Professional Documents

Culture Documents

Generator Specifications: 1-General

Uploaded by

getachew mengstieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Specifications: 1-General

Uploaded by

getachew mengstieCopyright:

Available Formats

Generator Specifications

1-General

This specification covers Diesel Engine driven electric generating alternators,

380/220Vac ±10% ,3ph,4 wires ,50HZ ,1500 rpm , continuous out put rating 15kVA,

and 0.8 PF at altitude 2200m ASL and 40C , weather proof canopy outdoor unit.

To supply the telecommunication services as an automatic units. It shall feed BTS

stations through electronic thyristor based rectifiers regulated. In addition, they shall

feed single phase and three phase air conditioners, single phase lights, fans etc.

The tenderer shall provide evidence that similar equipment has been supplied and

given satisfactory service . A list indicating the places where such equipment are in

operation shall be furnished .

2.1 Sites conditions

The derating for electric power generator sets shall be provided at following

conditions :

Altitude: up to 2500m ASL

Ambient Temp. : from -10 to 450 C

Humidity : up to 90%

Derating tables and curves shall be supplied by the tender.

2 –2 Engine

1500 RPM , industrial type, air cooled, in-line arrangement, direct injection, 4

stroke and anticlockwise rotation , oil pressure protection should be a switch

normally closed and temperature protection as a switch normally closed that be

provided.(normally close switch : that means it's contact still closed at normal

operation and don’t changes to open except in case of related fault exist)

Oil and Temperature analogue readers - sensor (VDO) type

2 – 3 cooling system

Air cooled system , centrifugal fan shall be heavy duty, anti-corrosion , easy to

maintain , and shall be sized for continuous full load. Belt fan switch shall be

include.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

2 – 4 Fuel System

• Fuel injection pump with fuel lift pump and full flow replaceable filter plus

separate preliminary fuel filter and electric fuel solenoid should be provided.

The tenderer shall furnish details of fuel injection pump, fuel consumption at

full load and at varying loads.

• Flexible hoses shall be used for connections to the input and output. Fuel drain

must be connected to an external outlet.

• All fuel-lines before the cut off valve (Solenoid) shall be fireproof.

2 – 5 Lubrication

Full pressure lubricating oil system, including an oil cooler, is to be fitted. The

tenderer shall indicate the frequency of changing oil.

2 – 6 Mechanical Type Governor

Under steady state conditions , whatever the load be , the rotational speed shall

remain between N and 1.04 N , where N is the normal speed in the event of a sudden

load variation of 0.25 l nominal , but with the load remaining between 0.5 L and L

nominal , m Where L nominal is the rated load , the instantaneous change in speed

should not exceed 4% of N . The rotational speed should then be returned within

offset limits is less than 3 seconds and stabilize in less than 8 seconds .

The tender shall enclose graphic diagrams showing the derating of his

units depending on altitudes , temp. and humidity varying .

2 – 7 service and power rating

The engine shall be selected for a 1000 h continuous power condition, unless

otherwise stated, such that its capacity is adequate to drive the associated alternator

and accessories continuously at rate output at an altitude of 2200 m, air temperature

of 40°C and relative humidity of 90%.

2 – 8 Exhaust system

• Exhaust system shall be provided with high standards and weather conditions.

• The outside exhaust system be manufactured from stainless steel materials.

2 – 9 Air Filter

Air Filters Shall be dry type, heavy duty, with replaceable elements. The

efficiency of the system at various stages shall be furnished.

2 – 10 Engine Safeguard

Oil protection shall be offered as standard. The system shall be arranged for

fail-safe operation by de-energizing a solenoid coupled to the fuel injection pump

2

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

with shutdown protection against high cylinder temperature, low lubricating oil

pressure, coolant temperature, belt failure, or any other fault.

2 –11 Flexible Coupling

A heavy duty flexible block coupling shall be fitted between the engine and the

alternator to absorb the transmission of shock loads . details should be offered by

the tender.

2 –12 Batteries

The battery shall be fitted on the vibration free main chassis complete with all

the necessary acceessories ,flexible interconnecting cables and lugs. The battery

shall be heavy duty, free maintenance type with suitable capacity to be enough for

current cold starting (CCS) at the worst conditions. The battery is to be supplied

in a dry-charged condition securely placed on a rack .

The battery shall be kept in good condition for starting the gensets and shall be

adequately charging either from mains supply and / or from the genset supply

through the unit control panel.

