Professional Documents

Culture Documents

IJETER Vol 8 Issue 9 M 01

Uploaded by

ashar shidqiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IJETER Vol 8 Issue 9 M 01

Uploaded by

ashar shidqiCopyright:

Available Formats

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

Optimization on the Hydrolysis Process of Cellulose

From Corn Husk To Glucose with Activated Carbon

Catalyst Sulfonated

Didi Dwi Anggoro

Department of Chemical Engineering, Faculty of Engineering

Diponegoro University, Semarang, Indonesia

anggorophd@gmail.com

Ashar Shidqi

Master Program of Chemical Engineering, Faculty of Engineering

Diponegoro University, Semarang, Indonesia

asharshidqi@gmail.com

Abstract – The purpose of this research was to determine the chain polysaccharide of 1,4β-glycosidic which binds in a D-

optimization from the hydrolysis process using an activated glucose unit [2]. This cellulose can replace fossil sources used

carbon catalyst to convert cellulose to glucose. The design of this as fuel, because cellulose is a renewable source of biomass

research consisted of four stages, that is manufacture of

[3].

catalysts, cellulose hydrolysis process, glucose yield test and

Corn husk has a high cellulose fiber content, so it is suitable for

optimization process. The research data is plotted in a

mathematical model that is optimized using software of Statistica conversion to glucose by hydrolysis. Cellulose is the main

10 with Response Surface Methodology (RSM) and ANOVA element needed in making glucose. The results of Prasetyawati's

methods. From the RSM method was obtained mathematical study (2015) stated that the chemical composition of corn husk

equation model for the relationship of the combination of included 19,05% lignin; 6,47% ash; 5,80% hemicellulose; and

temperature, time and amount of catalyst to glucose levels, that 68,68% cellulose. Dried corn husks can be hydrolyzed using solid

is: Y = 25,0457 + 0,579x1 – 0,111x12 + 6,471x2 + 2,798x22 + 4,697x3 acid catalysts that are environmentally friendly [4].

+ 2,965x32 + 1,241x1x2 + 0,996x1x3 + 0,675x2x3. ANOVA method The following table contains the composition of the skin content

produces a value of determination coefficient (R2) as big 0.91545.

of corn:

In this research, the optimum temperature is at 70°C, the

Table 1.1 Chemical Composition of Corn Husk.

optimum time is at 2 hours, and the optimum amount of catalyst

is at 11 grams. Results of Glucose yield obtained from the Chemical Composition Corn Husk (%)

optimal operating conditions is 31%. Cellulose 68,68

Hemicellulose 5,80

Keywords: RSM Method; ANOVA Method, Cellulose, Activated Lignin 19,05

Carbon Catalyst, Glucose. Ash 6,47

Source : Prasetyawati's study (2015)

1. INTRODUCTION The Generally, reaction of cellulose hydrolysis can be expressed

During this time corn husk waste is not utilized maximally, as follows:

So that it disturbs the surrounding environment. Usually (C6H10O5)n + nH2O nC6H12O6

unused corn husk waste is immediately burned. The The degree of cellulose polymerization is indicated by the length

consequence is air pollution everywhere which can interfere of the polymer chain, which is n. Decreasing 1 mole of cellulose

with breathing. So the corn waste, especially the husk should will produce n moles of glucose. Based on this reaction equation,

be used to reduce environmental pollution. Based on BPS data cellulose hydrolysis can actually be done using only water, but

for 1993 - 2018, the average corn production in Indonesia hydrolysis like this requires a very long time. To speed up the

reaches 15 million tons per year [1]. reaction, a catalyst needs to be added, which can be done using a

In this research, corn husk will be hydrolyzed cellulose to get catalyst of sulfonated activated carbon [5].Cellulose molecules are

glucose. Cellulose is an organic compound which is a straight

ISSN: 2454-6410 ©EverScience Publications 1

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

microfibils of glucose which are bound to one another to form very long polymer chains [6].

Mechanism of cellulose hydrolysis reaction that begins with the Therefore an optimization is needed to determine the

reaction of protons from acids that interact with hydrogen bonds optimum conditions of hydrolysis which includes hydrolysis

in cellulose. Oxygen that connects two glucose molecules and temperature, hydrolysis time and the addition of the amount

forms a conjugate acid. Breaking the C-O bond and breaking the of catalyst [6]. Determination of optimization in the process

conjugate acid into a carbonium ion ring. Adding water (H2O) of cellulose hydrolysis from corn husk using the Response

will release glucose and proton molecules [7]. Surface Methodology (RSM) method with the help of

The technology used in hydrolyzing cellulose is acid software statistica 10.

hydrolysis and enzyme hydrolysis. Both have drawbacks in

the process of hydrolysis which the drawbacks that generate 2. METODOLOGY

waste which is very dangerous and also make use of acid and 2.1. Materials

enzyme costs are very expensive. Hydrolysis technology

The materials used in this study are as follows: solution of

using sulfonated activated carbon catalyst is the right solution, technical H2SO4 96%, dried corn husk, aquades, benedict

because it does not cause hazardous waste and in terms of cost solution, activated carbon from coconut shell

is also very relatively cheap [8].

