Professional Documents

Culture Documents

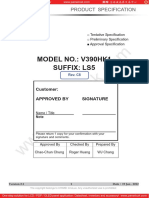

Product Specifications

Uploaded by

Edgar Oliveira PassosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Specifications

Uploaded by

Edgar Oliveira PassosCopyright:

Available Formats

Doc. No.

:1P074-00

Product Specifications

Customer Standard

Description 10.2” TFT EPD Panel

Model Name EZ102CT011

Date 2014/12/10

Doc. No. 1P074-00

Revision 01

Customer Approval

Date

The above signature represents that the product specifications, testing regulation, and

warranty in the specifications are accepted

Design Engineering

Approval Check Design

黃 黃 柯

2014.12.10 2014.12.10 2014.12.10

富瑞 富瑞 建宏

No.71, Delun Rd., Rende Dist., Tainan City 71743, Taiwan (R.O.C.)

Tel: +886-6-279-5399 Fax: +886-6-270-5857

Rev.: 01 Page: 1 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

Copyright

Pervasive Displays Incorporated All rights reserved.

This document is the exclusive property of Pervasive Displays Inc. (PDI) and shall not be

reproduced or copied or transformed to any other format without prior permission of PDI. ( PDI

Confidential )

本資料為龍亭新技股份有限公司專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

龍亭新技股份有限公司 Pervasive Displays Inc.

No.71, Delun Rd., Rende Dist., Tainan City 71743, Taiwan (R.O.C.)

Tel: +886-6-279-5399

http://www.pervasivedisplays.com

Rev.: 01 Page: 2 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

Table of Contents

Revision History ........................................................................................................... 6

Glossary of Acronyms ................................................................................................... 7

1 General Description ................................................................................................ 8

1.1 Overview ..................................................................................................... 8

1.2 Features ...................................................................................................... 8

1.3 Applications ................................................................................................. 8

1.4 General Specifications ................................................................................... 9

1.5 Mechanical Specifications............................................................................. 10

2 Absolute Maximum Ratings .................................................................................... 12

2.1 Absolute Ratings of Environment .................................................................. 12

2.2 Reliability Test Item .................................................................................... 13

3 Electrical Characteristics ........................................................................................ 14

3.1 Absolute Maximum Ratings of Panel .............................................................. 14

3.2 Recommended Operation Conditions of Panel ................................................. 14

3.3 Source driver Ac characteristics .................................................................... 15

3.4 Gate driver AC characteristics ...................................................................... 16

3.5 Power ON/OFF sequence.............................................................................. 17

4 Application Circuit Block Diagram ........................................................................... 18

5 Panel Pin Assignment ............................................................................................ 19

5.1 Terminal Pin Assignment .............................................................................. 19

6 Optical Characteristics........................................................................................... 21

6.1 Test Conditions ........................................................................................... 21

6.2 Optical Specifications .................................................................................. 21

6.3 Ghosting.................................................................................................... 24

7 Packing ............................................................................................................... 25

8 Precautions.......................................................................................................... 27

9 Definition of Labels ............................................................................................... 29

Rev.: 01 Page: 3 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

List of Figures

Figure 1-1 EPD Drawing ................................................................................. 11

Figure 2-1 Operating Range of Relative Humidity and Temperature ..................... 12

Figure 4-1 Application Circuit Block Diagram .................................................... 18

Figure 6-1 Optical measurement ..................................................................... 22

Figure 6-2 Definition of Viewing Angle to Measure Contrast Ratio ........................ 23

Figure 7-1 Packing Diagram ........................................................................... 25

Figure 9-1 Model Labels ................................................................................. 29

Figure 9-2 Definition of Model Labels ............................................................... 30

Figure 9-3 Carton Label ................................................................................. 31

Figure 9-4 Pallet Label ................................................................................... 31

Rev.: 01 Page: 4 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

List of Tables

Table 1-1 General Specification ......................................................................... 9

Table 1-2 EPD Mechanical Specification ............................................................ 10

Table 1-3 FPC Specification ............................................................................ 10

Table 2-1 Absolute Ratings of Environment ...................................................... 12

Table 2-2 Reliability Test Item......................................................................... 13

Table 3-1 Absolute Maximum Ratings of Panel .................................................. 14

Table 3-2 Recommended Operation Conditions of Panel ..................................... 14

Table 5-1 Terminal Pin Assignment .................................................................. 19

Table 6-1 Optical Test Conditions .................................................................... 21

Table 6-2 Optical Measurement with D65 light source ........................................ 21

Rev.: 01 Page: 5 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

Revision History

Page

Version Date Section Description

(New)

Ver.01 2014/12/10 All All Specification first issued.