2 –13 Components Guard

All exposed parts of the engine and alternator accessories shall be fully

guarded . Guards shall be all arround the coupling , generator air intakes, and any

rotating parts.

3 – Alternator

1. The alternator shall be brushless type , class H, design of welded steel

construction, three phase , four wire, screen protected ,star connected rotating

field, salient pole, self excited, self regulated type.

2. The overload characteristic should be able to handle (300%) or more of the

rated power of the alternator for at least 10 seconds and 110% of rated

power continuously for at least one hour every 12 hours .

3. Alternator shall withstand short circuit fault conditions without any damage

with full protection against abnormal conditions.

4. All protections shall be in details by the tender.

3 – 1 compliance

All specification Shall comply with Standard Specifications British B.S 2613 or

German VDE 0530 or French NFC 51 – 100 and 112, or the recommendations of

the International Electrotechnic board. The standard applied shall be mentioned

in the offer .

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

3 – 2 Excitation System

Permanent magnets (PMG) in exciter field is prefered (for fast voltage build up

both after a short circuit and also after a long time of inactivity).

Self excitation is acceptable, if it gives fast voltage build up both after a short

circuit and also after a long time of inactivity. The exciter technique shall be

technically described in full details by the tenderer .

3- 3 Automatic Voltage Regulator(AVR)

Under Steady state conditions, the output voltage should be held to within + 5%

of nominal for all load values and for any power factor between 0.8 and 1 ,

whatever be the alternator temperature. Schematic diagram for A.V.R shall be

provided . The AVR full technical data shall be provided .

3 – 4 Wave shape

The output waveform should be pure sine. The residual harmonic percentage

between full load and no load should no exceed +5% .

3 –5 Sensing Dangerous Conditions

Sensing electrical conditions which might cause damages to the generator

e.g. high and low output voltages and frequency and sudden severe phase

unbalance .

In such circumstances and any fault electric problem the control equipment

shall immediately isolate the generator from the load, stop the diesel engine and

raise an alarm.

3 -6 Wiring and Conduits

Engine and alternator Control wiring shall be multi-strand annealed

copper conductor encased by cross-linked Polyethylene insulation resistant to

heat, abrasion, oil, water, antifreeze, and diesel fuel. Wiring shall be suitable for

continuous use at 120 C (250F ) with insulation not brittle at -50C (-60F ) .

Cables shall be enclosed in nylon flexible conduit which is slotted to allow easy

access and moisture to escape.

3 –7 Finish

(a) The engine color shall remain the original colour as supplied by the

manufacturer.

(b) Rubber hoses used on lubricating oil or fuel systems and rubber belts shall

not be painted.

(c) Rubber material, which is not fire or fuel proof, is not acceptable.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

4 – Generator Control Panel (A.M.F)

4–1 The control panel shall be fitted on the generator set to work as

the following:

a) Automatically starts up the generator set when the voltage of the

triple phase public supply ( mains ) goes outside 0.95 and 1.05 of its

nominal value , or when main frequency goes outside the limit of 46 and 52

Hz , and when there is a phase messing or phase sequence reversing .

b) Automatically checks on diesel engine, electric alternator, and all

generator set main devices by means of appropriate devices and fitting .

c) Automatically cuts off the generator set when the signal come from ATS to

stop the generator set for any reason (for example : mains voltage is

restored to nominal voltage and frequency) , and automatically , it stops

the genset for any abnormal action .

d) Operation, monitoring, measurements and protections processes should be

done by using electronic card. It's preferred to be DEEP SEA type. The

card shall contain The following functions:

• Operation mode selection :

The card shall contain at least three operation modes:

1- Auto operation mode

2- Manual operation mode

3- Test operation mode

• Monitoring, display and protection functions :

1. Ac (line – line / line – neutral) Voltage values monitoring, display

and protection.

2. Ac Current values monitoring, display and protection .

3. Frequency values monitoring, display and protection.

4. Phase sequence and missing protections.

5. Running hours for the generator set .

6. Mode selector switch ( off – Auto. – Manual) .

7. Battery DC voltage.

8. Battery DC ampere.

9. Oil pressure value (par).

10. Engine Temp. Value (cº).

• Indictors and alarms lights for :

1. G.S working normal

2. Starting failure

3. High engine temp (Shutdown).

4. Low oil pressure (Shutdown).

5. Battery charger fail .

5

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

6. Over speed (Shutdown).

7. Belt rupture (Shutdown).

8. Generator output voltage missing/ failure (Shutdown).

9. Over load (Trip).

10. Dynamo charge fail

11. Frequency failure (Shutdown).

4 - 2 Protections devices :

- G.S output circuit breaker with thermal over load protection 4 pole

(MCCB), meeting protection at least IP 22, over load current adjustable

from (1.5 – 10) rated current, and short circuit current at least 16kA.