Based on research of Rispiandi (2015), Explain that the 2.2. Experimental Procedure

results of the sulfonated activated carbon catalyst performance In this research, three variables are used to be tested. These

test from a coconut shell have a very significant effect on the variables are the hydrolysis temperature, hydrolysis time, and

reaction of cellulose into glucose. this is due to the more the addition of the amount of catalyst. The hydrolysis

catalysts, the more protons that play a role in chemical temperature is given a lower limit, a middle limit, an upper

reactions. In accordance with Xiang et al (2005) who limit of 500C, 700C and 900C. Hydrolysis time is given a limit

concluded that the higher the concentration of acid, the faster of 1 hour, 2 hours and 3 hours. While the amount of catalyst

the reaction time because more and more available H + is 3 grams, 6 grams and 9 grams. After that it was run using

groups. Thus, so many catalysts are used in this variable, software of statistica 10 and obtained 16 runnings as a

benchmark experiment. After carrying out the hydrolysis

resulting in% yield and cellulose conversion to glucose also

process, glucose results from the hydrolysis filtrate were

increases. tested qualitatively using benedict solution and quantitatively

Based on the research of Ashadi (2013), glucose levels using a spectrophotometer. Glucose test results were

produced from the hydrolysis process are influenced by the optimized by the Response Surface Methodology (RSM)

hydrolysis temperature, hydrolysis time and the addition of method with the help software of Statistica 10 so that the

the amount of catalyst. Increasing the reaction temperature in optimum conditions of cellulose hydrolysis from corn husk

the hydrolysis process would lower glucose levels resulting obtained in the form of temperature, time and the addition of

from glucose that is formed will be degraded further [12]. catalysts.

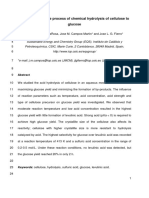

H2SO4 96% Solution Activated Carbon 250 g Fresh Corn Husk

Sulfonation Reaction in the Reaction Flask Washed Clean

with a Temperature 200 0C

Dried

Cooled at Room Temperature

Sulfonated Activated

Aquades

Cut into Small Pieces Carbon Catalyst

Filtering by Vacuum Pump

Sieved with a Size of Hydrolysis Using an

Washing with Aquades to Neutral pH (pH 7) 30 mesh Autoclave Reactor

Drying with Temperature of 100 0C to a Separation of Catalyst

Constant Weight and Filtrate

Characterzation of Sulfonated Activated Analysis of Glucose Yield Using

Carbon Catalyst Including SEM and BET Tests Sepectrophotometer UV-Vis

RESULTS

Figure 2. Flow AND

ChartDISCUSSIONS

of Hydrolysis Process

Figure 1. Flow Chart of Catalyst Making

ISSN: 2454-6410 ©EverScience Publications 2

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

3. Experimmental Results unit area of the sample. surface area is influenced by particle

size, pore size, pore shape and pore arrangement in particles.

The results of this research are listed in table 1 which shows

Identification of surface area of sulfonated activated carbon

that the highest glucose yield were obtained 31%. The

was carried out by a BET (Brunaur Emmet Teller) test. Based

relationships between the three independent variabels

on the analysis of these test results it is known that activated

(temperature of hydrolysis, time of hydrolysis and additional

carbon from coconut shell has a surface area of 51.372 m2/g.

amount of catalyst) and glucose yield were research [13].

3.1. Characteristics of Activated Carbon Sulfonated 3.2. Test of Catalyst Performences

The surface of activated carbon can be seen using a Scanning From this table the results of the glucose yield test using this

Electron Microscope (SEM) to determine the presence of spectrophotometer can be seen that the highest glucose yield

large pores on the surface of activated carbon. Test results of values were obtained with variables with operating conditions

SEM that appear and shape of the catalyst surface at a temperature of 700C, 2hours time and the amount of

morphology are amorphous so that the chance for a reaction is catalyst 11 grams glucose yield reached 31%. This is because

even greater. The shape of the catalyst surface influences the there is a saturation point during the process of cellulose

interaction of the reaction process [14]. From the SEM test hydrolysis, so that at excessive temperatures can cause

results for 3000x magnification obtained the following glucose yield to be demaged. The excess catalyst will also

results: interfere with the hydrolysis process cellulose. This is also

influenced by the temperature treatment, the amount of

catalyst and different time, so that the glucose yields obtained

are also different. This is due to the increase in reaction

temperature, the length of reaction time and the addition of

excess catalysts which can accelerate the hydrolysis process

which results in breaking the lignin and cellulose bonds [13].

