Professional Documents

Culture Documents

(Grade 1.5) GR181-EN-Timken-Spec-Sheet

Uploaded by

nacerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Grade 1.5) GR181-EN-Timken-Spec-Sheet

Uploaded by

nacerCopyright:

Available Formats

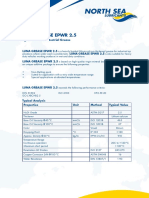

Product Data Sheet

TIMKEN® MILL GREASE (NLGI Grade 1.5)

Lubricating Grease

Part Numbers

GR181D 180 kg (400 lb) drum

GR181B tote quantities available

Product Description and Intended Use

TIMKEN Mill Grease is an NLGI No. 1½ high performance lubricating grease used when

resistance to water washout and broad operating temperatures are absolutely necessary. The

formulation of this product provides unsurpassed resistance to extreme pressures and corrosion

(including salt spray), as well as exceptional mechanical stability even in the presence of water.

TIMKEN Mill Grease is highly recommended for steel mill and paper mill applications. It

contains no heavy metals or other environmentally undesirable additives.

Product Application

TIMKEN Mill Grease can be applied from ambient temperatures of - 10° F to + 400° F (- 23° C

to + 204° C) depending on lubrication system design and method of application. TIMKEN Mill

Grease has an operating range of - 40° F to + 400° F (- 40° C to + 204° C) once in the application

(depending on frequency of application). Follow equipment manufacturer’s recommendations

concerning lubrication frequencies.

Compatibility of Grease

TIMKEN Mill Grease is generally compatible with calcium, calcium 12-OH stearate, calcium

complex, calcium sulfonate, lithium, lithium complex and polyurea thickened greases. TIMKEN

recommends that all grease be removed from the application prior to changing greases. Then the

lubrication interval is reduced by half for the first lubrication cycle before resuming the normal

lubrication interval.

Handling and Storage

Store in a dry area away from heat and open flame. See Material Safety Data Sheet for more

information.

Shipping and Disposal Information

Follow governmental regulations pertaining to the shipping and disposal of this product. Do not

reuse container. See Material Safety Data Sheet for more information.

TIMKEN® MILL GREASE

Product Specifications – Typical

Color Tan

NLGI Grade 1½

Penetration, Unworked ASTM D 217 290-315

Penetration, Worked 60 Strokes, ASTM D 217 290-315

Penetration Change, 100000 Strokes, ASTM D 217 +/- 5 %

Wheel Bearing, ASTM D 1263, Modified 325°F (163° C) 0.4 Grams

Dropping Point, ASTM D 2265 572° F (300° C)

Oxidation Stability, ASTM D 942, 100 hours at 99° C 5 psi (35 kPa)

Four-Ball Wear, ASTM D 2266, 40 kg, 1200 RPM, 75°C, Scar mm 0.45 Max.

Four-Ball EP, Weld Point, ASTM D 2596, kgf 500

Timken OK Load, ASTM D 2509, Pounds 60

Copper Strip Corrosion, ASTM D 4048 1a

Corrosion Preventive Properties, ASTM D 1743 Pass

Oil Separation, ASTM D 1742 0.2 %

Water Washout, ASTM D 1264 , 175°F (79° C), % Loss 3.00

Salt Fog Test, B-117, hours +2,000

Base Fluid Properties:

Viscosity @ 100° C, ASTM D 445, Centistokes 30 – 34

Viscosity @ 40° C, ASTM D 445, Centistokes 430 – 490

Viscosity Index 95

Pour Point, ASTM D 97 - 12° C

Flash Point, ASTM D 92 255° C

Date: November 18, 2008

Product: TIMKEN Mill Grease NLGI Grade 1.5

You might also like

- Timken Mill Grease NLGI 1 Resists Water WashoutDocument2 pagesTimken Mill Grease NLGI 1 Resists Water WashoutThe WorshipperNo ratings yet

- Renolin CLP - enDocument7 pagesRenolin CLP - enDANE80No ratings yet

- Ceran-Xm-220 TDS v171128Document2 pagesCeran-Xm-220 TDS v171128phucdc095041No ratings yet

- Polyurea Grease TdsDocument2 pagesPolyurea Grease TdsBanti SidhiwalaNo ratings yet

