Professional Documents

Culture Documents

Fuel Power Conditioner - PDS

Uploaded by

sijinjoyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fuel Power Conditioner - PDS

Uploaded by

sijinjoyCopyright:

Available Formats

Marine Chemicals

Fuel Oil Chemicals: Heavy Fuel Oil Treatment

FUEL POWER CONDITIONER 25 LTR

Product group: 650 Product number: 778785

Unitor™ FuelPower™ Conditioner is the solution for stability & compatibility issues from

asphaltenic sediment with the new VLSFO introduced through IMO 2020. Unitor™

FuelPower™ Conditioner stabilizes and stops sludge formation in fuel tanks. Unitor™

FuelPower™ Conditioner also improves separation reducing the amount of sludge

wasted.

Product information

This product supersedes product no: 766154

Fuel stability and compatibility is an increasing problem with modern marine heavy fuels, especially with blending of low sulfur fuels.

The solution for handling these unstable and incompatible fuels is Unitor™ FuelPower™ Conditioner, it stabilizes and stops sludge

formation in fuel tanks.

Unitor™ FuelPower™ Conditioner also improves separation reducing the amount of sludge wasted keeping the fuel homogeneous

through the whole fuel system delivering a stable fuel ready for combustion.

Features

Stabilizes fuel blends, reducing compatibility problems

Disperses and prevents sludge formation

Reduces the amount of sludge wasted in the centrifugal separator

Benefits

The conditioning properties of Unitor™ FuelPower™ Conditioner ensures your fuel is stable and that a minimum of sludge is

wasted in tanks and centrifugal separators

With purifier working efficiently, filters clean and fuel system in good shape you can focus on the important things

Specification

General Physical properties

Invent Hazard Material (IMO/EU) classification C-6 Appearance Clear, light brown

Density [kg/dm3] 0,84

Flash Point [°C] >61

Form Liquid

Technical data

Not Compatible May swell rubber and synthetic rubber

Documents

No Objection Letter Wartsila

Supplier’s declaration of Conformity (SDoC)

Directions for use

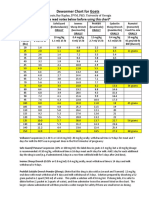

**Dosage and Control**

Ideally, FuelPower Conditioner should be dosed directly into the bunker tank prior to bunkering. However, it can be introduced to

the settling tank or during transfer from storage. Dosage rates are best determined from the results of fuel analysis, i.e. sediment

content or compatibility test which is easily performed on board using the Compatibility Test Kit.

ASTM SPOT 1 2 3 4 5

DOSE RATE **1:20 000 1:10 000 1:5000 1:2500 1:1000

TSP Dosage

Comment

level (ppm)

0,01– 1:25 000

Due to the indication of poor reserve stability of some VLSFO, we advise a low protective dosage.

0,03 (40 ppm)

0,03– 1:20 000 When the TSP increases the reserve stability of the fuel will also be poorer, so we advise a low protective

0,06 (50 ppm) dosage.

0,06– 1:15 000 (67 Once the TSP approaches the max specification sludging will most likely occur. Reserve Stability will also be

0,1 ppm) poor, so a higher dosage is recommended.

0,1– 1:10 000

With a TSP out of specification it is important to have a good impact on the sludging with a higher dosage.

0,2 (100 ppm)

0,2– 1:5 000 A far-off spec TSP fuel is never a good idea to use but when it occurs it is important to be able to reduce

0,5 (200 ppm) sludging and operational impact as much as possible.

1:1 000 We would not recommend using any of these fuels but if there is no choice a high dosage needs to be used to

0,5+

(1000 ppm) have a chance to reduce the sludging from these fuels

* Avoid using this fuel if possible.

** Fully compatible blends, with a sediment percentage of less than 0.05, should not require treatment for incompatibility. Marginal

number 1 spots may cause sludging if the fuel is not handled carefully, so some treatment may be necessary, especially if other

problems such as water content or corrosion are apparent.

If test results are not available, an initial dose of 1:15 000 is recommended, and adjustments made as necessary.

The average dosage for FuelPower Conditioner is 1:15 000 or 67 ppm. When starting a dosage into a fuel tank it is advisable to use a

staged dosage to avoid high amounts of sludge from the fuel into purifiers and filters. This is especially important if the fuel tank has

not been cleaned for an extended period of time. With a stage dosing smaller amounts of sludge will be picked up and over a longer

period of time.