Other than that, In addition, increasing the temperature, time

and amount of catalyst can increase the rate of hydrolysis

reaction. An increase in the rate of this reaction can affect the

operation of the hydrolysis process. If the operating

conditions are made in excess, then the glucose yield will be

degraded, thereby causing glucose yield can be decreased

[16]. Therefore, look for the value of the most optimum

Figure 3. Result Test of Sulfonated Actived Carbon Catalyst

conditions, so that the glucose yield can be obtained results

With SEM

the most. Research data shows that the most glucose yield is

The SEM test results show that the surface morphology of the produced under optimal conditions is not excessive (Number

catalyst is amorphous (arranged irregularly) so that the chance of Experimental Run 13).

The SEM test results show that the surface morphology of the The highest glucose yield can be achieved by adding a

catalyst is amorphous (arranged irregularly) so that the chance sulfonated activated carbon catalyst. this is due in the

of a reaction is even greater (Figure 1). The shape of the hydrolysis process, the H + group from the acid will change

catalyst surface influences the interaction of the reaction

the group of cellulose fibers present in the husk of corn into

process. For SEM sulfonated activated carbon the surface

structure appears more open compared to activated carbon free radical groups. a free radical group of cellulose fibers

before disulfonation [9]. which then binds to the OH- group of aquades and reacts with

With the same magnification of 3.000x it is seen that the hydrogen bonds on cellulose, thus forming a large amount of

morphological structure of the activated sulfonated carbon is reducing sugars. when a large acid concentration results from

more open, so that reactants (cellulose) more easily enter the the addition of a solid acid catalyst, the need for H + ions is

surface of the catalyst so that it is possible to interact more very fulfilled, so that free radical groups formed from

easily with H + groups that are bound to the surface and form cellulose and glucose are formed very maximal. the more H +

glucose [9]. groups as binding of free radicals that are formed, the more

In the field of nanomaterial BET can be used to measure glucose is formed. this is because the H+ group which makes

surface area. The purpose of BET testing is to determine the the cellulose fiber group binds to OH-.

surface area of the active side on the sulfonated activated

carbon catalyst. Surface area is the number of pores in each

ISSN: 2454-6410 ©EverScience Publications 3

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

Table 1. Test results for glucose yield

Experimental Temperature of Additional amount Time of hydrolysis Glucose yield

Run hydrolysis (0C) of catalyst (grams) (hours) (%)

1 50 3 1 11

2 90 3 1 14

3 50 9 1 17

4 90 9 1 20

5 50 3 3 23

6 90 3 3 25

7 50 9 3 27

8 90 9 3 28

9 70 6 1 16

10 70 6 0,5 15

11 70 6 4 28

12 70 1 2 15

13 70 11 2 31

14 35 6 2 9

15 105 6 2 29

16 70 6 2 25

3.3. Optimization Using RSM Method The accuracy of the mathematical model can be analyzed with

The results of the research were analyzed by the RSM method ANOVA which is shown in table 2. The accuracy of this

with the help software of statistical 10 to find out the most method can be seen from the coefficient of determination

optimal conditions. The results of the optimization process (R2), which reached 0.91545. Value of R2 The closer it is to

obtained matamatis equation 1 is a model that shows the number 1, the better the ANOVA analysis results related to

relationship between the hydrolysis temperature, hydrolysis the results of research conducted [17]. This indicates that

time and the weight of activated carbon catalyst of the glucose 91.545 % of the total variation in the results obtained is

content is expressed as the following equation: represented in the model. The accuracy of this model can also

Y = 25,0457 + 0,579x1 – 0,111x12 + 6,471x2 + 2,798x22 + be seen from the results of the calculation of the F (ratio of

4,697x3 + 2,965x32 + 1,241x1x2 + 0,996x1x3 + 0,675x2x3. mean square) value is greater than the value of P (probability)

[18]. The values of F (ratio of mean square) showed

Descripton: Y = Yield of glucose (%) statistically significant regression results at the level of 5%.

x1 = Temperature of hydrolysis For a value of P (proability) less than 0.05, then the variable

(0C) is very influential in getting the yield [19]. Analysis of

x2 = Time of hydrolysis (hours) variants obtained from software of Statistica 10 can be seen in

x3 = amount of catalyst (grams) Table 2.