- 4-pole GS out put surge protection device.

- Suitable MCBs protection for all input and output (AC /DC) circuits.

4 – 3 Battery charger:

- Automatic Battery charging (shall be adjustable charge current

(up to 5 A)) , 12VDC.

4 – 4 Alarm Retransmission:

- Gen set running (shall be potential contact)

- Gen set failure (shall be potential contact)

4 – 5 Labeling and Fixtures:

• Each parts shall be labeled similar to the drawings .

• All wires and terminals shall be labeled according to the drawings.

• All wire terminals and lugs should be tightly fixed.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

5 – ATS Automatic transfer switch.

The ATS unit shall beseparate, floor mounted,supported by a stand and can be

fixed to the wall if needed. ATS described as follow :

ATS panel shall be control the operation and the protection for two sources

and the load , whatever the type of the sources is (that means the two sources

can be two generators , main and one generator or, main 1 and main 2) . This

type of ATS shall be equipped with :

• One- High efficiency 12-volt DC electronic programmable logic controller, to

control the two sources working in two main operation modes (auto/manual).

• The PLC shall have interface port suitable for inserting external back -up

Memory and/or connecting PC interface Cable. And 12- volt 6-amphours

battery shall be provided.

• Each PLC shall be equipped with, programming-supervision software and

connecting cable.

• One selector switches to show the current case of primary operation modes.

(Enable Auto operation switch).

• Two (on/off) switches to select the auxiliary operation modes in binary code

Each switch will send a status signal to programmable logic controller

(on=1,off=0) and each switch related with one Source. Number one always

related to the Mains source and number 0 always related to the Generator.

• Two Digital modules to measure and display the operation parameters and

protect load circuit, (one module per one source).

• Three Current transformers that to be connected with special module.

• One digital module read CTs current, display current values for each phase

and protect load circuit.

• Six indicator lamps to indicate source available, source on load case and,

source failure (three lamps for each source (source1 & source2).

• MCBs circuit breakers to protect control components of ATS circuits.

• Power terminals which connect between sources and ATS contactors.

• Control and Alarm terminals which connect control cables between sources

and ATS.

• Free contact terminals to transmit alarms from ATS relays (normally

open/close contacts) to special external alarm box.

• Four – dc relays to receive alarms signals come from the sources.

• Other parts may be required for design.

• ATS LOAD circuit breaker with thermal over load protection 4

pole (MCCB), meeting protection at least IP 22, with adjustable

over load and short Circuit current ratio. The over current up at

least 16kA.

• Load terminals which connect the out-put of ATS with the load cable.

The ATS dimensions should not be less than (W x D x H)= 600 x 250 x800 mm.

7

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

• Two selector switch for chosen the loading as follows:

o Mode Selector switches (Manual – OFF-Automatic) mains tansfer.

o Loading selector switch (source1-Off-source2)

o Two Contactors, Four pole suitably rated, Mechanically and electrically

interlocked.

5-2 Operation mechanism

1- Primary operation modes:

1. Auto operation starting and/or loading shall be don via the PLC.

By sending signals to plc and close the contactors circuits.

There are three aux operation operation modes determined by the status of two toggle

switches as follow:

- on- on : reveal that the sources are : mains-mains

- on- off : reveal that the sources are: mains- generator

- off-on : reveal that the sources are: generator- mains

- off-off : reveal that the sources are: generator- generator

2. Manual operation for starting and loading the two sources.

3. Programmed PLC timers:

All timers shall be adjustable and implemented in software, no external hardware

timer will be accepted. the following timer shall be exist.

- Incoming source failure timer

- Incoming source restoration timer

- Sources supply/incoming supply loading timers

- Engine cooling-off timer (in case one or both of the source is/are generator).

- In case the two sources are two Gen-sets; with Auto operation mode, each

Gen-set shall operate each gen set for 6 hour and 2 hour rest frequently.

5- 4 Digital measuring instruments within the card:

5- 4- 1 characteristics:

– Input voltage: 220-240VAC

– Operating frequency: 50Hz

– Housing: flush mount

– Degree of protection: IP54 on front.

8

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

5- 4- 2 Programming protection relay:

The out-put relay(s) shall be available within the module with changeover contact (s).

And will be activated when the following conditions:

- High /low voltage

- Phase missing

- High /low frequency

- Phase sequence

- Over and short circuit current .

6 - Lifetime , Vibration & Noise

The Tenderer shall state in his offer the expected lifetime of the engine

generator sets, under the specified operation conditions .

Detailed figures regarding the vibration and the noise levels shall also be

provided in the tender .

7- Any other facilities

Improvements or deviations shall be stated clearly in the offer and shall be

considered in evaluating the tender.

8- Spare parts

- Spares for each engine.

- Spares for each Alternator.

- Spares for each control panel.

- Spares for each A.T.S.

9- Complete set of documents including

- Electrical diagrams.

- Electronic diagrams.

- Engine hand book.

- Workshop hand book.

- Spare part manual with identification No. for each parts and device.

- Full technical detailed data for all units shall be provided with the offer.

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

Any provided offer with out complete technical data for all units and part

will be output of evaluation.

10- Tenderer shall provide information about manufacturer’s current

location and product country of origin for the following equipment

- Engines

- Alternators

- Fuel pump

- Solenoid valve ( shut down dives )

- Dynamo charger

- Starter motors

- Sensors for engine temp.

- Sensors for oil pressure

10

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

11- LIST OF THE REQUIRED MATERIALS

Capacity at

No Description specified site QTY.

condition

1

Gen set with Automatic control panel 15kVA 120

2 ATS control for TWO sources 15KVA 80

4 Genset mechanic & electrical spare parts

5 ATS Electrical Spare parts

Notes

1- The tenderer shall indicate clearly the manufacturer ,country of

manufacturing and the country of origin .

2- Complete and detail technical specifications and manfacturer original

catalogues for all equipments and devices of the system shall be

submited along with the offer.

3- The Tenderer must quote two separate optional quotations for

carrying out the trainning course for Yemen Mobile engineers.

The first quotation is for carrying out the trainning in out of

Yemen, the other alternative quotation is for Trainning abroad

for five engineers for a period of three weeks at least to cover

topics mechanical , electrical and control. The Training

Program must be described in details, specifying trainning

course duration etc…

11

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

12- Engine Suggested spare parts

NAME OF model

ITEM DESCRIPTION Qty. U.P

COMPANY NO.

1 Oil filter

2 Fuel filter

3 Air filter

4 Injector nozzle with washer

5 Manual fed pump

6 Sensor h. temp.

7 Sensor reading temp (sender).

8 Sensor low oil pressure

9 Sensor reading oil press

(sender).

10 Main fan V. belt

11 Dynamo charge

12 Top head gasket set

13 Piston (per engine) set

14 Cylinder(per engine) set

15 Brach (journal bearing) set

16 Starter motor

17 Solenoid valve

18 Dynamo charger

The tenderer shall provide the spare part lists with item code no. full description , no. of tems

and diagrams of each item have been mentioned.

The spare part lists , should be provided with the spare parts hand book .

12

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

13- SPARE PARTS FOR EACH GENSET CONTROL PANEL

COMP. Model

ITEM DESCRPTION QTY. U.P

NAME NO.

13

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

14 -SPARE PARTS FOR EACH ATS units

ITEM DESCRPITION COMP. Model Qnty U.P

NAME NO.

14

PDF created with FinePrint pdfFactory Pro trial version http://www.fineprint.com

You might also like

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- 3.26 Lv-GensetDocument17 pages3.26 Lv-Gensetjinfong upcNo ratings yet

- 16620s01 Standby Generators PDFDocument6 pages16620s01 Standby Generators PDFVICTOR JOSE VILORIANo ratings yet

- Att 03, GTR-ElectricalDocument4 pagesAtt 03, GTR-ElectricalSiriepathi SeetharamanNo ratings yet

- 25 Kva - Three Phase Under Slung Inverter FOR Roof Mounted Ac Package UnitDocument29 pages25 Kva - Three Phase Under Slung Inverter FOR Roof Mounted Ac Package UnitAbhaya Kumar NayakNo ratings yet

- Chapter-4 Electrical Auxiliary Systems PDFDocument83 pagesChapter-4 Electrical Auxiliary Systems PDFSachin YadavNo ratings yet

