you know abe

Boo.

CHECKING THE PICK-UP

With the engine of:

Discennoe he eaecr (1) and ke the reatras

{on the picup wies tein.

ting prtabi asta (scale 1000), measur the

reetance betwoen the Buniyatow (8G) wie ard

(qeennite (OB) wire terminals,

Standard reacing: 2400

DBasconnoet tno connor

(sing ster test he roitane beswoen the te

allo he ahoel side ard the engine ack:

Standard reading: 00

ithe resstance reaig isin or less than the

Salo value, the pick mse be replacs

(CHECKING THE ¢.04, CONTROL UNIT

Remove the rot she

Disconnect the elects connector () from tha 6.

‘ont ut

Connect the postive {+} and ragatve ()teminas of

{ porabo tester to al eternal oo the C.D

‘onto a (3), checking the contuly and messing

the resistance,

the contruty an rxstance exdgs correspcns to

‘he values shown In fhe table bec, be O.Di- carol

unt is probaby goca

“eet be raitance Between he terminal, a ehwwn,

oh. 6. Biolease 00 2001-05

trical system ‘Scarabeo 150

‘Acaumion Foe a

{As there are diodes, condensers and other eloc-

‘tonic components inside the C.D. control unt,

‘the mesturement method deeeribed here ie only

approximate

inorder to make a more detiniive check, either

replace the contol unit with ne that you are sure

Is good, or cary out the chocks described In

‘CHECKING THE ELECTRICAL SYSTEM FROM THE |

DL. CONTROL UNIT CONNECTOR.

(CHECKING THE ELECTRICAL SYSTEM FROM THE

‘EDI. CONTHOL UNIT CONNECTOR

Remove the front hits

Disconsc the electrical connector (1) from te C.D

‘onto unt

Using 2 prado tester on the etecical connector (1),

‘ake the reacigscescibed nthe abe,

2). Pelcup ornina (yellowioray wie (G1). 2 3 4

'3) 7.5 us torminal (roteacx wie (FIN),

4) HT coltrminal(whelpurple wre iN). 1

5} Ground terminal (ive wie (3)

1) Fie! round trial esneitack we (GN),

1) Pic-upterminal(ellwbive wire (6)

7 6 ‘s

‘pilion aed Tending out of ange

ee scone pee ator | "heer folowing

eben ardbteyaw BS 3S ine ta)_| 08 aap wing

isa (8) an erga end @ ainsio [oot a

elbwtiad (GR ang erga pang o eines | 0-1 ag

[nieve Gi) ad eine ge e ormeiay | 0-2 col wi

shee (BU) ard eae one) &. ns (0) | iy wig

{col pian scone)

ae TA a aT we | eT wae

(exotieom somata, ses

avin (GPG) and aie end o ‘se a_| iy Poo

Ite values ae cooet anda malluneion esos, thonthe C.D. convo uni is dtiay deocive and must be

replace.

(7 This readeg must show the bat votage

Bolease 00 2601-05 s ||

Electrical system, _ ‘Scarabeo 150

COOLANT TEMPERATURE

GAUGE

‘wrina biacRam

Wiring tagram key

41) Coolant temperature gauge

2) Termistor

5) dattery

2) etn sites

5} votagerequitor

5) tolgiion

Remove the rear ang athe a box

Disconnect ominal (7) (whee wre (8) am

the thor,

CConnot a 25 W rsstor (to ermal (7)

“urn theigiton etch fo posson ">:

‘Chock tat the point (8) goes fo the start of the rod

one (Max’} wn a oleranoe or 5

ch. 6 Bolease 00 2001-05

trical system, ‘Scarabeo 150

CHECKING THE CONDITION OF THE

‘THERMISTOR

Frrave the thrmister (1), (600 REMOVING THE

COOLANT THEAMISTOR}.