Table 2. Variant Analysis with ANOVA Method

Effect SS Df MS F P R2

x1 15,9730 2 15,9730 1,7588 0,4330 0,91545

x12 50,1514 2 50,1514 7,3481 0,0551

x2 55,8993 2 55,8993 9,0455 0,0112

x22 53,1018 2 53,1018 7,2393 0,0560

x3 0,5534 2 0,5534 0,0621 0,9836

x32 57,8076 2 57,8076 8,2020 0,0865

x1x2 5,0957 2 5,0957 0,5923 0,5945

x1x3 20,1526 2 20,1526 3,8995 0,3911

x2x3 18,7354 2 18,7354 5,1217 0,2554

Error 42,5262 6 6,887

Total SS 303,3013 24

ISSN: 2454-6410 ©EverScience Publications 4

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

Analysis of the optimum operating conditions can use that independent variable and the dependent variable z axis shows.

response surface analysis using charts and graphs of 3- In the contour graph of surface areas of color, so that it can be

dimensional optimization surface contours. Graph 3 seen from this graph the point - the point of interaction of two

dimensional optimization consists of two independent variables results in a clear, where by the most optimal

variables and one dependent variable, so that one other interaction is located in the oldest red area [21] .The graph

variable is a constant number [20]. The axis of x and y are the can be seen in the image below:

Figure 4. Graph contour of hydrolysis temperature vs time hydrolysis reaction

Figure 5. Graph contour of temperature hydrolysis reaction vs addition amount of catalyst

Figure 4 shows that the most optimum glucose level is in the reacehed 31% with mathematical equations Y = 25,0457 +

temperature range of 700C to 900C and the optimum time on 0,579x1 – 0,111x12 + 6,471x2 + 2,798x22 + 4,697x3 + 2,965x32

the range of 2 to 4 hours. Whereas in Figure 5 shows that the + 1,241x1x2 + 0,996x1x3 + 0,675x2x3. Values of R2 predicted

addition of amount the most optimum on catalyst is in the with the model can approach the values obtained from the

range of 10 grams - 12 grams. results of experimental which is 0,91545.

3. CONCLUSION REFERENCES

[1] E. Prasetyawati, R. and Ratih, Chemical Composition of Corn Husk.

The process of cellulose hydrolysis reaction from corn husk Bandung, 2015.

using sulfonated activated carbon catalyst resulted in [2] G. W. Huber, “Rane Ni-Sn Catalyst for H2 from Biomass – Derived

optimum operating conditions at 700C, 2 hours and 11 grams Hydrocarbons,” J. Sci., vol. 30, no. 2, pp. 205 – 208, 2003.

of catalyst. In that optimum conditions, glucose levels [3] P. C. Badger, “Ethanol From Cellulose: A General Review,”

ISSN: 2454-6410 ©EverScience Publications 5

International Journal of Emerging Technologies in Engineering Research (IJETER)

Volume 8, Issue 9, September (2020)

Alexandria ASHS Press., vol. 25, no. 7, pp. 17–21, 2002. [17] G. B. Borglum, “Starch Hydrolysis for Cellulose Production,” J. Arbor

[4] G. Wilson, J.R., Rees, M., Holst, N., Thomas, M.B. and Hill, “Waste Sci. Michigan, vol. 23, no. 5, pp. 297–310, 2015.

and biomass of corn husk biological and integrated control of corn [18] A. N. M. Z. Alizera Z, Aishah Nor S. A, Talibien A, “Immobilized

husk waste.,” in Canberra, ACIAR Proceeding, 2011, vol. 102, no. 7, lipase- catalyzed transesterification of Jatropha curcas oil:

pp. 271–281. Optimization and Modelling,” J. Taiwan Inst. Chem. Eng., vol. 17, no.

[5] F. Ahmad and Kun Harisman, “Ratio of The Effectiveness of Making 5, pp. 445–451, 2013.

Glucose From Waste Paper With Hydrolysis Process of Acids and [19] Y. Wyman, C. E., Dale, B. E., Elander, R. T., Holtzapple, M., Ladisch,

Enzymes,” J. Nat. Mater. Technol., vol. 1, no. 1, pp. 6–11, 2017. M. R., and Lee, “Optimization of Coordinated development of leading

[6] C. E. Yang Bairus and Wayman, “Biotechnology for Cellulosic biomass pretreatment technologies,” Bioresour. Technol., vol. 96, no.

Glucose,” Chem. Eng. Sci., vol. 65, no. 23, pp. 555–563, 2017. 23, p. 159–166., 2015.

[7] Z. Joksimovic, G., and Markovic, “Investigation of the Mechanism of [20] M. S. and E. M. De Idral Daniel, “The Making of Bioethanol From

Acidic Hydrolysis of Cellulose,” Acta Agric. Serbica J., vol. 12, no. Sago Palm Waste With Process Hydrolysis of Acid and Using

24, pp. 51–57, 2017. Saccharomyces cereviseas,” J. Chem. Unand, vol. 1, no. 2, pp. 39–45,

[8] F. Andrussy, P. Cercey, Hamelinck, C. N, and van Hooijdon G, 2015.

