Professional Documents

Culture Documents

Datasheets For Bucket Type Strainer

Uploaded by

becpavanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheets For Bucket Type Strainer

Uploaded by

becpavanCopyright:

Available Formats

Doc No: NOCL-KEN-GEC-

ENGINEERING CONSULTANCY Prepared : CPK

ATF-PR-STR-001

SERVICES

G

Review : CPK REV 1

Approve : ACS Sheet 1 of 2

Bucket Type Strainer

Date :19.09.20

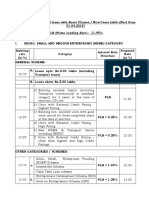

Datasheet for Bucket Type Strainer

PROJECT

ATF STORAGE FACILITY AT GAUTAM BUDDHA INTERNATIONAL AIRPORT

BHAIRAHAWA, NEPAL

CLIENT

M/s KEN-AJAD J/V

OWNER

NEPAL OIL CORPORATION LIMITED (NOCL)

1 19.09.20 INCORPORATED BV COMMENTS CPK CPK ACS

0 31.07.20 ISSUED FOR APPROVAL CPK CPK ACS

REV REV DATE PURPOSE PREPD REVWD APPD

NEPAL OIL

GABATIA ENGINEERS &

CORPORATION LIMITED

(NOCL)

DATASHEET FOR 'Y' TYPE STRAINER G CONSULTANTS

ATF STORAGE FACILITY AT GAUTAM BUDDHA

INTERNATIONAL AIRPORT

REV. DATE DESCRIPTION BY PROJECT NAME:

1 19.09.20 INCORPORATED BV COMMENTS CPK LOCATION: BHAIRAHAWA, NEPAL

NAME Bucket Type Strainer TAG NUMBER

GENERAL

TAG NO. STR-001/002 SIZE (in) 6"

P&ID NO. NOCL-KEN-GEC-ATF-PR-PID-001 SERVICE ATF

SPEC CS QTY. 2 Nos (Note-9)

RATING 150#

OPERATING CONDITIONS

DESIGN PRESSURE (barg) 15 CORROSION ALLOWANCE (inch) 0.0625

DESIGN TEMPERATURE (ºC) 55 DENSITY (kg/m3) 770-830

OPERATING PRESSURE (barg) ATM

OPERATING TEMPERATURE (ºC) 50

CONSTRUCTION

END CONNECTION FLANGED MANUFACTURER TBD

FLG RTG, FACING & FINISH 150#,CS,ASTM A 105,RF & 125 AARH DESIGN CODE -

MESH SIZE (micron) 50 BOTTOM DRAIN 3/4" Solid Threaded Tap with Plug

MAX. PRESSURE DROP AT - 50% MAX. PRESSURE DROP AT - CLEAN

0.8 0.5

CLOGGED CONDITION (barg) CONDITION (barg)

CONSTRUCTION MATERIAL

Spiral Wound SS316 + Grafoil Ι ASME B16.20,

BODY CS,ASTM A 105 GASKETS

2mm

BOTTOM FLANGE CS, 150#,CS,ASTM A 105,RF COVER CS,ASTM A 105

SCREEN SS 304 O-RING BUNA N

OTHERS

"A" (in) VTC "D"(in) VTC

OVERALL DIMENSION WITH

"B"(in) VTC "E"(in) VTC

G.A.DRAWING

"C" (in) VTC WEIGHT(LB) VTC

INSPECTION AND TEST

HYDROSTATIC TEST YES TEST PRESSURE TestingStd. API 598

PNEUMATIC TEST NO

NDT AS REQUIRED

NOTE

(1) VTC - Vendor to Confirm

(2) Materails indicted shows minimum matullurgical requirements.

(3) Submission of GA Drawing for approval along with TAG no.

(4) Operation & Maintenance manual (1 No.) to be submitted (If applicable)

(5) Spare list (1 No.) to be submitted

(6) Guarantee / Warrantee Certificate to be submitted

(8) The entire internals of strainer which will come into contact with ATF to be handled shall be epicoated

(9) All strainers shall be supplied with spare basket complete with straining element.