De inatrated nthe Hour, Sonnac a pocket ester 2)

(Getto chmmater meas) othe thermo (1),

Inmeree the hermstor oa recoptace (9 containing

Imgrse a thomameto (4) wih a range of 0°10

‘80°C a" to 902") the same receptacle

Postion te rosepace over a burner (3 an Slowly

Feat bqus

Check ho Tomperature reading on the thermometer

fa the thomistrresing onthe teste

‘heck tat ho themistor responds fo the temperate

Ss Shown balan

‘Coolant temperature | _ Standard values

scr) Tay

50" (122 = 226260

15230") 26810

the values do not change, or Hf tey fe too

‘uch irom those Inthe table, replace the there

mstor with a new one

2001-05 ch. 6

Electrical syst

‘Scarabeo 150

ELECTRIC COOLING FAN

PS eum

‘WIRING DIAGRAM

Wiring eagram key

1) Beet fan

2) Thermal swach

5) battery

9) Main tuse

5) to votage requir

8) toigniton swics

‘CHECKING THE CONDITION OF THE

ELECTRIC FAN

To check the werking state othe fan (1), precoed as

‘oto:

Femeve the oe pane

Disconnect wo aleticl terminal (9) are (4) am

‘ha thermal switch (2) and connec: them upiogober.

Ite lan doesnt rn

Chock thatthe connacor (8) i lugged in propor.

“Tune tan marwaly and choc ta he bids 0

rottouch the suppor,

Ite fan rotates rea

Chock th recharging systom (se CHECKING THE

RECHARGE SYSTEK andthe maintuse (coe

‘CHANGING FUSES),

ch

Electrical system Scarabeo 150

CHECKING THE CONDITION OF THE

‘THERMAL SWITCH

Remove the tear pane

Ferave the tharal sth (1) (600 REMOVING THE

‘COOLANT THERMAL SWITCH)

‘As iustatedin be Ture, connect a portable ester

£2) (cto shmmotr mos) tothe ermal seth (1),

Irmors the thermal swish in ecepace (3) con

taining coolant.

Inmere atermemotr (4) wih a range of 0 to

130-6 (2 fo 02°F) inte sae receptacle,

Poston he rooptade over a bumer (8) ard souly

feat the qu.

Choa thal he tomporaturacoang on th thermo

‘ran the tharmal stich rea onto testa

arespont he data inte abe

‘Standard values

ret

toes than 96° (194°)

aie than 100" (22

the values die om those shown a he abo,

change the tema Soh

FUELLEVEL CIRCUIT

‘Win DIAGRAM

ot A ge it sv

]

Jace

¥

‘ 7

1) Foal level nator

Foal oel sensor

Battery

) ignition owen

Fuel recorve warring ft (yellow amber coor

to volage regulator

"onion ston

Beloase 00 2001.05.

FUELLEVEL INDICATOR

roar feig.

Disconnect the way connector (8) rom the ul

senea()

checking the pot

Connect 10 resistor othe gray/groen (GV) and

ue () wes of connector (8) (ig ice).

‘Chock tat he pointer (8) goes to, wy a tokrance

ons.

Fepeat the operation using @ 902 resistor and chock

that ne potas () goes 2 (2c) wih a leraroe of

25

(Checking the fuel reserve waring ight

Make a det conecion (eistance 0) betwean

‘he erangetlack (APN) ar bus (8) wires on conse

(8) (wring side); cack ha th ua reserve ware

ing igh ighs up.

‘ring etagram key

8) Sway comnoctr

8) Poiner

4) Ful reserve warring ight

11) Fosllevel nator

ch.6.

Scarabeo:

Boloase 00

2905-05

m= Ss

‘wi Sere ‘reading

apse] ga) ae

| wa |e

saroeeae aT — coe

al

FUEL LEVEL SENSOR

‘Checking the condition

move ne rear aig.

