Professional Documents

Culture Documents

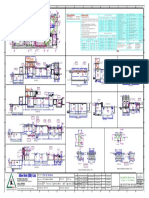

Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/day

Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/day

Uploaded by

Kamrul HasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/day

Alim Knit (BD) LTD.: Plant Capacity: 50 m3/hr Plant Operating Time: 22 Hr/day

Uploaded by

Kamrul HasanCopyright:

Available Formats

1 2 3 4 5 6 7 8

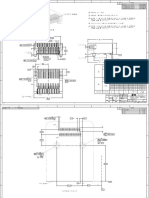

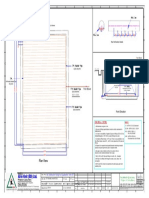

18 Dry Sludge Storage, DSS RCC 6880 L x Ver. W x 3350 D 77.72 -

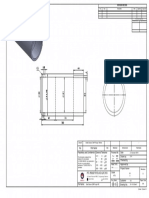

GENERAL NOTES: Chemical Mixing Tank (CMT) Details

5220 L x 3630 W x 2100 D, FB 300 0.68

17 Clear Water Tank, CWT RCC 34

Plant Capacity : 50 m3/hr 1. All dimension are given in mm. 16 Sludge De-watering System, SDS - - - -

A Sl. No. Chemical Mixing Tank Volume Size Mixing Tank Weight

15 Sludge Tank-2, ST-2 RCC 2200 L x 2850 W x 1400 H, FB 400 6.27 - A

Plant Operating Time: 22 hr/day 2. Capacity of all tanks are working capacity, total capacity to be larger. (liter) (mm) (kg)

14 Sludge Tank-1, ST-1 RCC 3200 L x 2850 W x 1800 H, FB 640 10.58 -

1 Lime 3000 1523D x 1943H 4000

3. Hydraulic Retention time (HRT) of effluent is on the basis of peak flow 13 Contact Stabilization Tank, CST RCC 4700 L x 3500 W x 4700 H, FB 300 72.38 1.5

2 FeSO4 3000 1523D x 1943H 4000

rate 50 m3/hr.

12 Platform for Chemical Mixing Tank, PCMT RCC 8550 L x Var. W - -

3 PAM 1500 1257D x 1435H 2500

4. Wall, Roof & Foundation thickness for all recommended 11 Post Aeration Tank, PAT RCC 6960 L x Var. W x 3400 H, FB 400 50 1

4 NaOH 500 927D x 914H 1000

modification construction are estimated, so need to be reviewed 10 Media Filter System, MFS MS 1550Ø x 3350H x 3 Nos. - -

and confirmed by stress analysis. 5 H2SO4 500 927D x 914H 1000

9 Filter Feed Tank, FFT RCC 7800 L x Var. W x 2970 H, FB 350 28.82 0.58

6 Nutrient 1 300 724D x 838H 700

5. All Tanks floor to be sloped 1:200 towards Pump Sump. 8 Secondary Clarifier, SC RCC 7900 Ø x 3000 H, FB 230 136 2.7

7 Nutrient 2 300 724D x 838H 700

7 Aeration Tank, AT RCC 12900 L x 10700 W x 4270 H, FB 400 600 12

6. All Grating to be removable type. 8 PE 1500 1257D x 1435H 2500

B 6 Neutralization Tank, NT RCC 4580 L x Var. W x 4530 H, FB 520 88 1.76

B

7. All stairs, working floor & walkway must have safety fencing & Chemical Service Tank (CST) Details 5 Reactor Clarifier (1st Clarifier), RC RCC 7000 Ø x 4150 H, FB 410 144 2.9

shed to protect from sun and rain. 4 Flocculation Tank, FT RCC 1775 L x 1530 W x 2200 H x 2 Nos, FB 350 10 0.2

8. All internal & external surface to be painted with Epilux, STL/Epilux 5 Sl. No. Chemical Service Tank Volume Size Service Tank Weight 3 Coagulation Tank, CT RCC 1250 Ø x 2440 H, FB 340 2.6 0.05

