Professional Documents

Culture Documents

Waste Heat Recovery in Cement Plant PDF

Waste Heat Recovery in Cement Plant PDF

Uploaded by

Dope WorldOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waste Heat Recovery in Cement Plant PDF

Waste Heat Recovery in Cement Plant PDF

Uploaded by

Dope WorldCopyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 5, May - 2014

Waste Heat Recovery in Cement plant

S. Nivethidha Priyadarshini1, D. B. Sivakumar2

1

Master of Technology Student, ANNA UNIVERSITY Trichy, INDIA

2

Assistant Professor, Department of Mechanical Engineering, ANNA UNIVERSITY Trichy, INDIA

Abstract— Cement production has been one of the most reducing the high cost of electrical energy and the

energy intensive industries in the world. In order to produce emissions of greenhouse gases. In cement plant the exit

clinker, rotary kilns are widely used in cement plants. To gases from Rotary kilns, pre-heater and Calciners are used

achieve effective and efficient energy management scheme, to heat the incoming feed material and gases are cooler

thermal energy audit analysis was employed in the Dalmia

around 300 to 350 °C in 4 stage pre-heater and then

cement plant. Reduction of the production cost and

consumption cost is very much important because of exhausted to the atmosphere.

that waste heat recovery is implemented in the cement

industry. The waste heat recovery reduces the Green house

gas emissions and enhances the overall system performance.

The aim of this work is to determine the Power

Generation by utilizing the waste exit gases from the II. SYSTEM DESCRIPTION AND DATA SOURCE

Pre-heater, Grate cooler. By using the various Energy

Auditing instrument the exhaust gas temperature, Dust The cement industry has an important role in

concentration , Surface temperature, Velocity were the economy based on its production. During the

identified. A detailed analysis of Grate cooler, Preheater production of Cement natural resources are consumed

are done and the possible approaches of heat recovery in large amounts. The most important raw materials

from some major heat loss sources. for the manufacture of cement are limestone (CaCO3)

RT

and clay or calcareous clay in which both Components

Keywords-E n e r g y a u d i t ; H e a t l o s s ; are already naturally mixed. The components are

Preheater;

milled and dried with flue gases from the clinker kiln.

Cooler; Heat recovery; Clinker; Steam cycle ;

IJE

Depending on the type of cement to be produced, the

I. INTRODUCTION following product may be added to the dried limestone

subsequently: Pyrite ash, fly ash from coal fired power

Waste heat recovery from the hot gases in the

plants, sandy clay and filter ash from the electrostatic

system can be considered as a potential option to improve

precipitator present. The mixture obtained is ground

energy efficiency in industrial processes. The Waste heat

and subsequently fired in a rotary furnace to cement

is heat, which is generated in a process by way of fuel

clinkers. For heating, various fuels and other

combustion or chemical reaction, and then dumped into

combustible materials, for example coal dust,

the environment even though it could still be reused for

petroleum coke, etc., are used. Depending on the type

some useful and economic purpose. The essential quality

of preheating of the material, it is differentiated

of heat is not the amount but rather its temperature of the

between grate and cyclone preheating, whereby the

waste heat gases and the economics involved. Large

starting materials are preheated to 700 to 800°C. The

quantity of hot flue gases is generated from Boilers, Kilns,

raw materials pass through the rotary furnace towards

Ovens and Furnaces. If some of this waste heat could be

the flame. In the hottest zone, the material being fired

recovered, a considerable amount of primary fuel could be

reaches temperatures of around 1450°C.The cement

saved. The energy lost in waste gases cannot be fully

plant considered is Dalmia Cement––Unit 2,

recovered. Waste heat Recovery means allowing the waste

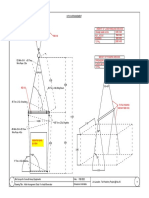

Trichirapalli, India. A schematic of the plant (Fig. 1)