You might also like

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanNo ratings yet

- Storage Tank Data SheetDocument16 pagesStorage Tank Data SheetSalman EngineeringNo ratings yet

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDocument8 pagesSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungNo ratings yet

- Steel StandardsDocument53 pagesSteel StandardsSureshNo ratings yet

- PMS Rev 0Document36 pagesPMS Rev 0rami ghorbelNo ratings yet

- Acceptance LetterDocument17 pagesAcceptance LetterSarah Mae FailamanNo ratings yet

- Work Order NDTDocument1 pageWork Order NDTTito FernandezNo ratings yet

- Contractor ITP Shell & Tube Heat ExchangerDocument16 pagesContractor ITP Shell & Tube Heat ExchangerAlexandru AsmarandeiNo ratings yet

- DWS 2510 Valve SpecificationDocument7 pagesDWS 2510 Valve SpecificationsudjonoNo ratings yet

- Comments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplyDocument2 pagesComments Resolution Sheet Against Comments Given by Bureau Veritas - GEC ReplybecpavanNo ratings yet

- Glycol Regenerator Design and SpecificationsDocument4 pagesGlycol Regenerator Design and SpecificationsraulgaldoNo ratings yet

- T Type Strainer Butt Weld 1 PDFDocument1 pageT Type Strainer Butt Weld 1 PDFprashant mishraNo ratings yet

- Request Form JaimonDocument306 pagesRequest Form JaimonjaimonjoyNo ratings yet

- SCH-00-J-7000 Inst. Cable Schedule Rev - 3Document28 pagesSCH-00-J-7000 Inst. Cable Schedule Rev - 3Kishore KrishnaNo ratings yet

- Bisep Hot Tapping Plugging 1Document7 pagesBisep Hot Tapping Plugging 1mospt100% (1)

- Oisd Gen 235 PDFDocument110 pagesOisd Gen 235 PDFPankaj GoelNo ratings yet

- A869-6-44-0005 PMS For RevampDocument950 pagesA869-6-44-0005 PMS For RevampMastram HatheshNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- PIPE CLASS SPECIFICATIONDocument138 pagesPIPE CLASS SPECIFICATIONbadelitamariusNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Purchase Spec. For Tubes (Sa213 TP321)Document5 pagesPurchase Spec. For Tubes (Sa213 TP321)Daison PaulNo ratings yet

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- Pressure RegulatorDocument2 pagesPressure RegulatorSemangraya76No ratings yet

- Purchase Spec. For Nozzles Swage (Sa106b)Document4 pagesPurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNo ratings yet

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocument10 pagesClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarNo ratings yet

- NPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20Document132 pagesNPK-000-L8-SD-4025-K-REV.2 - PIPING STANDARD SUPPORT DRAWINGS - Replace 07-11-20MuhammadNurrahmanNo ratings yet

- Sor BPCL KochiDocument79 pagesSor BPCL KochiPrafulla PatilNo ratings yet

- Data Sheet 26 - Fig FT702 150 T StrainerDocument1 pageData Sheet 26 - Fig FT702 150 T StrainerSteve NewmanNo ratings yet

- Reservior Skid Assl Qap AlfaDocument1 pageReservior Skid Assl Qap AlfaajmainNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-InitialDocument24 pagesRas Markaz Crude Oil Park Project (Phase1) Material Take-Offs For Piping Bulks-Initialanil pkNo ratings yet

- Data Sheet For T-8101.RevCDocument5 pagesData Sheet For T-8101.RevCSuresh SjNo ratings yet

- 1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseDocument3 pages1308-306-MEC-DTS-001 - Rev.1 - Cryogenic Flexible HoseKira RaNo ratings yet

- 12 Chaturvedi EIL PresentationDocument12 pages12 Chaturvedi EIL Presentationget2anushNo ratings yet

- Volume3A MechDocument321 pagesVolume3A MechAdeel JamilNo ratings yet

- Aviation Biofuel Is A Growing IndustryDocument6 pagesAviation Biofuel Is A Growing IndustryCarl FreerNo ratings yet

- Pressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)Document6 pagesPressure/Vacuum Relief Valves: (Breather Valves and Conservation Vents)KOMATSU SHOVELNo ratings yet

- Kurs 1 UsdDocument49 pagesKurs 1 UsdSahrul RamadanNo ratings yet

- AE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksDocument6 pagesAE-S-3527 Rev. 2: REV Prepared by Approved BY Date RemarksQualityNo ratings yet

- Project: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetDocument36 pagesProject: Date Jobno: Designed ACTIVITY: Utility Pipe/ Valve Workshop Checked SheetGeorge Georgian100% (1)

- EIL - Piping StandardsDocument1 pageEIL - Piping StandardsPrem DixitNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument6 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PShanjiNo ratings yet

- Cost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionDocument9 pagesCost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionjnmanivannanmechNo ratings yet