Coal Tar Epoxy with suitable primer, Berger or equivalent paint. (liter) (mm) (kg) 2 Equalization Tank, ET RCC 12000 L x 9000 W x 3700 D, FB 750 470 9.4

1 Lime 1500 1257D x 1435H 2500 600 W x 750 D - -

Media Filter Units Details 1 Effluent Collection Channel, ECC RCC

2 FeSO4 1500 1257D x 1435H 2500 Working

Item HRT

Volumetric Capacity Size Operating Weight Sl. No. MOC Size Capacity

Sl. No. Item 3 PAM 1000 1067D x 1353H 1500 (HR)

(liter) (mm) (kg) (M3)

4 NaOH 150 558D x 710H 500 Existing Plant PS - Pump Sump,

1 Iron Removing HRT - Hydraulic Retention Time,

Filter, IRF 6000 1550D x 3350H 11000 H2SO4 100 457D x 660H 500 Recommended Modification (Civil) FB - Free Board, DC - Distribution Chamber

5

C 2 Multi Grade

6000 1550D x 3350H 11000 6 Nutrient 1 150 558D x 710H 500 Recommended Modification (Metal Part) Var. - Variable,

IL - Inlet Launder,

Wall - Boundary Wall

FGL - Finished Ground Level

C

Filter, DMF Recommended Pipe Layout TOC - Top of Concrete

7 Nutrient 2 200 724D x 610H 500 DL - Delivery Launder,

3 Activated Carbon BOP - Bottom of Pipe

6000 1550D x 3350H 10000 PE 1000 1067D x 1353H 1500 DP - Delivery Pipe,

Filter, ACF 8 LL - Liquid Level

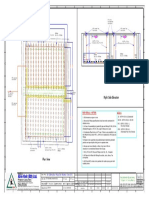

3200 2200

3 4

D CT FT D

39760

14

PS

1780

PS

2850

4000

14

4 ST 1 ST 2

1830

Ø

1250.0000

4 5130

Ø1250

Blower

790

Blower 8

2050 610 Blower SC

300

PS

620

PS

Waste Water Inlet Channel

E Pump

7 9 PS E

6960

1300

2 5 FFT

1400

RC AT 900

ET

8200

Ø7 400

2100 PS 11

17700

00

PAT

70

Ø

14660

12000

12000

12900

PS

Effluent Channel

750

450

F 1 Pump F

ECC 18

6500

Baffle

DSS

6120

10

1400

400 SDS

DC1

5660

5530

5500

6 12 PS 16 MFS

5 6 7

NT PCMT CWT 600

Drain

600 10700 Bore

3940

3800

CST

9000 700

1000

1000

13

DC2

PS Hole

560

1 2 430

3 2910

Effluent Outlet 8

4

3950 Drain 4580

5180 Drain

1220

G Drain Drain Drain G

9000 3440 8090 11500 11450

46000

PLAN

CLIENT:

H

Alim Knit (BD) Ltd.

Project Location:

DWG. TITLE: Plant Layout

DWG. NO.:ETP 50-AKBL-02-PL/R2 SCALE: NTS SHEET: A3

Engr. Jahid Abedin

Engr. Jahid Abedin

Dr. Tarekh Rasul

Dr. Tarekh Rasul

27/11/2018

05/08/2018 H

C:\Users\Jahid\Pictures\Alim logo.jpg

Kashimpur, Nayapara, Gazipur, Bangladesh. Engr. Abu Musa Dr. Tarekh Rasul 13/07/2018

O : PROJECT: 1st Floor, R#12, H#11, Niketan, Gulshan, Dhaka-1212, Bangladesh

Engr. Abu Musa Engr. Shohely Sarker 06/07/2018 Mobile: 01882 433 779, 01841 160101, Email: bedc.bd@gmail.com

Siaam Tower (Level9th 10th), Plot No # 15,117, Mymensingh

PROJECT NO.:ETP-04 START DATE: 30/04/2018 REV. DESCRIPTION DRAWN CHECKED APPROVED DATE SIGNATURE WITH SEAL THIS DRAWING AND ALL INFORMATION CONTAINED HERE ON IS THE PROPERTY OF BEDC. MUST NOT BE COPIED OR

Road, Sector #3, Uttara Model Town Dhaka-1230, Bangladesh. REPRODUCED WITHOUT WRITTEN CONSENT.