Rev.: 01 Page: 6 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

Glossary of Acronyms

EPD Electrophoretic Display (e-Paper Display)

EPD Panel EPD

EPD Module EPD with TCon board

TCon Timing Controller

TFT Thin Film Transistor

MCU Microcontroller Unit

FPC Flexible Printed Circuit

FPL Front Plane Laminate

SPI Serial Peripheral Interface

COG Chip on Glass

PDI Pervasive Displays Incorporated

Rev.: 01 Page: 7 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

1 General Description

1.1 Overview

This is a 10.2” a-Si TFT active matrix Electronic Paper Display (EPD) module. Since this

module has high resolution, 160dpi, it can display fine pattern easily. Additionally, this

module needs not only no power while hold pattern due to the bi-stable character of

EPD but also ultra low power to update pattern.

1.2 Features

- a-Si TFT active matrix Electronic Paper Display(EPD)

- Resolution: 1024 x 1280

- Ultra low power consumption

- Super Wide Viewing Angle - near 180°

- Extra thin & light

- SPI interface

- RoHS compliant

1.3 Applications

- e-POP/Signage

- Electronic bulletins

- Office Automation

- Navigator

Rev.: 01 Page: 8 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

1.4 General Specifications

Table 1-1 General Specification

Item Specification Unit Note

Outline Dimension 171.76(H) x 218.30(V) x 1.20(T) mm (1)

Active Area 162.56(H) x 203.20(V) mm

Driver Element a-Si TFT active matrix -

FPL Aurora Mb -

Pixel Number 1024 x 1280 pixel

Pixel Pitch 0.15875 x 0.15875 (160dpi) mm

Pixel Arrangement Vertical stripe -

Display Colors Black/White -

Surface Treatment Anti-Glare -

Note (1): Not including the FPC.

Rev.: 01 Page: 9 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

1.5 Mechanical Specifications

Table 1-2 EPD Mechanical Specification

Item Min. Typ. Max. Unit Note

Horizontal(H) 171.46 171.76 172.06 mm

Glass Size Vertical(V) 218.00 218.30 218.60 mm

Thickness(T) 1.0 1.2 1.4 mm (1)

Weight 91.7 110 g

Note (1): Not including the Masking Film.

Table 1-3 FPC Specification

Item Pin numbers Pitch (mm) Connector Note

Board to Board

40 HRS DF23C-40DP-0.5V

Connector

Rev.: 01 Page: 10 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

Figure 1-1 EPD Drawing

PIN1

Rev.: 01 Page: 11 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

2 Absolute Maximum Ratings

2.1 Absolute Ratings of Environment

Table 2-1 Absolute Ratings of Environment

Value

Item Symbol Unit Note

Min. Max.

Storage Temperature TST -20 +60 ºC (1),(3)

Operating Ambient Temperature TOP 0 +50 ºC (1),(2),(3)

Note (1):

(a) 90 %RH Max. (Ta ≦ 40 ºC).

(b) Wet-bulb temperature should be 39 ºC Max. (Ta > 40 ºC).

(c) No condensation and no frost.

Note (2): The temperature of panel display surface area should be 0 ºC Min. and 50

ºC Max. Refresh time depends on operating temperature.

Note (3): In order to keep good performance of EPD, please refer to precaution for

storage condition.

Figure 2-1 Operating Range of Relative Humidity and Temperature

Rev.: 01 Page: 12 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

2.2 Reliability Test Item

Table 2-2 Reliability Test Item

Item Test Condition Note

High Temperature Operation 50 ℃ / 30 %RH for 240h (1) (2)

Low Temperature Operation 0 ℃ for 240h (1) (2)

High Temperature/Humidity

40 ℃ / 90 %RH for 168h (1) (2)

Operation

High Temperature Storage 60 ℃ / 26 %RH for 240h (1)(2)(3)

Low Temperature Storage -20 ℃ for 240h (1)(2)(3)

High Temperature/Humidity

50 ℃ / 80 %RH for 168h (1)(2)(3)

Storage

Thermal Cycles 1 Cycle:-20℃/30min → 60℃/30min,

(1)(2)(3)

( Non-operation ) for 100 Cycles

Drop from 97cm. ( ISTA )

Package Drop Test 1 corner, 3 edges, 6 sides. One drop (1)(2)(3)

for each.

Package Random Vibration Test 1.15Grms, 1Hz ~ 200Hz. ( ISTA ) (1)(2)(3)

Note (1): No condensation and no frost during test. End of test, function, mechanical,

and optical shall be satisfied.

Note (2): The test result and judgment are based on PDI’s 1bit driving waveform,

driving fixture and driving system.

Note (3): Stay white pattern for storage and non-operation test.

