Professional Documents

Culture Documents

TP Temp

Uploaded by

Rufus D SOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TP Temp

Uploaded by

Rufus D SCopyright:

Available Formats

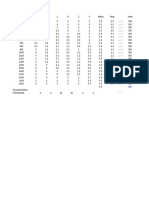

Boiler & Pressure Vessel Master Program - BPVM version 16403.17.76.

00

Date - 14 Jan 2020

Job description - 10TPH coal to gas conversion

Customer - New

Client - New

Calculation ID - 00001 - BPVM - 25/2019

Job number - 0586

Files used

Boiler file - 10-19.bd10

Customer file - 0586.bc10

Fuel file - natural gas.bd10

Site file - NewTown Country.bs10

Registration status - Legal copy.

This program run 0/1

This calculation 2

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

TUBE PLATE TEMPERATURE REPORT

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

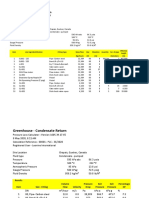

Boiler data - 10 - 1050

______________________________________________________________________

Boiler configuration = Wet back

Boiler type = Saturated steam

Boiler model = 10 - 1050

Elevated drum = False

Rated equivalent evaporation = 10500 [kg/hour]

Turn down ratio = 3 []

Feed water temperature = 58.8 [°C]

Blow down = 1 [%]

Use the standard model size to calculate flow = False

Use the standard model dimensions = False

Which standard dimensions to use = ???

The data file above was changed for these results.

The data file had not been saved at the time of the report.

Hence the above data may not be the same as the data file used.

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Tube Plate Temperature results

______________________________________________________________________

Estimate of the Tube and Tube Plate Temperature...

Tube plate temperature Wilson Tech. Note 25/77

Based on the true gas entry temperature for the fuel fired.

tpTemp.txt[2021-01-18 4:10:05 PM]

Fuel fired natural gas

Model 10 - 1050

Scale type Average boiler scale

Boiler rated capacity 12000 kg/hour 26460.000 lb/hr

Gas side heat transfer coeff. 158.9 W/m²K 27.972 Btu/h-ft²R

Temperature limit set by BS 2790 420.0 °C 788.000 °F

True gas entry temperature 1212.2 °C 2244.047 °F

Operating sat. water/steam temp. 208.0 °C 406.400 °F

Scale to give ligament temp > 420 1.00 mm 0.039 inch

Scale to give tube end temp > 420 0.50 mm 0.020 inch

Scale thermal conductivity 2.250 W/mK 1.300 Btu/hr-ftR

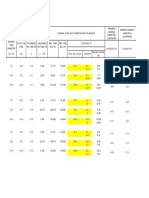

The effects of waterside scaling...

____________________________________________________________________

Temperatures (Celsius)

Scale h (water) Intermediate Ligament Tube end Ligament

(mm) (W/m² K) Difference Gas side Water side

____________________________________________________________________

0.0 11905 45.593 344.746 375.717 221.234

0.5 3266 42.692 399.957 428.957 284.306

1.0 1892 40.137 448.560 475.825 339.829

____________________________________________________________________

Notes

Dunn and Horton indicate creep can begin at 485 °C (p120).

______________________________________________________________________

tpTemp.txt[2021-01-18 4:10:05 PM]

You might also like

- Cooling TowerDocument44 pagesCooling TowerakarczNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Tech Description Cogen UnitDocument32 pagesTech Description Cogen Unitthawdar100% (1)

- My VentDocument3 pagesMy VentRufus D SNo ratings yet

- Integration of CCGT Plant and LNG TerminalDocument28 pagesIntegration of CCGT Plant and LNG Terminalcicko45100% (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Heat Recovery Presentation Rev 130213Document32 pagesHeat Recovery Presentation Rev 130213Budhi SaputraNo ratings yet

- Chapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument85 pagesChapter 2: Heat Exchangers Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallNadirah RahmanNo ratings yet

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Keston 30C ManualDocument80 pagesKeston 30C Manualstainless12No ratings yet