1 2 3 4 5 6 7 8

You might also like

- Daily Progress Report: Project: Godrej Commercial Hebbal Project, BangaloreDocument1 pageDaily Progress Report: Project: Godrej Commercial Hebbal Project, BangaloreShiva Kumar RNo ratings yet

- Manual CaseDocument6 pagesManual Casetiago de souza silvaNo ratings yet

- MRNA Vaccines Manufacturing Challenges and BottlenecksDocument12 pagesMRNA Vaccines Manufacturing Challenges and BottlenecksYsrafilKabawoNo ratings yet

- Pneumatic ENDocument9 pagesPneumatic ENFarai ChamisaNo ratings yet

- Pelton Turbine Question AnswerDocument8 pagesPelton Turbine Question AnswerKamrul HasanNo ratings yet

- 12 Volt Hydraulic Pump Mte 4850 PDFDocument1 page12 Volt Hydraulic Pump Mte 4850 PDFpurnomo100% (1)

- Mechanical Engineering Interview Questions With AnswersDocument25 pagesMechanical Engineering Interview Questions With AnswersKamrul HasanNo ratings yet

- Load SensingDocument8 pagesLoad SensingLiebherr100% (1)

- MEPP 457 Hydrogen TechnologiesDocument88 pagesMEPP 457 Hydrogen TechnologiesAshim LamichhaneNo ratings yet

- Microturbines: Applications for Distributed Energy SystemsFrom EverandMicroturbines: Applications for Distributed Energy SystemsRating: 5 out of 5 stars5/5 (1)

- Properties of Dental MaterialsDocument8 pagesProperties of Dental MaterialsSatya Asatya100% (1)

- PP Aaa PP1 128Document19 pagesPP Aaa PP1 128Rabah AmidiNo ratings yet

- Group 4 Travel Device: TYPE 1 (31N3-40010)Document35 pagesGroup 4 Travel Device: TYPE 1 (31N3-40010)АлексейNo ratings yet

- Mix Design C-20Document1 pageMix Design C-20ismail rashdanNo ratings yet

- Sales CatalogDocument32 pagesSales CatalogGURUDATT H MNo ratings yet

- Mongoose Mud Cleaner Spare Parts List-1Document3 pagesMongoose Mud Cleaner Spare Parts List-1bouteraaNo ratings yet

- QHM 2017-18Document16 pagesQHM 2017-18Ravi Kiran MNo ratings yet

- All Metric Dimensions Are in Brackets. Notes:: EQ-P1216-BDocument1 pageAll Metric Dimensions Are in Brackets. Notes:: EQ-P1216-BCy RamosNo ratings yet

- Ct60am 18fDocument2 pagesCt60am 18fKshitiz SrivastavaNo ratings yet

- V381 50 (00205363) DecryptDocument35 pagesV381 50 (00205363) DecryptgalicianmanNo ratings yet

- A7K Final Assembly X01: Torque Conversion TableDocument3 pagesA7K Final Assembly X01: Torque Conversion TableJULIO CESAR GASPAR SANCHEZNo ratings yet

- Media Charge - Dynamics - SAG Mills - ModifiedDocument85 pagesMedia Charge - Dynamics - SAG Mills - Modifiededwin javier valdivia guillenNo ratings yet

- Tank Construction Cost Solution.Document5 pagesTank Construction Cost Solution.Judges ConsultantsNo ratings yet

- Rexroth Open Center ValvesDocument14 pagesRexroth Open Center ValvesZamuel Torres GarcíaNo ratings yet