Rev.: 01 Page: 13 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

3 Electrical Characteristics

3.1 Absolute Maximum Ratings of Panel

Table 3-1 Absolute Maximum Ratings of Panel

Parameter Symbol Rating Unit

Logic supply voltage VDD -0.3 to +7 V

Source positive supply voltage VPOS -0.3 to +20 V

Source negative supply voltage VNEG +0.3 to -20 V

Max. drive voltage range VPOS-VNEG 40 V

Gate supply range VGG-VEE 40 V

Operating temp. range 0 to +50 ˚C

Ta = 25 ± 2 ºC

3.2 Recommended Operation Conditions of Panel

Table 3-2 Recommended Operation Conditions of Panel

Value

Parameter Symbol Unit

Min Typ Max

Signal Ground VSS - 0 - V

Logic Power VDD 3.0 3.3 3.6 V

Source positive Voltage VPOS 14 15 16 V

Source negative Voltage VNEG -16 -15 -14 V

Gate positive Voltage VGG VPOS+5 22 VEE+40 V

Gate negative Voltage VEE -21 -20 VNEG-5 V

Common voltage VCOM - -1.8 - V

Ta = 25 ± 2 ºC

Rev.: 01 Page: 14 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

3.3 Source driver Ac characteristics

CL

tcy

D0~D7,CE

tsu th

Parameter Symbol Min. Typ. Max. Unit

Clock CL cycle time tcy 40 - - ns

D0…D7, CE setup time tsu 8 - - ns

D0…D7, CE holt time th 1 - - ns

Required: one

First CL after CE rise CL rise during First CL after CE fall

LE high

CL

Stretch CL(low) to increase

delay time

CE tsu th

tLEdly tLEoff

LE tLE

tMh

tMsu

SHR

MODE0

MODE1

tOUT

tOUT

OUTx(to VSS)

OUTx(from VSS)

Parameter Symbol Condition Min. Typ. Max. Unit

LE on delay time tLEdly 40 - - ns

LE high-level pulse width tLEw 40 - - ns

LE off delay time tLEoff 40 - - ns

SHR,MODE0,MODE1 setup time tMsu 100 - - ns

SHR,MODE0,MODE1 hold time tMh 10 - - ns

Output settling time to +/-30mV tOUT Cload=50pf 100 - 12 us

Rev.: 01 Page: 15 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

3.4 Gate driver AC characteristics

PWCLK

CKV

Tsu Thd

STVD/U

(in) Tdt Tdt

STVD/U

(out) Tdo Tdo

VGG

GOn VEE

Twcl

OE

Toe Toe

GOn VGG

VEE

Txon Txon

XON

VGG

GOn VEE

Parameter Symbol Condition. Min. Typ. Max. Unit

Clock pulse width(High to low period) PWCLK 500 ns

STVD/STVU setup time Tsu 200 ns

STVD/STVU hold time Thd 300 ns

Driver output delay time Tdo CL=220pF 900 ns

STVD/STVU delay time Tdt CL=220pF 500 ns

Output enable pulse width Twcl 1 us

OE to driver output delay time Toe CL=220pF 900 ns

XON to driver output delay time Txon CL=220pF 10 us

Rev.: 01 Page: 16 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.:1P074-00

3.5 Power ON/OFF sequence

T5 T6

VGG

T4 T7

VPSO

T2 T3

T8 T9 T10

T1

VDD

Data

VNEG

VEE

Symbol Min. Max.

T1 20 ms -

T2 4 ms -

T3 4 ms -

T4 4 ms -

T5 100 us -

T6 100 us -

T7 4ms -

T8 4ms -

T9 4ms -

T10 20ms -

Rev.: 01 Page: 17 of 31 Date: 2014/12/10

This document is the exclusive property of PDI and shall not be reproduced or copied or transformed to any other format without

prior permission of PDI. ( PDI Confidential ) 本資料為龍亭新技專有之財產,非經許可,不得複製、翻印或轉變成其他形式使用。

Doc. No.1P074-00

4 Application Circuit Block Diagram

Figure 4-1 Application Circuit Block Diagram

Temp.

