Professional Documents

Culture Documents

!!!bimba Hydraulic Sjock absorbersBMS-1034 PDF

!!!bimba Hydraulic Sjock absorbersBMS-1034 PDF

Uploaded by

Slava75Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

!!!bimba Hydraulic Sjock absorbersBMS-1034 PDF

!!!bimba Hydraulic Sjock absorbersBMS-1034 PDF

Uploaded by

Slava75Copyright:

Available Formats

Product Instructions

Hydraulic Shock Absorber

LS, SS, and HS Series

Mount and lock shock absorber in place; provide a positive stop from face of piston (or button), equal to the

stroke length as shown in the table below.

USABLE STROKE

MODELS

(INCHES) (mm)

LS-02 .25 6.4

SS-02 .25 6.4

HS-02 .25 6.4

LS-04 .41 10.0

SS-04 .41 10.0

HS-04 .41 10.0

LS-09 .63 16.0

SS-09 .63 16.0

HS-09 .63 16.0

LS-17 .88 22.0

SS-17 .88 22.0

HS-17 .88 22.0

LS-31 1.56 40.0

SS-31 1.56 40.0

HS-31 1.56 40.0

CAUTION:

A. Only the usable stroke listed above should be used. If the full stroke is used, undesirable bottoming will occur

against the positive stop. It is, therefore, important to position the shock absorber such that only the usable

stroke is used. Stop collars are available to prevent the shock absorber from bottoming. They also ensure

that work being positioned is stopped at the same point every time.

B. If shocks are used at less than 5% of maximum rated energy per cycle, a smaller shock absorber should be used.

C. If initial impact force is too hard, the next lower dash number (less damping) may be required. If bottoming

is too hard at the end of stroke, the next larger dash number (greater damping) or a larger model may be

required. For additional information, refer to the Bimba catalog under Shock Absorbers.

D. Do not clamp or weld shock absorber body. Do not paint or damage surface finish of the piston rod.

For further information, scan

this QR code or visit

Bimba

www.bimba.com

25150 S. Governors Hwy Fax: +1 708 235 2014

University Park, IL 60484 Email: cs@imi-precision.com Form: BMS-1034

Tel: +1 800 44 BIMBA Website: www.bimba Rev. A

You might also like

- How to Build LS Gen IV Performance on the Dyno: Optimal Parts Combos for Maximum HorsepowerFrom EverandHow to Build LS Gen IV Performance on the Dyno: Optimal Parts Combos for Maximum HorsepowerRating: 5 out of 5 stars5/5 (1)

- Manual Stripping Machine - Mec - Unlocked PDFDocument460 pagesManual Stripping Machine - Mec - Unlocked PDFEdward Jr ChapetonNo ratings yet

- FlowBiz High Pressure Universal Design Non Return ValveDocument1 pageFlowBiz High Pressure Universal Design Non Return ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Project Data: Project Name Soluble Evaporation Project Number 027 Author Rajesh Description Date 5/17/2021 Design Code ENDocument32 pagesProject Data: Project Name Soluble Evaporation Project Number 027 Author Rajesh Description Date 5/17/2021 Design Code ENAbdul basithNo ratings yet

- Spare Parts List L90LS Sep 05Document40 pagesSpare Parts List L90LS Sep 05jhames limaNo ratings yet

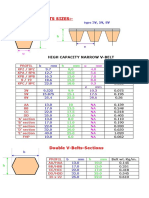

- Belt CalculationsDocument3 pagesBelt CalculationsGnana PrakashNo ratings yet

- K81 PCDocument61 pagesK81 PCAhmad FirdausNo ratings yet

- (1952) Válv. Ventosa Dav-Ms DorotDocument3 pages(1952) Válv. Ventosa Dav-Ms DorotHOSMANNo ratings yet

- Prince Wolverine - CatalogoDocument32 pagesPrince Wolverine - CatalogoIvan SoteloNo ratings yet

- Models HSR-B, HSR-BM, HSR-LB and HSR-LBM: Hsr25 B 2 QZ Uu C0 M +1200L P T MDocument2 pagesModels HSR-B, HSR-BM, HSR-LB and HSR-LBM: Hsr25 B 2 QZ Uu C0 M +1200L P T Msiunatsu8985No ratings yet

- H-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application ProgramDocument241 pagesH-10207 81 CBC 00-001F FT-220KV Switchyard Lcu6 Application Programnguyen rinNo ratings yet

- Hydraulic Sealing Products - Size ChartsDocument71 pagesHydraulic Sealing Products - Size ChartsEnrique MurgiaNo ratings yet

- Catalog A760eDocument4 pagesCatalog A760eautomaticosbrasilNo ratings yet

- Gad 20406510 10 En-00 PDFDocument1 pageGad 20406510 10 En-00 PDFErikikoNo ratings yet

- Daiwa - SALTIST® HYPER SPEED LEVER DRAG PDFDocument3 pagesDaiwa - SALTIST® HYPER SPEED LEVER DRAG PDFDarcy JF SilvaNo ratings yet

- 061522009-0615 ADA ControlDocument1 page061522009-0615 ADA ControlDelphi CrackerNo ratings yet

- SR & SRC Series PDFDocument6 pagesSR & SRC Series PDFIwan SbNo ratings yet

- HEX Lugs Price ListDocument10 pagesHEX Lugs Price ListAvoor KhanNo ratings yet

- HS 915Document1 pageHS 915Đạt LêNo ratings yet

- HS 915Document1 pageHS 915Đạt LêNo ratings yet

- IKYBI ShockabsorberDocument7 pagesIKYBI ShockabsorberLeonard KeaneNo ratings yet

- PCB & Electronics HardwareDocument84 pagesPCB & Electronics HardwaresciucNo ratings yet

- May 29 - 17..Document61 pagesMay 29 - 17..Dhananjay Kumar0% (1)

- Finolex Flexible WireDocument4 pagesFinolex Flexible WirerameshqapcbaNo ratings yet

- Cooling Water Line HydDocument7 pagesCooling Water Line HydpavanNo ratings yet

- ST 403Document17 pagesST 403amrNo ratings yet

- Global Standard Type LM Guide Model SHS: Structure and FeaturesDocument16 pagesGlobal Standard Type LM Guide Model SHS: Structure and Featurescesar cadelaNo ratings yet

- Catalogo MARESA 2007Document79 pagesCatalogo MARESA 2007Alberto PopushoyNo ratings yet

- 025a1s10dxxd52rx (Sa Actuator)Document1 page025a1s10dxxd52rx (Sa Actuator)sathish1801No ratings yet

- Bar Bending Schedule: Title: Commercial BLDG Cutting ListDocument22 pagesBar Bending Schedule: Title: Commercial BLDG Cutting ListJet ArcaNo ratings yet

- 油套管规格表Document3 pages油套管规格表Forest MoNo ratings yet

- BS 5950Document2 pagesBS 5950adihindNo ratings yet

- Manhours & Method Statement - Pump ManualDocument5 pagesManhours & Method Statement - Pump ManualbecpavanNo ratings yet

- Fluids-Utility en 2016-01-01Document38 pagesFluids-Utility en 2016-01-01realesjNo ratings yet

- Seaboard CatalogDocument21 pagesSeaboard Catalogdmccaulley11No ratings yet

- Calculator SullairDocument1 pageCalculator SullairyanethNo ratings yet

- Master List of Drawings Nov 2019Document67 pagesMaster List of Drawings Nov 2019Kanhaiya Lal YadavNo ratings yet

- Ms Trading Pipefittingcatalogue Dec2016 ElectronicDocument44 pagesMs Trading Pipefittingcatalogue Dec2016 ElectronicANV100% (1)

- Sectional Drawing Tag Numbers Bill of Material: Leser GMBH & Co. KG, GermanyDocument1 pageSectional Drawing Tag Numbers Bill of Material: Leser GMBH & Co. KG, Germanyashish shrivastavNo ratings yet

- CoaxialDocument24 pagesCoaxialHakan ÜçokNo ratings yet

- Models HSR-CB, HSR-CBM, HSR-HB and HSR-HBM: Hsr35 CB 2 QZ ZZHH C0 M +1400L P T MDocument2 pagesModels HSR-CB, HSR-CBM, HSR-HB and HSR-HBM: Hsr35 CB 2 QZ ZZHH C0 M +1400L P T Msiunatsu8985No ratings yet