“Prospectc For Ethanol From Lignocellulosic Biomass: Techno - [21] Putri Anggraeni and Zaqiah Addarojah, “Hydrolysis of Water

Econmic Performance As Development Progresses,” Utrecht Hyacinth Cellulose to Glucose With Catalys of Sulfonated Activated

University, 2005. Carbon,” J. Chem. Ind. Technol., vol. 2, no. 3, pp. 63–69, 2013

[9] D. Dwi. Anggoro, P. Purwanto, and Rispiandi Rispiandi, “Hydrolysis

of Eichhornia Crassipes to Glucose Over Sulfonated Active Carbon

Catalyst,” Malaysian J. Fundam. Appl. Sci., vol. 11, no. 2, pp. 67–69, Authors

2015. Didi Dwi Anggoro optained his Professor degree

[10] T. Reynando, W. Xiang Qian, Lee Y.Y., Petterson Par O., from Diponegoro University, Semarang, Central

“Heterogeneous Aspects of Acid Hydrolysis of α-Cellulose.,” Appl. Java, Indonesia. He has interest in research areas

Biochem. Biotechnol., vol. 103, no. 24, pp. 505–514, 2005. Catalyst and Chemical Reaction Process. He

[11] R. W. Ashadi, “Liquid and solid sugar manufacture of Pod Brown achieved his Ph.D from Malaysia at 2003. There

using sulfuric acid, enzymes and a combination of both,” Elsevier are quite a few number of conference proceedings

B.V., Bogor, 2013. and journal publications are in his profile.

[12] T. Brandberg, “Continuous fermentations of Undetoxified Dilute Acid

Lignocellulose Hydrolysate by Saccharomyces cerevisae ATCC 96581

Using cell Recirculation,” Biotechnol. Prog., vol. 25, no. 17, pp. 21– Ashar Shidqi He is still in the process of

26, 2005. completing his education at the Masters Program

[13] H. Sun, F., and Chen, “Enhanced enzymatic hydrolysis of wheat straw at Diponegoro University, Semarang, Indonesia.

by aqueous glycerol pretreatment,” Bioresour. Technol., vol. 99, no. his research interest in the field of simulation

21, pp. 656–661, 2018. processes using chemical engineering software.

[14] Q. Wicanda, Mochida Isao, Ho Yoon Seong, “Catalysts in Syntheses He obtained his bachelor's degree from Semarang

and Carbon Precusors,” J. Brazil Chem. Sociation, vol. 17, no. 6, pp. State University in 2018.

159–173, 2016.

[15] L. Rachona, E. Fan, S., Daniel J, Riley Cyntia J, Dowe Nancy, Farmer

Jody, Ibsen Kelly N., Ruth Mark J, Toon Susan T, “A glucose process

development unit: initial operating experiences and result with a corn

fiberstock,” Bioresour. Technol., vol. 91, no. 6, pp. 179–188, 2014.

[16] Q. Zubir, C. A., Sanchez, and O. J., “Glucose production: Process

design trends and integration opportunitis,” Chemie Ing. Tech., vol. 9,

no. 5, pp. 252–257, 2017.

ISSN: 2454-6410 ©EverScience Publications 6

You might also like

- Ijeter 95892020Document5 pagesIjeter 95892020ashar shidqiNo ratings yet

- Amezcua-Allieri Et Al 2017 Study of Chemical and Enzymatic Hydrolysis of CellulosicDocument11 pagesAmezcua-Allieri Et Al 2017 Study of Chemical and Enzymatic Hydrolysis of CellulosicKike CamNo ratings yet

- ViewFreeArticle PDFDocument5 pagesViewFreeArticle PDFMaria Alyssa EdañoNo ratings yet

- Kumar 2015Document8 pagesKumar 2015sanjiv KumarNo ratings yet

- Optimization of Sugar Cane Bagasse Pretreatment Process Using RSMDocument10 pagesOptimization of Sugar Cane Bagasse Pretreatment Process Using RSMInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Published ProceedingsDocument8 pagesPublished ProceedingsmagribisnisNo ratings yet

- Maktum - BioresTech - Reduced SizeDocument8 pagesMaktum - BioresTech - Reduced SizeArief WidjajaNo ratings yet

- Ampas SaguDocument9 pagesAmpas Sagumardian azuraNo ratings yet

- Decolorization and Chemical Regeneration of Granular Activated Carbon Used in Citric Acid RefiningDocument8 pagesDecolorization and Chemical Regeneration of Granular Activated Carbon Used in Citric Acid RefiningWaheed Ahmad BhattiNo ratings yet

- Green Synthesis of Sulfonated Activated Carbon From Palm Kernel ShellDocument7 pagesGreen Synthesis of Sulfonated Activated Carbon From Palm Kernel ShellAnnis DesfiNo ratings yet

- Biomass and BioenergyDocument14 pagesBiomass and BioenergyJelian GraceNo ratings yet