Flash Sensor

e-Paper DC/DC

Timing Circuit

Customer side Controller

Driving Board

Board

FPC

PDI side

e-Paper

Panel

Rev.: 01 Page: 18 of 31 Date: 2014/12/10

Doc. No.1P074-00

5 Panel Pin Assignment

5.1 Terminal Pin Assignment

Table 5-1 Terminal Pin Assignment

No. Signal Type Connected to Function

1 VNEG P VNEG Source driver negative power supply

2 VPOS P VPOS Source driver positive power supply

3 VNEG P VNEG Source driver negative power supply

4 VPOS P VPOS Source driver positive power supply

5 VNEG P VNEG Source driver negative power supply

6 VPOS P VPOS Source driver positive power supply

7 GND P Ground Grounding

8 NC - Floating

9 GND P Ground Grounding

10 GND P Ground Grounding

11 D0 I MCU Bit0 of the data bus

12 D1 I MCU Bit1 of the data bus

13 D2 I MCU Bit2 of the data bus

14 D3 I MCU Bit3 of the data bus

15 D4 I MCU Bit4 of the data bus

16 D5 I MCU Bit5 of the data bus

17 D6 I MCU Bit6 of the data bus

18 D7 I MCU Bit7 of the data bus

19 GND P Ground Grounding

20 GND P Ground Grounding

21 CE1 I MCU Chip Enable 1

Rev.: 01 Page: 19 of 31 Date: 2014/12/10

Doc. No.1P074-00

No. Signal Type Connected to Function

22 CE2 I MCU Chip Enable 2

23 CE3 I MCU Chip Enable 3

24 CE4 I MCU Chip Enable 4

25 OE I MCU Output enable

26 OE123L I MCU Output enable 1, 2 and 3 (connected)

27 CL I MCU Pixel Clock

28 LE I MCU Latch enable

29 U/D I MCU Gate scan direction

30 VCOM P VCOM Common voltage (backplane)

31 CKV I MCU Line clock

32 STVD I/O MCU / - Gate start pulse. When U/D=1, the pin is input.

33 SHR I MCU Source scan direction

34 STVU I/O MCU/ - Gate start pulse. When U/D=0, the pin is input.

35 VST P VCOM Common voltage (capacitor line)

36 VDD P VDD Logic supply voltage

37 VEE P VEE Gate driver negative power supply

38 VDD P VDD Logic power supply

39 VGG P VGG Gate driver positive power supply

40 NC - Floating

Note (1): Type:

I: Input

O: Output

P: Power

Rev.: 01 Page: 20 of 31 Date: 2014/12/10

Doc. No.1P074-00

6 Optical Characteristics

6.1 Test Conditions

Table 6-1 Optical Test Conditions

Item Symbol Value Unit

Ambient Temperature Ta 252 ºC

Ambient Humidity Ha 5010 %RH

Supply Voltage VCC & VDD 3.3 V

6.2 Optical Specifications

Table 6-2 Optical Measurement with D65 light source

Rating

Item Symbol Unit Note

Min. Typ. Max.

θx=θy=0

Contrast ratio CR - 7:1 - -

(1),(2),(3),(4)

Refresh time Tr - 3.2 - sec (3)

θx=θy=0

Wx - 0.31 -

White (1),(4)

-

Chromaticity

Wy - 0.33 -

Reflectance R% 32 - % (1),(4)

Note (1): Panel is driven by PDI waveform without masking film and optical

measurement by CM-700D with D65 light source and SCE mode.

Rev.: 01 Page: 21 of 31 Date: 2014/12/10

Doc. No.1P074-00

Figure 6-1 Optical measurement

Rev.: 01 Page: 22 of 31 Date: 2014/12/10

Doc. No.1P074-00

Note (2): Definition of Viewing Angle (x, y):

Figure 6-2 Definition of Viewing Angle to Measure Contrast Ratio

Note (3): Refresh time is the time that e-paper particles move not including the power

on and off time. The refresh time is measured at 25ºC.The refresh time and

contrast ratio varies due to different films, display performance

requirements, and ambient temperatures.

Note (4): Contrast ratio (C.R.): The Contrast ratio is calculated by the following

expression. C.R. =(R% White) / (R% Black). Reflectance is measured at

120 seconds after refresh.

Rev.: 01 Page: 23 of 31 Date: 2014/12/10

Doc. No.1P074-00

6.3 Ghosting

Below are two test methods to verify that ghosting within an acceptable range.

Test 1 and Test 2 use measured data to calculate Delta E which is a single

number representing the distance between two colors in a 3 dimensional color

space. Test 1 and Test 2 are performed at 25ºC.

Test 1: White to Black Ghosting

White Black White A A’

Measure the △E*ab

Refresh Refresh after And reflection ratio of

immediately 1 hour storage A and A’

Test 2: Black to White Ghosting

Black Black Black B B’

Measure the △E*ab

Refresh Refresh after

And reflection ratio of

immediately 1 hour storage

B and B’

The formula is used to calculate Test1 and Test2. For example of Test 2:

△E*ab = [ (LB – LB’)2 + (aB – aB’)2 + (bB – bB’)2 ]1/2

Rating

Item

Min. Typ. Max.

Test 1

- - 2

△E*ab

Test 2

- - 2

△E*ab

Note: Panel is driven by PDI waveform without masking film and optical

measurement by CM-700D with D65 light source and SCE mode.

Rev.: 01 Page: 24 of 31 Date: 2014/12/10

Doc. No.1P074-00

7 Packing

Figure 7-1 Packing Diagram

1set EPD

F/B-EPE

Tray UP/DOWN-EPE

17X1=17Pcs

2 P cEs m p tTyr a y

Drier x2

D r i e r D r i e r

1Pcs

Empty R/L-EPE

Tray

17Pcs Full Tray

Plastic bag

Carton

Carton_Label

1Pcs

Empty

Tray

Vacuum Packaging

Note:

Rev.: 01 Page: 25 of 31 Date: 2014/12/10

EMPTY BOX

Doc. No.1P074-00

Pallet Label

Film

PP Belt

Protector

Pallet

17(pcs)x40(BOX)=680pcs

Sea / Land / Air Transportation

Rev.: 01 Page: 26 of 31 Date: 2014/12/10

Doc. No.1P074-00

8 Precautions

(1) The EPD Panel / Module is manufactured from fragile materials such as glass and

plastic, and may be broken or cracked if dropped. Please handle with care. Do not

apply force such as bending or twisting to the EPD panel during assembly.

