Professional Documents

Culture Documents

QR 0810 Dry Pipe Valve - Testing

Uploaded by

Le DucCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QR 0810 Dry Pipe Valve - Testing

Uploaded by

Le DucCopyright:

Available Formats

QUICK

RESPONSE

Saving life and property through effective licensing, plan review,

and inspection of fire protection systems.

August 2010

DRY PIPE VALVE – TESTING

Dry system piping must undergo the same 2 hour, 200 psi hydrostatic test that all

other systems are subject to. (This test should NOT be done against the dry valve

clapper.) Additionally, NFPA 13 (2002 edition) requires that the dry system piping be

air tested at 40 psi for 24 hours without losing more than 1½ psi of air pressure in

that time period. Finally, NFPA 13 requires that the dry pipe valve be “trip tested”

alone without a quick-opening device, and then with the quick-opening device, if

installed. The purpose of the last test is to measure the time it takes to “trip” (open)

the dry pipe valve and the time for water to reach the most remote part of the system.

The focus here is on the “trip test” and the normal air pressure. The “trip test” must

be conducted starting with the normal amount of air pressure that will be carried in

the system. The common “differential-type” dry valve will require about ¼ air

pressure to static water pressure to hold the dry pipe valve clapper shut. Newer

“hydraulic assist-type” dry valves may require as little as 13 psi of air to operate

properly. Always follow the manufacturer’s recommendations for the air-to-water

pressure ratio and be sure the “trip test” is performed starting at the recommended

“normal” system air pressure. Allowing anything less than normal air pressure during

the performance test might result in a successful 60-second delivery time to the test

connection, but it would not be an accurate representation of how the system will

perform when the normal, permanent air pressure is applied to the system.

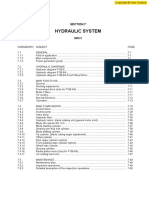

Standard Differential-type Dry Valve Low-differential, hydraulic assist type

Quick Response is presented monthly by the

Minnesota State Fire Marshal – Fire Protection Section

www.fire.state.mn.us

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- X-Mass Tree Change Out and Corrective Maintenance Procedure - Samir AbassiDocument6 pagesX-Mass Tree Change Out and Corrective Maintenance Procedure - Samir AbassinappyNo ratings yet

- Fire Detection and Fire Alarm System Inspection and Servicing ReportDocument7 pagesFire Detection and Fire Alarm System Inspection and Servicing ReportLe DucNo ratings yet

- SWPMDocument560 pagesSWPMFernando Angel Ortiz Rodriguez67% (3)

- Testing & Adjusting PW200/ 220-7Document13 pagesTesting & Adjusting PW200/ 220-7Teknik Makina100% (2)

- Diagrama Electrico 416FDocument34 pagesDiagrama Electrico 416FPlstina RamsNo ratings yet

- The Gaylord Installation, Operation & Maintenance Manual For "Elx" Series HoodsDocument35 pagesThe Gaylord Installation, Operation & Maintenance Manual For "Elx" Series HoodsMatthewNo ratings yet

- SM - F156 (1) .6A - 7 - EN, HIDRULIKADocument70 pagesSM - F156 (1) .6A - 7 - EN, HIDRULIKAJosip BrajeNo ratings yet

- QR1209DryPipeValveOperation PDFDocument1 pageQR1209DryPipeValveOperation PDFLe DucNo ratings yet

- QR1208FirePumpsContlr PDFDocument1 pageQR1208FirePumpsContlr PDFLe DucNo ratings yet

- QR1210GlassBulbFluid PDFDocument1 pageQR1210GlassBulbFluid PDFLe DucNo ratings yet

- QR1207 Preact SysDocument1 pageQR1207 Preact SysLe DucNo ratings yet

- QR 0912 List of SprinklersDocument1 pageQR 0912 List of SprinklersLe DucNo ratings yet

- QR 0710 Dry Pipe Valve - ExhausterDocument1 pageQR 0710 Dry Pipe Valve - ExhausterLe DucNo ratings yet