- Sis 2.0.1Document1 pageSis 2.0.1Yasser Abo AmmarNo ratings yet

- STPL PTS BDocument1 pageSTPL PTS BOktovianus TeguhNo ratings yet

- Man L2832a EngineDocument5 pagesMan L2832a EngineNam Anh TrầnNo ratings yet

- Tank Datasheet - CS-8000KL - RADocument1 pageTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayNo ratings yet

- Production of Purified Terephthalic Acid Using The Spray ProcessDocument2 pagesProduction of Purified Terephthalic Acid Using The Spray ProcessSurya SureshNo ratings yet

- Water Trap OmegaDocument2 pagesWater Trap OmegaSeyedAli TabatabaeeNo ratings yet

- Place Loose Hardware in Polybags. 2. Customer Assembly Drawing Sheet 2. 3. in Use Drawing Sheet 3 and 4. NotesDocument4 pagesPlace Loose Hardware in Polybags. 2. Customer Assembly Drawing Sheet 2. 3. in Use Drawing Sheet 3 and 4. NotesDebabrata SahaNo ratings yet

- Layout Insinerator 03Document1 pageLayout Insinerator 03Bandungmechatronics CenterNo ratings yet

- KOMPLET K JC 805 WebDocument5 pagesKOMPLET K JC 805 WebAlberto LopezNo ratings yet

- Tools Op Specs V8 4258146 01Document1 pageTools Op Specs V8 4258146 01Gharib HashemNo ratings yet

- Vibhutipura Charging Shed BOQ R00Document5 pagesVibhutipura Charging Shed BOQ R00newattelectricNo ratings yet

- Yonah/RC410MD/IXP450 BLOCK DIAGRAMDocument51 pagesYonah/RC410MD/IXP450 BLOCK DIAGRAMKAD kadNo ratings yet

- AC31 Series 90Document3 pagesAC31 Series 90Anderson PelissariNo ratings yet

- PDF Mustang 2066 2076 2086 - CompressDocument20 pagesPDF Mustang 2066 2076 2086 - CompressAlfredo Amaya H. CIA SAS.No ratings yet

- Test Apparatus DesignDocument11 pagesTest Apparatus Designzafarchem_iqbalNo ratings yet

- Eng CD 1761987 C1Document2 pagesEng CD 1761987 C1ZorbanfrNo ratings yet

- Key Elements To Revive The Mature Handil FieldDocument12 pagesKey Elements To Revive The Mature Handil Fieldb mNo ratings yet

- QECX61Document1 pageQECX61Thushianthan KandiahNo ratings yet

- Orion Conveyorized Twin Station Stretch Wrappers CTS Mechanical DrawingsDocument43 pagesOrion Conveyorized Twin Station Stretch Wrappers CTS Mechanical DrawingsTony BravoNo ratings yet

- WT RTA6 96E: Do Not Scale This PrintDocument1 pageWT RTA6 96E: Do Not Scale This PrintGopiNo ratings yet

- Jayson Guansing Dwg-A3-Size - PDF 2Document1 pageJayson Guansing Dwg-A3-Size - PDF 2ADONIS PLATINONo ratings yet

- Ma 149B V4 2000Document1 pageMa 149B V4 2000Antonio CarlosNo ratings yet

- Assy, Led Panel, Osw, Ov-Iii: LP4 LP3Document2 pagesAssy, Led Panel, Osw, Ov-Iii: LP4 LP3Sergio Lopez AranoNo ratings yet

- BRAKE SYSTEM HyundaiDocument6 pagesBRAKE SYSTEM HyundaiAfshin GhafooriNo ratings yet

- Mve SC Series Spec SheetDocument2 pagesMve SC Series Spec SheetБранко ЛуковићNo ratings yet

- INT MT 58 CatalogDocument27 pagesINT MT 58 CatalogSilvio Alfredo Vindell CruzNo ratings yet

- REPEATER IDER ISD25xx - Repeater Ider Isd2590 16f877aDocument1 pageREPEATER IDER ISD25xx - Repeater Ider Isd2590 16f877amanuel contrerasNo ratings yet

- MSAxial Piston MotorCatalogue MA2V v12Document24 pagesMSAxial Piston MotorCatalogue MA2V v12Diệu PhạmNo ratings yet