(2) It is recommended to assemble or install EPD panels in a clean working area. Dust

and oil may cause electrical shorts or degrade / scratch / den the protection sheet

film.

(3) Do not apply pressure to the EPD panel in order to prevent damaging it.

(4) Do not connect or disconnect the interface connector while the EPD panel is in

operation.

(5) Please support the bezel with your finger while connecting the interface cable such as

the FPC.

(6) Do not stack the EPD panels / Modules.

(7) Do not press the FPC on the glass edge or Pull FPC up / down to 90°.

(8) Do not touch the FPC lead connector.

(9) Do not touch IC bonding area. It may scratch TFT lead or damage IC function.

(10) Wear a Wrist Strap (Grounding connect) when handling and during assembly.

Semiconductor devices are included in the EPD Panel / Module and they should be

handled with care to prevent any electrostatic discharge (ESD). (An Ion Fan may be

needed in assembly operation to reduce ESD risk.)

(11) Keep the EPD Panel / Module in the specified environment and original packing boxes

when storage in order to avoid scratching.

(12) Do not disassemble or reassemble the EPD panel.

(13) Use a soft dry cloth without chemicals for cleaning. Please don’t press hard for

cleaning because the surface of the protection sheet film is very soft and without hard

coating. This behavior would make dent or scratch on protection sheet.

(14) Please be mindful of moisture to avoid its penetration into the EPD panel, which may

cause damage during operation.

(15) It’s low temperature operation product. Please be mindful the temperature different

to make frost or dew on the surface of EPD panel. Moisture may penetrate into the

EPD panel because of frost or dew on surface of EPD panel, and makes EPD panel

damage.

(16) High temperature, high humidity, sunlight or fluorescent light may degrade the EPD

panel’s performance. Please do not expose the unprotected EPD panel to high

temperature, high humidity, sunlight, or fluorescent for long periods of time. Please

store the EPD panel in controllable environment of warehouse and original package:

Without sunlight, without condensation, a temperature range of 15ºC to 35ºC, and

humidity from 30%RH to 60%RH.

(17) The ink used for marking the Panel ID number is erased easily by solvent. Please

avoid using solvent to clean the EPD panel.

Rev.: 01 Page: 27 of 31 Date: 2014/12/10

Doc. No.1P074-00

(18) The EPD is vacuum packed.

(19) Before approved by PDI and customer, products and product specifications may be

subject to change without notice. Confirm that you have received the latest product

standards or specifications before final design, purchase or use.

(20) PDI makes every attempt to ensure that its products are of high quality and reliability.

However, contact PDI sales office before using the product in an application that

demands especially high quality and reliability or where its failure or malfunction may

directly threaten human life or cause risk of bodily injury, such as aerospace,

aeronautics, nuclear power, combustion control, transportation, traffic, safety

equipment or medical equipment for life support.

(21) Design your application so that the product is used within the ranges guaranteed by

PDI particularly for maximum rating, operating supply voltage range, heat radiation

characteristics, installation conditions and other characteristics. PDI bears no

responsibility for failure or damage when used beyond the guaranteed ranges. Even

within the guaranteed ranges, consider normally foreseeable failure rates or failure

modes in semiconductor devices and employ systemic measures such as fail safes, so

that the equipment incorporating PDI product does not cause bodily injury, fire or

other consequential damage due to operation of the PDI product.

(22) This product is not designed to be radiation resistant.

Rev.: 01 Page: 28 of 31 Date: 2014/12/10

Doc. No.1P074-00

9 Definition of Labels

Figure 9-1 Model Labels

XXXXXXXXXX-XX

XEXXXXXXXXXXXXXXXXXXX

Barcode=ID No.(21 Digits)

XXXXXXXXXX-XX

XEXXXXXXXXXXXXXXXXXXX

Rev.: 01 Page: 29 of 31 Date: 2014/12/10

Doc. No.1P074-00

Figure 9-2 Definition of Model Labels

XXXXXXXXXX-XX (1~12) Customs control information

XEXXXXXXXXXXXXXXXXXXX

(18~21)Serial NO.

(15~17)Manufacture Year/Month/Day

(12~14)FPL LOT NO.

(2~11)Model Name

(1)Manufacture vender code

Rev.: 01 Page: 30 of 31 Date: 2014/12/10

Doc. No.1P074-00

Figure 9-3 Carton Label

Model Name. Carton Serial No. Q'TY.