- Premium Industrial Gear Oils Energol GR-XPDocument2 pagesPremium Industrial Gear Oils Energol GR-XPakun leptopNo ratings yet

- Grease 082504referenceDocument6 pagesGrease 082504referencesmhea123No ratings yet

- Extreme pressure aluminum grease protects heavy equipmentDocument3 pagesExtreme pressure aluminum grease protects heavy equipmentIngeniero aicNo ratings yet

- Engen Premium EP SeriesDocument2 pagesEngen Premium EP SeriesNunoNo ratings yet

- 1275 EnuDocument2 pages1275 EnuJan HendriksNo ratings yet

- Pehp0002 02Document2 pagesPehp0002 02Manuel Moreno GalarzaNo ratings yet

- Product Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDocument3 pagesProduct Data Sheet: 100 Gear Oil Extreme Pressure Gear OilDiegoNo ratings yet

- High Temperature-Grease-pds-EngDocument3 pagesHigh Temperature-Grease-pds-Engdavide comuzziNo ratings yet

- Shell Turbo T32: Performance, Features & Benefits Main ApplicationsDocument3 pagesShell Turbo T32: Performance, Features & Benefits Main ApplicationsPandu SatrioNo ratings yet

- Eastman 2197 Turbo-Oil TDS - SkySupplyUSADocument2 pagesEastman 2197 Turbo-Oil TDS - SkySupplyUSASkySupplyUSANo ratings yet

- TorqGear SeriesDocument1 pageTorqGear SeriesSameh RadwanNo ratings yet

- Ficha Tecnicas Royal Hammer Paste PDS XDocument2 pagesFicha Tecnicas Royal Hammer Paste PDS XAndres AgudeloNo ratings yet

- Foodmax Grease CAS S 2 LS - TDS - 263701301 - ENDocument2 pagesFoodmax Grease CAS S 2 LS - TDS - 263701301 - ENDeath Heart100% (1)

- Eastman Turbo Oil 25 TDSDocument2 pagesEastman Turbo Oil 25 TDSbarcaza_13No ratings yet

- EP-2 Industrial GreaseDocument1 pageEP-2 Industrial GreaseEnrique PeraltaNo ratings yet

- Grease PropertiesDocument4 pagesGrease Propertiescarlos sotoNo ratings yet

- Tech Data: Turbonycoil 600 L B A G T FDocument2 pagesTech Data: Turbonycoil 600 L B A G T FJeremias UtreraNo ratings yet

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDocument3 pagesGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianNo ratings yet

- Aeroshell Grease 58: Main ApplicationsDocument2 pagesAeroshell Grease 58: Main ApplicationsSophia RoseNo ratings yet

- Hilubric Ep 1Document1 pageHilubric Ep 1ANILNo ratings yet

- Yours' Maintenance Solution: HD Lithium Complex GreaseDocument1 pageYours' Maintenance Solution: HD Lithium Complex GreaseSiong Wu SiewNo ratings yet

- Super Tauro PAG: LubricantsDocument1 pageSuper Tauro PAG: LubricantsSaurav SharmaNo ratings yet

- AmsoilSyntheticOilProductInfo SheetsDocument2 pagesAmsoilSyntheticOilProductInfo Sheetsapi-19921780No ratings yet

- BP Energrease Ls and Ls-Ep: DescriptionDocument2 pagesBP Energrease Ls and Ls-Ep: DescriptionbenjaminNo ratings yet

- Grasa Multiproposito CatDocument2 pagesGrasa Multiproposito Catrolex21No ratings yet

- Long Life Jelly Grease 45000 KMS: Description & ApplicationDocument1 pageLong Life Jelly Grease 45000 KMS: Description & ApplicationChaitanya NandaNo ratings yet

- Series 2000 Synthetic Racing Grease Data BulletinDocument2 pagesSeries 2000 Synthetic Racing Grease Data Bulletinbrian5786No ratings yet

- Mobilgear SHC 3200 6800 PdsDocument2 pagesMobilgear SHC 3200 6800 PdsMohamed SalemNo ratings yet

- Foodmax Grease CAS S 2 HS - TDS - 263701201 - ENDocument2 pagesFoodmax Grease CAS S 2 HS - TDS - 263701201 - ENDeath HeartNo ratings yet