- BPCL PuneDocument9 pagesBPCL PuneDeependra SinghNo ratings yet

- AFMC (Medical) Solved Paper 2013 PDFDocument32 pagesAFMC (Medical) Solved Paper 2013 PDFAnkur BanerjeeNo ratings yet

- Reconstruction Airport Expansion JointsDocument5 pagesReconstruction Airport Expansion JointsaltipatlarNo ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Tanky 53 KL Rev.1Document187 pagesTanky 53 KL Rev.1Priyo Jati WahyonoNo ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- Instrumentation Scheme of Thermal Power PlantDocument39 pagesInstrumentation Scheme of Thermal Power Plantgdreddy25No ratings yet

- 7-12-0009 Rev 7Document2 pages7-12-0009 Rev 7sahilNo ratings yet

- Liter Tank DetailDocument281 pagesLiter Tank DetailrkpragadeeshNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- Boq of Ball Float ValveDocument1 pageBoq of Ball Float Valvem 418No ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Ethylene StorageDocument5 pagesEthylene StoragedatNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Inst - Name Tag Class Category Process Function Instrument - Type - Description Instrume NT - Type - NameDocument21 pagesInst - Name Tag Class Category Process Function Instrument - Type - Description Instrume NT - Type - NamebecpavanNo ratings yet

- A.2 - 317-07-21-1246 R-2 P & IdDocument5 pagesA.2 - 317-07-21-1246 R-2 P & IdbecpavanNo ratings yet

- E.1 - 317-Inst-001 System Architecture DrawingDocument1 pageE.1 - 317-Inst-001 System Architecture DrawingbecpavanNo ratings yet

- G.2 - 317-DS-FF-002 Datasheet For Fire Water PumpDocument2 pagesG.2 - 317-DS-FF-002 Datasheet For Fire Water PumpbecpavanNo ratings yet

- OISD 117 - Specimen Fire Water and Foam Deamnd Calculation SheetDocument2 pagesOISD 117 - Specimen Fire Water and Foam Deamnd Calculation SheetbecpavanNo ratings yet

- Instrumentation Engineer ResumeDocument4 pagesInstrumentation Engineer ResumebecpavanNo ratings yet

- ISOMETRIC DRAWING FOR NEW LUBE OIL TANKSDocument1 pageISOMETRIC DRAWING FOR NEW LUBE OIL TANKSbecpavanNo ratings yet

- Isometric Drawing For New Lube Oil TanksDocument1 pageIsometric Drawing For New Lube Oil TanksbecpavanNo ratings yet

- Process CommentsDocument8 pagesProcess CommentsbecpavanNo ratings yet

- Iso 11Document1 pageIso 11becpavanNo ratings yet

- New Lube Oil Tank Isometric DrawingDocument1 pageNew Lube Oil Tank Isometric DrawingbecpavanNo ratings yet

- Isometric Drawing For New Lube Oil TanksDocument1 pageIsometric Drawing For New Lube Oil TanksbecpavanNo ratings yet

- Iso 14Document1 pageIso 14becpavanNo ratings yet

- Iso 09Document1 pageIso 09becpavanNo ratings yet

- New Lube Oil Tank Isometric DrawingDocument1 pageNew Lube Oil Tank Isometric DrawingbecpavanNo ratings yet

- Iso 05Document1 pageIso 05becpavanNo ratings yet

- ISOMETRIC DRAWING FOR NEW LUBE OIL TANKSDocument1 pageISOMETRIC DRAWING FOR NEW LUBE OIL TANKSbecpavanNo ratings yet

- Iso 12Document1 pageIso 12becpavanNo ratings yet

- Iso 06Document1 pageIso 06becpavanNo ratings yet

- 6" Existing Hdr-8: 4"-PR-0008-CSDocument1 page6" Existing Hdr-8: 4"-PR-0008-CSbecpavanNo ratings yet

- Isometric Drawing For New Lube Oil TanksDocument1 pageIsometric Drawing For New Lube Oil TanksbecpavanNo ratings yet

- Process Safety Time Calculation - LOPA (SIF) 296Document2 pagesProcess Safety Time Calculation - LOPA (SIF) 296becpavan100% (1)

- Iso 01Document1 pageIso 01becpavanNo ratings yet

- Iso 03Document1 pageIso 03becpavanNo ratings yet

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocument2 pagesAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanNo ratings yet

- Iso 10Document1 pageIso 10becpavanNo ratings yet

- Iso 07Document1 pageIso 07becpavanNo ratings yet

- HPCL Piping Layout DiagramDocument1 pageHPCL Piping Layout DiagrambecpavanNo ratings yet

