Professional Documents

Culture Documents

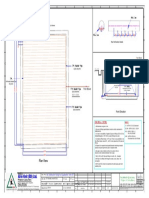

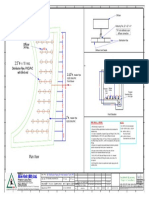

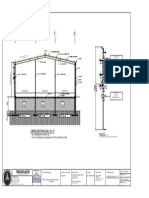

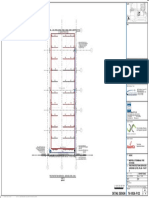

Alim Knit (BD) LTD.: Plan View

Uploaded by

Kamrul HasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alim Knit (BD) LTD.: Plan View

Uploaded by

Kamrul HasanCopyright:

Available Formats

1 2 3 4 5 6 7 8

A A

6"∅ x 2 nos.

Act. Sludge Inlet

GI/SS 304/cPVC

10700

9340 4"∅, Header Pipe 4"∅, Header Pipe

GI/SS 304/cPVC GI/SS 304/cPVC

4"∅, Header Pipe 80 80 80 80 80

GI/SS 304/cPVC 1.1/2"∅ x 16 Nos. Diffuser

Distribution Pipe, PVC/cPVC 16 x 11 = 176 Nos. LL +2650 LL +2650

620

100

100

100

100

230

230

B 1.1/2"∅ x 16 Nos. 1.1/2"∅ x 16 Nos.

B

Distribution Pipe, PVC/cPVC Distribution Pipe, PVC/cPVC

3780

3500

3500

6050

Diffuser Diffuser

Blind 16 x 11 = 176 Nos. Blind

16 x 11 = 176 Nos. Blind Blind

End End

End End

100

100

400 550 550 550 350 350 550 550 550 400

100

C C

6250

4960

4"∅, Header Pipe

GI/SS 304/cPVC

D D

6"∅ x 2 nos.

6"∅, Header Pipe Act. Sludge Inlet

GI/SS 304/cPVC GI/SS 304/cPVC

From Blower

Right Side Elevation

4"∅, Header Pipe

GI/SS 304/cPVC

E E

GENERAL NOTES:

4960

GI - ASTM A 53 Gr.B, Galvanized

6250

1. All dimension are given in mm.

2. Pipe and all fittings specifications should be strictly maintained for SS 304 - ASTM A 240, Gr. SS 304

reliable service. PVC - ASTM D 1785 Gr. I,

3. In Case of unavailability of graded GI pipe and fittings SS 304, 20 Shc. Poly Vinyl Chloride

(Welded/Flanged) or cPVC 40. Shc. pipe & fittings to be used. cPVC - ASTM D 1784 Gr. I,

4. Considered effluent temp. is 40° max. If there is any possibility to rise Chlorinated Poly Vinyl Chloride

F the effluent temp. above 40°C , all PVC to be replaced by cPVC pipe and

F

fittings

5.All pipes to be supported and guided/clamped maintaining standard

practice and span length which given in separate sheet.

620 6. No pipe can be set directly on floor of any tank. 100 mm

4"∅, Header Pipe 1.1/2"∅ x 16 Nos. 16 x 11 = 176 Nos. clearance to be maintained between floor & pipe.

GI/SS 304/cPVC Distribution Pipe, PVC/cPVC Diffuser

7. All GI, PVC & cPVC Pipe and Fittings to be Shc. 40. , threaded.

8. All Pipes to be fitted with fittings like socket, union, elbow, Tee

G as required. G

Plan View 9. All MS and RCC surface to be painted with coalter epoxy paint with

suitable primer.

CLIENT:

H

Alim Knit (BD) Ltd.

Project Location:

DWG. TITLE: Air Distribution Piping for Aeration Tank (AT)

DWG. NO.:ETP 50-AKBL-04-ADP.AT/R1 SCALE: NTS SHEET: A3

H

C:\Users\Jahid\Pictures\Alim logo.jpg

Engr. Jahid Abedin Engr. Shohely Sarker 30/08/2018

Kashimpur, Nayapara, Gazipur, Bangladesh.