heat to leave the process, but converting into electricity

shows the flow of various streams and the

before it is discharged at lower temperature level to the

components of the plant. The plant runs on dry process

environment. Therefore, after the efficiency of a cement

with a four stage suspension preheater and an inline

plant has been driven to the economic optimum, the

Calciners. The production capacity is 3018 tonne per

remaining waste heat is converted into electricity. Waste

day. It is the pyroprocessing unit that includes the

heat recovery system: The waste heat available in the

preheater, the Calciners, the kiln and the clinker

exhaust gases can be recovered and used for drying the

cooler. The streams into the system are the raw

moisture in the raw material and coal or for generating

material, the air into the cooler and the coal fired into

power. In addition to the plan of reducing of energy

the kiln and the Calciners. The streams leaving the

consumption in cement production process, the recovery

system are clinker out from the cooler, the exhaust

waste heats can be achieved in order to produce the

gases from the preheater and the hot air out from the

electrical energy by utilization cogeneration power plant.

cooler.

This means no additional fuel consumption and thus,

IJERTV3IS051014 www.ijert.org 814

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 5, May - 2014

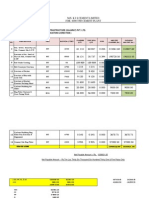

III. MASSBALANCE AND ENERGY BALANCE capacity would declare an efficiency of 55% based on dry

A. Mass balance process methodology. The overall efficiency of the system

can be improved by recover some of the heat losses.

The average compositions for dried coal

are shown in Fig. 1 Based on the coal composition, the IV.WASTEHEAT RECOVERY AND POWER

net heat value has been found to be 30,600kJ/kg-coal. GENERATION

The stream data obtained from the plant is used to There are opportunities that exist within the

perform a mass balance over the system. It is usually plant to capture the heat that would otherwise be wasted to

more convenient to define mass/energy data per kg the environment and utilize this heat to generate

clinker produced per unit time. The mass balance of electricity. The most accessible and, in turn, the most cost

the kiln system is summarized in Fig. 3. All gas effective waste heat losses available are the clinker cooler

streams are assumed to be ideal gases at the given discharge and the kiln exhaust gas. The exhaust gas from

temperatures. the Preheater is, on average , 361 ̊ C, and the temperature

of the air discharged from the cooler stack is 268˚C.The

B. Energy balance hot gases from the preheater and cooler are passed through

In order to analyze the kiln system the waste heat recovery boiler. Water is circulated through

thermodynamically, the following assumptions are the WHRB. Latent heat from the hot gas is transferred to

made the water and it is converted to steam. The steam is

expanded in the turbine and then it is condensed and the

1. Steady state working conditions.

condensed water is passed through the WHRG and the

2. The change in the ambient temperature is process repeats.The electricity generated would offset a

neglected. portion of the purchased electricity, thereby reducing the

3. Cold air leakage into the system is negligible. electrical demand.

Power generation

4. Raw material and coal compositions do not

Generally the waste heat recovery efficiency is 22.7%.The

change.

total heat available for power generation is 9.92Mcal/hr.

5. Averaged kiln surface temperatures do not Gross power generation

change. = Total heat available for power generation*WHR

efficiency*1000

RT

Based on the collected data, an energy balance is applied

to the kiln system. The Datum Temperature is taken as = 9.92 * 0.227 * 1000/860

20˚C. Based on the collected data, an energy balance is Assuming 8000h usage, we find

applied to the kiln system. The Datum Temperature is Energy saved = power generated * Hour usage

IJE

taken as 20˚C. The pertinent equations used in evaluating = 2620 * 8000

the different Heat transfer components of the systems = 20960000 Kwh/year

energy balance are shown inTable1.The Relevant data and

constants are obtained from on site measurements, plant Cost savings = Unit price of electricity * Energy saved

records Peray [8].The result presented in Table 1, shows = 3.75 * 20960000

that fuel combustion generate 97.3% (780 kJ/kg clinker) = 78,600,000 Rupees/year

of the total heat input to the unit. The sensible heats with

the raw materials, fuel and air entering the coolers heat

content are very small. The total sensible heats with

streams are about 0.2% of the total heat input to the unit.

