Professional Documents

Culture Documents

Pressure Test Procedure FOR Portable Methanol Injection Package (GBWP-A-4200)

Uploaded by

dharwin apOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Test Procedure FOR Portable Methanol Injection Package (GBWP-A-4200)

Uploaded by

dharwin apCopyright:

Available Formats

GAJAH BARU PROJECT

PRESSURE TEST PROCEDURE

FOR

PORTABLE METHANOL INJECTION PACKAGE

(GBWP-A-4200)

A 08-12-09 ISSUED FOR COMMENT (IFC) GOH P K

REV DATE DESCRIPTION ORIGINATOR REVIEWED APPROVED

STATUS CODE : A = Issued for Comment - B = Issued for Approval - C = Approved for Construction - D = As Built

Info = For Information – X = Document Cancelled

© This document is copyright.

No part may be reproduced or used without the written permission of Premier Oil

PREMIER OIL NATUNA SEA B.V. – GAJAH BARU PROJECT

Contract No : CO-07-138

Weatherford

R

VENDOR NAME:

PT WEATHERFORD INDONESIA

Doc. No. : CO-07-138-200-42-AA-M-402 CLASS REVISION STATUS

P.O. No. : 464876 1 A A

GAJAH BARU PROJECT

TABULATION OF REVISED PAGES

REVISIONS REVISIONS

SHEET SHEET

A B C D E F G H A B C D E F G H

1 X 51

2 X 52

3 X 53

4 X 54

5 X 55

6 X 56

7 57

8 58

9 59

10 60

11 61

12 62

13 63

14 64

15 65

16 66

17 67

18 68

19 69

20 70

21 71

22 72

23 73

24 74

25 75

26 76

27 77

28 78

29 79

30 80

31 81

32 82

33 83

34 84

35 85

36 86

37 87

38 88

39 89

40 90

41 ATTACHMENT \ APPENDIX

42 1 A

43 2 B

44 3 C

45 4 D

46 5 E

47 6 F

48 7 G

49 8 H

50 9 I

Weatherford

R

Page 2 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

DESCRIPTION OF CHANGES

Description of Change (as clouded for

Location of Change /

Revision drawing/block lined at right side for

Section / Page Affected

document)

A ALL FIRST ISSUE

Weatherford

R

Page 3 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

CONTENTS

Description Page No

TABULATION OF REVISED PAGES............................................................................................................... 2

DESCRIPTION OF CHANGES........................................................................................................................ 3

CONTENTS...................................................................................................................................................... 4

S A F E T Y N O T I C E ................................................................................................................................... 5

1. INTRODUCTION................................................................................................................................ 6

1.1 Abbreviations.................................................................................................................................. 6

1.2 Reference Documents.................................................................................................................... 6

2. PREPARATION................................................................................................................................. 7

2.1 Safety Precautions.......................................................................................................................... 7

2.2 Reference Drawings........................................................................................................................ 7

2.3 Test Equipment............................................................................................................................... 7

2.4 Test Requirements.......................................................................................................................... 8

4. LEAK CHECKS FOR PNEUMATIC LINES.....................................................................................10

5. COMPLETION.................................................................................................................................. 10

7. RESULTS......................................................................................................................................... 11

8. ACCEPTANCE................................................................................................................................. 12

Weatherford

R

Page 4 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

SAFETY NOTICE

ELECTRICAL

WARNING

WORKING ON THIS SYSTEM MAY INVOLVE WORKING WITH LIVE POWER. EXERCISE

CAUTION WHEN WORKING ON THE SYSTEM WITH POWER SUPPLIES SWITCHED ON.

CAUTION

THIS SYSTEM CONTAINS ELECTROSTATICALLY SENSITIVE EQUIPMENT THAT MAY BE

DAMAGED IF CORRECT HANDLING PROCEDURES ARE NOT OBSERVED.

MECHANICAL

WARNING

THIS SYSTEM CONTAINS HEAVY ITEMS OF EQUIPMENT. CARE IS REQUIRED WHEN

REMOVING AND REPLACING HEAVY EQUIPMENT. FAILURE TO OBSERVE REASONABLE

SAFETY PRECAUTIONS MAY RESULT IN PERSONAL INJURY.