DOSAGE

DOSING COMMENT

LEVEL

1st Time 1:25 000 Initial dosage not to upset the tank

Second and third dosages can be done a bit higher as most of the easily available sludge will

2nd Time 1:20 000

be gone

3rd time and

1:15 000 From the 3rd dosage and forward the recommended dosage of 1:15 000 can be used

forward

Related products

Is frequently bought together with

571356 ROCOR NB LIQUID 25 LTR 571687 DISCLEAN 25 LTR

571364 VAPTREAT 25LTR 698720 AUTOTREAT - 25 LTR

765018 ENVIROCLEAN 25 LTR

This page is printed from:

https://www.wilhelmsen.com/product-catalogue/products/marine-chemicals/fuel-oil-chemicals/heavy-fuel-oil-treatment/fuel-power-conditioner-

25-ltr/

You might also like

- Drug Treatment: A Guide to Properties, Choice, Therapeutic Use and Economic ValueDocument4 pagesDrug Treatment: A Guide to Properties, Choice, Therapeutic Use and Economic ValueAmitKumarNo ratings yet

- Gas lubricating oil and coolant specifications for W220 enginesDocument12 pagesGas lubricating oil and coolant specifications for W220 enginesshahin gholamiNo ratings yet

- Hägglunds - Choice of Hydraulic Fluid PDFDocument2 pagesHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosNo ratings yet

- DSR Fiber Rope Catalogue PDFDocument15 pagesDSR Fiber Rope Catalogue PDFsijinjoyNo ratings yet

- Dieselpower Enhancer 25 LTRDocument2 pagesDieselpower Enhancer 25 LTRGohNo ratings yet

- Aderco L1050 Introduction Brochure + Instructution SheetDocument7 pagesAderco L1050 Introduction Brochure + Instructution Sheetdanpo0450% (2)

- Fowa CheckerDocument10 pagesFowa CheckerJoko NugrohoNo ratings yet

- Aderco L1050 Introduction Brochure + Instructution SheetDocument7 pagesAderco L1050 Introduction Brochure + Instructution SheetSaw WinNo ratings yet

- 9 - Paul B AMS - Presentation - 1!4!2012Document50 pages9 - Paul B AMS - Presentation - 1!4!2012anhntran4850No ratings yet

- Marine Fuel Stability and Compatibility IssuesDocument4 pagesMarine Fuel Stability and Compatibility IssuesRebekah SchmidtNo ratings yet

- Oxidation Inhibitor For Insulating Oil - Power Transformer ApplicationDocument8 pagesOxidation Inhibitor For Insulating Oil - Power Transformer ApplicationdwijanuarNo ratings yet

- Truck Maintenance and Operation ISX15 (EPA 2013) : Quick Reference GuideDocument2 pagesTruck Maintenance and Operation ISX15 (EPA 2013) : Quick Reference GuideMARIO CONTRERASNo ratings yet

- Turbine Oil Condition Monitoring: Oil is the LifebloodDocument13 pagesTurbine Oil Condition Monitoring: Oil is the LifebloodJagadish PatraNo ratings yet

- PDS Eneos Sustina 5W-30Document2 pagesPDS Eneos Sustina 5W-30Tony WijayaNo ratings yet

- PAPER Final FractionationDocument7 pagesPAPER Final FractionationkaruniaNo ratings yet

- Pds Hempadur Primer 15300 En-GbDocument2 pagesPds Hempadur Primer 15300 En-Gbdkdkdkdkdkdk_No ratings yet

- Maintain Transformer OilDocument80 pagesMaintain Transformer Oilajaynmenon100% (2)

- Oxidation Inhibitors For Insulating Oil-IARGray2008Document8 pagesOxidation Inhibitors For Insulating Oil-IARGray2008Juan MarNo ratings yet

- Oil Sampling IntervalsDocument3 pagesOil Sampling IntervalsshivNo ratings yet

- Typical Properties Freight Classification Shipping: Sustainable SolutionsDocument14 pagesTypical Properties Freight Classification Shipping: Sustainable SolutionsAmit BishtNo ratings yet

- Eneos Sustina Product Data Sheet 2016Document2 pagesEneos Sustina Product Data Sheet 2016dan0410No ratings yet

- Additive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Document35 pagesAdditive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Mazhar HussainNo ratings yet

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980No ratings yet

- HEMPADUR 15400: DescriptionDocument2 pagesHEMPADUR 15400: Descriptionherysyam1980No ratings yet