Therefore, total heat input of 801.9 kJ/kgclinker is

required to maintain Clinkerization reactions temperatures

for the clinker formation. The total heat input is generated

from combustion heat and total sensible heat with the total

heat input to the unit. The total heat input is generated

from combustion heat and total sensible heat with the

material streams. During clinker formation, 413.2

kJ/kgclinker of heat is released, about 51.5% of the total

heat input. This percentage gives a measure of the thermal

efficiency of the kiln systems. The overall efficiency can

be improved by recovering some of the heat losses. The

recovered energy can then be used for several purposes,

such as electricity generation. There are few major heat

losses that would be considered for recovery. Theseare

heat losses by Preheater exhaust gas (24.4%), from cooler

stack (12.8%) and Radiation and convection losses Fig2. Mass balance of the system

(6.1%).The overall system efficiency can be defined by

Q5/Qtotal input = 413/801.9= 0.515 or 51.5% which can be

regarded as low. Some kiln system operating at full

IJERTV3IS051014 www.ijert.org 815

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 5, May - 2014

An additional cost will be required for maintenance of the power

generation unit. For the whole system shown in fig 3, based on

our calculations, we were able to determine a budget estimation

of 136400000 rupees/year. We can make a rough estimate for a

simple payback period.

Simple payback period = (Implementation cost)/(Cost savings)

= 136400000/78600000

= 1.73 years

Operational approach for thermal energy saving opportunities

Potential opportunities for improving energy efficiency of the

pyroprocessing unit could be achieved from the following

operational approach

- Upgrading existing equipments in the pyroprocessing unit

Fig 1.Composition of coal

Table 1 Heat balance of the kiln system

Heat Input

Description Equation used Data Results(kcal/kgclinker)

kiln Feed Q1=mCp(T2-T1) m=0.2155kg/kg clinker, 15.1(1.9%)

Cp=215kJ/kg˚C,T1=20˚C,T2=60˚C

Cooling air Q2=mCp(T2-T1) m=1.816kg/kg clinker, 5.1(0.6)

RT

Cp=0.31J/kg˚C,T1=20˚C,T2=29˚C

Coal dust Q3=mCp(T2-T1) m=1.816kg/kg clinker, 1.70(0.2%)

sensible heat Cp=0.31J/kg˚C,T1=68˚C,T2=20˚C

From fuel(By Q4 - 780(97.3%)

IJE

difference)

Total Heat 801.9(100%)

Heat Output

Description Equation used Data Results(kcal/kgclinker)

Heat of Q5= (4.11*Al2O3)+ Al2O3 = 5.630 413.2(51.5%)

formation (6.48*Mgo) Mgo = 0.850

+(7.646*CaO)+(- CaO= 64.870

5.1165*SiO2)+(- SiO2 = 21.160

0.59*Fe2O3) Fe2O3 = 5.340

Kiln feed Q6=kilnfeed Kilnfeedrate = 215TPH Moisture in kiln feed = 4.6(0.6%)

moisture rate*Moisture in 0.5%

temperature kilnfeed*540/clinker Clinkerproduction =125.73TPH

production

Coal dust Q7=Fuel rate*moisture Fuel rate = 15.3 2.2(0.3%)

moisture in Moisture in coal dust = 3.310%

temperature coaldust*540/clinker Clinkerproduction =125.73TPH

production

Heat through Q8 = mCp(T2 -T1) m=1.621 kJ/kg clinker, 195.7(24.4%)

Preheater Cp=0.354kJ/kg˚C,T1=20˚C,T2=361˚C

exhaust gas

Heat through Q9= mCp(T2 -T1) m=1.621 kJ/kg clinker, 12.8(1.6%)

dust entrained Cp=0.100kJ/kg˚C,T1=20˚C,T2=361˚C

in Preheater

exhaust gas

Heat through Q6= mCp(T2 -T1) m=1.307 kJ/kg clinker, 102.78(12.8%)

cooling vent air Cp=0.317kJ/kg˚C,T1=20˚C,T2=268˚C

Heat through Q7= mCp(T2 -T1) m=1kg/kg clinker, 21.7(2.7%)