(10 Digits) (9 Digits) (3 Digits)

EXXXXXXXXX CXXXXXXXX Q'TY:XXX RoHS

(3 Digits)

XXXXXXXXXX-XX

(10 Digits) (9 Digits) Customs control information

Bar Code=Model Name.+Carton Serial No.+Q'TY.(22 Digits)

Carton Label

Figure 9-4 Pallet Label

Model Name.

(10 Digits)

Pallet Serial No.

EXXXXXXXXX Q'TY.

(7 Digits) CXXXXXX Q'TY:XXXXX (5 Digits)

GW:XXXXKg RoHS

Weight.

PERVASIVEDISPLAYS

(10 Digits) (7 Digits) (5 Digits)

Bar Code=Model Name.+Pallet Serial No.+Q'TY.(22 Digits)

Pallet Label

Rev.: 01 Page: 31 of 31 Date: 2014/12/10

You might also like

- Troubleshooting Electronic Circuits: A Guide to Learning Analog ElectronicsFrom EverandTroubleshooting Electronic Circuits: A Guide to Learning Analog ElectronicsNo ratings yet

- Tarlac - San Antonio - Business Permit - NewDocument2 pagesTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- MD.070 A E T D: USG PO ReportDocument10 pagesMD.070 A E T D: USG PO ReportGops989No ratings yet

- DL CoMP (eRAN12.1 - 02)Document57 pagesDL CoMP (eRAN12.1 - 02)CosminDNo ratings yet

- SP-000-11360-0003 - 01 Instruction For Vendor Documentation PDFDocument33 pagesSP-000-11360-0003 - 01 Instruction For Vendor Documentation PDFNima SharifiNo ratings yet

- R&D Procedure - Product - Development - HandbookDocument45 pagesR&D Procedure - Product - Development - HandbooksumanNo ratings yet

- TEG Design ManualDocument15 pagesTEG Design ManualEryl Yeong100% (1)

- ADCO SIL ProcedureDocument42 pagesADCO SIL ProcedureGianfrancoMangiapaneNo ratings yet

- How To Guide To Oauth and API SecurityDocument12 pagesHow To Guide To Oauth and API Securitysilviuleahu100% (1)

- Management by ObjectivesDocument30 pagesManagement by ObjectivesJasmandeep brar100% (4)

- Hortors Online ManualDocument11 pagesHortors Online Manualtshepang4228No ratings yet

- Huawei Optical Network Maintenance Reference NA-20110812-CDocument95 pagesHuawei Optical Network Maintenance Reference NA-20110812-Cscribd01No ratings yet

- GPO-EN-SPE-40104 - General Engineering Specification For Packaged Equipment (US)Document144 pagesGPO-EN-SPE-40104 - General Engineering Specification For Packaged Equipment (US)Alina Ioana Prahoveanu100% (2)

- Embedded DSP Processor Design: Application Specific Instruction Set ProcessorsFrom EverandEmbedded DSP Processor Design: Application Specific Instruction Set ProcessorsNo ratings yet

- 240-56355754 Field Equipment Installation StandardDocument10 pages240-56355754 Field Equipment Installation StandardiabhuaNo ratings yet

- Foreclosure of REMDocument10 pagesForeclosure of REMShanelle NapolesNo ratings yet

- GS Ep Tec 260 enDocument61 pagesGS Ep Tec 260 enCesarNo ratings yet

- Successfully Allocating Risk and Negotiating A PPP ContractDocument12 pagesSuccessfully Allocating Risk and Negotiating A PPP ContractWilliam Tong100% (1)

- Handbook of Metric Drive Components PDFDocument1,282 pagesHandbook of Metric Drive Components PDFjaisanmecaNo ratings yet

- BD User Guide AP131400DAA - 2013-12-17Document168 pagesBD User Guide AP131400DAA - 2013-12-17Edhem SmailbegovićNo ratings yet

- Financial Business Intelligence: Trends, Technology, Software Selection, and ImplementationFrom EverandFinancial Business Intelligence: Trends, Technology, Software Selection, and ImplementationNo ratings yet

- LEBV4830Document371 pagesLEBV4830anton100% (1)

- LIC Product PositioningDocument15 pagesLIC Product PositioningRasika Pawar-HaldankarNo ratings yet

- 8010028-01-OM-001 - O&M-Manual Rio Turbio 1+2 - enDocument62 pages8010028-01-OM-001 - O&M-Manual Rio Turbio 1+2 - enjose almironNo ratings yet

- Aficio 4002-5002 D129/D130 SERVICE MANUALDocument1,401 pagesAficio 4002-5002 D129/D130 SERVICE MANUALiageek74% (19)

- JAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0Document21 pagesJAW - 00-K - 11a - 040 - PP - 144 - Commissioning ITP - MV System Essential Boards - 00BDA10 - Rev.0MedrouaNo ratings yet