- 115 AllDocument8 pages115 Alljob_openings4094No ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Short Time Over Load of Transformer PDFDocument107 pagesShort Time Over Load of Transformer PDFIrfan AliNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Feed Heater Performance PDFDocument32 pagesFeed Heater Performance PDFsukdev_22No ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Aqua Top Planning DocumentDocument100 pagesAqua Top Planning DocumentAnghel DumitriuNo ratings yet

- Metal TDocument2 pagesMetal TRufus D SNo ratings yet

- 77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016From Everand77th Conference on Glass Problems: A Collection of Papers Presented at the 77th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, OH, November 7-9, 2016S. K. SundaramNo ratings yet

- Process Calculations For DesignDocument26 pagesProcess Calculations For DesignOmprakaash MokideNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Delta Performance MVDocument36 pagesDelta Performance MVJosé MacedoNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Techstuff 3.09Document130 pagesTechstuff 3.09Víctor Rojas100% (1)

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Keston 170 Boiler ManualDocument54 pagesKeston 170 Boiler ManualPaul HendersonNo ratings yet

- A.O. Smith Servicing Guide 320991-000Document72 pagesA.O. Smith Servicing Guide 320991-000ToMNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Gas1 ManDocument11 pagesGas1 ManLahiru DilshanNo ratings yet

- WCR Heat Exchanger CourseDocument24 pagesWCR Heat Exchanger Coursebadboys123No ratings yet

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Turbine Heat Rate and EfficiecyDocument48 pagesTurbine Heat Rate and EfficiecyPralay Raut100% (6)

- Heat Transfer in Polymer Composite Materials: Forming ProcessesFrom EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNo ratings yet

- Energy Audit Methodology For FOR Turbine Cycle: M.V.Pande Dy - Director NPTI, NagpurDocument33 pagesEnergy Audit Methodology For FOR Turbine Cycle: M.V.Pande Dy - Director NPTI, NagpurKrishnan Santhanaraj100% (1)

- Cooling Tower Efficiency Calculations PDFDocument4 pagesCooling Tower Efficiency Calculations PDFhbithoNo ratings yet

- Geothermal Energy: Sustainable Heating and Cooling Using the GroundFrom EverandGeothermal Energy: Sustainable Heating and Cooling Using the GroundNo ratings yet

- Segarra Morales Rubén Waldir Lab Prq-203 Ing. Petróleo y Gas NaturalDocument6 pagesSegarra Morales Rubén Waldir Lab Prq-203 Ing. Petróleo y Gas NaturalKiara Galarza CerónNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- 16.efficiency Management Sytems PresentationsDocument67 pages16.efficiency Management Sytems Presentationsrahul100% (1)

- Warm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandWarm Air Heating: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Heat ExchangersDocument107 pagesHeat ExchangersMAMADO2015No ratings yet

- Aqua MasterDocument14 pagesAqua MasterbejntNo ratings yet

- CFBC DCPP at A Glance.Document20 pagesCFBC DCPP at A Glance.Sumit SuryavanshiNo ratings yet

- AO Smith Service HandbookDocument72 pagesAO Smith Service HandbookMinhnghia360No ratings yet

- 10the Optimisation and Design of Large Scale Multi-Stage Flash Distillation PlantsDocument16 pages10the Optimisation and Design of Large Scale Multi-Stage Flash Distillation Plantsbandi.shandrasekharNo ratings yet

- Design Concept of Crude Oil Distillation Column DesignDocument24 pagesDesign Concept of Crude Oil Distillation Column DesignArjumand UroojNo ratings yet

- Heat Rate & Heater Level ControlDocument8 pagesHeat Rate & Heater Level ControlTn MuralidharaNo ratings yet

- A Study of Cooling System of A Spark Ignition Engine To Improve Thermal EfficiencyDocument5 pagesA Study of Cooling System of A Spark Ignition Engine To Improve Thermal Efficiencyscribd_20_emmanuelfaure0% (1)

- Turton AppBDocument114 pagesTurton AppBamms9988No ratings yet

- PP Lab Manual 2015Document20 pagesPP Lab Manual 2015Abdul Fatir Khan100% (1)

- Assignment 3 of Casein Plant Design2Document15 pagesAssignment 3 of Casein Plant Design2Latifani Ayu ChaerunnisaNo ratings yet