Clinker Cp=0.189kJ/kg˚C, T1=20˚C,T2=135˚C

Radiation 48.8(6.1%)

and convection losses ___ __

(cooler, kiln,

preheater,

Duct)

Total Heat loss __ __ 801.9(100%)

IJERTV3IS051014 www.ijert.org 816

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 5, May - 2014

Table 2 Heat utilization

Description Equation used Data Results(Mcal/hr)

Preheater heat m=0.34kg/kg clinker, 26.36

available from Cp=204 kJ/kg˚C, T= 380 ˚C

exhaust gas Q1= mCp(T2 -T1)

Cooler Heat 18.97

Available m=0.34kg/kg clinker,

from Exit Q2= mCp(T2 -T1) Cp=204 kJ/kg˚C, T= 380 ˚C

Gases

Preheater Heat Q3= mCp(T2 -T1) 25.04

available for Raw mill m=0.34kg/kg clinker,

and Coal mill at Cp=204 kJ/kg˚C, T= 361 ˚C

WHRS Outlet

Preheater Heat Q4= mCp(T2 -T1) m=0.354 kJ/kg clinker, 1.32

available for boiler Cp=204kJ/kg˚C,T1=361˚C,T2=380˚C

Total heat from Q5= mCp(T2 -T1) m=99kg/kg clinker, 12.29

Cooler mid tap for Cp=0.317 kJ/kg˚C, T= 400 ˚C

boiler

Useful cooler heat Q6= mCp(T2 -T1) m=99 kJ/kg clinker, 8.59

available at 120 ˚c Cp=0.31kJ/kg˚C,T1=120˚C,T2=400˚C

exit temp for cooler

mid tap boiler

Unused heat Q7= mCp(T2 -T1) m=99 kJ/kg clinker, 3.69

vented to atm Cp=0.31kJ/kg˚C,T1=120˚C,T2=400˚C

at 120˚Cfrom

cooler midtap

boiler

Total heat available Q4+Q6 Q4=1.32 9.92

for power generation Q6=8.60

RT

IJE

Fig 3.Waste heat recovery power plant

- Combustion system improvement - Replacing high carbon fuel with low carbon fuel (i.e.

- Adding multistage preheater with Pre-Calciners switching

- Adopting new pyroprocessing technologies From coal to natural gas)

- Utilizing alternative fuel such as harvesting energy from - Applying a low clinker to final cement mixture ratio (i.e.

Biomass and waste fuel for kiln firing increasing the ratio of cement additives that do not require

Pyroprocessing)

IJERTV3IS051014 www.ijert.org 817

International Journal of Engineering Research & Technology (IJERT)

ISSN: 2278-0181

Vol. 3 Issue 5, May - 2014

V.CONCLUSIONS

A detailed energy audit analysis, which can be

directly applied to any dry kiln system, has been made for

a specific key cement Plant. According to the result

obtained the overall system efficiency is 51.53%.The

major heat loss sources have been determined as kiln

exhaust (19.15%), cooler exhaust (12.8%) Heat through

Preheater gas (24.4%) and combined radiative and

convective heat transfer from kiln surfaces (6.1%).The

Preheater Exhaust gas temperature is (361̊C) and Cooler

Exhaust gas temperature (268˚C) which are used in waste

heat boiler for power generation. A waste heat recovery

steam generation system was selected showing the energy

saving potential of 2.62 MW from the waste heat streams

with simple pay back of 30 months.

VII.REFERENCES

[1] Vedat Ari, “Energetic and exergetic assessments of a cement rotary

kiln system”, Scientific Research and Essays Vol. 6(6), pp. 1428-

1438, 18 March, 2011.