- Im50 Service ManualDocument59 pagesIm50 Service ManualJAVIER100% (1)

- SOP-Iron Ore Crushing Hauling To Port-RevDocument7 pagesSOP-Iron Ore Crushing Hauling To Port-RevAgus BudiluhurNo ratings yet

- Software Requirements SpecificationDocument28 pagesSoftware Requirements SpecificationKamal SharmaNo ratings yet

- Ges C0201 01 Sis HW FDS R4.01.00Document105 pagesGes C0201 01 Sis HW FDS R4.01.00Priyansh SaxenaNo ratings yet

- 1P108-00 02 E2215cs062 20160311 PDFDocument29 pages1P108-00 02 E2215cs062 20160311 PDFRachele DaniNo ratings yet

- Product SpecificationsDocument29 pagesProduct SpecificationsHuynh Tien ThinhNo ratings yet

- 1P226-00 01 E2154js0c1 20201019Document28 pages1P226-00 01 E2154js0c1 20201019Inventor TestNo ratings yet

- JPX01 MDF Product DescriptionDocument33 pagesJPX01 MDF Product DescriptionAbhishek Srivastava0% (1)

- Document Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Document15 pagesDocument Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Solikhul HarisNo ratings yet

- NO HLD 10 TPSH 810008 - Rev00 Electrical Isolation Procedure TotalDocument16 pagesNO HLD 10 TPSH 810008 - Rev00 Electrical Isolation Procedure TotalAUGUSTA WIBI ARDIKTANo ratings yet

- Investigation Report 05.12.2017 Lifting Operation Failure During Tower Erection Investigatigations by Arber DoganiDocument35 pagesInvestigation Report 05.12.2017 Lifting Operation Failure During Tower Erection Investigatigations by Arber DoganiArber DoganiNo ratings yet

- ST5461D07-1 - Product Spec - Ver0 2 20160726Document32 pagesST5461D07-1 - Product Spec - Ver0 2 20160726Birciu ValiNo ratings yet

- Cdns Qspi Flash CTRL and Phy Design SpecificationDocument149 pagesCdns Qspi Flash CTRL and Phy Design SpecificationYuinYee ChewNo ratings yet

- Benq W 1070 Service Manual PDFDocument142 pagesBenq W 1070 Service Manual PDFNguyen Lan Rivaret100% (2)

- DatasheetDocument28 pagesDatasheetGastonNo ratings yet

- V320BJ6 LD1 CmimeiDocument35 pagesV320BJ6 LD1 CmimeiNurjaman ElektroNo ratings yet

- Kiloview Manual Encoder E1Document45 pagesKiloview Manual Encoder E1Gerson CarrilloNo ratings yet

- v460hj1 l01 Cmi MeiDocument37 pagesv460hj1 l01 Cmi MeiSasha HesenliNo ratings yet

- SoftSpeed TDDocument16 pagesSoftSpeed TDIonNo ratings yet

- PLDSS7-4300244422-H02-0005 - ITP For Blasting and Painting - 03Document11 pagesPLDSS7-4300244422-H02-0005 - ITP For Blasting and Painting - 03minhhieu.qcNo ratings yet

- 31400835-Hardware Description (V100R007 04)Document741 pages31400835-Hardware Description (V100R007 04)Fabricio IzaNo ratings yet

- Manual 64001 SB Side Entry MixerDocument57 pagesManual 64001 SB Side Entry MixermatiasmermacoraNo ratings yet

- V216BG1 LE1 CHIMEIInnoluxDocument33 pagesV216BG1 LE1 CHIMEIInnoluxMarko VujinovićNo ratings yet

- E Series NDI Encoder User Manul V2.0Document47 pagesE Series NDI Encoder User Manul V2.0Rishab SharmaNo ratings yet

- New Discovery TMDocument261 pagesNew Discovery TMbashir3047No ratings yet

- A-Dec Dental Lights and Monitor Mounts - Service GuideDocument64 pagesA-Dec Dental Lights and Monitor Mounts - Service GuideJuancarlosNo ratings yet

- Instrumentarium Dental OP-200, OC-200 Dental Panorama X-Ray - User Manual PDFDocument136 pagesInstrumentarium Dental OP-200, OC-200 Dental Panorama X-Ray - User Manual PDFChandra Noor Satriyo100% (1)

- Model Name: T550QVR04.0: Issue Date: 2016/09/22 Preliminary Specifications ( ) Final SpecificationsDocument29 pagesModel Name: T550QVR04.0: Issue Date: 2016/09/22 Preliminary Specifications ( ) Final SpecificationskevinalleinNo ratings yet

- Datasheet PDFDocument43 pagesDatasheet PDFCriis RamirezNo ratings yet

- Controlled DisclosureDocument12 pagesControlled DisclosureJinyoung ChoiNo ratings yet