- K. Optimization of Hydrolysis Conditions Using CentralDocument12 pagesK. Optimization of Hydrolysis Conditions Using CentralAbreham BekeleNo ratings yet

- Biogas Potential From Anaerobic Co-Digestion of Faecal Sludge With Food Waste and Garden WasteDocument9 pagesBiogas Potential From Anaerobic Co-Digestion of Faecal Sludge With Food Waste and Garden WasteGreen MyanmarNo ratings yet

- Clean Production of Corn Stover Pulp Using Koh+Nh Oh Solution and Its Kinetics During DelignificationDocument9 pagesClean Production of Corn Stover Pulp Using Koh+Nh Oh Solution and Its Kinetics During DelignificationSagar DhuriNo ratings yet

- Jin 2017Document8 pagesJin 2017Marielle BanzonNo ratings yet

- Enzymatic Saccharification of Sugarcane Bagasse Using Ash - Supplemented Hydrogen Peroxide As Pre-TreatmentDocument15 pagesEnzymatic Saccharification of Sugarcane Bagasse Using Ash - Supplemented Hydrogen Peroxide As Pre-TreatmentIJAERS JOURNALNo ratings yet

- FTIR and SEM Analysis of Thermo Chemical Fractionated Sugarcane BagasseDocument7 pagesFTIR and SEM Analysis of Thermo Chemical Fractionated Sugarcane BagasseLuis LopezNo ratings yet

- Research Article: Structural Analysis of Alkaline Pretreated Rice Straw For Ethanol ProductionDocument10 pagesResearch Article: Structural Analysis of Alkaline Pretreated Rice Straw For Ethanol ProductionShankar AcharNo ratings yet

- Applied Thermal EngineeringDocument10 pagesApplied Thermal EngineeringArif HidayatNo ratings yet

- Rafael Ejemplos 1Document10 pagesRafael Ejemplos 1Antonio MoncayoNo ratings yet

- Elimination of Glucose in Egg WhiteDocument6 pagesElimination of Glucose in Egg WhiteRocio R. LamadridNo ratings yet

- Desain Reaktor IsomerisasiDocument7 pagesDesain Reaktor IsomerisasiIka Y. RachmawatiNo ratings yet

- Guo 2012Document10 pagesGuo 2012santiago HernandezNo ratings yet

- Lignocellulosic Properties of Coffee Pulp Waste AfDocument7 pagesLignocellulosic Properties of Coffee Pulp Waste AfYamid Andrés Yepes LondoñoNo ratings yet

- Reaction Kinetics in Conversion Process of Pineapple Leaves Into GlucoseDocument5 pagesReaction Kinetics in Conversion Process of Pineapple Leaves Into GlucoseArvin DalisayNo ratings yet

- 1 s2.0 S0920586120304600 MainDocument8 pages1 s2.0 S0920586120304600 Mainbruno barrosNo ratings yet

- Continuous Biohydrogen Production From Fruit Wastewater at Low PH ConditionsDocument10 pagesContinuous Biohydrogen Production From Fruit Wastewater at Low PH ConditionsNurkholis Bin AbdulNo ratings yet

- BLANCO - 2019 - Dark Fermentative Biohydrogen Production From Synthetic CheeseDocument10 pagesBLANCO - 2019 - Dark Fermentative Biohydrogen Production From Synthetic CheeseThobiasNo ratings yet

- Research Article: Silica Sol-Gel Entrapment of The Enzyme ChloroperoxidaseDocument11 pagesResearch Article: Silica Sol-Gel Entrapment of The Enzyme ChloroperoxidaseShalwa 29No ratings yet

- Chemical Engineering Journal: Mali Hunsom, Chaowat AutthanitDocument10 pagesChemical Engineering Journal: Mali Hunsom, Chaowat AutthanitRonald BustamanteNo ratings yet

- Industrially Relevant Hydrolyzability and Fermentability of Sugarcane Bagasse Improved Effectively by Glycerol Organosolv PretreatmentDocument13 pagesIndustrially Relevant Hydrolyzability and Fermentability of Sugarcane Bagasse Improved Effectively by Glycerol Organosolv PretreatmentHarshad Vinay SavantNo ratings yet

- 1 s2.0 S0360319922042458 MainDocument11 pages1 s2.0 S0360319922042458 Mainranjani093No ratings yet

- Fuel Processing Technology: Rudemas Manosak, Siripong Limpattayanate, Mali HunsomDocument8 pagesFuel Processing Technology: Rudemas Manosak, Siripong Limpattayanate, Mali HunsomLuki Wahyuning TiyasNo ratings yet

- Optimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using HCLDocument12 pagesOptimization of Conditions For The Preparation of Activated Carbon From Mango Nuts Using HCLAJER JOURNALNo ratings yet