Disconnect tne 3tay connecter (1) onthe fuel level

sensor

Using 2 portable tester (3) (eto ohmster mode) on

the connect (1) (eansor ee:

‘Connect up the graygreen (GV) are bio (8) wires

and check that the readings match te tale vats in

the wo sensor postion (ert! and upide down

CConnact up the orangatak (WN) arabe () wes

land oheck hate readings match the tale vats In

the wo sensor postions (erica! and upside-down

Been wires] Sencor postion

sevgeen S| verroa, | ania 00a

oa :

cergee i] ursmccom | 41008

Soni)

wamgebie RT| aaron

Maceo) RTCA. oe

cpeec| ursocoom | =a

CHECKING THE AUTOMATIC CHOKE

(COLD START)

Remove the airbox

Disconnect the cortaspondingelctical cnnoctr.

Remove the automatic choke (2) rom the carburet:

{see DISASSEMBLING THE CARBURETOR).

‘Wil unl he choke gets to ambien! iemperatire (10°

to 25°00"t0 777)

Power up he choke with 12.V do

‘or thee mites, check hat the pointe (2) has

snowed Tovar at eae 9 en (0.1

‘Checking the circuit

“This tastcan be dono in two ways ihr:

‘th me engine of using a special mutstr

wih tn engine king (1600 ep), checking that there

i voltage athe terminals of connector () (rout

$id) (tne cet working propery 2 {0 W bub

shou ght)

_on.6 EE

2 00

lectrical syst

‘SWITCHES,

Using a portale stor, chack te continuity of te

‘Siches and eter tothe spot able or each

SWE Replace te swtch is aut.

1) HORN BUTTON.)

nae

ae

~ | oo

2) HIGHILOW BEAM SELECTOR (=)

EN [en [wn | or]

#5} O-[-O

oe OFS

2) DIRECTION INDICATOR SWITCH (<.)

6) 1GNITION BUTTON

Tew | Ree

3

oto

7 IGNITION SWITCH

eae |]

EGE) on. Roloaso00___2001.05

6) BRAKE LIGHT FRONT SWITCH

Beer | viG

on | OO

9) BRAKE LIGHT REAR SWITCH

Tw Rar | vie

on | O--0

‘CARBURETOR HEATER

WIRING DIAGRAM

Wiring diagram key

4) tigation creut

2) asta creat

53) Thermal sich

Heater

3) Batery

6) anion swecn

CHECKING THE HEATER

Using a tstrin ommeter mod

resistance ate termina’.

Correct

ue: Sto 180 at 25°C (7F)

Belease 00

ch.6

arabe

Electrical system ‘Scarabeo 150

(CHECKING THE THERMAL SWITCH

Using a tester in ohrmeter mode, tat the oon ty

oft thermal switch acevo tomperatces,

Less than 3:0 (87.4) Creator than 16° (60°F)

comes vse 02

(CHECKING THE PRESSURE SENSOR

‘Tocheck the concn of he sensor, proceed a

folows:

Take of the ser cover (1)

Clsconnect he slcrca terminal rom the senso: 2).

Using aster (cala x 1000), check ha cranuiy

‘etwaen the tab trial (3) andthe sensor bod.

‘Correct value with engine off: 002

Correct value with engine running: ©

ite reatings donot corespond to the tated values,

‘heok the engine level an replace the sensor with

‘Sew oe, Icessary.

Belease 00 2001.05

Electrical system,

STARTER CIRCUIT

Location of components (s8e LOCATION OF COM:

PONENTS}

wing eageam hoy

2 Set mat

3) Sener

5), Bras ight ron swicn

10) Brae ig roar ston

18) lon anton

15) rao igh

38) StnerButon

portant:

For safety reasons, the engine wil start with the

"button only when one of the two brake levers

's pulled

‘TROUBLESHOOTING

|. STARTER MOTOR DOESN'T TURN

(Oheck the battery (CHECKING THE BATTERY),

Check the 7.9 use

(Check the starter tor wring connsctons

(heck the starter ay (CHECKING THE STARTER

RELAY).

