Professional Documents

Culture Documents

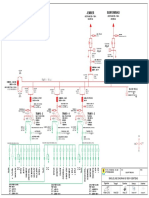

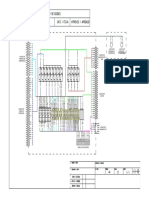

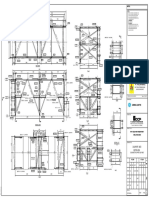

0186-PLN-CMI-033-054-1020 - Rev00 - SR Steel Structure - Plan View Platform TOS. - 8.657 - TOS. - 5.085 and TOS. - 1970 - Eng DWG

Uploaded by

javierOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0186-PLN-CMI-033-054-1020 - Rev00 - SR Steel Structure - Plan View Platform TOS. - 8.657 - TOS. - 5.085 and TOS. - 1970 - Eng DWG

Uploaded by

javierCopyright:

Available Formats

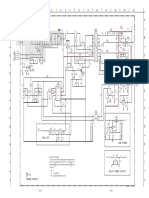

S3 HEA200

A36 S3 HEA200 General notes :

A36

North 270 3839 250 1. Steel

-8657 mm -8657 mm According to ASTM norm :

S3 HEA200 S239 HEA160 S239 HEA160 - ASTM A36 (or equivalent to be approved by CMI) : minimum yield point = 248 MPa ;

A36

2185 5274 A36 A36 North ultimate tensile strength = 400 MPa

S247 HEA160 568 1617 -5.085 - ASTM A572gr50 (or equivalent to be approved by CMI) :

32

32

32

32

76 777 80 A36 7 minimum yield point = 345 MPa ; ultimate tensile strength = 450 MPa

-8.625 -8.625

1005 190

1005 190

- All connection plates welded to member in steel ASTM A572gr50

840 95

840 95

Handrailing Floor Mounting 320 will aslo be made of ASTM A572gr50.

8 S374 CHS60.3X3.91

S300 L60/6 9 9

A36 4 TOS. -8.657 A106B

2.Welding

3 BOG. -8.657 Stairs -8.657 -->-5.085

- Weld material must be minimum equal to base materials.

S315 UNP160 Handrailing S331 UNP240 - Unless indicated otherwise, all welds are minimum 5mm and

A36 A36

917

Ladder -5.085 --> -3.485

all welds will be continuous.

3572

1427

260

260

S245 HEA160 - All given welds dimensions are as European way : throat dimension.

6 A36 For leg size, multiply throat dimension by 1,42.

2 2

1000

1000

5 5 76 777 80 S330 UNP240 - After welding, all column top and bottom base plates must be checked

S11 CHS88.9X5.49 76 777 80 S11 CHS88.9X5.49

A36

for flatness and if necessary machined to reach a perfect contact.

2854

A106B

A106B S331 UNP240

A36

S206 HEA140 Section 1 - 1 Section 2 - 2

3.Bolts

1937

S300 L60/6 A36 Scale: 1:40 - Have to be determined following CMI references :

1 1 Scale: 1:40

41°

A36 S240 HEA160 S330 UNP240

-8657 mm Connection Book 82003/50F04 and standards.

1427

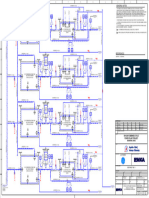

TOS. -5.085

1300

1300

A36 A36

- In general, ASTM A325 M bolts will be used, with exception of ASTM A490 M

Handrailing Floor Mounting S245 HEA160 BOG. -5.085

3 4

A36

S375 CHS60.3X3.91

1000 -8.625 High-Strength Bolts for connections on main supports, columns and platforms.

- All bolts are galvanized, except ASTM 490 M HS which are black steel.

A106B

- All bolts are supplied with one nut A563 M and 2 hardened washers F436 M.

West East S315 UNP160

A36

-8657 mm -8657 mm - Bolts, nuts and washers are according to ASTM.

1080 10 10

S3 HEA200 4.Tightening

A36 S246 HEA160 Section 5 - 5 - All ASTM A490 M High-Strength bolts must be tighten with a calibrated

8

32

A36 Scale: 1:40

dynamometric tool.