- RF Firehose Friction RevisedDocument94 pagesRF Firehose Friction RevisedOnur SürücüNo ratings yet

- Technical Specification - Mangalore Station PipingDocument21 pagesTechnical Specification - Mangalore Station PipingbecpavanNo ratings yet

- Math ProjectDocument18 pagesMath ProjectChar LotteNo ratings yet

- Journey by Night EssayDocument2 pagesJourney by Night Essaystillwakingsleep100% (2)

- Irc 097-1987Document10 pagesIrc 097-1987kruttika_apNo ratings yet

- Thuja's Effectiveness Against SmallpoxDocument361 pagesThuja's Effectiveness Against SmallpoxFrank NavaNo ratings yet

- Tempt Me, Marry MeDocument832 pagesTempt Me, Marry MeCharlotte Selin BautistaNo ratings yet

- From Paragraph to Essay: Structure and ComparisonDocument21 pagesFrom Paragraph to Essay: Structure and ComparisonDiego EscobarNo ratings yet

- The Yale-Brown Obsessive Compulsive Scale I. Development, Use, and ReliabilityDocument6 pagesThe Yale-Brown Obsessive Compulsive Scale I. Development, Use, and Reliabilitynurulhafizhah01No ratings yet

- Long Test MILDocument3 pagesLong Test MILBern PabNo ratings yet

- Student Admission FormDocument2 pagesStudent Admission FormOmmsai co2011No ratings yet

- Soal Usbn MGMP Binggris UtamaDocument10 pagesSoal Usbn MGMP Binggris UtamaNurlinah SakkaNo ratings yet

- Chapter - 08 Civics Confronting Marginalisation: Invoking Fundamental RightsDocument2 pagesChapter - 08 Civics Confronting Marginalisation: Invoking Fundamental Rightsnbs saraswathiNo ratings yet

- Notes-RJ Speed Seduction Gold WalkupsDocument7 pagesNotes-RJ Speed Seduction Gold Walkupsdulixuexi100% (1)

- Diabetic Retinopathy: Basic InformationDocument12 pagesDiabetic Retinopathy: Basic InformationipkNo ratings yet

- 7.nuclear Chemistry and Environmental Chemistry ExerciseDocument38 pages7.nuclear Chemistry and Environmental Chemistry ExerciseYogy YNo ratings yet

- Road Kill Cafe MenuDocument1 pageRoad Kill Cafe MenuwjannuschNo ratings yet

- Jounal Club 1 BagavathDocument13 pagesJounal Club 1 Bagavathpraveen kumarNo ratings yet

- Relationship Wide of House VentilationDocument5 pagesRelationship Wide of House VentilationNova RizkenNo ratings yet

- 1Document7 pages1mmNo ratings yet

- PowerStop Shock Absorber CatalogDocument24 pagesPowerStop Shock Absorber CatalogAfiyat Nur100% (1)

- 310 SRU Thermal Reactor Chemistry and Design SRU Buenos Aires 2018Document27 pages310 SRU Thermal Reactor Chemistry and Design SRU Buenos Aires 2018Nastaran BagheriNo ratings yet

- KalasarpaDosha RemedyDocument28 pagesKalasarpaDosha RemedyAnita Kadavergu100% (1)

- !!! CA OPTIWAVE 24-80Ghz Highlights en 170523Document28 pages!!! CA OPTIWAVE 24-80Ghz Highlights en 170523Luz Stella Calixto GomezNo ratings yet

- CSFDocument5 pagesCSFjalan_zNo ratings yet

- HIST2601 HSienaDocument6 pagesHIST2601 HSienaQuinn HarringtonNo ratings yet

- Deccan 12Document4 pagesDeccan 12Ehtesam khanNo ratings yet

- DJ Brothers ISO 22000-2018 ManualDocument40 pagesDJ Brothers ISO 22000-2018 ManualSunith Desai100% (1)

- Tiic Interest RateDocument3 pagesTiic Interest RatePriyaNo ratings yet

- Listado de Precios HADocument6 pagesListado de Precios HAgloria c.fernandezNo ratings yet

- Clear ViewDocument6 pagesClear ViewJamieNo ratings yet

- Hubungan Antara Aktivitas Fisik Dan Screen Time Dengan Status Gizi Pada Siswa-Siswa SMP Kristen Eben Haezar 2 ManadoDocument11 pagesHubungan Antara Aktivitas Fisik Dan Screen Time Dengan Status Gizi Pada Siswa-Siswa SMP Kristen Eben Haezar 2 ManadorezkaNo ratings yet