Professional Documents

Culture Documents

Section 2 - Gas Turbine Performance PDF

Section 2 - Gas Turbine Performance PDF

Uploaded by

frdn0 ratings0% found this document useful (0 votes)

38 views20 pagesOriginal Title

Section 2 - Gas Turbine Performance - Copy.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views20 pagesSection 2 - Gas Turbine Performance PDF

Section 2 - Gas Turbine Performance PDF

Uploaded by

frdnCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

Gas Turbine Performance

• Factors affecting performance

– Ambient conditions

– Humidity/Altitude

– Fuel

• Performance Calculations

• Performance Monitoring

For Training Purposes Only 1

Ambient Conditions

For Training Purposes Only 2

Humidity

For Training Purposes Only 3

Altitude

For Training Purposes Only 4

Inlet and Exhaust Losses

• Inlet Air Filtration, silencing, evaporative

coolers add to pressure losses

• An HRSG or similar heat recovery

device would cause pressure losses in

the system

• The effects of pressure losses above

would be unique to each system design

For Training Purposes Only 5

Fuels

% Design Output

For Training Purposes Only 6

LHV Fuel Considerations

• Increased turbine mass flow drives up

compressor pressure ratio, eventually

encroaching on compressor surge limit.

• The higher turbine power may exceed

fault torque limits. In many cases, a

larger generator may be needed.

• High Fuel Volumes increases fuel piping

and valve sizes.

For Training Purposes Only 7

Performance Monitoring

• Install Instrumentation or alternatively

use station instruments

• Allow Turbine Operation to stabilise at

Base Load for 1 Hour

• Take performance measurements at

prescribed intervals usually every 3

mins

• Do performance calculations

For Training Purposes Only 8

Example of Performance Data

For Training Purposes Only 9

ISO Turbine Ratings

• ISO Rating are calculated at

– 59 Deg F (16 Deg C) Ambient Temperature

– Sea Level i.e. Ambient Pressure 14.7 psia

– 60% Relative Humidity

• Pre 1970’s NEMA Rating were calculated at

– 80 Deg F (27 Deg C) Ambient Temperature

– 1000ft/300m Altitude

• To convert NEMA to ISO multiply by 1.12

For Training Purposes Only 10

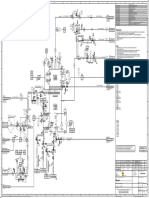

Performance Instrumentation

FILTER COMPRESSOR

HOUSE

For Training Purposes Only 11

Performance Calculations

• Heat Consumption

• Heat Rate

• Calculating Factors

• Power Output

For Training Purposes Only 12

Heat Consumption

Qr = Vf * Qlo

Heat Consumption Volumetric Flow Lower Calorific

Rate of Fuel Value of Fuel

For Training Purposes Only 13

Heat Rate

Qpn = Qr / Pn

Heat Rate Heat Consumption Net Power Output

For Training Purposes Only 14

Net Power Output

Pn = Pact - Paux

Net Power Actual Power Auxiliary Power

Output Output Consumption

For Training Purposes Only 15

Corrected Power Output

Ambient Humidity

Factor

Pc = Pn * 1/Atf * 1/Apf *1/ Ahf

Corrected Net Power Output Ambient Ambient Pressure

Net Power Temperature Factor Factor

For Training Purposes Only 16

Ambient Temperature Correction

For Training Purposes Only 17

Corrected Heat Rate

Ambient Humidity

Factor

Qc = Qpn * 1/Atf * 1/Apf * 1/Ahf

Corrected Heat Rate Ambient Ambient Pressure

Heat Rate Temperature Factor Factor

For Training Purposes Only 18

Efficiency

E = Pn / Qr

Efficiency Net Power Output Heat Consumption

For Training Purposes Only 19

GE Frame 5 Power

Calculations

For Training Purposes Only 20

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- KAD L3 Manual Rev A 03-19Document90 pagesKAD L3 Manual Rev A 03-19Jordan Magaña MoralesNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Material Product Data Sheet Nickel Cobalt Chromium Aluminum Yttrium (Nicocraly) Thermal Spray PowdersDocument5 pagesMaterial Product Data Sheet Nickel Cobalt Chromium Aluminum Yttrium (Nicocraly) Thermal Spray PowdersfrdnNo ratings yet

- Offshore Technology Report: Testing and Analysis of Relief Device Opening TimesDocument82 pagesOffshore Technology Report: Testing and Analysis of Relief Device Opening TimesLeo MilojevićNo ratings yet

- 475 DatasheetDocument1 page475 DatasheetfrdnNo ratings yet

- 8737Document1 page8737frdnNo ratings yet

- Ds Prox Intro 1009Document2 pagesDs Prox Intro 1009frdnNo ratings yet

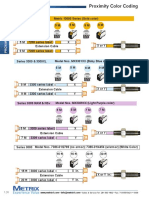

- Ds Proximity Color Coding 1009Document1 pageDs Proximity Color Coding 1009frdnNo ratings yet

- Ds Prox XDCR Specs 0310Document2 pagesDs Prox XDCR Specs 0310frdnNo ratings yet

- Ds 5510 5516 0610Document2 pagesDs 5510 5516 0610frdnNo ratings yet

- RR Avon 1534 2Document3 pagesRR Avon 1534 2frdn100% (1)

- DS TXR5521 ProximityTransmittersDocument2 pagesDS TXR5521 ProximityTransmittersfrdnNo ratings yet

- Purchase Order Template 01 - TemplateLabDocument1 pagePurchase Order Template 01 - TemplateLabfrdnNo ratings yet