O : PROJECT: Engr. Jahid Abedin Engr. Shohely Sarker 14/08/2018

1st Floor, R#12, H#11, Niketan, Gulshan, Dhaka-1212, Bangladesh

Siaam Tower (Level9th 10th), Plot No # 15,117, Mymensingh Mobile: 01882 433 779, 01841 160101, Email: bedc.bd@gmail.com

PROJECT NO.:ETP-04 START DATE: 30/04/2018 REV. DESCRIPTION DRAWN CHECKED APPROVED DATE SIGNATURE WITH SEAL THIS DRAWING AND ALL INFORMATION CONTAINED HERE ON IS THE PROPERTY OF BEDC. MUST NOT BE COPIED OR

Road, Sector #3, Uttara Model Town Dhaka-1230, Bangladesh. REPRODUCED WITHOUT WRITTEN CONSENT.

1 2 3 4 5 6 7 8

You might also like

- 05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1Document1 page05 - Second Floor Beam & Slab Layout Details - r2 (05.08.21) - Sheet-1PackiarajNo ratings yet

- Alim Knit (BD) LTD.: Plan ViewDocument1 pageAlim Knit (BD) LTD.: Plan ViewKamrul HasanNo ratings yet

- 10END30BR001Document1 page10END30BR001Valesh MonisNo ratings yet

- Jis B2316 PDFDocument1 pageJis B2316 PDFOluwachidiNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- VP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Document1 pageVP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Vasilica BArbarasaNo ratings yet

- JFN01 05 033 ADocument1 pageJFN01 05 033 Aluca.laniNo ratings yet

- Asa BR 3Document1 pageAsa BR 3Valdir VidalNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Bouche À Feu3Document1 pageBouche À Feu3Pierre Yves AdamiNo ratings yet

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Document1 page0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadNo ratings yet

- SEE DRAWING 1925-001A - PC For Pull Cord Cable Installation: Req'D QtyDocument1 pageSEE DRAWING 1925-001A - PC For Pull Cord Cable Installation: Req'D QtyYerko NavarroNo ratings yet

- Shuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001Document1 pageShuqaiq 3 Independent Water Project: Ro Building T7 GDF02-001ABAID ULLAHNo ratings yet

- Denah PantryDocument1 pageDenah PantryHERI SURYADINo ratings yet

- Part No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveDocument1 pagePart No. (2pcs) Part No. (4pcs) : 2. All Plate Minimum 6mm or AboveIwan AbdurahmanNo ratings yet

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Bai Tap Kiem Tra Be Nuoc MaiDocument1 pageBai Tap Kiem Tra Be Nuoc MaiTiêu Dao ca caNo ratings yet

- Ilovepdf MergedDocument21 pagesIlovepdf MergedNITHIN MATHEWNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- P1359 SWA S001 - Rev4Document1 pageP1359 SWA S001 - Rev4geethsanNo ratings yet

- 7Document1 page7Modasser NewazNo ratings yet

- F122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanDocument1 pageF122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailNo ratings yet

- Piping Isometric - 10Document1 pagePiping Isometric - 10CosminMarianNo ratings yet

- QDT 310 Dimension Drawing Antwerp 9827 8053 00Document1 pageQDT 310 Dimension Drawing Antwerp 9827 8053 00Uriel JimenezNo ratings yet

- Sewer Line LayoutDocument1 pageSewer Line LayoutDexter GalianNo ratings yet

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISODocument1 pageD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodNo ratings yet

- C.3-141-Temporary Fence H.5MDocument1 pageC.3-141-Temporary Fence H.5MYudi CasanovaNo ratings yet

- Piping Isometric - 7Document1 pagePiping Isometric - 7CosminMarianNo ratings yet