- Cellulose HydrolysisDocument28 pagesCellulose HydrolysisMohamedNo ratings yet

- 18 Testing... (pp.83-87)Document5 pages18 Testing... (pp.83-87)Asriandy RamadhanNo ratings yet

- Nurlina DKK 2015 Pengolahan Limbah Cair Dengan TawasDocument11 pagesNurlina DKK 2015 Pengolahan Limbah Cair Dengan Tawasmay andy dwi wantoroNo ratings yet

- A Novel Facile Two-Step Method For Producing Glucose From CelluloseDocument24 pagesA Novel Facile Two-Step Method For Producing Glucose From Celluloseza vaNo ratings yet

- Integrated Production of Biofuels and Succinic Acid From Biomass After Thermochemical PretreatmentsDocument16 pagesIntegrated Production of Biofuels and Succinic Acid From Biomass After Thermochemical PretreatmentsJames TomosoriNo ratings yet

- Improving Biogas Production of Sugarcane Bagasse by Hydrothermal Pretreatment - PentingDocument5 pagesImproving Biogas Production of Sugarcane Bagasse by Hydrothermal Pretreatment - PentingDadangNo ratings yet

- Production of Ethanol From MolassesDocument5 pagesProduction of Ethanol From MolassesKrishna PotluriNo ratings yet

- Advanced Treatment ofDocument9 pagesAdvanced Treatment ofangginoviariNo ratings yet

- F1C121039 - Finkyasti Nur Adman - Tugas Bahasa Inggris SainsDocument9 pagesF1C121039 - Finkyasti Nur Adman - Tugas Bahasa Inggris SainsFinkyasti Nur AdmanNo ratings yet

- Accepted Manuscript: Bioresource TechnologyDocument35 pagesAccepted Manuscript: Bioresource TechnologyFarah TalibNo ratings yet

- Obtaining of Reducing Sugars From Kikuyu Grass (Pennisetum Clandestinum)Document4 pagesObtaining of Reducing Sugars From Kikuyu Grass (Pennisetum Clandestinum)Víctor Julio Daza MNo ratings yet

- A Comparison Between Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Using Steam-Pretreated Corn StoverDocument2 pagesA Comparison Between Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Using Steam-Pretreated Corn StoverSaleha ShamsudinNo ratings yet

- Separation of Oily Sludge and Glycerol From BiodieDocument6 pagesSeparation of Oily Sludge and Glycerol From BiodieFernando RibeiroNo ratings yet

- Mía TháiDocument7 pagesMía Tháitranb2014450No ratings yet

- Improved Upstream Processing For Detoxification and Recovery of XylitolDocument5 pagesImproved Upstream Processing For Detoxification and Recovery of XylitolMARIA CAMILA MU�OZ COMETANo ratings yet

- Extended Abstract - Muhammad Rafi Kalevi - SMA THURSINA IIBS - ISIFDocument10 pagesExtended Abstract - Muhammad Rafi Kalevi - SMA THURSINA IIBS - ISIFcyber.kay17No ratings yet

- Investigation of IsobutaneDocument17 pagesInvestigation of IsobutanedafinaNo ratings yet

- ResearchDocument91 pagesResearchOmprkash PatelNo ratings yet

- Purification of Crude Glycerol From Transesterific PDFDocument11 pagesPurification of Crude Glycerol From Transesterific PDFesiNo ratings yet

- PPI UK Inggris - Pratiwi Eka PutriDocument2 pagesPPI UK Inggris - Pratiwi Eka PutripratiwiNo ratings yet

- Fuel Processing Technology: Chun Sheng Goh, Hui Teng Tan, Keat Teong Lee, Abdul Rahman MohamedDocument6 pagesFuel Processing Technology: Chun Sheng Goh, Hui Teng Tan, Keat Teong Lee, Abdul Rahman MohamedHadi AmirkhaniNo ratings yet

- Physical Characterization of Activated Carbon Derived From Mangosteen Peel PDFDocument5 pagesPhysical Characterization of Activated Carbon Derived From Mangosteen Peel PDFMark Noel SanteNo ratings yet

- Structured Polyvinyl AlcoholZeoliteCarbon CompositDocument11 pagesStructured Polyvinyl AlcoholZeoliteCarbon CompositFarah TalibNo ratings yet

- 5638 19564 1 PBDocument8 pages5638 19564 1 PBMUHAMMAD HANIF ROSYIDI 2041201010No ratings yet

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeFrom EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNo ratings yet

- New Polymers for Encapsulation of Nutraceutical CompoundsFrom EverandNew Polymers for Encapsulation of Nutraceutical CompoundsJorge Carlos Ruiz RuizNo ratings yet

- Journal Pre-ProofDocument18 pagesJournal Pre-Proofashar shidqiNo ratings yet

- PDFDocument157 pagesPDFashar shidqiNo ratings yet

- Peserta Ziaroh 2020 SementaraDocument1 pagePeserta Ziaroh 2020 Sementaraashar shidqiNo ratings yet