- 2 Nos. Ver Bracing Required As Drawn MKD' - 2Vb-22: Bolt List For Assembly MKD' 2Vb-22 X 2 Dia. Qty. Bolt GradeDocument1 page2 Nos. Ver Bracing Required As Drawn MKD' - 2Vb-22: Bolt List For Assembly MKD' 2Vb-22 X 2 Dia. Qty. Bolt Grademo3azNo ratings yet

- 4CC-6CC-8CC Spare Parts ListDocument17 pages4CC-6CC-8CC Spare Parts ListJohan SmitNo ratings yet

- F4-PFS205 DiagramDocument21 pagesF4-PFS205 DiagramncirNo ratings yet

- Shaft Sleeve CWP Pump 170mm Revisi PDFDocument1 pageShaft Sleeve CWP Pump 170mm Revisi PDFwawan dweeNo ratings yet

- Certificate of Quality: Paraffinic Process Oil Prosol P-1500 Group IDocument1 pageCertificate of Quality: Paraffinic Process Oil Prosol P-1500 Group ISusi SusilawatiNo ratings yet

- Shaft Sleeve CWP Pump 180mm RevisiDocument1 pageShaft Sleeve CWP Pump 180mm Revisiwawan dweeNo ratings yet

- Intake Screen For River Pump Size 24in-X-24inDocument1 pageIntake Screen For River Pump Size 24in-X-24inmoh. rusli bahtiarNo ratings yet

- Separator TechnologyDocument2 pagesSeparator TechnologysterlingNo ratings yet

- 2023 Sunketess Energy Storage Battery Product BrochureDocument20 pages2023 Sunketess Energy Storage Battery Product BrochureJesse XiaNo ratings yet

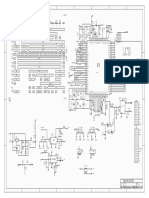

- HP Pavilion DM3 Diagram H310UA1 - HPMH-40GAB4000-D000 - RevdDocument35 pagesHP Pavilion DM3 Diagram H310UA1 - HPMH-40GAB4000-D000 - Revd20230508No ratings yet

- Denah Lokasi Pemboran Sumur Ijn-01: CMT Shop Batch Mixer CMT UnitDocument1 pageDenah Lokasi Pemboran Sumur Ijn-01: CMT Shop Batch Mixer CMT UnitAli Al MufidiNo ratings yet

- Northstar Battery AGM 8DDocument2 pagesNorthstar Battery AGM 8Dcarvalle5No ratings yet

- How Does Francis Turbine Work ?: Runner - at The Heart of The SystemDocument3 pagesHow Does Francis Turbine Work ?: Runner - at The Heart of The SystemKamrul HasanNo ratings yet

- How Different Type of Losses Affect in Centrifugal Pump Frictional LossDocument3 pagesHow Different Type of Losses Affect in Centrifugal Pump Frictional LossKamrul HasanNo ratings yet

- Innovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraDocument51 pagesInnovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraKamrul HasanNo ratings yet

- Nature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Document34 pagesNature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Kamrul HasanNo ratings yet

- Suitability of Pelton, Francis and Kaplan TurbinesDocument2 pagesSuitability of Pelton, Francis and Kaplan TurbinesKamrul HasanNo ratings yet

- About Ice DetailsDocument10 pagesAbout Ice DetailsKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Process Flow Diagram For EtpDocument1 pageAlim Knit (BD) LTD.: Process Flow Diagram For EtpKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: General NotesDocument1 pageAlim Knit (BD) LTD.: General NotesKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Recommended Process Flow DiagramDocument1 pageAlim Knit (BD) LTD.: Recommended Process Flow DiagramKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Plan & SectionsDocument1 pageAlim Knit (BD) LTD.: Plan & SectionsKamrul HasanNo ratings yet

- Advanced Insulationfor Subsea ApplicationDocument2 pagesAdvanced Insulationfor Subsea ApplicationAforbajeNo ratings yet