- KSVRDocument2 pagesKSVRngomanhlinh2009No ratings yet

- Brass Cable Glands (Indoor & Outdoors Types)Document2 pagesBrass Cable Glands (Indoor & Outdoors Types)ThilinaNo ratings yet

- 03 - Cie - Cable Glands - (3.45 - 3.46)Document2 pages03 - Cie - Cable Glands - (3.45 - 3.46)ThilinaNo ratings yet

- GRE - WorksDocument5 pagesGRE - WorksUmer IlliasNo ratings yet

- DNV Cert of WinchDocument6 pagesDNV Cert of WinchSRARNo ratings yet

- Toggle ClampsDocument37 pagesToggle ClampsRavi Arjun KumarNo ratings yet

- Venta Cot.2646Document2 pagesVenta Cot.2646Jessica López QuintoNo ratings yet

- UntitledDocument44 pagesUntitledpsychemediaNo ratings yet

- Code 61/62 Flange Clamps, Split: Hydraulic Flanges and Components and Dual Seal FlangesDocument4 pagesCode 61/62 Flange Clamps, Split: Hydraulic Flanges and Components and Dual Seal FlangesHuy NguyễnNo ratings yet

- ION EXCHANGE Modified SDocument2 pagesION EXCHANGE Modified SVinay YadavNo ratings yet

- ACS V4 Assembly Drawings PDFDocument37 pagesACS V4 Assembly Drawings PDFIonuţ-Alexandru BătrînacheNo ratings yet

- Ventas Ronnie Agosto 2019Document20 pagesVentas Ronnie Agosto 2019OmarBarrientosNo ratings yet

- Illustration 29 07 2017 PDFDocument1 pageIllustration 29 07 2017 PDFGlenn D. KleinNo ratings yet

- 2-Bolt Flange: LF 200 PTI SeriesDocument1 page2-Bolt Flange: LF 200 PTI SeriesAniket SharmaNo ratings yet

- CONN 02aDocument19 pagesCONN 02aAbdul basithNo ratings yet

- Metallic Flexible ConnectorsDocument20 pagesMetallic Flexible ConnectorsHari KrishnaNo ratings yet

- Juki MO-3704-OE4 MO-3714-BE6 MO-3716-DE4Document57 pagesJuki MO-3704-OE4 MO-3714-BE6 MO-3716-DE4bacanaslegalNo ratings yet

- 13 TaylorDocument12 pages13 TaylorAlberto SanchezNo ratings yet

- Steel and Its Heat Treatment: Bofors HandbookFrom EverandSteel and Its Heat Treatment: Bofors HandbookRating: 2.5 out of 5 stars2.5/5 (3)

- !!!chlorate Cell PDFDocument20 pages!!!chlorate Cell PDFSlava75No ratings yet

- !!!project Flow PDFDocument1 page!!!project Flow PDFSlava75No ratings yet

- !!!electoliz PDFDocument18 pages!!!electoliz PDFSlava75No ratings yet

- Urinal Screens: Pee'in Is Believe'inDocument2 pagesUrinal Screens: Pee'in Is Believe'inSlava75No ratings yet

- !!!flyer - EU-Mirapol SurfN PDFDocument2 pages!!!flyer - EU-Mirapol SurfN PDFSlava75No ratings yet

- !!!EVA 019 AtevaOverviewGradesSheet TS EN 0416 PDFDocument2 pages!!!EVA 019 AtevaOverviewGradesSheet TS EN 0416 PDFSlava75No ratings yet

- !!!mould Quotation With 1 Cavity SINO210052A PDFDocument1 page!!!mould Quotation With 1 Cavity SINO210052A PDFSlava75No ratings yet

- !!!проработать FPLSHCM - 214 - 1 PDFDocument36 pages!!!проработать FPLSHCM - 214 - 1 PDFSlava75No ratings yet

- !!!!eva Flexaren - Product - Overview - en PDFDocument2 pages!!!!eva Flexaren - Product - Overview - en PDFSlava75No ratings yet

- Press Release: Henkel Rewards Suppliers For Outstanding ContributionsDocument3 pagesPress Release: Henkel Rewards Suppliers For Outstanding ContributionsSlava75No ratings yet

- The ProcessDocument43 pagesThe ProcessCarmel ThereseNo ratings yet

- Etha FoamDocument4 pagesEtha Foaml561926No ratings yet

- MOTORTECH Manual EmCon5 01.50.002 EN 2016 01 WEB PDFDocument112 pagesMOTORTECH Manual EmCon5 01.50.002 EN 2016 01 WEB PDFheri setyawanNo ratings yet

- (L8) - (JLD 2.0) - Current Electricity - 27th JuneDocument43 pages(L8) - (JLD 2.0) - Current Electricity - 27th JuneAtishay VermaNo ratings yet

- Energy and Work 6Document21 pagesEnergy and Work 6Yash SharmaNo ratings yet

- Weir Minerals México: Azteca Procesos, S.A. DE C.VDocument47 pagesWeir Minerals México: Azteca Procesos, S.A. DE C.VCEHU88No ratings yet

- A Simulation Model For A Single Cylinder Four-Stroke Spark Ignition Engine Fueled With Alternative FuelsDocument20 pagesA Simulation Model For A Single Cylinder Four-Stroke Spark Ignition Engine Fueled With Alternative FuelsMadhusudan BarotNo ratings yet

- Draft Report On Sustainable Urban Transport - Principles and Guidelines For Indian CitiesDocument256 pagesDraft Report On Sustainable Urban Transport - Principles and Guidelines For Indian CitiesNarinder KhajuriaNo ratings yet

- Experimental Investigation of Waste Glass Powder PDFDocument6 pagesExperimental Investigation of Waste Glass Powder PDFYuliusRiefAlkhalyNo ratings yet

- 000000000001013900Document188 pages000000000001013900shawnr737667% (3)

- IEA, IEA. World Energy Outlook 2019-Analysis-IEA. World Energy Outlook 2020Document464 pagesIEA, IEA. World Energy Outlook 2019-Analysis-IEA. World Energy Outlook 2020ppourmoghaddamNo ratings yet

- Exercises: Section 1.3 Standards and Units Section 1.4 Unit Consistency and ConversionsDocument1 pageExercises: Section 1.3 Standards and Units Section 1.4 Unit Consistency and ConversionsCyn SyjucoNo ratings yet

- JEE Atomic Structure Formula SheetsDocument11 pagesJEE Atomic Structure Formula SheetsbsarkarNo ratings yet

- Life Cycle Assessment of Photovoltaic Electricity Generation PDFDocument9 pagesLife Cycle Assessment of Photovoltaic Electricity Generation PDFLeonardo CaldasNo ratings yet

- Amphib CarrierDocument104 pagesAmphib Carrierwilk42No ratings yet

- 20 Bridge Plug MetricDocument1 page20 Bridge Plug MetricKim MissonNo ratings yet

- Hvsi 804RDocument16 pagesHvsi 804RMurali SubramaniNo ratings yet

- Isat 2010 Set - BDocument12 pagesIsat 2010 Set - BpremsempireNo ratings yet

- Cse Sem1 PDFDocument9 pagesCse Sem1 PDFAkash GauravNo ratings yet

- CBSE Class 12 CHEMISTRY PROJECT (Cold Drinks)Document18 pagesCBSE Class 12 CHEMISTRY PROJECT (Cold Drinks)ArnavAD100% (7)

- Cities and BuildingsDocument60 pagesCities and BuildingsAndon Setyo WibowoNo ratings yet

- PE Lecture No.09Document16 pagesPE Lecture No.09Nikhil GobhilNo ratings yet

- SM DH Series ManualDocument154 pagesSM DH Series Manualkikyangello90No ratings yet

- 5129 s07 QP 1Document16 pages5129 s07 QP 1airulyantiNo ratings yet

- ME F341 Prime Movers and Fluid MachinesDocument3 pagesME F341 Prime Movers and Fluid MachinesKartikeya TiwariNo ratings yet

- OTCQB Company ListDocument119 pagesOTCQB Company ListtbconantNo ratings yet

- Aplicaciones Del MC10116Document4 pagesAplicaciones Del MC10116julio gamboaNo ratings yet

- Ways To Prevent Air PollutionDocument6 pagesWays To Prevent Air PollutionRahul HanumanteNo ratings yet

- Modelos Maquina Sicor ItalianaDocument104 pagesModelos Maquina Sicor ItalianaAscensores MbsasNo ratings yet

- Continental Industrial PDFDocument359 pagesContinental Industrial PDFDavidNo ratings yet