- QR0206Document1 pageQR0206Le DucNo ratings yet

- QR 0712 PitchDocument1 pageQR 0712 PitchLe DucNo ratings yet

- Fire PumpsDocument11 pagesFire PumpsLe DucNo ratings yet

- APPENDIX B - Pump Station Design GuidelinesDocument7 pagesAPPENDIX B - Pump Station Design GuidelinesLe DucNo ratings yet

- Installing Flow Meters On Dairies: Marsha Campbell Mathews University of California Cooperative ExtensionDocument14 pagesInstalling Flow Meters On Dairies: Marsha Campbell Mathews University of California Cooperative ExtensionLe DucNo ratings yet

- Data Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Document2 pagesData Sheet 7.04 Issue C: Test & Drain Valve Fig. 801Le DucNo ratings yet

- 411UDAC Dress Panel Installation 51130Document2 pages411UDAC Dress Panel Installation 51130Said RomeroNo ratings yet

- Brake Caliper Bleeder Valve Repair Kit: Work InstructionsDocument8 pagesBrake Caliper Bleeder Valve Repair Kit: Work InstructionsdcranskiNo ratings yet

- List of PanelsDocument1 pageList of PanelsMohammed MadiNo ratings yet

- Fiche - Technique - Motorbox 300 KG Direct ControlDocument3 pagesFiche - Technique - Motorbox 300 KG Direct ControlGerardo Di LoretoNo ratings yet

- Range:: L&T 72 L&T 90-3 L&T 180Document10 pagesRange:: L&T 72 L&T 90-3 L&T 180memanjuvNo ratings yet

- Book 4Document26 pagesBook 4Elvitech IndiaNo ratings yet

- Disc BrakesDocument4 pagesDisc BrakesNavam JainNo ratings yet

- Forgotten Firearms of August CoendersDocument12 pagesForgotten Firearms of August CoendersRoddy PfeifferNo ratings yet

- Manual Conversor WeidmullerDocument15 pagesManual Conversor WeidmullerAlmir PereiraNo ratings yet

- How Does A Theodolite Works?: Equipment and MaterialsDocument4 pagesHow Does A Theodolite Works?: Equipment and MaterialsLyn SNo ratings yet

- RP Tech ManualDocument517 pagesRP Tech ManualAlex GurleniaNo ratings yet

- MDocument46 pagesMdefida2680No ratings yet

- Electric Plugs Per CountryDocument4 pagesElectric Plugs Per Countryandrei_bertea7771No ratings yet

- Laser Light Localizer: Option Installation InstructionsDocument20 pagesLaser Light Localizer: Option Installation InstructionsVlady Lopez CastroNo ratings yet

- 0 Chapter12 PrintersDocument45 pages0 Chapter12 PrintersNitin BelgaonkarNo ratings yet

- Addressable Fire Alarm System Quote Soch Phoenix Mall of AsiaDocument1 pageAddressable Fire Alarm System Quote Soch Phoenix Mall of AsiaKhuzemaBarodawalaNo ratings yet

- HardwareDocument83 pagesHardwareEkhlas MamdouhNo ratings yet

- CLORIOUS - Control ValvesDocument4 pagesCLORIOUS - Control ValvesRM HaroonNo ratings yet

- Le 1000 Express LiteDocument9 pagesLe 1000 Express LiteBob AbouTahaNo ratings yet

- BLOCK STU 63-2x115Document2 pagesBLOCK STU 63-2x115Lod 1No ratings yet

- Type 2 Type 3 AK 47Document6 pagesType 2 Type 3 AK 47Kirun RulesNo ratings yet

- Proposal Package SWRO - 03-02-2020Document7 pagesProposal Package SWRO - 03-02-2020Osama AhmedNo ratings yet

- Model GPY: Technical Data Submittal DocumentDocument13 pagesModel GPY: Technical Data Submittal DocumentLwigy SaavedraNo ratings yet

- Technical Specification HLM 25-3SDocument2 pagesTechnical Specification HLM 25-3SScHasZerNo ratings yet