- Ismos 3 - Passman - Review Fuel System Microbial Conatmination Control Draft MSCRPT FM Ismos-3 Jun 2011Document66 pagesIsmos 3 - Passman - Review Fuel System Microbial Conatmination Control Draft MSCRPT FM Ismos-3 Jun 2011Arluky NovandyNo ratings yet

- Publications SEA HLM 419Document101 pagesPublications SEA HLM 419Devendra NiranjanNo ratings yet

- 002 Deep Drawing GuidelinesDocument34 pages002 Deep Drawing GuidelinesMohit WaniNo ratings yet

- EVAN BLIZZARD - 20-21 PhET Simulation - Molecular GeometryDocument7 pagesEVAN BLIZZARD - 20-21 PhET Simulation - Molecular GeometryEVAN BLIZZARDNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNo ratings yet

- Allen: Aieee - 2012 Test Paper With Answer (Held On Sunday 29 APRIL, 2012)Document5 pagesAllen: Aieee - 2012 Test Paper With Answer (Held On Sunday 29 APRIL, 2012)rishabhk28995No ratings yet

- Chartek 7 Protecting Lives, Protecting Assets BrochureDocument2 pagesChartek 7 Protecting Lives, Protecting Assets BrochureAhmed IbrahimNo ratings yet

- ICSE Class 10th ABSORPTION BY ROOT NotesDocument28 pagesICSE Class 10th ABSORPTION BY ROOT NotesGagan AgrawalNo ratings yet

- Setting of CementDocument15 pagesSetting of CementefaasdfNo ratings yet

- Zoo Lab ActivityDocument1 pageZoo Lab ActivityHarold DavidNo ratings yet

- Salt ConterntDocument4 pagesSalt ConterntChristian JosephNo ratings yet

- Refractory Materials and Systems For Incineration Processes: D. A. JarvisDocument4 pagesRefractory Materials and Systems For Incineration Processes: D. A. JarvisPrince DhakaNo ratings yet

- Ns GroutDocument2 pagesNs GroutKishore Nayak kNo ratings yet

- Fluids Exp 2Document9 pagesFluids Exp 2Ely ReyesNo ratings yet

- Santiago Pena Clavijo - Forrest Foundation Post-Doctoral Fellowships PDFDocument2 pagesSantiago Pena Clavijo - Forrest Foundation Post-Doctoral Fellowships PDFSantiago Peña ClavijoNo ratings yet

- OK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.60: Tig Rods (Gtaw) Mild Steel RodssankuNo ratings yet

- t1-p1-2 Spectra-Structure Correlations in The Mid and Far InfraredDocument34 pagest1-p1-2 Spectra-Structure Correlations in The Mid and Far InfraredCorvusdav EspinNo ratings yet

- K-Vitamin SafetyDocument31 pagesK-Vitamin SafetyvukicsvikiNo ratings yet

- The Effect of Light On Silver Halides: ExperimentDocument3 pagesThe Effect of Light On Silver Halides: ExperimentGerman CarleNo ratings yet

- Term Test 2a, 59-230, 2015, Marking Scheme, Revised PDFDocument10 pagesTerm Test 2a, 59-230, 2015, Marking Scheme, Revised PDFAV&P LordNo ratings yet

- 07a1bs07 Engineering ChemistryDocument7 pages07a1bs07 Engineering ChemistrychemistrymasterNo ratings yet

- Manual de Calentadores A Gas Hayward PDFDocument4 pagesManual de Calentadores A Gas Hayward PDFLuis Eduardo Herrera BonillaNo ratings yet

- Excel UnitOpDocument28 pagesExcel UnitOpChava TututiNo ratings yet

- 19BME073 Plasma Cutting Lab ReportDocument2 pages19BME073 Plasma Cutting Lab ReportMeet LadNo ratings yet

- Sikaflex® Construction+: Product Data SheetDocument4 pagesSikaflex® Construction+: Product Data SheetQuality JamNo ratings yet

- HT Simdis (D7196 - D7500) PDFDocument34 pagesHT Simdis (D7196 - D7500) PDFAMMARNo ratings yet