[2] G. Kabir, A.I.Abubakar, U.A. El-Nafaty, “Energy audit and

conservation opportunities for pyroprocessing unit of a typical dry

process cement plant”, Chemical Engineering Programme, Abubakar

Tafawa Balewa University, Energy 35 (2010) 1237-1245.

[3] Shaleen Khurana, Rangan Banergee, Uday Gaitonde, “Energy

balance and cogeneration for a cement plant”. Applied Thermal

Engineering 22 (2002) 485–494.

[4] N.A.Madlool, R.Saidura, M.S.Hossain, N.A.Rahim, “A critical

RT

review on energy use and savings in the cement industries”,

Renewable and Sustainable Energy Reviews 15 (2011) 2042–2060.

[5] M.G.Rasul, W.Widianto, B.Mohanty, “Assessment of the thermal

performance and energy conservation opportunities of a cement

IJE

industry in Indonesia”, Applied Thermal Engineering 25 (2005)

2950–2965.

[6] TahsinEngin, Vedat Ari, “Energy auditing and recovery for dry type

cement rotary kiln systems––A case study”, Energy Conversion and

Management 46 (2005) 551–562.

[7] Aly Moustafa Radwan, “Different Possible Ways for Saving Energy

in the cement production”, Advances in Applied Science Research,

2012, 3 (2):1162-1174.

[8] Peray KE. Cement manufacturer’s handbook. New York, NY:

Chemical Publishing Co., Inc.; 1979.

[9] N.A. Madlool, R. Saidur, M.S. Hossain, N.A. Rahim, “A critical

review on energy use and savings in the cement industries”,

Renewable and Sustainable Energy Reviews 15 (2011) 2042–2060.

[10] A. Ramesh, Leo. A. J, G. Madhu, “Energy audit of thermal utilities

in a cement plant”, International Journal of Mechanical Engineering

(IJME) Vol. 2, Issue 2, May 2013, 11-22.

[11] S. Karellas, A.D. Leontaritis, G. Panousis, E. Bellos, E.

Kakaras, “Energetic and exergetic analysis of waste heat

recovery systems in the Cement industry”, Energy 58 (2013)

147-156.

IJERTV3IS051014 www.ijert.org 818

You might also like

- Propulsion Trends in Container VesselsDocument30 pagesPropulsion Trends in Container VesselsrafecarNo ratings yet

- CAPL Cement GlossaryDocument15 pagesCAPL Cement GlossaryrefeiiNo ratings yet

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFAnonymous Cxriyx9HIXNo ratings yet

- FAD Calculation For CompressorDocument2 pagesFAD Calculation For CompressorDurjoy ChakrabortyNo ratings yet

- Akbulut Sample Midterm 1Document11 pagesAkbulut Sample Midterm 1tony4dongNo ratings yet

- 06 GDP and Economic GrowthDocument3 pages06 GDP and Economic GrowthAkash Chandak0% (2)

- NH - Bad Bartlett - The Josiah Bartlett Center and NH Watchdog Answer The Call of The Koch BrothersDocument60 pagesNH - Bad Bartlett - The Josiah Bartlett Center and NH Watchdog Answer The Call of The Koch BrothersprogressnowNo ratings yet

- Reverse Air Bag House PDFDocument4 pagesReverse Air Bag House PDFRanga VamshiNo ratings yet

- Technical Specification of VSK PDFDocument28 pagesTechnical Specification of VSK PDFmaran.suguNo ratings yet

- Jaypee Cement Plant Grinding Uniit-3Document27 pagesJaypee Cement Plant Grinding Uniit-3sunil kumar patelNo ratings yet

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFPraveen Awasthi100% (1)

- Gujarat Sidhee Cement Limited-SmitDocument26 pagesGujarat Sidhee Cement Limited-SmitHimadri MahatoNo ratings yet

- Presep Air Separator VTP enDocument6 pagesPresep Air Separator VTP enBrunoNo ratings yet