- Renolin CLPDocument6 pagesRenolin CLPjacl88No ratings yet

- Premium Tool Joint Compound for Oilfield Tubular GoodsDocument1 pagePremium Tool Joint Compound for Oilfield Tubular GoodsFzl2No ratings yet

- Shell Food Industry FM GREASE 2Document2 pagesShell Food Industry FM GREASE 2Luka BornaNo ratings yet

- Shell Turbo Oil T 32 TDSDocument2 pagesShell Turbo Oil T 32 TDSBahim BahimanNo ratings yet

- Mobil-Glygoyle-460 (Aceite Reductor de Velocidad - Faja de Elevación)Document2 pagesMobil-Glygoyle-460 (Aceite Reductor de Velocidad - Faja de Elevación)michael gutierrezNo ratings yet

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezNo ratings yet

- Shell Omala Oil 320 Eng M0010Document2 pagesShell Omala Oil 320 Eng M0010Ady MihailaNo ratings yet

- Molykote G 1001 PdsDocument2 pagesMolykote G 1001 PdsDicky PratamaNo ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- Castrol Molub-Alloy 243 ArcticDocument2 pagesCastrol Molub-Alloy 243 ArcticMaciejNo ratings yet

- Komatsu OilsDocument200 pagesKomatsu OilsBrian Careel100% (1)

- Amsoil Racing Grease g1243Document2 pagesAmsoil Racing Grease g1243amsoilromaniaNo ratings yet

- SM750Document2 pagesSM750Gantungan KulkasNo ratings yet

- SYNGEAR SH-1000 SERIES 340253 PI GB enDocument5 pagesSYNGEAR SH-1000 SERIES 340253 PI GB enCleiton Luiz CordeiroNo ratings yet

- Eni Ote GT 32 Tds 7755 - EnuDocument2 pagesEni Ote GT 32 Tds 7755 - EnumvanzijpNo ratings yet

- Equate EMDA 6200Document2 pagesEquate EMDA 6200HichamSalamaNo ratings yet

- GPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1Document2 pagesGPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1abid azizNo ratings yet

- ACCROLUBE SpecDocument3 pagesACCROLUBE SpecCarlos LoresNo ratings yet

- Eastman 2380 Tech SheetDocument2 pagesEastman 2380 Tech SheetAndy MaxNo ratings yet

- GrasaDocument2 pagesGrasaeduardoNo ratings yet

- Gulf Therm Aug12 - 20120903171744Document1 pageGulf Therm Aug12 - 20120903171744Nashrul HakimNo ratings yet

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- Shell Spindle OilsDocument2 pagesShell Spindle OilsMoutaz IsmailNo ratings yet

- Industrial Gear Oil Ep 68, 100, 150, 220, 320, 460, 680Document1 pageIndustrial Gear Oil Ep 68, 100, 150, 220, 320, 460, 680FilipposNo ratings yet

- Bel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1Document2 pagesBel Ray Molylube Ultra Open Gear Lubricant PDS 12june2023 1xxx yyyNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Tache de HuileDocument1 pageTache de HuilenacerNo ratings yet

- Lubrication Fundamentals, Second Edition-Auteur: Don M. Pirro, Ekkehard Daschner - Isbn 1420029231, 9781420029239Document1 pageLubrication Fundamentals, Second Edition-Auteur: Don M. Pirro, Ekkehard Daschner - Isbn 1420029231, 9781420029239nacerNo ratings yet

- (Grade 2.5) 7405 - PDS - NSL - LUNA - GREASE - EPWR - 2 PDFDocument1 page(Grade 2.5) 7405 - PDS - NSL - LUNA - GREASE - EPWR - 2 PDFnacerNo ratings yet

- Lubrication Fundamentals, Second Edition-Auteur: Don M. Pirro, Ekkehard Daschner - Isbn 1420029231, 9781420029239Document1 pageLubrication Fundamentals, Second Edition-Auteur: Don M. Pirro, Ekkehard Daschner - Isbn 1420029231, 9781420029239nacerNo ratings yet

- Astmd5 2006Document4 pagesAstmd5 2006Rabbani RxgNo ratings yet

- BasicsofACHEBrochure WebDocument33 pagesBasicsofACHEBrochure WebTrần Tuấn VũNo ratings yet

- API560-Comparison-Fired Heaters For Refinery Service 102018Document105 pagesAPI560-Comparison-Fired Heaters For Refinery Service 102018ashutosh_garg_10100% (1)