- Diesel Generator 150kVA To 500kVADocument13 pagesDiesel Generator 150kVA To 500kVAAhmed BahaaNo ratings yet

- D-07 11kv SwitchgearDocument12 pagesD-07 11kv SwitchgearShri Anvesha D100% (1)

- Marathon Max GenDocument4 pagesMarathon Max GenUmar RajputNo ratings yet

- DZB200M&JDocument41 pagesDZB200M&Jvijayrockz06No ratings yet

- Scope of WorkDocument3 pagesScope of WorkAhmad El KhatibNo ratings yet

- AGN 238 - General Application and Operational Conditions For STAMFORD AlternatorsDocument20 pagesAGN 238 - General Application and Operational Conditions For STAMFORD AlternatorsNos GoteNo ratings yet

- Updated Specification For Standardization Panel and Allied Equipment For Khyber PakhtunkhwaDocument13 pagesUpdated Specification For Standardization Panel and Allied Equipment For Khyber PakhtunkhwaIjaz AhmadNo ratings yet

- Technical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsDocument46 pagesTechnical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsanuragpugaliaNo ratings yet

- Electrical Power: Part 1: GeneralDocument5 pagesElectrical Power: Part 1: Generalterminator_palitoNo ratings yet

- MOH Technical Specification For 150kVA DG FINAL 16 Sept 08Document14 pagesMOH Technical Specification For 150kVA DG FINAL 16 Sept 08devanathspNo ratings yet

- Minerbolter Class NotesDocument10 pagesMinerbolter Class NotesSivalya SivaramanNo ratings yet

- UNDP Iraq Diesel Generator Technical SpecificationDocument8 pagesUNDP Iraq Diesel Generator Technical SpecificationAhmed AbdulnaimNo ratings yet

- GeneratorsDocument13 pagesGeneratorsKhyle Laurenz DuroNo ratings yet

- Employer's Requirements for Inverter TransformersDocument50 pagesEmployer's Requirements for Inverter TransformersMohamed Dhia YousfiNo ratings yet

- Chapter 5 Generator TransformerDocument27 pagesChapter 5 Generator TransformerAnonymous nwByj9LNo ratings yet

- E 03 - Generator PDFDocument11 pagesE 03 - Generator PDFTrườngThànhLêNo ratings yet

- VFDDocument9 pagesVFDVenkatesh RaoNo ratings yet

- 2x1400 Sayhoot Technical Documents CompletedDocument17 pages2x1400 Sayhoot Technical Documents Completedengnajeeb75No ratings yet

- Electric Comment 26 20 00Document9 pagesElectric Comment 26 20 00Imtiyaz KhanNo ratings yet

- محولات توزيع 11-0.4 كي فيDocument13 pagesمحولات توزيع 11-0.4 كي فيhamza mandlwiNo ratings yet

- 9.8 Inverter Transformer Station (ITS) : 9.8.1 EnclosureDocument7 pages9.8 Inverter Transformer Station (ITS) : 9.8.1 Enclosurekser82No ratings yet

- Technical Specifications Valve Actuators ScopeDocument6 pagesTechnical Specifications Valve Actuators ScopeBilalPervezNo ratings yet

- Circuit Breaker GTSDocument31 pagesCircuit Breaker GTScpandey01_688066930No ratings yet

- T e C H N I C A L S P e C I F I C A T I o N o F K I o S K T y P e 1 1 / 0 - 4 K V S U B - S T A T I o N 2 5 0, 4 0 0 & 6 3 0 K V ADocument14 pagesT e C H N I C A L S P e C I F I C A T I o N o F K I o S K T y P e 1 1 / 0 - 4 K V S U B - S T A T I o N 2 5 0, 4 0 0 & 6 3 0 K V AAhmed JaNo ratings yet

- 4 ActsspecDocument13 pages4 ActsspecVictor Ortega SamNo ratings yet

- Generator & Transformer ProtectionDocument63 pagesGenerator & Transformer ProtectionKrishna Kumar100% (1)

- Maintenanceboth Q and ADocument46 pagesMaintenanceboth Q and AMMS SNo ratings yet

- 3.HT Motor SpecificationDocument18 pages3.HT Motor SpecificationsidearthmanNo ratings yet

- ICF - Control Panel - Manual (1999)Document27 pagesICF - Control Panel - Manual (1999)sangramjitNo ratings yet