- False AirDocument665 pagesFalse AirSantanu PachhalNo ratings yet

- Bucket ElevatorsDocument11 pagesBucket ElevatorsMehmet CNo ratings yet

- Chapter 1Document56 pagesChapter 1Surbhi JainNo ratings yet

- AFR Process Presentation - 22.11.2016Document34 pagesAFR Process Presentation - 22.11.2016Rohit SolomonNo ratings yet

- Cement PlantDocument15 pagesCement Plantengr.kamran100% (1)

- Ultratech Report FinalDocument78 pagesUltratech Report FinalrahulNo ratings yet

- ZKG IndiaDocument4 pagesZKG IndiaRaviKumarNo ratings yet

- Coal Mill Wear Measurement 29.09.2014Document1 pageCoal Mill Wear Measurement 29.09.2014Durga PrasadNo ratings yet

- Pneumatic Conveying: Technology You Can TrustDocument16 pagesPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinNo ratings yet

- Vertical Roller MillDocument3 pagesVertical Roller MillChaitanya Chinta0% (1)

- Turbo Air Classifier DesignDocument21 pagesTurbo Air Classifier Designnayan patelNo ratings yet

- M/S. K J S Cement Limited For-6000 TPD Cement PlantDocument22 pagesM/S. K J S Cement Limited For-6000 TPD Cement Plantvinod_eicsNo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- WHRS and PP For Cement Plants - Todays Boiler Spring 2014Document2 pagesWHRS and PP For Cement Plants - Todays Boiler Spring 2014ash22202No ratings yet

- Caustic Soda From Natural Trona 2014Document5 pagesCaustic Soda From Natural Trona 2014MauRmzNo ratings yet

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDocument5 pagesGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Manual RF Baghouse CollectorDocument24 pagesManual RF Baghouse Collectorheroj83100% (1)

- Modefied Cooler2Document71 pagesModefied Cooler21977jul100% (2)

- Bag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFDocument14 pagesBag Filters Types, Working Principles & Daily Maintenance - INFINITY FOR CEMENT EQUIPMENT PDFRICARDOALEXBORGES100% (2)

- Questionnaire For Evaluation of Ball Mills.: ContentsDocument16 pagesQuestionnaire For Evaluation of Ball Mills.: ContentsThaigroup CementNo ratings yet

- Weigh Feeder MechanicsDocument1 pageWeigh Feeder MechanicsVijay Bhan67% (3)

- Fil Tax Jet Pulse FilterDocument4 pagesFil Tax Jet Pulse FilterM.IBRAHEEMNo ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- Better Grinding Systems: Figure 1: DeglomeratorDocument5 pagesBetter Grinding Systems: Figure 1: DeglomeratorGerman Gabriel Anaya VegaNo ratings yet

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- GGBFS Opeartion ManualDocument41 pagesGGBFS Opeartion ManualPushpendra Kumar KushwahaNo ratings yet

- Ball Mill OperatingDocument14 pagesBall Mill OperatingCao Ngoc AnhNo ratings yet

- Energy Consumption Benchmark Guide: Cement Clinker ProductionDocument14 pagesEnergy Consumption Benchmark Guide: Cement Clinker ProductionVisnu SankarNo ratings yet

- Roller Mill FundamentalsDocument11 pagesRoller Mill Fundamentalshidrastar123100% (1)

- UltraTech AFR Presentation PDFDocument11 pagesUltraTech AFR Presentation PDFRandeep YadavNo ratings yet

- E0012 FLS L61 PM em MR01 01 - R1.0 PDFDocument4 pagesE0012 FLS L61 PM em MR01 01 - R1.0 PDFVegaGonzalezNo ratings yet

- MHR21924 CMC Chapter CCDocument48 pagesMHR21924 CMC Chapter CCDede KaladriNo ratings yet

- Cement Production ProcessDocument2 pagesCement Production ProcessNishant Ajitsaria100% (1)