- Lax02 05 122 BDocument1 pageLax02 05 122 Bluca.laniNo ratings yet

- 51062-ADR 70-MEC-025 - 0 - ADR - 2nd Elution - Thermal Pressure ChimneyDocument1 page51062-ADR 70-MEC-025 - 0 - ADR - 2nd Elution - Thermal Pressure ChimneyNur SugiartoNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- FL3B-474-P-2603 As BuiltDocument1 pageFL3B-474-P-2603 As BuiltAlbet MulyonoNo ratings yet

- BL90-30 - 951784Document1 pageBL90-30 - 951784Bps PSNo ratings yet

- 1SBB505165D3501Document2 pages1SBB505165D3501sara ramadanNo ratings yet

- CEGP OC053.2023 DW M 001.rev2Document1 pageCEGP OC053.2023 DW M 001.rev2Milagros MuedasNo ratings yet

- Indus Hospital Floor Plans - 08.06.2020Document13 pagesIndus Hospital Floor Plans - 08.06.2020Ritika AnandNo ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- 3-C-50006-A 1Document4 pages3-C-50006-A 1Yousab CreatorNo ratings yet

- Soot Blower Doc 1Document1 pageSoot Blower Doc 1chandabwNo ratings yet

- 11010P1-DG6206001 0 PDFDocument1 page11010P1-DG6206001 0 PDFNidhin T BNo ratings yet

- Drawing For Lubrication MillDocument2 pagesDrawing For Lubrication MillDeepakNo ratings yet

- HP-Electrical-drawing-MM1121602 6000vDocument12 pagesHP-Electrical-drawing-MM1121602 6000vatanas zafirovNo ratings yet

- The Sweeney My ArrangementDocument4 pagesThe Sweeney My Arrangementbasil tielNo ratings yet

- A2 PDFDocument1 pageA2 PDFEMERSON GAPUZNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- PlanoDocument1 pagePlanoandresNo ratings yet

- Specifications:: Section DDDocument1 pageSpecifications:: Section DDBharani Madamanchi100% (1)

- KEELE Map ColourDocument1 pageKEELE Map ColourHotCatonablankblankNo ratings yet

- 33kV Standard DrawingDocument15 pages33kV Standard DrawingsheshidharrajubNo ratings yet

- J3BGDF02BR025 01 01Document1 pageJ3BGDF02BR025 01 01saleem naheedNo ratings yet

- Str.03-Design of Frame C-B2 To F2-1Document1 pageStr.03-Design of Frame C-B2 To F2-1Khoi DuongNo ratings yet

- 2021 Columbary 12nov A01Document1 page2021 Columbary 12nov A01ice creaNo ratings yet

- Legend:: Ground Floor Lighting Layout Srcond Floor Lighting LayoutDocument1 pageLegend:: Ground Floor Lighting Layout Srcond Floor Lighting LayoutKurt Glenn Dayag MathisNo ratings yet

- Bar Bending Schedule: 2000mm Wide X 5990mm Long TroughDocument92 pagesBar Bending Schedule: 2000mm Wide X 5990mm Long TroughanoginNo ratings yet

- 2016 07 18 Avidxchange RCP 1st 2nd 1Document2 pages2016 07 18 Avidxchange RCP 1st 2nd 1Harold Christian UpaoNo ratings yet

- Gasmasr DrawingsDocument13 pagesGasmasr Drawingsmostafa eshmawyNo ratings yet

- Differential: Powered By, Asif Zahidul Haq Mpe - 5 Batch Team AbhijatrikDocument7 pagesDifferential: Powered By, Asif Zahidul Haq Mpe - 5 Batch Team AbhijatrikKamrul HasanNo ratings yet

- Innovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraDocument51 pagesInnovating Industrial Design Curriculum in A Knowledge-Based, Participatory and Digital EraKamrul HasanNo ratings yet

- ThermodynamicsDocument26 pagesThermodynamicsSathya NarayananNo ratings yet

- 151 ADocument19 pages151 AViru JaiNo ratings yet

- ThermodynamicsDocument26 pagesThermodynamicsSathya NarayananNo ratings yet

- Mechanical Measurements and Instrumentation Digital MaterialDocument256 pagesMechanical Measurements and Instrumentation Digital MaterialSai Praneeth100% (1)