- CV Jubilee Bubala Environmental SpecialistDocument4 pagesCV Jubilee Bubala Environmental SpecialistNomayi100% (2)

- MF ISIN CodeDocument49 pagesMF ISIN CodeshriramNo ratings yet

- Stage 112SE Manual FenderDocument8 pagesStage 112SE Manual FenderDjuang Septa KhalidaNo ratings yet

- F5 GTM Concepts Guide v11Document209 pagesF5 GTM Concepts Guide v11Majnu SmNo ratings yet

- LFJ All OrdersDocument195 pagesLFJ All Orderskate jackNo ratings yet

- Bismillah Skripsi Herlina Rozaaaa-1Document57 pagesBismillah Skripsi Herlina Rozaaaa-1Saidi NetNo ratings yet

- HistoryDocument20 pagesHistoryAlexandru RomînuNo ratings yet

- Apparent Dip PDFDocument2 pagesApparent Dip PDFanon_114803412No ratings yet

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet

- Piano: Grade 2: PiecesDocument4 pagesPiano: Grade 2: PiecesnolozeNo ratings yet

- Som-Ii Uqb 2019-20Document23 pagesSom-Ii Uqb 2019-20VENKATESH METHRINo ratings yet

- Irregular Verbs Multiple ChoiceDocument2 pagesIrregular Verbs Multiple Choicecloudcatching0% (1)

- Lembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Document11 pagesLembar Jawaban Skillab Evidence Based Medicine (Ebm) Nama: Rafika Triasa NIM: 040427223270003Yahya Darmais FaridNo ratings yet

- Lesson 2: Weaving A Mannahatta Muir WebDocument2 pagesLesson 2: Weaving A Mannahatta Muir WebTamas SzamosfalvyNo ratings yet

- Sustainability - Research PaperDocument18 pagesSustainability - Research PapermrigssNo ratings yet

- Dispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsDocument41 pagesDispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsSantiago OrtizNo ratings yet

- Research Trends On Environmental Energy and Vulnerability - 2021 - Energy andDocument27 pagesResearch Trends On Environmental Energy and Vulnerability - 2021 - Energy andCynthia Mac-beathNo ratings yet

- Consumer Reports Buying Guide 2021Document227 pagesConsumer Reports Buying Guide 2021fatso68100% (1)

- Chapter 3 Week 1 Inductive and Deductive ReasoningDocument57 pagesChapter 3 Week 1 Inductive and Deductive ReasoningDiane Agcaoili Edra50% (6)

- KPW FSO Yetagun Presentation 250713Document36 pagesKPW FSO Yetagun Presentation 250713muhamadrafie1975No ratings yet

- Course Outline TP WindowsDocument6 pagesCourse Outline TP WindowsAnonymous PcPkRpAKD5No ratings yet

- Ejc-M13 - FN953205Document203 pagesEjc-M13 - FN953205JoséNo ratings yet

- T e 2552674 Percy Polls Peculiar Plants Fiction Year 5 Reading Comprehension - Ver - 5Document20 pagesT e 2552674 Percy Polls Peculiar Plants Fiction Year 5 Reading Comprehension - Ver - 5mariam osamaNo ratings yet

- San Lam Stratus FundsDocument2 pagesSan Lam Stratus FundsTiso Blackstar GroupNo ratings yet

- Forcepoint Email Security Configuration Information v8.5Document64 pagesForcepoint Email Security Configuration Information v8.5ajay chaudharyNo ratings yet

- Recipe of Medical AirDocument13 pagesRecipe of Medical AirMd. Rokib ChowdhuryNo ratings yet

- SP Manual Addendum For OS 3 - 03Document2 pagesSP Manual Addendum For OS 3 - 03kevmac88No ratings yet

- Chapter Three: Business Plan PreparationDocument26 pagesChapter Three: Business Plan PreparationwaqoleNo ratings yet

- Module 3 - Tennnis: Cit Colleges of Paniqui Foundation IncDocument14 pagesModule 3 - Tennnis: Cit Colleges of Paniqui Foundation IncLahra BalanciaNo ratings yet

- WEEK 7 ICPS - and - ICSSDocument31 pagesWEEK 7 ICPS - and - ICSScikguhafidzuddinNo ratings yet