HYDRAULIC

WARNING

THIS SYSTEM INCLUDES EQUIPMENT WITH CONTAINED HYDRAULIC AND PNEUMATIC

HIGH PRESSURES. IT IS ESSENTIAL FOR PERSONNEL TO FAMILIARISE THEMSELVES

WITH PRESSURISED EQUIPMENT BEFORE WORKING ON THE EQUIPMENT. FAILURE TO

OBSERVE REASONABLE SAFETY PRECAUTIONS MAY RESULT IN PERSONAL INJURY.

CAUTION

EQUIPMENT MAY BE DAMAGED IF CORRECT PRESSURE RATINGS ARE NOT ADHERED

TO.

COSHH

All reasonable precautions have been taken to ensure that the Controls of Substances

Hazardous to Health (COSHH) regulations are met.

The equipment supplied as part of this system has been manufactured with materials that

do not contain properties deemed hazardous to the health of the user.

Weatherford

R

Page 5 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

1. INTRODUCTION

The purpose of this document is to provide instructions for the hydrostatic testing by PTWI. This

document is in line with PTWI Quality Procedure ~ reference to standard operation work instruction,

SOWI-OP-09 – Hydraulic / Pneumatic Pressure Test.

Please tick check boxes adjacent to corresponding paragraphs to confirm acceptance, or make

comments referring to results in Section 8.

1.1 Abbreviations

PTWI - PT Weatherford Indonesia

PTSI - PT Saipem Indonesia

GA - General Arrangement

HP - High Pressure

LP - Low Pressure

PMIP - Portable Methanol Injection Package

WP - Working Pressure

1.2 Reference Documents

CO-07-138-200-42-SP-M-201 Rev C Specification for Portable Methanol Package

Weatherford

R

Page 6 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

2. PREPARATION

2.1 Safety Precautions

The following Safety Precautions will be observed during the Hydrostatic Test :

The test area will be cordoned off and the relevant signs/placard displayed.

All personnel involved with the testing will wear protective eye gear and safety

boots. WAP also recommend protective clothing (overalls and gloves) especially if

in contact with test fluid.

Only personnel directly involved with the test should be present/nearby.

Any fluid spilt will be cleared up or made safe from slippage immediately.

A Risk Assessment should be conducted if applicable.

2.2 Reference Drawings

Check that the latest revisions of the following drawings are available.

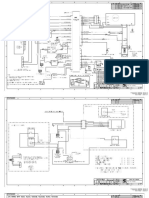

Piping & Instrument Diagram CO-07-138-200-42-DG-M-402

2.3 Test Equipments

PTWI will provide the following services and equipments to successfully perform the pressure

tests :

2.3.1 Hydraulic Engineer and Technicians.

2.3.2 Test fluid.- Water with < 30 ppm chloride.

2.3.3 Test gauges, range 0 ~ 3,000 PSI.

2.3.4 Shop air supply @ 10 barg.

2.3.5 Plugs and caps as required.

Note the pump used to leak check all lines shall be the package’s methanol injection pump :

Pump Make : Milton Roy

Pump Model : CP500V300CRTC

Pump Type : Plunger

Pump Tag No. : GBWP-P-4220

Max Flowrate : 8.71 LPH

Max. Pressure : 2,020 PSI

Test Pressure : 3,000 PSI

Plunger Speed : 1 ~ 45 stroke / min

Weatherford

R

Page 7 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

1. Test Requirements

Prior to testing:

2.4.1 Remove all relief valves and cap tubing / fitting.

2.4.2 Equipment which has previously been hydrostatically tested and certified by an

Inspection Authority can be excluded (e.g. pulsation damper). Ensure, as a far as

possible, that all tubing supplying the isolated component is tested.

2.4.3 Install test pressure gauge (Baker, S/n. 044319/1) at TP2.

2.4.4 Connect a compressed air supply to TP3.

2.4.5 Fit calibrated gauges to system under test.

2.4.6 Check calibration certificates of all test equipment used.

REMOVE

PSV-4202

CLOSE

BV1 -6

CLOSE

BV1-5

Weatherford

R

Page 8 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

3. PUMP PRESSURE TEST & TUBING LEAK CHECKS

Note: Max. Working Pressure = 2,020 PSI-g ; Test Pressure = 3,000 PSI-g.