- 220KV CVT 0 2 Metering AccuracyDocument12 pages220KV CVT 0 2 Metering AccuracyJAY PARIKHNo ratings yet

- Ministry of Electricity Technical Specification for Distribution TransformersDocument11 pagesMinistry of Electricity Technical Specification for Distribution TransformersFirass RefaiNo ratings yet

- HVAC Guide Specifications Commercial Air-Cooled Condensing UnitsDocument4 pagesHVAC Guide Specifications Commercial Air-Cooled Condensing UnitsHazemNo ratings yet

- SECTION 16233 Motors & StartersDocument5 pagesSECTION 16233 Motors & StartersDolyNo ratings yet

- Variable Frequency Speed Controllers ProjectDocument8 pagesVariable Frequency Speed Controllers ProjectNicodemus Ervino MandalaNo ratings yet

- 225 kV Guinea-Mali Interconnection Project: Specifications for Substation 225/30 kV of Beyla and NzérékoréDocument10 pages225 kV Guinea-Mali Interconnection Project: Specifications for Substation 225/30 kV of Beyla and Nzérékoréamulya00428No ratings yet

- Gs 18ms 1pdDocument11 pagesGs 18ms 1pdRitesh JhaNo ratings yet

- Technical Specification For 20 MVA Transformer PDFDocument21 pagesTechnical Specification For 20 MVA Transformer PDFamulya00428100% (10)

- 26 36 23 Ats Single Operator Open TransitionDocument7 pages26 36 23 Ats Single Operator Open TransitionRaed Al-HajNo ratings yet

- Requirements For Electrical MachineryDocument3 pagesRequirements For Electrical MachineryAnkit DedhiyaNo ratings yet

- Generator ProtectionDocument30 pagesGenerator ProtectionShahzad Bhatti100% (2)

- Power Transformer (General)Document17 pagesPower Transformer (General)Syed Moiz NaqviNo ratings yet

- Technical Specification for Auto TransformerDocument53 pagesTechnical Specification for Auto TransformerPremBhushanNo ratings yet

- Equipment Capacities and DescriptionDocument2 pagesEquipment Capacities and DescriptionJhon Micheal AlicandoNo ratings yet

- Chapter 2 Generator and AccessoriesDocument43 pagesChapter 2 Generator and AccessoriesAnonymous nwByj9LNo ratings yet

- Suggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Document12 pagesSuggested Specification For Automatic Transfer Switches: 10-2006 1 Publication 3163Pardeep KhosaNo ratings yet

- 1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance ParametersDocument8 pages1.0 Specification of Equipment / Material and Installation Standards 1.1 Specifications For Water Cooled Centrifugal Chiller Performance Parametersعامر شیخNo ratings yet

- Power Energy - Tender SpecsDocument6 pagesPower Energy - Tender SpecsAbdul-Madid Ciudad GuimbaNo ratings yet

- Chapter 3. Alternator: 1. DescriptionDocument21 pagesChapter 3. Alternator: 1. DescriptionGabriel QuijadaNo ratings yet

- IRS S 91-93 - Transformer RectifierDocument7 pagesIRS S 91-93 - Transformer Rectifiernvnrajesh123No ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Installation and Operating Instructions: Astro 2 Circulator ModelsDocument8 pagesInstallation and Operating Instructions: Astro 2 Circulator Modelsgetachew mengstieNo ratings yet

- 04 FAO - Drilling Instruction HandbookDocument49 pages04 FAO - Drilling Instruction HandbookMVM62No ratings yet

- Payment For Reactive PowerDocument48 pagesPayment For Reactive Powergopal krishnanNo ratings yet

- 5 Sem PDFDocument7 pages5 Sem PDFNikhil GurawaNo ratings yet

- Analysis of Load Balancing Algorithms Using Cloud Analyst: Simar Preet Singh, Anju Sharma and Rajesh KumarDocument14 pagesAnalysis of Load Balancing Algorithms Using Cloud Analyst: Simar Preet Singh, Anju Sharma and Rajesh Kumargetachew mengstieNo ratings yet

- 0g2152 PDFDocument151 pages0g2152 PDFEnderNo ratings yet

- The Incremental Load Balance Cloud Algorithm by Using Dynamic Data DeploymentDocument2 pagesThe Incremental Load Balance Cloud Algorithm by Using Dynamic Data Deploymentgetachew mengstieNo ratings yet