(Check te stanor buton "(CHECKING THE

STARTER BUTTON,

{Check he brake ght atch (CHECKING THE

BRAKE LIGHT SWITCHES),

3 pelea co 200108 crs ||

Electrical syst

‘Scarabeo 150

1. STARTER MOTOR TURNS BUT ENGINE

DOESN'T TURN OVER,

Check he starter mato, the sorag ech and the

spragctch goat

(C.STARTER MOTOR TURNS BY ITSELF, WITHOUT

PRESSING THE BUTTON

(Chock tho starter mote wring conection.

(Chock ho stator olay (CHECKING THE STARTER,

RELAY}.

INSPECTION DATA

(CHECKING THE STARTER RELAY

‘isco al the wires rom hor (1)

Using str in omer mod, est be contnty

botwoon te power trmina (MS sroH),

Coste value nin

Power up the power contacts connector witha 12V

bate.

‘sing tester in otmmetr mage, test the continaty

batween the power trminas. Cored vaio: 0.

(CHECKING THE STARTER MOTOR

Disconnect the spark lug exp, seh te ignition

‘ute fo ON and start up math he ammeter conrectod

tothe saner motor era.

Normal values 8 A 15 at anning speed

‘Using astern obmmetr mado, est be resistance

between the pocibve and negative ternal of re

Sater moto: Normal valu 0.210%.

(CHECKING THE STARTER BUTTON

‘connect he burton coat.

Using a eso in ometor moc, tst the contr

‘twton the contacts nthe preseod an ost ps

tions by testing the connactions (MAIN HIRING.

DIAGRAM

coi |e oease 00 2004.05

Scarabeo 160

TURN SIGNAL CIRCUIT

Locson of conponenss08 LOCATION OF CO

PONENTS)

vnc DIAGRAM

; A

eae az

R

2 I

% BH @@ WW

ai] 4] aq) 2a) w6

e's a".

ostve VR | [BN 3 =

eyconotee

14) Fight eartu signa

40) Leltreartum signa

18) Turn sgnal elector

22) Paver

24) Loft tam signa warring ight

50) Right wn ional warning bt

831) Fron aight wm signal

2) Frontiot um signal

TROUBLESHOOTING

A.InbIcaToRs DON'T WORK

Chock the buts

(Chock th um sina wing connections

(Check the un signal selector

‘Check the genera power supply excl

Fopiaos th fash

'. INDICATORS STAY LIT PERMANENTLY WITH:

OUT FLASHING.

(Oneck the bub specfeatons.

(Chock th eattry (CHECKING THE BATTERY),

piace the facet.

Ficlease 00 201-05

(eee

Electrical system ‘Scarabeo 150

‘CHECKING THE TURN SIGNAL SELECTOR

Disconnect te elector connector

Using ats in mater modo, test the conti

between tne rs inne erent postions by testing

tho conracions (ace MAIN WIRING WIRING DI

GRAM

HORN CIRCUIT

Location of components (668 LOCATION OF COM:

PONENTS),

WIRING OVAGRAM

Positive key-controlled

35) Hom

40) Hom bution

‘TECHNICAL DATA

Hom rv 06.

EE) cn lease 0 2001-05 B

Electrical syst

‘TROUBLESHOOTING

[A DOESNT SOUND, OR SOUNDS BADLY

(Chock the batery (CHECKING THE BATTERY,

(Check the Pom wtng connections.

(Check the rem Button (CHECKING THE HORN

euTTON),

(Chock the hom (CHECKING THE HORN,

'8. SouNDS conTINUOUSLY

(Check the hom wtngcomectins.

(Chock tha rom Button (CHECKING THE HORN

BUTTON),

IsPECTION DATA

CHECKING THE HORN

Disconnect the hom ang ten pomar't eat tom a

12 Vater. Replace Ft coose sour.

‘Aust the hor adusterifthe hom nes unsaistac.

‘ony.

(CHECKING THE HORN BUTTON

Disconnect tne buton connector.