- Material Product Data Sheet Metcolite Grits: Quick FactsDocument3 pagesMaterial Product Data Sheet Metcolite Grits: Quick FactsfrdnNo ratings yet

- Material Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderDocument3 pagesMaterial Product Data Sheet Iron Chromium Aluminum Yttrium (Fecraly) Thermal Spray PowderfrdnNo ratings yet

- Frame 9001E Combustion PDFDocument2 pagesFrame 9001E Combustion PDFfrdn100% (1)

- Ge Pgt10 Pgt16: Advanced Repairs Available Only From Liburdi Turbine ServicesDocument2 pagesGe Pgt10 Pgt16: Advanced Repairs Available Only From Liburdi Turbine ServicesfrdnNo ratings yet

- Frame 6001B NozzlesDocument2 pagesFrame 6001B NozzlesfrdnNo ratings yet

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocument1 pageCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine Turbinefrdn100% (1)

- Marine Gas Turbine: PerformanceDocument2 pagesMarine Gas Turbine: Performancefrdn100% (1)

- TB5000 SGT-200/Tornado SGT-100/Typhoon: Advanced Repairs Available Only From Liburdi Turbine ServicesDocument2 pagesTB5000 SGT-200/Tornado SGT-100/Typhoon: Advanced Repairs Available Only From Liburdi Turbine ServicesfrdnNo ratings yet

- Gas Turbine Engineering Services: Independent Engineering and AnalysisDocument2 pagesGas Turbine Engineering Services: Independent Engineering and AnalysisfrdnNo ratings yet

- Understanding Post Mix June 2015Document89 pagesUnderstanding Post Mix June 2015Spotsa LadangsNo ratings yet

- References USDocument33 pagesReferences USWillian CastroNo ratings yet

- Surface ChemistryDocument39 pagesSurface ChemistryDereje BeyeneNo ratings yet

- Air Compressor Trouble-Shooting, Problems, The Causes, SolutionsDocument7 pagesAir Compressor Trouble-Shooting, Problems, The Causes, SolutionsMiliani AhmedNo ratings yet

- Properties of Ideal GasesDocument32 pagesProperties of Ideal GasesdvanupkleNo ratings yet

- CorkenDocument4 pagesCorkenLuis Pol SistiNo ratings yet

- DPPR 270519 Utility+etpDocument1 pageDPPR 270519 Utility+etpRavi ShankarNo ratings yet

- Chapter 4 Fluid Flow in Porous Media - 2Document72 pagesChapter 4 Fluid Flow in Porous Media - 2Hiếu Nguyễn TrungNo ratings yet

- Factors Controlling Borehole Performance: R.) AmesDocument14 pagesFactors Controlling Borehole Performance: R.) AmesElmer MayenNo ratings yet

- Experiment 1 - Fluid Flow Measurements LDocument9 pagesExperiment 1 - Fluid Flow Measurements LClifford Dwight RicanorNo ratings yet

- Homework Enthalpy CalculationsDocument2 pagesHomework Enthalpy CalculationsErnur Teginbaev100% (1)

- Packages - Rhino BBR Electric PackageDocument1 pagePackages - Rhino BBR Electric PackageNarayan SinghaniaNo ratings yet

- Revista Brasileira de Engenharia Agrícola e AmbientalDocument7 pagesRevista Brasileira de Engenharia Agrícola e AmbientalEzra PakarNo ratings yet

- Typical Hydrostatic-Vents DrainsDocument1 pageTypical Hydrostatic-Vents Drainsrats182No ratings yet

- Calculation Research For LNG VaporizerDocument11 pagesCalculation Research For LNG VaporizerDuyen Tran VanNo ratings yet

- Inspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4Document7 pagesInspection & Testing of Pressure Vessels and Pressure Relieving Devices - 4DeepakNo ratings yet

- ONGC Training ReportDocument61 pagesONGC Training ReportKumar VikramadityaNo ratings yet

- API 6D ExtractedDocument3 pagesAPI 6D ExtractedSam JoseNo ratings yet

- Unit 330Document22 pagesUnit 330mohamed ghorabNo ratings yet

- KJLC Ed09 Sec05 Web200910Document22 pagesKJLC Ed09 Sec05 Web200910NickMoloNo ratings yet

- +rostrupnielsen1984 - (Catalytic Steam Reforming)Document117 pages+rostrupnielsen1984 - (Catalytic Steam Reforming)Faris Hamidi100% (1)

- The Rising Water: Purpose of The WorkDocument3 pagesThe Rising Water: Purpose of The WorkSamy ReyesNo ratings yet

- WMA06 Section 1.0 Presentation Rev1a PDFDocument33 pagesWMA06 Section 1.0 Presentation Rev1a PDFLeo PalNo ratings yet

- 6-BIM Models - (127-131)Document6 pages6-BIM Models - (127-131)samriddh25No ratings yet

- "The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Document11 pages"The Comparison of Stamicarbon and Saipem Urea Technology": October 2016Anonymous iuFpXLNo ratings yet

- Local Media8092592512293728315Document8 pagesLocal Media8092592512293728315Bowie S. PascualNo ratings yet

- No No Matrik Nama KumpulanDocument4 pagesNo No Matrik Nama Kumpulantuan siti atirahNo ratings yet

- SHC 310 Hydraulics Kinematics or Fluid Dynamics ObjectivesDocument12 pagesSHC 310 Hydraulics Kinematics or Fluid Dynamics ObjectivesBrendon GovaNo ratings yet