3.1 Fill methanol tank, GBWP-T-4200, with at least 75% of water.

3.2 Open BV1-3. Keep BV1-4 closed.

3.3 Open BV1-8, and slowly increase pump output pressure by adjusting PCV-4201.

Monitor PI-4202 and test gauge while regulating.

3.4 Slowly increase pressure (ensure all air is bled from the system), continue to

increase to about 500 PSI.

3.5 Pump stroking frequency should be at 40 ~ 45 spm. Remove cover and adjust the

black knob on the pump controller, if necessary.

3.6 Allow system to stabilise for 10 minutes and visually inspect for leaks.

3.7 Increase system pressure incrementally 25%, 50% 75%, 100% to test pressure

3,000 PSI (approx. 1½ times of max. working pressure).

3.8 Allow pressure to stabilise for five minutes, if necessary slowly increase back to

test pressure. Check system pressure drop over a 15-minute period.

Allow 5 % pressure variation during the test.

3.9 After the 15-minute time lapse, close BV1-8, and remove air supply. De-regulate

PCV-4201 till PI-4201 reads zero (0) PSI.

3.10 Open BV1-6 to vent residue pressure back to tank. Ensure that PI-4202 and test

gauge reading have drop to zero (0).

Weatherford

R

Page 9 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

4. LEAK CHECKS FOR PNEUMATIC LINES

Note: Air Working Pressure = 65 PSI-g ; Test Pressure = 100 PSI-g

4.1 Reduce pump stroking frequency to zero (0), by adjust the black knob on the pump

controller.

4.2 Connect air supply to TP3.

4.3 Open BV1-8, and set regulated air pressure to 50 PSI. Monitor PI-4201when

adjusting PCV-4201.

4.4 Allow system to stabilise for 10 minutes and visually inspect for leaks. If needed,

apply soap solutions on all threaded joints and fittings, to ensure NO air leakage.

4.6 Increase system pressure incrementally 50%, 100% to test pressure 100 PSI

(approx. 1½ times working air pressure).

4.7 Allow pressure to stabilise for five minutes, if necessary slowly increase back to test

pressure. Check system pressure drop over a 15-minute period.

Allow 5 % pressure variation during the test.

4.8 When 15 minutes have lapsed, close BV1-8, and remove air supply. De-regulate

PCV-4201 till PI-4201 reads zero (0) PSI.

4.9 Open BV1-9 to removed trapped air in the pneumatic lines.

5. COMPLETION

6.1 Remove test gauge from TP2.

6.2 Refit the relief valves onto their respective lines.

6.3 This document serves as a Pressure Test Report, when completed.

This completes the test.

Weatherford

R

Page 10 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

7. RESULTS

PARAGRAPH DESCRIPTION COMMENTS

Weatherford

R

Page 11 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

8. ACCEPTANCE

This concludes the hydrostatic test for the scope of this contract. This certifies that the tests detailed

in this procedure were satisfactorily completed and witnessed by the undersigned (any outstanding

work is annotated on the Results pages).

TITLE NAME SIGNATURE DATE

PT Weatherford Indonesia

PT Transalindo Eka Persada

PT Saipem Indonesia

Company’s Representative

MIGAS Inspector

3rd Party Inspector

Weatherford

R

Page 12 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

GAJAH BARU PROJECT

Weatherford

R

Page 13 of 13 Doc. No. : CO-07-138-200-42-AA-M-402

Rev : A – Date : 08.12.2009

You might also like

- 154D3502AA D: Elementary DiagramDocument1 page154D3502AA D: Elementary DiagramYas AlbNo ratings yet

- 536E4525 Gen Arr. RWF-II-222 Screw Compress.Document1 page536E4525 Gen Arr. RWF-II-222 Screw Compress.Jose TorrezNo ratings yet

- IndraDocument2 pagesIndravsv mnaNo ratings yet

- Multi Purpose Hall SF LayoutDocument1 pageMulti Purpose Hall SF LayoutShivraj KmNo ratings yet

- Hadjret HRSG Operation Training ManualDocument87 pagesHadjret HRSG Operation Training ManualYanis KemounNo ratings yet

- P.topo ADocument1 pageP.topo AGamadiel MéndezNo ratings yet

- Anti Crash Barrier For Rectangular Piers - Shop DrawingDocument1 pageAnti Crash Barrier For Rectangular Piers - Shop DrawingAshish BavdaneNo ratings yet