Using atestrin ammeter mode, est fhe contnty

botwoon the contacts nthe pressed ard rot pos:

‘ions y ening the comnacions (WAIN WIRING

DIAGRAM)

ES Belgase 00 2001-05

ch.6

cot

Electrical syster ‘Scarabeo 150

BRAKING LIGHTS CIRCUIT

Lacan of components (ose LOCATION OF Cont

PONENTS),

WIRING DIAGRAM

; GI, start button

Swen rap

9) Brake ight ron mitch

10) Brake ight roar evs

15) Talght BRAKE taht

TROUBLESHOOTING

|. BRAKE LIGHT STAYS LIT CONTINUOUSLY

‘Check hott connacons.

(hecho brake lght for sich (CHECKING THE

BRAKE LIGHT FRONT AND REAR SWITCH).

(Check he rake ght rear such (CHECKING THE

BRAKE LIGHT FRONT AND REAR SWITCH.

B. BRAKE LIGHT DOESNT SWITCH ON

‘Choc ho bulb sn bul olde

Cec he brake arcu wng connecons.

(heck the general powor supply crea

‘Check he rake ton font awe (CHECKING 7

BRAKE LIGHT FRONT AND REAR SWITCH).

‘Check he brake gt rear swich (CHECKING TH

BRAKE LIGHT FRONT AND REAR SWITCH.

EEQG|! cnc _ Release 00 2001.05,

Electrical system Scarabeo 150

INSPECTION DATA

(CHECKING THE BRAKE LIGHT

FRONT AND REAR SWITCH

Cisconnact he etch wire:

(Operate the brako an test the esstance between

the 2 sich emia, using tester ia ohmometer

Normal valve with brake engages: 02.

ermal al wth Sree not engeped: infin.

UGHT CIRCUIT

Location of components (S86 LOCATION OF COM.

PONENTS),

WIRING DIAGRAM

tgnition switen Aen g54,

1) Roar paring ight

2) Fight highiow Beam slot:

5} Dastooata ight

‘3 Lowbeam warming Hohe

Fron parking ight

6} Lowthigh boar ight

7) Uetthigiow bear selector

{3} High beam wari ght

9} Loanse plate ght

00 2001.05, ch. 6

trical system

UGHT CIRCUIT m «>

Lecation of components (S88 LOCATION OF COM

PONENTS)

WIRING DIAGRAM

tonion swe <2 2 Y

L

1) Roe patting ight

3) Dashboard ight

3) Low beam warning ght

5) Fron parking ight,

8) Cough oa gre

7) Lettnhow boa selector

8) High beam warning lake

9) Ueense late ight

‘TROUBLESHOOTING

‘A.A BULB DOESN'T WORK

Check the bu,

‘Chock for votage on the bul ler terminals

(Check the wring connections,

NONE OF THE LIGHTS WORK.

(Chock the Rit highow beam selectors EU" orion

‘Chock the 15 A use.

©. BULBS BURN OUT FREQUENTLY

(Chock for excessive vibration om heights an check

that rone of me lghs are wuching against partso!

the motorayce without fenble causing.

(Chock the wing connections.

(Chock the votageragator {CHECKING THE VOLT

[AGE REGULATOR.

Beieass 00 2001-05,

Electrical system Scarabeo 150

NOTE

2201.05 che |

Ghassi

‘Searabeo 150

Chassis

can ch.7 Release 00 2001-05,

‘Scarabeo 150

Acaution

‘any of the bodywork components of his ve-

‘eles employ tangs and slot, as well astreaded

{fasteners to retain them inploce

Upon reassembly of any ofthese components,

censure thatthe tangs ft coreetly inte the appro

rate slots.

‘Aso, upon |

‘moderately.

Be caretul not to ovetightn the screws. you do,

‘the component you sre alsching, as wel as the

surrounding plas and painted components, wi

be lroparably damaged,

sscombly, tighton tho ser

weonly

ANTL-THEFT HOOK

‘The anfthet hook (1) is postions on the et seo

the vehicle, near ho passenger foots.

To prvent ih vehi rom bang stolen, te adie

abl to secure i wit the apriia "ody Guard ar

noted cab (2

Do not use the hook to it the vehicle or for any,

purpose other than securing the vehicle onco

has been parked.

UNLOCKING / LOCKING THE SADDLE,

OPERATION

‘To unlock the sade, proceed as follows:

Page the vehi on tha centr sand, (se PLACING

“THE VEHICLE ON THE STAND),

Pace the ignition Key (5) the Ignition swichstering

NOTE Tum the kay (8) without pressing it

“Tame key (2) courtrlotnise (etwas) unl you

aa the snap hatinseats thatthe cade lek

spe

“Tm ine key (9) back poston“

Lite sca (4), (se8 UNLOCKINGILOGKING THE

ADDI

[NOTE insrut yeu customers that betors towering

‘docking the ead (6 hey should make sure Nat

thoy have Rot the grit key under he sade

Tock the sade:

Lower ara press wthoutexoring too much pes:

sure), us making te sade lock snap shut

‘AcauTon

‘The vohiole should never be left unattended with-

‘oul the saddle being propery locked,

Bslease 00 201-05

Chassis ‘Scarabeo 150

SAFETY HELMET

‘Thanks othe soley hemel cas, you ne longer nave

{bear the crash halmet er ote ject wit you

‘very bine you park the vehi

“To reach the safety helmet case:

Pace the case toy (}in he safely holmt case ock

Tum ine case kay (9) courterlochuse etwas)

Le ook unk (8)

Lita epen the case cove (7).

[NOTE The case can cortin one safety het:

Two case keys ao supplied ogater wih fo etide

(one spare kay

NOTE rst our customer not keep he spe

case ay wih hi veto,

“A warnon

“Te safety hlmet case must never bo overosded.

NOTE Batre lenng ard ncing to ae coer

Dir aye kt cae

NOTE Wnon you nave loca he cas ovr, rove

‘recs oy) rom haste helmet ak

‘A.cauTion

Do not eave this vehicle unattended without ensur-

ing hatte eas cover (7) 1s property locked.

Never earry any bags ot parcels fo the safety helmet

‘iso, a this may seriously compromise the

‘ranseuvrobty an the stay of te vehicle,

REMOVING THE CENTRAL

INSPECTION COVER

ead carefully MAINTENANCE,

‘a wanton

Before carving out the following operations, et

‘the engine and the exhaust silencer cool dows

‘unt they each room temperature.

Failure to observe this warning mn ted to ser

Place the vehlle onthe centr stand, (ee PLACING

‘THE VEHICLE ON THE STAND),

nec ae remove tho sere (1),

‘AcauTion

Proceed with cre.

Do not damage the tangs andr tho slots in wich

they tt

Handle the plastic and painted components with

care and avotd seraping or damaging therm.

Remove the coral inspecton over 2).

“A.cauTION

Upon reassembly fit the tangs correctly inthe

appropriate sots.

Upon reassembly tghton tho serows only mad

sly. Be careful not fo overtighion the screw

{his will darnage the surounding plastic and

painted components,

ch.7. Release 00 2001

REMOVING THE SADDLE

ead earetlly MAINTENANCE.

Awannna.

Before carrying out the folowing operations,

let the engine and the exhaust silencer cool down

‘ntl they reach room temperature

Fallure fo observe thie waning can leadtogeri-

us bur,

Ferovete corral inspection cover, (sa@ FEMOV.

ING THE CENTHAL INSPECTION COVER,

Lite saci, (se8 UNLOCAINGILOGKING THE

SADDLE}.

Unsrow and romeave the seoms (1)

‘AccauTion

Provood with ont.

Do not damage the tangs andlor tho slots in which

they ft

Acauion

andthe plate and painted components wih

caret aveld seraping or damaging them.

Pulte rear pans gery outward (Pes) (tt ard

fh) ofthe contra fain (2.

Ferove he cota fang (2) by witharawing it

‘onward (Pes. 6).

‘Acaurion

Upon esssembly, it the tange correctly nthe

appropiate sits

Upon reassembly, tighton tho serows only moder-

ally, Be careful not to overtighin the scrom,

{his wil damage the surrounding plastic and

Panted componente,

olease 00 2001.05 ch.7

Chassi Scarabeo 150

REMOVING THE SAFETY HELMET CASE

Fed caretully MAINTENANCE.

Poe the vec on the centr stand (ese PLACING.

‘THE VEHICLE ON THE STAND),

Spon he saety name caze (1), (ene SAFETY

HELMED,

Take the holmet anor any oter object out ofthe

case (1,

‘Accaumion

‘Unscrew and remove only the three nuts (2) and

the tree serous (3) (nse the eras hole caso),

Do not unserew any of the nuts and screws that

‘the pare! grid to the vehicle.

Hold the three ruts (2), unscrew ad remove thettree

serows (3)

‘Screw (tightening torque: 12m (12 kgm).

etive the tes nals (2) and widow the thes

spacer (4).

Ge the safety hesmet cas (1), rae and emavel

NOTE Tha nn rt spare (6) mt be wether

from the parcel grid (6 by pling thom unwards wile

the rear spacer (7) must be waherawn by paling

dwar,

Withdraw the wo front spacers (5 ard retive the

washers (6),

Withdraw the rear seace

Maximum alowed weight: 3g (661 Ib).

‘Maximum allowed weight on the parcel grid (8):

9g (18.84 be)

[NOTE Store the remaves components together

‘a safety helmet case (1)

the tres nuts

thothwoe Sees (2):

thestvee spacers

‘eo Wont spac

“ne ear sce (7)

Inctéor be able to reassemble ham oowoety

than yu rental the safety helmet case

and washer

ch.7 Beloase 00 2004.05

Chassi ‘Scarabeo 150

REMOVING THE PARCEL GRID SUPPORT

ead caretlly PRECAUTIONS ANO GENERAL

INFORMATION.

alee up th ead (UNLOCKINGILOCKING THE

SADOLE}

Remove the safety helmet case (REMOVING THE

SAFETY HELMET CASE}.

Loosen andremave he 6 screws (

“Tightening torque fr serows (1):

27 New 2.7 kgm) [19.9 Fes)

“Take out te bushings rom tne parce gid support

Remove the complete parcel gd suppor (2).

REMOVING THE FUEL TANK COVER

(SADDLE COMPARTMENT)

Bead carey PRECAUTIONS AND GENERAL

iirontaTiOn

Fomave te seco! suppon rid (REMOVING THE

FARBEL SoPROnr Ghig)

‘Remove the ead compartmart (REMOVING THE

EABOLE COMPARTMENT)

Ferove the sat eck (REMOVING THE SADDLE

Bex

Fmove the ar cloner (REMOVING THE AR

LEANER

{eaten an remove he 9 crows 1} ht secur the

rearing

{acre a remove the screws (3 anakeep the

washers

‘itr the parol eather tbe ().

caution

Proceed with ca

Do not damage the tbs andlor corresponding tab

‘lots

Handle painted parts carefully, without seraping or

Gomaging them

Withdraw the complete sade compartment (5)

2001.05

Chassis Scarabeo 150

REMOVING THE REAR FAIRING

Fead carefully PRECAUTIONS AND GENERAL

INFORMATION.

Remove te sade compartment (REMOVING THE

SADDLE COMPARYMENT)

Disconnect he sacral coanecions (1),

Remove the Scense pate Roker ard ine lense ate.

Loosen and remove the screws (2)

rome back

Acaurion

Proceed wih cre.

Do not damage the tabs andlor corresponding tab

Handle painted parts carefully without serapag or

damaging them,

Femove the compet ear ating (4) (long wit the

aig rom me back

REMOVING THE REAR ARCH

‘Read carefully PRECAUTIONS AND GENERAL

INFORMATION.

Remove thera aking (REMOVING THE REAF

FAIRING),

osen and remove the 2 screws (1).