- 2012 - Design, Fabrication and Commissioning of RDF PDFDocument72 pages2012 - Design, Fabrication and Commissioning of RDF PDFHilmi Gazali TvkNo ratings yet

- Alkali Bypass WHRPP Nov - 11 PDFDocument18 pagesAlkali Bypass WHRPP Nov - 11 PDFNinad Bhave100% (1)

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- Cement Mill Note BookDocument4 pagesCement Mill Note BookK.SRINIVAS RAONo ratings yet

- Cement Plant Design-1Document14 pagesCement Plant Design-1Towfiq Hossain Tasku100% (2)

- Amrit Cement Industrial ReportDocument38 pagesAmrit Cement Industrial Reportmanish mohan upadhyayNo ratings yet

- KEP Presentation NCJWDocument28 pagesKEP Presentation NCJWfilu786No ratings yet

- CCX CycloneDocument4 pagesCCX CycloneMageshNo ratings yet

- Rotary Kiln SimulatorDocument10 pagesRotary Kiln SimulatorPassmore DubeNo ratings yet

- Cement Mill: History Materials Ground Temperature Control Ball MillsDocument5 pagesCement Mill: History Materials Ground Temperature Control Ball MillsAli HadiNo ratings yet

- Pneumatic Barrel Pumps Model SAF1-YL Und SAF2-YL: Owner Manual Operating Instructions and Service Parts ListDocument17 pagesPneumatic Barrel Pumps Model SAF1-YL Und SAF2-YL: Owner Manual Operating Instructions and Service Parts Listredwan al-mustafaNo ratings yet

- Process Design NotesDocument12 pagesProcess Design NotesAli HüthütNo ratings yet

- Comminution 2Document159 pagesComminution 2Kumar RajeshNo ratings yet

- V3i5 Ijertv3is051014 PDFDocument5 pagesV3i5 Ijertv3is051014 PDFRaja ShannmugamNo ratings yet

- CFD Modeling of Waste Heat Recovery On The Rotary Kiln System in The Cement IndustryDocument17 pagesCFD Modeling of Waste Heat Recovery On The Rotary Kiln System in The Cement Industryghada ghoudiNo ratings yet

- Sinter Coolers: International Journal For Research in Applied Science & Engineering Technology (IJRASET)Document3 pagesSinter Coolers: International Journal For Research in Applied Science & Engineering Technology (IJRASET)iaetsdiaetsdNo ratings yet

- Waste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliDocument10 pagesWaste Management: Fabio Dal Magro, Haoxin Xu, Gioacchino Nardin, Alessandro RomagnoliKARAN KHANNANo ratings yet

- Applied Thermal Engineering: Adem Atmaca, Recep YumrutasDocument10 pagesApplied Thermal Engineering: Adem Atmaca, Recep YumrutasAnonymous N3LpAX100% (1)

- Energy ManagementDocument20 pagesEnergy Managementhasan_jafri_2No ratings yet

- TG SynchronizationDocument7 pagesTG SynchronizationDurjoy Chakraborty100% (1)

- H2 KoreanDocument3 pagesH2 KoreanDurjoy ChakrabortyNo ratings yet

- Glass Fibre Reinforced Products PDFDocument16 pagesGlass Fibre Reinforced Products PDFDurjoy ChakrabortyNo ratings yet

- Comparison of Counter Flow and Cross Flow CoolingDocument2 pagesComparison of Counter Flow and Cross Flow CoolingDurjoy ChakrabortyNo ratings yet

- Coal FLowDocument28 pagesCoal FLowDurjoy ChakrabortyNo ratings yet

- Restriction Orifice Diamater CalculationDocument1 pageRestriction Orifice Diamater CalculationDurjoy ChakrabortyNo ratings yet

- Waste To Energy Plant in SuratDocument18 pagesWaste To Energy Plant in SuratDurjoy ChakrabortyNo ratings yet

- Gas TurbineInlet Air CoolingDocument41 pagesGas TurbineInlet Air CoolingDurjoy ChakrabortyNo ratings yet