- MASAR - ONGP - FSD - ENH000041 - Add Fields in The Nomination Subitems - V1.1Document21 pagesMASAR - ONGP - FSD - ENH000041 - Add Fields in The Nomination Subitems - V1.1Mayank KumarNo ratings yet

- ApplicationNote Small Size Spectra Yellow v05 200814Document23 pagesApplicationNote Small Size Spectra Yellow v05 200814Inventor TestNo ratings yet

- MODEL: ST5461D07-1: Ver. 2.1 Date: 30.nov.2016Document32 pagesMODEL: ST5461D07-1: Ver. 2.1 Date: 30.nov.2016Mehedi Hasan bappiNo ratings yet

- Datasheet 2Document28 pagesDatasheet 2JEORJENo ratings yet

- ALC887Document82 pagesALC887EmmanuelchatoNo ratings yet

- Trident 4DWAVE-DX Technical Reference ManualDocument50 pagesTrident 4DWAVE-DX Technical Reference ManualDian NoviantiNo ratings yet

- 31401505-Hardware Description (V100R006 01)Document1,063 pages31401505-Hardware Description (V100R006 01)david velazquez orozcoNo ratings yet

- HLD Sample PDF FreeDocument38 pagesHLD Sample PDF FreeJohny CageNo ratings yet

- UL Unified Video Steering (SRAN12.1 - 01)Document45 pagesUL Unified Video Steering (SRAN12.1 - 01)waelq2003No ratings yet

- MC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1Document8 pagesMC20005-WHP-WI-P-0114 Liquid Seal Pot Datasheet Work Instruction - RevD1nguyenmainamNo ratings yet

- MODEL NO.: V390HK1 Suffix: Ls5: Product SpecificationDocument50 pagesMODEL NO.: V390HK1 Suffix: Ls5: Product SpecificationAngelos AnagnostouNo ratings yet

- Product Information DIGSI 5 V07.50Document56 pagesProduct Information DIGSI 5 V07.50g-bearNo ratings yet

- Gcse Economics 8136/1: Paper 1 - How Markets WorkDocument19 pagesGcse Economics 8136/1: Paper 1 - How Markets WorkkaruneshnNo ratings yet

- Important Questions Mba-Ii Sem Organisational BehaviourDocument24 pagesImportant Questions Mba-Ii Sem Organisational Behaviourvikas__ccNo ratings yet

- Tamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Document12 pagesTamil Nadu Industrial Establishments (Conferment of Permanent Status To Workman Act, 1981Latest Laws TeamNo ratings yet

- Managerial Economics - 1Document36 pagesManagerial Economics - 1Deepi SinghNo ratings yet

- Network Administration and Mikrotik Router ConfigurationDocument17 pagesNetwork Administration and Mikrotik Router ConfigurationbiswasjoyNo ratings yet

- Thermo King Tool Catalog Part 2Document53 pagesThermo King Tool Catalog Part 2Alb NewgateNo ratings yet

- MB0048 Operation Research Assignments Feb 11Document4 pagesMB0048 Operation Research Assignments Feb 11Arvind KNo ratings yet

- Lae ReservingDocument5 pagesLae ReservingEsra Gunes YildizNo ratings yet

- Media ReportDocument46 pagesMedia ReportAndrew AB BurgoonNo ratings yet

- GRE Computer Science SyllabusDocument2 pagesGRE Computer Science SyllabusSameer Ahmed سمیر احمدNo ratings yet

- 19C Financials WNDocument60 pages19C Financials WNbishwabengalitolaNo ratings yet

- UN-HABITAT Quick Quide Urban Mobility Plans For Review - Fri 01-Feb-2013Document59 pagesUN-HABITAT Quick Quide Urban Mobility Plans For Review - Fri 01-Feb-2013tarekyousryNo ratings yet

- List of Newly and Migrated Programs For September 2022 - WebsiteDocument21 pagesList of Newly and Migrated Programs For September 2022 - WebsiteRMG REPAIRNo ratings yet

- ETA-1 Service PDFDocument44 pagesETA-1 Service PDFgansolNo ratings yet

- Title To The ProjectDocument14 pagesTitle To The ProjectJatinChadhaNo ratings yet

- FMDQ Codified Rule Book FGN BondsDocument65 pagesFMDQ Codified Rule Book FGN BondsOladipupo Mayowa PaulNo ratings yet

- Exchange Rates JBDocument9 pagesExchange Rates JBboss9921No ratings yet

- Unilever Financial PerformanceDocument9 pagesUnilever Financial PerformanceAbdul QayumNo ratings yet

- Memorandum of AgreementDocument6 pagesMemorandum of AgreementJomar JaymeNo ratings yet

- Print Design Business Model CanvasDocument3 pagesPrint Design Business Model CanvasMusic Da LifeNo ratings yet

- 1 General: Fig. 1.1 Industrial RobotDocument40 pages1 General: Fig. 1.1 Industrial RobotArunNo ratings yet