- Nature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Document34 pagesNature of Industrial Designs: Subject-Intellectual Property Rights (Paper 2)Kamrul HasanNo ratings yet

- Home WorkDocument152 pagesHome Workra44993541No ratings yet

- Pelton Turbine Question AnswerDocument8 pagesPelton Turbine Question AnswerKamrul HasanNo ratings yet

- Suitability of Pelton, Francis and Kaplan TurbinesDocument2 pagesSuitability of Pelton, Francis and Kaplan TurbinesKamrul HasanNo ratings yet

- How Different Type of Losses Affect in Centrifugal Pump Frictional LossDocument3 pagesHow Different Type of Losses Affect in Centrifugal Pump Frictional LossKamrul HasanNo ratings yet

- Chapter3 AnswersDocument3 pagesChapter3 AnswersKamrul HasanNo ratings yet

- How Does Francis Turbine Work ?: Runner - at The Heart of The SystemDocument3 pagesHow Does Francis Turbine Work ?: Runner - at The Heart of The SystemKamrul HasanNo ratings yet

- IAST Lect05 PDFDocument16 pagesIAST Lect05 PDFKevin JoseNo ratings yet

- Air ChargingDocument4 pagesAir ChargingARUNGREESMANo ratings yet

- About Ice DetailsDocument10 pagesAbout Ice DetailsKamrul HasanNo ratings yet

- Abedin-2013-Energy Balance of inDocument14 pagesAbedin-2013-Energy Balance of inMochamad SolehNo ratings yet

- Qip Ice 08 Fuel Air CyclesDocument20 pagesQip Ice 08 Fuel Air CyclesGaurav DahiyaNo ratings yet

- IC EngiesDocument28 pagesIC EngiesAshwyn VinayNo ratings yet

- Ci EnginesDocument32 pagesCi EnginesammuvarshNo ratings yet

- IC EnginesDocument15 pagesIC Enginesjegan172No ratings yet

- Combusion in ICEDocument14 pagesCombusion in ICEMachineryengNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- Solidwize: Online Solidworks TrainingDocument9 pagesSolidwize: Online Solidworks Trainingjuanito pipas0% (1)

- Alim Knit (BD) LTD.: Process Flow Diagram For EtpDocument1 pageAlim Knit (BD) LTD.: Process Flow Diagram For EtpKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: General NotesDocument1 pageAlim Knit (BD) LTD.: General NotesKamrul HasanNo ratings yet

- X 10 Nos.: Alim Knit (BD) LTDDocument1 pageX 10 Nos.: Alim Knit (BD) LTDKamrul HasanNo ratings yet

- Alim Knit (BD) LTD.: Coagulation Tank With AgitatorDocument1 pageAlim Knit (BD) LTD.: Coagulation Tank With AgitatorKamrul HasanNo ratings yet

- Gas StoichiometryDocument9 pagesGas StoichiometryJoshua RomeaNo ratings yet

- Masculine Ideal in The Old Man and The SeaDocument5 pagesMasculine Ideal in The Old Man and The Seaapi-295869808No ratings yet

- 90 + 100 + 5 - 7. 5 Tens, 3 Hundreds, 8 Ones - 8. 400 + 1000 + 20 + 8 - 9. 5 Hundreds, 6 Tens, 9 Ones - 10. 1 Hundred, 1 Thousands, 3 OnesDocument2 pages90 + 100 + 5 - 7. 5 Tens, 3 Hundreds, 8 Ones - 8. 400 + 1000 + 20 + 8 - 9. 5 Hundreds, 6 Tens, 9 Ones - 10. 1 Hundred, 1 Thousands, 3 OnesLorna HerillaNo ratings yet

- BuiltLean Get Lean GuideDocument22 pagesBuiltLean Get Lean Guideirda100% (1)

- Manonmaniam Sundaranar University: B.B.A. - Ii YearDocument61 pagesManonmaniam Sundaranar University: B.B.A. - Ii YearLovely Dhanaa4848No ratings yet

- Make An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Document5 pagesMake An Acknowledgment Receipt Showing A Full Payment of A Loan (Extinguishment by Payment)Kim Cyrah Amor GerianNo ratings yet

- The Economic Report of The PresidentDocument35 pagesThe Economic Report of The PresidentScribd Government DocsNo ratings yet

- Islamic Gardens: The Model of Alhambra Gardens in Granada: October 2020Document29 pagesIslamic Gardens: The Model of Alhambra Gardens in Granada: October 2020Yuna yasillaNo ratings yet

- Definition and Characteristics of LawDocument7 pagesDefinition and Characteristics of LawJeannylyn NavarroNo ratings yet

- West Olympia Background Reports 14Document122 pagesWest Olympia Background Reports 14Hugo Yovera CalleNo ratings yet

- TVM-Excel Function Solved ProblemDocument16 pagesTVM-Excel Function Solved ProblemIdrisNo ratings yet

- Supplementary: Materials inDocument5 pagesSupplementary: Materials inEvan Siano BautistaNo ratings yet

- Roman Empire Revived TheoryDocument173 pagesRoman Empire Revived TheoryBrenoliNo ratings yet

- Multiple Choice Questions: Energy and MetabolismDocument75 pagesMultiple Choice Questions: Energy and MetabolismJing LiNo ratings yet

- ELT Catalog Secondary PDFDocument26 pagesELT Catalog Secondary PDFRafael Cruz IsidoroNo ratings yet

- Courtney Loper-ResumeDocument2 pagesCourtney Loper-Resumeapi-354618234No ratings yet

- (Socks, Shoes, Watches, Shirts, ... ) (Index, Middle, Ring, Pinky)Document7 pages(Socks, Shoes, Watches, Shirts, ... ) (Index, Middle, Ring, Pinky)Rosario RiveraNo ratings yet

- Axie Infinity Reviewer - by MhonDocument29 pagesAxie Infinity Reviewer - by MhonGodisGood AlltheTime100% (2)

- Atty. SungaDocument22 pagesAtty. SungaKris MercadoNo ratings yet

- BYD Case StudyDocument12 pagesBYD Case StudyELIZANo ratings yet

- HOME ECO (Decision Making 1-3)Document3 pagesHOME ECO (Decision Making 1-3)Ruth Belle HolgadoNo ratings yet

- Magness - The Tomb of Jesus and His Family - Exploring Ancient Jewish Tombs Near Jerusalem's Walls Book ReviewDocument5 pagesMagness - The Tomb of Jesus and His Family - Exploring Ancient Jewish Tombs Near Jerusalem's Walls Book Reviewarbg100% (1)

- The Achaeans (Also Called The "Argives" or "Danaans")Document3 pagesThe Achaeans (Also Called The "Argives" or "Danaans")Gian Paul JavierNo ratings yet

- Special Power of Attorney 2017-Michael John Dj. OpidoDocument2 pagesSpecial Power of Attorney 2017-Michael John Dj. OpidoJhoanne BautistaNo ratings yet

- Inventory Management (Pertemuan V)Document85 pagesInventory Management (Pertemuan V)Asep RahmatullahNo ratings yet

- Defence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Document3 pagesDefence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Siddharth MuthukumarNo ratings yet

- Nephrology and HypertensionDocument33 pagesNephrology and HypertensionCarlos HernándezNo ratings yet

- 7 P's of McDonaldsDocument11 pages7 P's of McDonaldsdd1684100% (4)

- Magic Maze: Props IncludedDocument4 pagesMagic Maze: Props IncludedarneuhüdNo ratings yet

- Syllabus Mathematics (Honours and Regular) : Submitted ToDocument19 pagesSyllabus Mathematics (Honours and Regular) : Submitted ToDebasish SharmaNo ratings yet