- Unc Unf Metric Thread Chart Northwest FastenerDocument1 pageUnc Unf Metric Thread Chart Northwest FastenerthailanNo ratings yet

- ELX214 Coursework Lab (20%) - 2013 - UpdatedDocument33 pagesELX214 Coursework Lab (20%) - 2013 - UpdatedTeEbhan ChAnthira SeEkaranNo ratings yet

- ToyotaDocument128 pagesToyotaІван ПрунькоNo ratings yet

- Transmission Stall Testing Procedure ExplainedDocument3 pagesTransmission Stall Testing Procedure Explainednamduong368No ratings yet

- SR No Part No. Description Qnty MRP ValueDocument4 pagesSR No Part No. Description Qnty MRP ValueArif MamunNo ratings yet

- Contoh Turbin Gas 1Document5 pagesContoh Turbin Gas 1Alfan FathNo ratings yet

- Eaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedDocument2 pagesEaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedBart JohnNo ratings yet

- Ge12ti Co Gen-GDocument2 pagesGe12ti Co Gen-GTilok DasNo ratings yet

- Crankshaft deflection measurements fleet manualDocument7 pagesCrankshaft deflection measurements fleet manualJose OrtizNo ratings yet

- Vgf10074 - VGF SE Packaging Guide 5-12-17Document192 pagesVgf10074 - VGF SE Packaging Guide 5-12-17DIego83% (6)

- Mikasa MTDocument25 pagesMikasa MTBAHRNo ratings yet

- JMT Auto Production Operations Management ProjectDocument10 pagesJMT Auto Production Operations Management ProjectKhushwinder KaurNo ratings yet

- Cat PotenciaDocument12 pagesCat PotenciaGustavo Vargas100% (1)

- 4801 GBDocument2 pages4801 GBMuhd Khir Razani100% (1)

- A Direct Torque Controller For Permanent Magnet Synchronous Motor DrivesDocument6 pagesA Direct Torque Controller For Permanent Magnet Synchronous Motor DrivesGo GoNo ratings yet

- Pre Budget Revenue AnalysisDocument86 pagesPre Budget Revenue AnalysisArpit Ravi ShankerNo ratings yet

- Crane ChecklistDocument3 pagesCrane ChecklistAbdul Rehman SheikhNo ratings yet

- D8R Ii Serv1736 SlidesDocument112 pagesD8R Ii Serv1736 SlidesArnold Quispe C100% (2)

- Sharp Machine Tools LinesDocument4 pagesSharp Machine Tools LinessharpmachinetoolsNo ratings yet

- Water Cooled Screw Chiller: Flooded Type 365 - 1500kW (R134a) Direct Expansion Type 255 - 1490kW (R22)Document42 pagesWater Cooled Screw Chiller: Flooded Type 365 - 1500kW (R134a) Direct Expansion Type 255 - 1490kW (R22)Kashif RockNo ratings yet

- D9R Disa and AsseDocument128 pagesD9R Disa and AsseCollins ManseloNo ratings yet

- 4SP ENGINE (Donaldson Internal MTG) HOR EXH OXY - SA (JIC) (VER 04)Document21 pages4SP ENGINE (Donaldson Internal MTG) HOR EXH OXY - SA (JIC) (VER 04)sandyNo ratings yet

- Service Information SummaryDocument282 pagesService Information SummaryKent StoråkerNo ratings yet

- SP 340 SFDocument56 pagesSP 340 SFElif FotokopiNo ratings yet

- 14.lubricant ViscositiesDocument4 pages14.lubricant ViscositiesDanter AlvaradoNo ratings yet

- Final Form 2 373Document12 pagesFinal Form 2 373Abood RainNo ratings yet

- 870 JD Tech Data Sheet 072919 1Document2 pages870 JD Tech Data Sheet 072919 1Anibal José Gómez ArrietaNo ratings yet

- XCMG 958h PDFDocument638 pagesXCMG 958h PDFmumu mushu100% (1)

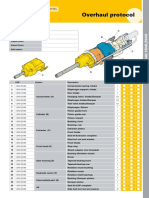

- 7 Overhaul Protocol COP 1240 1640 1840 2540 LR-ForMDocument2 pages7 Overhaul Protocol COP 1240 1640 1840 2540 LR-ForMChachou MohamedNo ratings yet

- SB 09-2916a Reg. MooneyDocument16 pagesSB 09-2916a Reg. MooneyJavier Leonidas0% (1)