- Gas Properties No CoolingDocument8 pagesGas Properties No CoolingRufus D SNo ratings yet

- Vancouver HumidtyDocument2 pagesVancouver HumidtyRufus D SNo ratings yet

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDocument30 pagesWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNo ratings yet

- 0611 SZL25 2.45 PaDocument2 pages0611 SZL25 2.45 PaRufus D SNo ratings yet

- Dioxin FuransDocument2 pagesDioxin FuransRufus D SNo ratings yet

- Woodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursDocument30 pagesWoodlands Dairy - FX3-66XW - Wood - Pellet Dust - 8760 HoursRufus D SNo ratings yet

- Superheat HeaderDocument2 pagesSuperheat HeaderRufus D SNo ratings yet

- 0446 - MU To Surge Tank - 900Document2 pages0446 - MU To Surge Tank - 900Rufus D SNo ratings yet

- VU-40 - NG - Enbridge - 8760 HoursDocument1 pageVU-40 - NG - Enbridge - 8760 HoursRufus D SNo ratings yet

- SZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursDocument1 pageSZS35-3.0-300.Q - Methane Rich Gas - 8760 HoursRufus D SNo ratings yet

- S 4500 - 1100 - Wood - 55% Wood - 8760 HoursDocument1 pageS 4500 - 1100 - Wood - 55% Wood - 8760 HoursRufus D SNo ratings yet

- Secondary SH SummaryDocument2 pagesSecondary SH SummaryRufus D SNo ratings yet

- 8000.1700 - Wood - 30% Moisture - 8760 HoursDocument1 page8000.1700 - Wood - 30% Moisture - 8760 HoursRufus D SNo ratings yet

- 0574 - CR240-80Document2 pages0574 - CR240-80Rufus D SNo ratings yet

- 0611 - HPS200-250Document2 pages0611 - HPS200-250Rufus D SNo ratings yet

- DealkalizerDocument2 pagesDealkalizerRufus D SNo ratings yet

- Heating System Pressure DropDocument4 pagesHeating System Pressure DropRufus D SNo ratings yet

- GreensandfilterDocument1 pageGreensandfilterRufus D SNo ratings yet

- 1615.00209 - BCPDocument4 pages1615.00209 - BCPRufus D SNo ratings yet

- SoftenerDocument2 pagesSoftenerRufus D SNo ratings yet

- Tube ExpansionDocument1 pageTube ExpansionRufus D SNo ratings yet

- GlassfilterDocument1 pageGlassfilterRufus D SNo ratings yet

- Safety Valve VentDocument3 pagesSafety Valve VentRufus D SNo ratings yet

- CipDocument2 pagesCipRufus D SNo ratings yet

- 0259 - HMIP Chimney HeightDocument1 page0259 - HMIP Chimney HeightRufus D SNo ratings yet

- G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MDocument11 pagesG/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/M G/MRufus D SNo ratings yet

- Chimney CodesDocument3 pagesChimney CodesRufus D SNo ratings yet

- 0234 - Chimney Structural - R0Document7 pages0234 - Chimney Structural - R0Rufus D SNo ratings yet

- 0259 - CAA Chimney HeightDocument2 pages0259 - CAA Chimney HeightRufus D SNo ratings yet

- EffDocument7 pagesEffRufus D SNo ratings yet

- Base Plate IPE200 Fe250Document32 pagesBase Plate IPE200 Fe250Tejas SawantNo ratings yet

- Good OneDocument94 pagesGood OneVishal PattanshettiNo ratings yet

- 1.2. Linear Spaces 1Document4 pages1.2. Linear Spaces 1Muhammad ShoaibNo ratings yet

- Cambridge International General Certificate of Secondary Education (9-1)Document20 pagesCambridge International General Certificate of Secondary Education (9-1)Pranav BISUMBHERNo ratings yet

- Dielectric AbsorptionDocument4 pagesDielectric AbsorptionbookbumNo ratings yet

- OPTI 370 Syllabus S22 (Updated)Document7 pagesOPTI 370 Syllabus S22 (Updated)AhmedphmaNo ratings yet

- Yongnuo 560 EX II Flash User ManualDocument1 pageYongnuo 560 EX II Flash User ManualEj CoombsNo ratings yet