- 1811 Reclaiming SystemsDocument4 pages1811 Reclaiming SystemsDurjoy ChakrabortyNo ratings yet

- Word Information Muet 12 Aug 12Document2 pagesWord Information Muet 12 Aug 12KENNY CHONG SOON JIE MoeNo ratings yet

- Air India 4th MayDocument1 pageAir India 4th MaySumit JainNo ratings yet

- NPTA Effective Development CooperationDocument4 pagesNPTA Effective Development CooperationnailaweoungNo ratings yet

- FIAT Final ReportDocument51 pagesFIAT Final ReportbilljohnsonNo ratings yet

- Cost Analysis Long RunDocument16 pagesCost Analysis Long RunChitrini ChalmelaNo ratings yet

- AFST Sample TestDocument1 pageAFST Sample Testsad gurlNo ratings yet

- EXIMDocument17 pagesEXIMManwendra SinghNo ratings yet

- Database Prosedur LasDocument132 pagesDatabase Prosedur LasArief PutraNo ratings yet

- World Class Manufacturing FinalDocument22 pagesWorld Class Manufacturing FinalSanjog Devrukhkar100% (4)

- International Business 12e (Ball)Document50 pagesInternational Business 12e (Ball)vdchuongNo ratings yet

- Tom Zaniello - The Cinema of Globalization - A Guide To Films About The New Economic Order-Cornell University Press (2018)Document230 pagesTom Zaniello - The Cinema of Globalization - A Guide To Films About The New Economic Order-Cornell University Press (2018)jczenkoan5617No ratings yet

- CompaniesDocument12 pagesCompanies2020dlb121685No ratings yet

- Durham County Policy Surplus Real PropertyDocument5 pagesDurham County Policy Surplus Real PropertySarahNo ratings yet

- Case 1 - RM - Prime Bank - Serving The CustomerDocument10 pagesCase 1 - RM - Prime Bank - Serving The CustomerParivesh DoshiNo ratings yet

- Abu Ali FHP-7Document1 pageAbu Ali FHP-7VERGEL BERNABENo ratings yet

- Government Schemes To Support Startups in IndiaDocument10 pagesGovernment Schemes To Support Startups in IndiaYedhu KNo ratings yet

- Three of World's Most Powerful Drug Syndicates Have Been Smuggling Shabu Into The Country, The Philippine Drug Enforcement Agency (PDEA) SaidDocument2 pagesThree of World's Most Powerful Drug Syndicates Have Been Smuggling Shabu Into The Country, The Philippine Drug Enforcement Agency (PDEA) SaidMark GenetaNo ratings yet

- PRICERV2Document89 pagesPRICERV2Abdelhay ElyadiniNo ratings yet

- AFISCO Insurance Corporation v. CADocument2 pagesAFISCO Insurance Corporation v. CAlealdeosa100% (2)

- LeveragedGrowth Monthly-Snapshot-February24 240304 195607Document26 pagesLeveragedGrowth Monthly-Snapshot-February24 240304 195607Tanay SawantNo ratings yet

- Agencies of HousingDocument16 pagesAgencies of HousingDarshan BNo ratings yet

- Jharkhand 04092012Document51 pagesJharkhand 04092012Ram NamburiNo ratings yet

- COVID Frontline Worker (Basic Care Support) : Log Book For On-the-Job Training (OJT)Document101 pagesCOVID Frontline Worker (Basic Care Support) : Log Book For On-the-Job Training (OJT)Sadia KhatunNo ratings yet

- Module 1 Cost ConceptsDocument3 pagesModule 1 Cost ConceptsAngela Miles DizonNo ratings yet

- What Is The World BankDocument4 pagesWhat Is The World BankPrincess KanchanNo ratings yet

- BFIDC and The Private Garden Owners Grow Rubber On Around 92Document7 pagesBFIDC and The Private Garden Owners Grow Rubber On Around 92abrarbd2004No ratings yet