6 -8.625 -8.625

1005 190

7 - All ASTM A325 M bolts must be tighten with an adequate dynamometric tool.

- Torque values will be given in Erection Procedure 82003/88E01 and its annexes.

300 1000 885

S240 HEA160 5. Walkways and platforms

Stairs -5.085 --> -1.970 Concrete tower A36 287 3700 250 - Channel flange connections will be done with washer DIN434 or equivalent.

12400 - Handrailings, gratings, ladders and stairs must be based on drawings

Section 4 - 4 82003/51011 and 82003/51012.

Scale: 1:40 - If necessary, handrailings, gratings have to be adapted by erector

S239 HEA160 S239 HEA160

Concrete tower South 1000

A36 A36

-1.970 during erection according equipments and pipings layout.

Plan view platform TOS. -8.657 to TOS. -5.085 Section 3 - 3

6.Fabrication, erection and tolerances

Scale: 1:40 - Fabrication must follow all requirements in CMI technical specification

Scale: 1:40

82003/50E01 and its annexes.

- Erection must follow all requirements in CMI technical specification

82003/88E01 and its annexes.

North 20 240 20 20 240 20 - Tolerances specification for manufacturing and erection must be

3115

respected 66000/99E99.

TOS. -5.085 S357 HEB240 S355 HEB240 S333 UNP240 - Painting must be in compliance with CMI specification 82003/49E01

BOG. -5.085 A36 A36

A36 and its annexes.

10

10

S332 UNP240 - Manufacturing and quality control must be in compliance with all requirement

A36

in CMI ITP 82003/96Q14 and its annexes.

38°

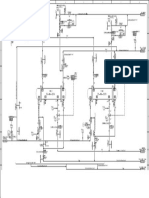

7.General

220

220

- For sections with vertical flanges, holes diameter 30mm must be drilled

in the horizontal web every 3000mm for dewatering.

-5.085

8. Abbreviations

10

10

Section 11 - 11 TOG = Top of Grating

PL20*220 * 2697 PL20*220 * 2697 PL20*220 * 2697 PL20*220 * 2697 Scale: 1:40 TOC = Top of Concrete

A36 A36 A36

A36 TOS = Top of Steel

MOS = Middle of Steel

Section 17 - 17 Section 18 - 18 BOS = Bottom of Steel

Scale: 1:10 Scale: 1:10 BOB = Bottom of Baseplate

11

9. Coordinates axis references

- Receiver relative coordinates origin is at center of receiver axis and BOS of

receiver lower radial support beams.

- Reference in reciever relative coordinates : X = 0 ; Y = 0 ; Z = 0

West East - Reference in plant relative coordinates : X = +2700,00 m ; Y = 2700,00 m ;

130

130

Z = +217,20 m (from ground level)

300 1000 885 16 - Reference in UTM absolute coordinates : X = +450793,577 m ;

+1.450 +1.450 +1.450 Y = +7481679,031 m ; Z = +1722,625 m (from sea level)

500

- Axis orientation : +X is East , +Y is North , +Z is Up

S333 UNP240 S332 UNP240

A36 A36

1320

10. Splices

S27 CHS114.3X6.02 - Welded splices are to be considered as material splices for pre-assemblies in workshop.

950

Handrailing A106B

Stairs -5.085 --> -1.970 - Bolted splices are to be considered as site connections.