- CHAPTER 1. Soil Formation.: A. Geotechnical Engineering C. Soil and Its ConstituentsDocument5 pagesCHAPTER 1. Soil Formation.: A. Geotechnical Engineering C. Soil and Its ConstituentsAngel RondillaNo ratings yet

- Clamp Overview: Standard SolutionsDocument32 pagesClamp Overview: Standard SolutionsArun JaisonNo ratings yet

- Hall Effect - CMP Assignment 1Document14 pagesHall Effect - CMP Assignment 1Meow ChaeNo ratings yet

- REC TwinPeak 2S Mono 72 Series Solar Panel Datasheet 1Document2 pagesREC TwinPeak 2S Mono 72 Series Solar Panel Datasheet 1Mark John Dy DaytoNo ratings yet

- 1 Sheet Fundamentals of Heat TransferDocument3 pages1 Sheet Fundamentals of Heat TransferManju MuruhanNo ratings yet

- Proposal - Shortcut - LNKDocument11 pagesProposal - Shortcut - LNKJohn kinder BasilioNo ratings yet

- Key Features:: Single 8" Two-Way 90° X 50° Full-Range Loudspeaker SystemDocument4 pagesKey Features:: Single 8" Two-Way 90° X 50° Full-Range Loudspeaker SystemRafRouf SehiliNo ratings yet

- 08 Chapter 16 Acid BaseDocument148 pages08 Chapter 16 Acid BaseDamla Nur GÜLNo ratings yet

- Chimney SizingDocument7 pagesChimney SizingAli MustafaNo ratings yet

- Mechanical Engineering Hydraulic Mechanics Important MCQ PDFDocument11 pagesMechanical Engineering Hydraulic Mechanics Important MCQ PDFGaneshNo ratings yet

- Switchgear Inspection Checklist: Section A - Customer DataDocument1 pageSwitchgear Inspection Checklist: Section A - Customer Data20082012No ratings yet

- Reinforced Concrete Design-Krishnaraju PDFDocument318 pagesReinforced Concrete Design-Krishnaraju PDFJustin100% (3)

- DC002234-004 - Rev. 7 - EN - FR - ESDocument48 pagesDC002234-004 - Rev. 7 - EN - FR - ESAxl EslonNo ratings yet

- Shear Wall and Diagrid SystemDocument47 pagesShear Wall and Diagrid SystemAashi GuptaNo ratings yet

- Maths QuestionsDocument25 pagesMaths QuestionsSha YosiNo ratings yet

- Investigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentDocument10 pagesInvestigation On Mechanical Properties of Wire Arc Additive Manufacturing (Waam) of 316L Stainless Steel Using Fem Simulation and ExperimentMohd AymanNo ratings yet

- Cambridge Assessment International Education: Combined Science 0653/43 October/November 2019Document10 pagesCambridge Assessment International Education: Combined Science 0653/43 October/November 2019Dada LimNo ratings yet

- AEMT Assignment1 2023Document2 pagesAEMT Assignment1 2023Sujay SNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768wawan100% (1)

- JSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Document39 pagesJSSC JDLCCE 2021 (Civil Engineering) Official Pape 230615 233342Bhuban KumbhakarNo ratings yet

- User Manual: 0$18$/ (' 862e INSTALLAZIONE UPS / Gruppi Statici Di Continuità Models Green Point 6÷20KVADocument61 pagesUser Manual: 0$18$/ (' 862e INSTALLAZIONE UPS / Gruppi Statici Di Continuità Models Green Point 6÷20KVAlamiaNo ratings yet

- Q4 Science 9 - Module 1Document23 pagesQ4 Science 9 - Module 1Danilo Saliog67% (6)

- Universitimalaysiaperlis: Emj32004 Power Systemengineering Laboratory Module2Document8 pagesUniversitimalaysiaperlis: Emj32004 Power Systemengineering Laboratory Module2ALINo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaFrom EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaRating: 4 out of 5 stars4/5 (5)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- Mooring System Engineering for Offshore StructuresFrom EverandMooring System Engineering for Offshore StructuresRating: 5 out of 5 stars5/5 (1)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet