Warehouse Report

Uploaded by

Ajinkya JagdaleWarehouse Report

Uploaded by

Ajinkya Jagdale- Introduction: Provides acknowledgments and an overview of the warehouse visit report, including purpose and characteristics of an ideal warehouse.

- Warehouse Management System: Describes the warehouse management system's role in supply chain management, with a focus on WMS and SAP SCM software usage.

- Floor Operations: Details the floor operations involved in warehousing, including picking, loading, and supervision activities.

- Equipment and Computer Station: Explains the types of equipment used in warehousing, such as pallets and forklifts, and the role of the warehouse computer station.

- Data Collection: Presents data collected from various warehousing companies, encompassing material details and warehousing practices.

Common questions

Powered by AIWarehouse racks have sections like HOLD, for temporarily damaged goods awaiting a client's RDA verification, and DMO, for entirely damaged goods deemed waste. These sections ensure proper categorization and handling of non-standard inventory, aiding in decision-making processes related to quality control and disposal .

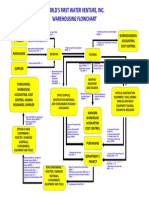

The Warehouse Management System (WMS) optimizes the movement and storage of materials by controlling associated transactions such as shipping, receiving, put away, and picking. It uses real-time information to direct and optimize storage based on bin utilization, monitors product progress through the warehouse, and facilitates communication between different station points within the warehouse infrastructure .

An ideal warehouse should be located at a convenient place to facilitate easy access and transportation. It should be mechanically and technologically advanced to enhance operational efficiency and accuracy. Large and adequate space is essential to accommodate varied storage needs, while protection from elements like sunlight, rain, dust, and moisture ensures the integrity of stored goods. Adequate parking and security measures safeguard property and facilitate smooth operation, while fire-fighting equipment and emergency services are crucial for safety and risk management .

The TP & Deployment department is responsible for order processing, planning transportation, and fulfilling customer requirements. They use SAP technology to perform all operations, facilitating order tracking, documentation, and efficient deployment of resources to ensure timely and accurate fulfillment of customer orders .

The e-way bill serves a documentation function in warehouse operations, confirming the legality and accountability of product movement. It's generated as part of the order processing in SAP and included in the documentation along with pick lists and other details necessary for tracking and compliance during transportation .

SCM integration with business processes like product discovery, materials purchase, and production planning enhances performance by enabling seamless product and information flow, leading to increased customer satisfaction at reduced costs. This holistic approach ensures that production matches demand accurately, inventory is optimized, and client orders are fulfilled efficiently using systems like SAP for processing and documentation .

Articulated machines facilitate warehouse operations by efficiently lifting and moving goods between different warehouse sections. They have the capacity to handle heavy loads up to 1600 kg and are essential for placing goods in rack units or transporting them between various storage zones, enhancing operational efficiency and safety .

During unloading, goods are checked for quantity, packaging quality, and any physical damage or leakage. The process involves security and supervisor documentation on checklists to verify the condition and specification of the received goods. Any discrepancies are reported, and products are categorized into sections such as HOLD for potentially damaged goods pending review by the RDA department, or DMO for confirmed waste or damaged items .

Having both supervisor and security checklists ensures a dual-layer verification system for all operations involving the movement of goods, whether incoming or outgoing. This redundancy helps catch errors, discrepancies, or fraud, ensuring that both the quantity and the quality of goods match the documented records before they are processed further .

Inventory management maintains desired stock levels by balancing customer service requirements against the costs of inventory investment. Factors influencing these levels include demand forecasts, lead times, storage capacities, product lifecycle stages, and organizational financial constraints. Proper management ensures optimal stock availability while minimizing costs .