4019 3909

3950

1947

S46 IPE140

A36

+0 +0 +0

1400 1454

-931 mm

3719

S335 UNP240 Stairs -1.970 --> +1.450 S356 HEB240

A36 S357 HEB240

S248 HEA160 S202 HEA140 A36 A36

A36 A36

1000

S334 UNP240

S357 HEB240

14 770 1000 1538 15 A36

A36

S30 CHS114.3X6.02

3485

12 12 A106B

TOS. -1.970 -2333 mm

BOG. -1.970 S203 HEA140

2608

A36

5085

1324

S251 HEA160

A36 S250 HEA160 S205 HEA140

16 A36 A36

S68 IPE140 11 1000

A36 S373 CHS60.3X3.91 17 17 S34 CHS114.3X6.02

A106B 18 18 A106B

2697

2697

13 13 -3.485 S34 CHS114.3X6.02

2686

115 885 992 1024 15 A106B

S355 HEB240

S371 CHS60.3X3.91

885 2900 234 3909 A36

1600

A106B

1480

14

S361 HEB240

S46 IPE140 A36

S249 HEA160 S372 CHS60.3X3.91

A36

South S245 HEA160

S354 HEB240

A36

A36 A36

A106B

-5.085 -5.085 -5.085

248

76

400

Plan view platform TOS. -5.085 to TOS. -1.970 2854

Scale: 1:40

S245 HEA160

Section 8 - 8

A36 Scale: 1:40

S28 CHS114.3X6.02 S29 CHS114.3X6.02

2854 A106B A106B

350

350

+1.450 +1.450 Section 6 - 6 Section 7 - 7

Scale: 1:40 Scale: 1:40

1450

180

190

190

+0 +0

180

+1.450 +1.450

500

500

3070

3070

S241 HEA160

S242 HEA160 A36

A36 S241 HEA160 S242 HEA160

1260

A36 A36

4376

1790

1790

950

S12 CHS88.9X5.49 S31 CHS114.3X6.02 S31 CHS114.3X6.02

A106B A106B

2257

S248 HEA160 A106B

A36

S249 HEA160 +0 +0 0 2015/02/17 First issue

A36

+1.450 -931 mm

D.P. D.V.J.

-1.970 -1.970 S32 CHS114.3X6.02 Rev. Edition

Description:

Signature Signature Signature

3349

A106B No.: Date:

S157 HEA140 Drawn: Reviewed: Approved:

A36

4019 2900 Location:

S388 CHS141.3X6.55

Section 12 - 12 Section 13 - 13 -2333 mm A106B North

Scale: 1:40

1402

Scale: 1:40

+0 S204 HEA140 -2333 mm

3420

A36

S334 UNP240

5085

5085

350

A36

S157 HEA140

+1.450 +1.450 S335 UNP240

A36

S33 CHS114.3X6.02

A106B

A36

S356 HEB240

38°

A36

S242 HEA160 S357 HEB240

A36

1100

A36

2686

2686

-1.970

180

S355 HEB240

Section 16 - 16 S354 HEB240 A36

+0 +0 Scale: 1:40 A36

Client: P. Engineer (if applicable):

S242 HEA160 Stamp: Signature: P.Eng.No:

S40 HEB180 A36

A36

S13 CHS88.9X5.49

A106B

-5.085 -5.085

1970

EPC Contractor:

S241 HEA160

1790

S14 CHS88.9X5.49

76

A36

A106B

1617 568 2185 Project:

S247 HEA160 Supplier Eng.:

S241 HEA160 A36 2185 S246 HEA160

A36

CSP Atacama 1

A36

-1.970 -1.970 Section 10 - 10

Section 9 - 9 Drawing No.:

Title and Subtitles:

Scale: Solar Receiver

S251 HEA160 Scale: 1:40 Scale: 1:40 0186-PLN-CMI-033-054-1020

A36 S250 HEA160 1:10

A36 Sheets: Sheet No.:

Steel Structure - Plan View Platform TOS. -8.657 ; 1 1

1:40

Section 14 - 14 Section 15 - 15 TOS. -5.085 And TOS. -1.970 - Engineering Drawing

Int. Drawing No.

Tekla Structures

Scale: 1:40 Scale: 1:40

82003/51020

Status First edition date

ALL HANDRAILING SIDE MOUNTING UNLESS NOTED OTHERWHISE This drawing and the design it covers are the property of CMI. They have been

merely loaned by express agreement of the borrower, who states that it cannot be

reproduced, copied, loaned, exhibited or used under any circumstances. As an

X Issue For Design (IFD)

Issue For Bid (IFB)

2015/02/17

exception, it can be used in a limited and private way, as long as CMI gives Issue For Purchase (IFP)

permission to the borrower for using it through a written consent . Issue For Construction (IFC)

As built

You might also like

- Determinacion de Los Costos de Soldadura para Union de FileteDocument26 pagesDeterminacion de Los Costos de Soldadura para Union de FiletejavierNo ratings yet

- Algorithms (Complete Course) :-Btech CSE: TopicsDocument4 pagesAlgorithms (Complete Course) :-Btech CSE: TopicsRahul SinghNo ratings yet

- Cell Transport WorksheetDocument2 pagesCell Transport WorksheetVictoria Niño D100% (1)

- McMillan 2007. Fish - Histology PDFDocument603 pagesMcMillan 2007. Fish - Histology PDFMarcela Mesa100% (1)

- Remove Support: Issued For ConstructionDocument1 pageRemove Support: Issued For Construction86tejasNo ratings yet

- Jember Banyuwangi: Trafo - 1 Trafo - 3 Trafo - 2Document1 pageJember Banyuwangi: Trafo - 1 Trafo - 3 Trafo - 2irfanNo ratings yet

- C13 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic SymbolsDocument2 pagesC13 On-Highway Engine Electrical System: Harness and Wire Electrical Schematic Symbolsfrancisco6jav-8856120% (1)

- Title of Thesis or Practicum or Research Proposal or Report: Firstname M. LastnameDocument17 pagesTitle of Thesis or Practicum or Research Proposal or Report: Firstname M. LastnameDozdi100% (3)

- MHC-GPX33 55 77 88Document1 pageMHC-GPX33 55 77 88Juliana Ribeiro100% (6)

- Companion 5 - DSP SCH PDFDocument4 pagesCompanion 5 - DSP SCH PDFManimaran MaranNo ratings yet

- Soalan Biologi Kertas 2 Tingkatan 4Document14 pagesSoalan Biologi Kertas 2 Tingkatan 4azszah100% (17)

- SUMMATIVE TEST NO 3. Aristotle Concept of MotionDocument2 pagesSUMMATIVE TEST NO 3. Aristotle Concept of MotionGeri Isabel Tampus0% (1)

- 01 E02STB007-W146693-03-0 - BC - Stress UpdateDocument1 page01 E02STB007-W146693-03-0 - BC - Stress Update86tejas100% (1)

- Spreader Beam Drawings & MTODocument3 pagesSpreader Beam Drawings & MTOsales ntscompaniesNo ratings yet

- Superheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6Document1 pageSuperheater 1 06HAH10 AC001 ST-Row 3/4 ST-Row 2/5 ST-Row 1/6DenkaNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- MB DD DW BP Ass GR 1002Document1 pageMB DD DW BP Ass GR 1002Ankur SinhaNo ratings yet

- Power+Supply+RSAG7 820 4716+hisenseDocument1 pagePower+Supply+RSAG7 820 4716+hisenseBruno SamosNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Elevation of Tower - 1 (Facing North) Part 3 of 3: LegendsDocument1 pageElevation of Tower - 1 (Facing North) Part 3 of 3: LegendsHozien OnofreNo ratings yet

- Elevation of Tower - 2 (Facing North) Part 3 of 3: LegendsDocument1 pageElevation of Tower - 2 (Facing North) Part 3 of 3: LegendsHozien OnofreNo ratings yet

- Bill of Material: Section A-ADocument1 pageBill of Material: Section A-APinak ProjectsNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- ST 03 CSDocument1 pageST 03 CSDareen BaredNo ratings yet

- Onco SRP Layout Piperack Routing-ModelDocument1 pageOnco SRP Layout Piperack Routing-ModelBagadi AvinashNo ratings yet

- Sync CKT Usb Power: (3) Schematic Diagram of D-BoardDocument1 pageSync CKT Usb Power: (3) Schematic Diagram of D-BoardБорис ПетрикNo ratings yet

- C9 Marine Engine Electrical System: Right/Top ViewDocument2 pagesC9 Marine Engine Electrical System: Right/Top ViewTariqMaqsoodNo ratings yet

- Issued For Construction Modular Isometrics: Remove TrunnionDocument1 pageIssued For Construction Modular Isometrics: Remove Trunnion86tejasNo ratings yet

- LOT AEP V2 24-06-2022-ModelDocument1 pageLOT AEP V2 24-06-2022-ModelMohamed RachikNo ratings yet

- Samsung / / / PCB Layout: SM-A505F GTDocument2 pagesSamsung / / / PCB Layout: SM-A505F GTRaul Del Castillo Merlo0% (1)

- Ab STR 104 B124Document1 pageAb STR 104 B124arainzada807No ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- 1SKL301B H 133 LG 00053 01 - SHT - 1Document1 page1SKL301B H 133 LG 00053 01 - SHT - 1Moein MovahhedNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Corrosion Loops Example 1 - Heat Exchangers Template1Document1 pageCorrosion Loops Example 1 - Heat Exchangers Template1Christian JoseNo ratings yet

- LOCATION:-26050 M: 12 MM Dia Tor@150 MMC/CDocument1 pageLOCATION:-26050 M: 12 MM Dia Tor@150 MMC/Cabhijeet sahuNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- STR 2883Document4 pagesSTR 2883eng.yehia.omara.kbhNo ratings yet

- AUDIO Sony HCD-H650Document4 pagesAUDIO Sony HCD-H650Nerta Natura100% (1)

- 300M Schematic DiagramDocument2 pages300M Schematic DiagramAdriano Andrade100% (3)

- Radio Por InternetDocument1 pageRadio Por InternetYury Dante Viza VilcaNo ratings yet

- Drawing No.: IssueDocument2 pagesDrawing No.: IssuevvkNo ratings yet

- G125-3829 Wiring Diagram Leyton Modificación PDFDocument1 pageG125-3829 Wiring Diagram Leyton Modificación PDFGustavo CofreasdfklpNo ratings yet

- C9 Generator Electrical SchematicDocument2 pagesC9 Generator Electrical SchematicKhaled Naseem Abu-SabhaNo ratings yet

- XA XA: P&Id Area 36 - Grinding SystemDocument1 pageXA XA: P&Id Area 36 - Grinding SystemGoulet KostNo ratings yet

- 17IPS06Document3 pages17IPS06SATBRAINNo ratings yet

- Rsag7.820.4614 PSDocument1 pageRsag7.820.4614 PSvasul.denusNo ratings yet

- Dc-380v-Out +24v-Out: FB Out VCC 1 2 3 4 5 6 7 8 ZCD NC VH 1 2 3 4 5 6 7 8Document1 pageDc-380v-Out +24v-Out: FB Out VCC 1 2 3 4 5 6 7 8 ZCD NC VH 1 2 3 4 5 6 7 8JosiasNo ratings yet

- 100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 019-019Document1 page100136C-051-DD-1841-1013 - 1 (Shop Drawing) - 019-019Tamil Arasu SNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- MUK-61-2-0784-001-9B4-1 Rev 1 110707 PDFDocument1 pageMUK-61-2-0784-001-9B4-1 Rev 1 110707 PDFSuresh MahalingamNo ratings yet

- S6 Shop DrawingDocument4 pagesS6 Shop DrawingahmedNo ratings yet

- CIN-AS-CO21 - Rev 0Document1 pageCIN-AS-CO21 - Rev 0Xu DuaNo ratings yet

- Cce hps-33rDocument1 pageCce hps-33rmarcellobbNo ratings yet

- 10END30BR001Document1 page10END30BR001Valesh MonisNo ratings yet

- Power Supply Skyworth 8M51BDocument1 pagePower Supply Skyworth 8M51BautreraNo ratings yet

- Street Light 1.30.23Document1 pageStreet Light 1.30.23MarkNo ratings yet

- Ms09a LaDocument8 pagesMs09a LaJose radhames ColladoNo ratings yet

- WTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02Document1 pageWTC-MQ-XAR-AR-EL-00201 (C) - West Elevation - 02xyzhynNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Led32b2100c/led32b2200/ Led39b2100c/ Led39b2200 715G5654P01001002SDocument2 pagesLed32b2100c/led32b2200/ Led39b2100c/ Led39b2200 715G5654P01001002SseggurNo ratings yet

- As-Built Precast Beam-04042023-Layout1Document1 pageAs-Built Precast Beam-04042023-Layout1kuchmenghyNo ratings yet

- 11 - Montage Drawings For Sandwich Panels - Rev 1Document1 page11 - Montage Drawings For Sandwich Panels - Rev 1samiNo ratings yet