Flemove the compet rear arch 2 fom being

GLOVE COMPARTMENT

1s poston st hana one inept

Saeiner sh

Sorc

Facts ny). nae cena

rea ay Soca Wa pao

aoe

caution

Before eking he oo) ake sr tha youve

sori lg Seta cSapioene

‘olock the door)" >

NOTE Ws retecnsayo ta a tart

Nona ty

sin sowed wight 3.21 (15k

EG! cz - Release 09

Chassi

Scarabeo 150

REMOVING

THE INNER FRONT SHIELD

ead carefully PRECAUTIONS AND GENERAL

INFORMATION.

Postion the motorcyce onthe canter stare

NOTE These instractons must be eared tor

th sides ofthe motoreyee

Remove th fectret rat (1),

(Open the glove comparmar: door (GLOVE COM.

PARTMENT),

Unsere and move he wo Bag-hook screws (2)

Femowe the bg book (3).

LUnerew and remove the sew

Uncrew and remove he &eeoms (8),

“caution

Proceed with ear,

Do not damage the tabs andor corresponding tb

sot

damaging them. ‘

witha ara move the inne ont hil, rotating

owas the sade,

REMOVING

THE FRONT INSPECTION COVER,

ead caretlly MAINTENANCE.

(Open the glove companmer,(@ GLOVE COM.

PARTMENT)

LUncetew ar move the sew (1)

Remove te ont inspection cover (2.

AcauTion

Upon reascambly fithe tangs correctly inthe

appropriate slots.

Upon reassembly tighten the screws only moder

ely, Be careful nat to ovetghten the screws,

{his wil damage the surrounding plastic and

painted companents,

201.05 ch.7 |

‘Scarabeo 150

REMOVING THE FRONT COVER

esd carefully MAINTENANCE.

Pace the voici on ths centr stand, see PLACING.

‘THE VEHICLE ON THE STAND},

Unseron and remove the seen (1).

Acaunon

Proceed with cre. Do not damage the tangs and!

forthe slots in wich they th

andl the plastic and painted compone

{aro and avoid scraping or damaging them.

Remove th ont cove (2) by puling it dowewards

wth

Acaution

Upon reessembly the tangs correctly in the

appropriate slots

‘Upon reassombly tighten the serows only medi

ely. Be earful not to overtighton the sors,

this wil damage the surounding plastic and

painted components

REMOVING THE FRONT SHIELD

ead carefully PRECAUTIONS AND GENERAL

INFORMATION.

Poston te motoryceon the cere stand

Femove the rnt cover (see REMOVING THE

FRONT COVER}

Remove the front rudquae (REMOVING THE

FRONT MUDGUARO).

LUnsrew anc remove he 4 crews (i

‘AcauTin

Proceed with care

Do net damage the tabs andor corresponding tab

ste

Handle painted part carefully, without scraping oF

«damaging them

LUnscew ane remove the 6 serews (2 that hte

Inner ont shld othe aut fon ad

| ra |

Chassis

‘Searabeo 150

tat the hor (2) on ts mauning bot so that oes

not scrape again! he shield when he shea is bong

removes,

Femove the use holder (2),

Unsren and remove the screw (5).

Remove he (8).

Pal the outer sie (7) away fom te ontinner

shied (8).

[NOTE A tim tg wt be necessary to separate the

‘two componoris. Eneurs thatthe tabs snap out

‘dearly and ae nt damaged, as yeu pul these

‘comonents apart

Aoaunon

When rofiting, ft the tabs property Int thei slots

@.

REMOVING THE FOOTREST

Read caretlly PRECAUTIONS AND GENERAL

INFORMATION and FUEL.

Postion the motorycle on he center stan

Remove the footrest mats (1).

Remove th ceil inspection cover (REMOVING

‘THE CENTRAL INSPECTION COVER),

Unsere anc rave the 7 soem 2.

[NOTE Tho fotowing operaions mustbecarod out

onbath sides othe motorcycle

eloase 002001

Chassis

Unsorow ae remove the 2 serene.