- IcetiaDocument15 pagesIcetiaashar shidqiNo ratings yet

- Conference Exergy Analysisof Reverse Osmosisfor Potable Waterand Land IrrigationDocument8 pagesConference Exergy Analysisof Reverse Osmosisfor Potable Waterand Land Irrigationashar shidqiNo ratings yet

- Partial Differential Equation With MatlabDocument284 pagesPartial Differential Equation With MatlabJuan Manuel OlivoNo ratings yet

- Romero Ternero2005Document11 pagesRomero Ternero2005ashar shidqiNo ratings yet

- Partial Differential Equation With MatlabDocument284 pagesPartial Differential Equation With MatlabJuan Manuel OlivoNo ratings yet

- Partial Differential Equation With MatlabDocument284 pagesPartial Differential Equation With MatlabJuan Manuel OlivoNo ratings yet

- Topic 1 - Tuned Mass DamperDocument45 pagesTopic 1 - Tuned Mass DamperdhanarajNo ratings yet

- Chapter 1 and 2 Pre OralDocument36 pagesChapter 1 and 2 Pre OralSherwin CruzNo ratings yet

- 5070 s14 QP 11Document16 pages5070 s14 QP 11OsamaRahimNo ratings yet

- RecrystallizationDocument13 pagesRecrystallizationDini F GunawanNo ratings yet

- Worksheet Physical and Chemical Changes LabDocument4 pagesWorksheet Physical and Chemical Changes Labapi-542317996No ratings yet

- Cremophor ELPDocument4 pagesCremophor ELPMd.ali-bin-saifullah50% (2)

- Bailey's Industrial Oil and Fat ProductsDocument15 pagesBailey's Industrial Oil and Fat ProductsSinem Gökçe Dursun25% (4)

- CID A-A-344B - Lacquer (Clear Gloss), With Notice 1Document4 pagesCID A-A-344B - Lacquer (Clear Gloss), With Notice 1エドワードNo ratings yet

- SKF BearingDocument75 pagesSKF Bearingli xianNo ratings yet

- CW December 2012Document68 pagesCW December 2012Clint FosterNo ratings yet

- Ip Group 4 Eggshell ChalkDocument16 pagesIp Group 4 Eggshell ChalkCatherine Ilagan100% (5)

- 2014 AFPM Cat Cracker Seminar - Evaluating Equilibrium Catalyst (Ecat) DataDocument43 pages2014 AFPM Cat Cracker Seminar - Evaluating Equilibrium Catalyst (Ecat) Datasaleh4060No ratings yet

- Is 253 1985Document35 pagesIs 253 1985MonirNo ratings yet

- Products Water Treatment Chemicals I.boiler Chemicals WhenDocument7 pagesProducts Water Treatment Chemicals I.boiler Chemicals Whenemerald_27No ratings yet

- Hydrocarbon Fuel CellDocument8 pagesHydrocarbon Fuel Cellsanthosh kumarNo ratings yet

- Tds Nexbase 3060Document2 pagesTds Nexbase 3060RMascilNo ratings yet

- Imo PipesDocument2 pagesImo PipesMöhämed Täyel100% (4)

- Diagnose and Repair Exhaust SystemsDocument38 pagesDiagnose and Repair Exhaust SystemslittleprayerbyjacksNo ratings yet

- Cambridge IGCSE: Combined Science 0653/43Document24 pagesCambridge IGCSE: Combined Science 0653/43Dhruva VengalaNo ratings yet

- EMK 6 - DatasheetDocument1 pageEMK 6 - Datasheetronaldb322No ratings yet

- Copper e FinalDocument12 pagesCopper e FinalgoranNo ratings yet

- Inorganic ChemistryDocument10 pagesInorganic Chemistrydebraj sethi100% (1)

- Tds-Smeww 2540 CDocument3 pagesTds-Smeww 2540 Csan chueNo ratings yet

- Kulka 2018Document4 pagesKulka 2018Cherif AbbasNo ratings yet

- AICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiDocument16 pagesAICHE S01 02 FCC Debutanizer Revamp For Flexibility and AddiSrbislav GenicNo ratings yet

- Proteins 1Document456 pagesProteins 1pareehan salmanNo ratings yet

- 1 s2.0 S0959652615002140 MainDocument286 pages1 s2.0 S0959652615002140 MainMaliha CheemaNo ratings yet

- 2313 F Alex Obiri Gyampoh ProposalDocument13 pages2313 F Alex Obiri Gyampoh ProposalSamuel SegbefiaNo ratings yet

- International Journal For Organic ChemistryDocument12 pagesInternational Journal For Organic ChemistryifaNo ratings yet

- Mock 1523Document58 pagesMock 1523Javaria AjmalNo ratings yet