- DRF - 10123323 - Caa - A Conectores de Acumuladores Mesa de OscilaciónDocument1 pageDRF - 10123323 - Caa - A Conectores de Acumuladores Mesa de OscilaciónRonald Rayme VenturaNo ratings yet

- 2 - Section ViewDocument1 page2 - Section ViewMj EdinNo ratings yet

- S8 Shop DrawingDocument4 pagesS8 Shop DrawingahmedNo ratings yet

- Tan 80 80 Tan 70 70 Tan 60 60 Tan 45 45 Cos 80 Cos 70 Cos 60 Cos 45Document1 pageTan 80 80 Tan 70 70 Tan 60 60 Tan 45 45 Cos 80 Cos 70 Cos 60 Cos 45javierNo ratings yet

- Cross Over The Root Centerline: Longitudinal Cracks Transverse Cracks Crater Cracks Base Metal CracksDocument1 pageCross Over The Root Centerline: Longitudinal Cracks Transverse Cracks Crater Cracks Base Metal CracksjavierNo ratings yet

- Report 5Document2 pagesReport 5javierNo ratings yet

- 3.1 Mitosis Ans PDFDocument7 pages3.1 Mitosis Ans PDFtess_15No ratings yet

- STOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsDocument14 pagesSTOD-GEN-AED-0000-ME-SPE-0012 - Functional Specification For AGP Booster PumpsAHMED AMIRANo ratings yet

- Sekar KSP - Hypoglicemia Ec Tipe 2 DMDocument28 pagesSekar KSP - Hypoglicemia Ec Tipe 2 DMdianarahimmNo ratings yet

- AkbarDocument13 pagesAkbarNihar HarinkhedeNo ratings yet

- RTI Online Submit Request FormDocument1 pageRTI Online Submit Request FormRinky SharmaNo ratings yet

- Device Related Error in Patient Controlled.17Document6 pagesDevice Related Error in Patient Controlled.17Ali ÖzdemirNo ratings yet

- Safety Data Sheet According To EEC-Regulation 91/155/EECDocument6 pagesSafety Data Sheet According To EEC-Regulation 91/155/EECANIBALLOPEZVEGANo ratings yet

- Pebble in The Pond by David MerrillDocument22 pagesPebble in The Pond by David MerrillKangdon Lee100% (3)

- Seuring+and+Muller 2008Document12 pagesSeuring+and+Muller 2008Stephanie Cutts CheneyNo ratings yet

- Chapter 4 IR ModelsDocument34 pagesChapter 4 IR ModelsYohannes KefaleNo ratings yet

- Soal Pas B.ing KLS 7Document2 pagesSoal Pas B.ing KLS 7Hernadi TaLaNo ratings yet

- Multiblend Feed FormulationDocument4 pagesMultiblend Feed FormulationIani ChihaiaNo ratings yet

- MLAHomeworkDocument4 pagesMLAHomeworkVANESSA SALDANANo ratings yet

- It Didn't Snow On Saturday. It Rained On SaturdayDocument1 pageIt Didn't Snow On Saturday. It Rained On SaturdayAnna Talhammer100% (1)

- Kurukh GrammarDocument184 pagesKurukh GrammarBHABANI SHANKAR MINZNo ratings yet

- CS687 - Access Control 1 - Spring 2020Document41 pagesCS687 - Access Control 1 - Spring 2020Dawit GetchoNo ratings yet

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Document23 pagesInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliNo ratings yet

- 0332713Document200 pages0332713JS DUFFEYNo ratings yet

- 100 Patient NamesDocument1 page100 Patient NamesTed anadiloNo ratings yet

- MineralsDocument40 pagesMineralsGhillian Mae GuiangNo ratings yet

- English: Quarter 1 - Module 1Document34 pagesEnglish: Quarter 1 - Module 1Roel MabbayadNo ratings yet

- LFS EksellDisplayDocument7 pagesLFS EksellDisplayillustratio.academyNo ratings yet

- Lecture 3 - Pressure Distribution in FluidDocument22 pagesLecture 3 - Pressure Distribution in FluidChristophe EmerichNo ratings yet