- Dieselpower Biocontrol 25 LTRDocument2 pagesDieselpower Biocontrol 25 LTRJayro BritoNo ratings yet

- Transformer Oil Analysis: Water ContentDocument12 pagesTransformer Oil Analysis: Water ContentSanjeev DhariwalNo ratings yet

- SRS 005 Ijreamv04i0743010 PDFDocument5 pagesSRS 005 Ijreamv04i0743010 PDFSatish ShahNo ratings yet

- Lo QualityDocument10 pagesLo QualityMohamed AshfaqNo ratings yet

- Lube Oil Analysis TestsDocument11 pagesLube Oil Analysis TestsPrudhvi RajNo ratings yet

- 002 - Brochure 2055g LightDocument23 pages002 - Brochure 2055g Lightmunawar786No ratings yet

- Limpiador de InyectoresDocument2 pagesLimpiador de InyectoresMiguel Angel RodriguezNo ratings yet

- Lab DeodorizerDocument5 pagesLab DeodorizerErnestoPartidasNo ratings yet

- Hempel Shopprimer 15890ZSDocument2 pagesHempel Shopprimer 15890ZSAnuar SalehNo ratings yet

- Carboguard 885 PDSDocument2 pagesCarboguard 885 PDSsyazwanjohnmazlanNo ratings yet

- Filtros HXN8GDocument16 pagesFiltros HXN8GAdan PachecoNo ratings yet

- Palm Oil - Peroxide ValueDocument2 pagesPalm Oil - Peroxide ValueIhsan Aditya0% (1)

- Guide of Transformer Oil TestingDocument5 pagesGuide of Transformer Oil Testingoorja.sachinborkarNo ratings yet

- Turbine Oil Condition Monitoring Training GuideDocument8 pagesTurbine Oil Condition Monitoring Training Guidemauriciojj100% (1)

- Tu91 1 All Siemens ZokDocument4 pagesTu91 1 All Siemens ZokEDBNo ratings yet

- DCWT PowderDocument2 pagesDCWT PowderNeeraj KumarNo ratings yet

- Oil Analysis GuidelinesDocument6 pagesOil Analysis GuidelinesOscar quiroga100% (1)

- Oil Breakdown TestingDocument5 pagesOil Breakdown TestingAshiq NafasNo ratings yet

- Maintenance Program For HFO Diesel EngineDocument11 pagesMaintenance Program For HFO Diesel EngineUmit CengNo ratings yet

- Millipore TestDocument13 pagesMillipore TestRajaSekarsajjaNo ratings yet

- Maintenance of TransformerDocument79 pagesMaintenance of Transformermuaz_aminu1422No ratings yet

- GEK28143a - Hydrocarbon LO RecommendationsDocument10 pagesGEK28143a - Hydrocarbon LO RecommendationssyedNo ratings yet

- Water Content Lube Oil StandardDocument11 pagesWater Content Lube Oil StandardalexmontellNo ratings yet

- TD06 00033Document6 pagesTD06 00033boris345678No ratings yet

- Marine Chemical Oil Test Kit GuideDocument2 pagesMarine Chemical Oil Test Kit GuideSuraj100% (1)

- 1lfi1149-En Transformer OilDocument14 pages1lfi1149-En Transformer Oiljosielalves2910No ratings yet

- Media Search - SEBU6400 - Cat Gas Engine Lubricant SOSDocument4 pagesMedia Search - SEBU6400 - Cat Gas Engine Lubricant SOSThepowerNo ratings yet

- Plan de Maintenance Atlas Copco ORX12 - GEMEXDocument3 pagesPlan de Maintenance Atlas Copco ORX12 - GEMEXPhilippe Dumont100% (1)

- Kathon FP 1.5 SpecDocument10 pagesKathon FP 1.5 SpecPawanNo ratings yet

- Eraspray ES81A HBDocument5 pagesEraspray ES81A HBdody andiNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- Castrol Tribol 1421Document3 pagesCastrol Tribol 1421gregcrNo ratings yet

- Ultra EL: Formulated To Last Up To 16,000 HoursDocument4 pagesUltra EL: Formulated To Last Up To 16,000 Hourselperrote3No ratings yet

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyFrom EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Comparison of Diesel and Petrol EnginesFrom EverandComparison of Diesel and Petrol EnginesRating: 2.5 out of 5 stars2.5/5 (3)

- Miura SoftnerDocument27 pagesMiura SoftnersijinjoyNo ratings yet

- Agua Sr200Document4 pagesAgua Sr200sijinjoyNo ratings yet

- PV Unit 7Document1 pagePV Unit 7sijinjoyNo ratings yet

- Henkel Ferroxyl TestDocument3 pagesHenkel Ferroxyl TestsijinjoyNo ratings yet

- Heated Viscometer: 125.4cS 1c.900 1c.992 2 50 5 100 5 126 132.5cS 2 00 2 40Document4 pagesHeated Viscometer: 125.4cS 1c.900 1c.992 2 50 5 100 5 126 132.5cS 2 00 2 40sijinjoyNo ratings yet

- Ballastguard Cip Cleaner 25 LTRDocument2 pagesBallastguard Cip Cleaner 25 LTRsijinjoyNo ratings yet

- JC 1 en VUc 7 DWBXHM Pa APV7 Cec DDocument1 pageJC 1 en VUc 7 DWBXHM Pa APV7 Cec DsijinjoyNo ratings yet

- Dispersant ROPME Sea AreaDocument4 pagesDispersant ROPME Sea AreasijinjoyNo ratings yet

- Descaling Liquid 25 LTR: Marine ChemicalsDocument3 pagesDescaling Liquid 25 LTR: Marine ChemicalssijinjoyNo ratings yet

- Viscosity Comparison: It Is Very Important That Both Samples Are at The Same TemperatureDocument2 pagesViscosity Comparison: It Is Very Important That Both Samples Are at The Same TemperaturesijinjoyNo ratings yet

- Ballast Water Treatment Performance EvaluationDocument19 pagesBallast Water Treatment Performance Evaluationsijinjoy100% (1)

- Lovibond CatalogDocument96 pagesLovibond CatalogsijinjoyNo ratings yet

- MEPC 2-Circ 26Document87 pagesMEPC 2-Circ 26sijinjoyNo ratings yet

- Leaflet Ferroxyl Test Kit NewDocument2 pagesLeaflet Ferroxyl Test Kit NewShailesh DeshmukhNo ratings yet

- Aalco Metals LTD Stainless Steel Innosoft Innoclean Innoprotect 127Document5 pagesAalco Metals LTD Stainless Steel Innosoft Innoclean Innoprotect 127sijinjoyNo ratings yet

- Understanding Ballast Water Management LR Guide PDFDocument29 pagesUnderstanding Ballast Water Management LR Guide PDFshanti prakharNo ratings yet

- BWM Guide June20Document66 pagesBWM Guide June20ugik arfiandiNo ratings yet

- Cleaning Economizer PDFDocument1 pageCleaning Economizer PDFsijinjoyNo ratings yet

- Mobilgard Cylinder Condition Monitoring BrochureDocument12 pagesMobilgard Cylinder Condition Monitoring Brochureavm4343No ratings yet

- Ballast Water Treatment Performance EvaluationDocument19 pagesBallast Water Treatment Performance Evaluationsijinjoy100% (1)

- X-Met 8000 Sulfur in Oil AnalyserDocument2 pagesX-Met 8000 Sulfur in Oil AnalysersijinjoyNo ratings yet

- ECOSOLUT 24 PDS and SDSDocument14 pagesECOSOLUT 24 PDS and SDSsijinjoy100% (1)

- Ballast Water Treatment Performance EvaluationDocument19 pagesBallast Water Treatment Performance Evaluationsijinjoy100% (1)

- Seaclean Plus 210 LTRDocument3 pagesSeaclean Plus 210 LTRviNo ratings yet

- Unitor Easyship Water Test KitDocument2 pagesUnitor Easyship Water Test KitsijinjoyNo ratings yet

- Test for DEHA in Water up to 0.5mg/lDocument1 pageTest for DEHA in Water up to 0.5mg/lVannex MensidorNo ratings yet

- Alfacaus: Cleaning Agent For Heat ExchangersDocument2 pagesAlfacaus: Cleaning Agent For Heat ExchangerssijinjoyNo ratings yet

- Gamazyme 700FN 12KGDocument2 pagesGamazyme 700FN 12KGVannex MensidorNo ratings yet

- Central Diabetes InsipidusDocument8 pagesCentral Diabetes InsipidusasdwasdNo ratings yet

- Common Calculations for Safe Medication AdministrationDocument6 pagesCommon Calculations for Safe Medication AdministrationPanJan BalNo ratings yet

- Name of The Medicinal Product: AdultsDocument9 pagesName of The Medicinal Product: Adultsddandan_2No ratings yet

- PharmacologyDocument5 pagesPharmacologyAndrea Charlotte Nicolas100% (1)

- Ketalar KetaminDocument10 pagesKetalar KetaminLeonardo JeversonNo ratings yet

- T H e Chemical of Hesperidin Perimental Medical Use Vitamin ReviewDocument7 pagesT H e Chemical of Hesperidin Perimental Medical Use Vitamin ReviewJeremiaNo ratings yet

- Guidelines For The Safe and Quality Use of Clozapine in The WA Health System PDFDocument49 pagesGuidelines For The Safe and Quality Use of Clozapine in The WA Health System PDFAdrian TintareanuNo ratings yet

- Template Continued On Page 2Document3 pagesTemplate Continued On Page 2JaneNo ratings yet

- Voloxal TabletsDocument9 pagesVoloxal Tabletselcapitano vegetaNo ratings yet

- Calculation of Oral Medications Doses for Solids and LiquidsDocument3 pagesCalculation of Oral Medications Doses for Solids and LiquidslanNo ratings yet

- Dosage Calculations 2014 3rd Canadian Edition Test BankDocument35 pagesDosage Calculations 2014 3rd Canadian Edition Test Bankbecalmarango.k8va100% (42)

- National Rabies Prophylaxis Guidelines - INDIADocument27 pagesNational Rabies Prophylaxis Guidelines - INDIADr.Sagindar100% (1)

- H1n1vaers InjectedDocument727 pagesH1n1vaers Injectedx2634No ratings yet

- CPT Code 99091 Alexander LDocument6 pagesCPT Code 99091 Alexander LBryan MorteraNo ratings yet

- ETHAMBUTOLDocument11 pagesETHAMBUTOLIrbasMantiniSyaifulNo ratings yet

- Integration of Personalized Drug Delivery and Digital HealthDocument19 pagesIntegration of Personalized Drug Delivery and Digital HealthRomelyn AngelNo ratings yet

- Pharmacy Patient Medication Profile Importance of Patient Medication ProfileDocument12 pagesPharmacy Patient Medication Profile Importance of Patient Medication Profilelevi pinedaNo ratings yet

- Poultry Disease Diagnosis - Picture Book-2Document2 pagesPoultry Disease Diagnosis - Picture Book-2बनकर परिवाराचा लाडका गोट्याNo ratings yet

- Psychiatric Mental Health Nursing Test Part 1Document9 pagesPsychiatric Mental Health Nursing Test Part 1yanee060% (1)

- Clopixol Patient Information Leaflet 2mg 10mg 20mg From Mind OrgDocument9 pagesClopixol Patient Information Leaflet 2mg 10mg 20mg From Mind OrgRevaz SurguladzeNo ratings yet

- Types of MixturesDocument2 pagesTypes of Mixtureskasonde.musonda8No ratings yet

- Medication Reconciliation Form: Part of The Medical RecordDocument2 pagesMedication Reconciliation Form: Part of The Medical Recordbella sobaNo ratings yet

- Mucinosis Por Un FarmadoDocument4 pagesMucinosis Por Un FarmadoLuluu CortésNo ratings yet

- Introduction To Dosage Forms and Drug Delivery Systems: PharmaceuticsDocument20 pagesIntroduction To Dosage Forms and Drug Delivery Systems: PharmaceuticsJelight Faith Salero GachoNo ratings yet

- Aldesleukin For Injection RX Only: DescriptionDocument16 pagesAldesleukin For Injection RX Only: Descriptionapi-26302710No ratings yet

- Tugas MedicineDocument2 pagesTugas MedicineRiza Ikhsan MuliaNo ratings yet

- PHCL Midterms - Lesson 1 (Calculation of Doses General Consideration)Document4 pagesPHCL Midterms - Lesson 1 (Calculation of Doses General Consideration)Lazaro, Javen Andrie A.No ratings yet

- 2C B FLY PsychonautWikiDocument9 pages2C B FLY PsychonautWikiUnivercity Of SockoviaNo ratings yet

- Drug Related Problems: A Systemic Literature ReviewDocument7 pagesDrug Related Problems: A Systemic Literature ReviewBaru Chandrasekhar RaoNo ratings yet