- Tolerance Clarification 720029483 PDFDocument1 pageTolerance Clarification 720029483 PDFQualitysm MicrotechprecisionengineeringNo ratings yet

- Hydr. CircuitDocument1 pageHydr. CircuitMohamed HassanNo ratings yet

- El DWG 001 Cover PageDocument1 pageEl DWG 001 Cover PageSumit TyagiNo ratings yet

- Equipment AssemblyDocument8 pagesEquipment AssemblyAkhtar AnsariNo ratings yet

- VRV Inq Master - SOUTH - 28FEB - O2J - NTHVDocument5 pagesVRV Inq Master - SOUTH - 28FEB - O2J - NTHVQwb V. HuynhNo ratings yet

- 110kV Dinh VuDocument264 pages110kV Dinh VuNguyễn Minh ĐứcNo ratings yet

- Purchased Part Specification: Current Revision ApprovedDocument9 pagesPurchased Part Specification: Current Revision ApprovedJavier Pineda Galvis100% (1)

- COCO P3 EXE TOYO PCE 000 STA GA 0002 AYBJ00120 - Rev.0 - APDocument5 pagesCOCO P3 EXE TOYO PCE 000 STA GA 0002 AYBJ00120 - Rev.0 - APNazrilMizarNo ratings yet

- Model Jockey Pump Controller:JP3: Wiring SchematicDocument2 pagesModel Jockey Pump Controller:JP3: Wiring SchematicUmair BaBer100% (1)

- Se JVCDocument25 pagesSe JVCpaco37No ratings yet

- 1YUX200001A0181 - G75 SPARE - Full Rawing - B - 20200403Document165 pages1YUX200001A0181 - G75 SPARE - Full Rawing - B - 20200403Văn NguyễnNo ratings yet

- DA/2 Area: Chain Link Fence (H 2.0m)Document1 pageDA/2 Area: Chain Link Fence (H 2.0m)heri_prasetyadiNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document5 pagesRas Markaz Crude Oil Park Project (Phase1)saravqwertyNo ratings yet

- Arranjo Geral - Vitoria Recycle Grinder and BlowerDocument1 pageArranjo Geral - Vitoria Recycle Grinder and BlowerAndré Andrade RamosNo ratings yet

- Attachment#2 Dedicated Cooling WaterDocument19 pagesAttachment#2 Dedicated Cooling WaterYusufNo ratings yet

- Project Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateDocument3 pagesProject Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateYogesh MittalNo ratings yet

- Project Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateDocument4 pagesProject Name: 18RRETEPD12430 and Oil Movement Area Units at Rre Installation of Closed Process CondensateYogesh MittalNo ratings yet

- SD-9781 Rev 6Document13 pagesSD-9781 Rev 6Amresh KumarNo ratings yet

- OU600456156R0Document1 pageOU600456156R0anton.olennikovNo ratings yet

- Piston PinDocument1 pagePiston PinMochammad ReshaNo ratings yet

- HKN SPD Ar DW 10906 ADocument1 pageHKN SPD Ar DW 10906 AHirushan MenukaNo ratings yet

- Customer Project Name Drawing No Revision No Order No Kontrol Panosu-TJ509-T-DOOSAN-DP126 E3-191010459 - StandartDocument11 pagesCustomer Project Name Drawing No Revision No Order No Kontrol Panosu-TJ509-T-DOOSAN-DP126 E3-191010459 - StandartАлександр ЩеблыкинNo ratings yet

- Door No. Location Description Quantity Opening D - 5 Lower Ground To 12Th Floor (Toilets at Retail Area) PVC Flush DoorDocument1 pageDoor No. Location Description Quantity Opening D - 5 Lower Ground To 12Th Floor (Toilets at Retail Area) PVC Flush DoorAl Noel 歡呼 ThordzNo ratings yet

- 220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Document200 pages220kV Da Bac - TEL, SER, FR, FL, TN48, INV Panel Drawing - R7Văn Ngọc NguyễnNo ratings yet

- E-EB-126-rev1 (Deck Plate) - ModelDocument1 pageE-EB-126-rev1 (Deck Plate) - ModelJoy FernandezNo ratings yet

- Typical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FutureDocument1 pageTypical Section (X-X) : MP1 MP2 MP3 MP4 Mp8 Future MP3 Mp7 Future Mp6 Future Mp5 FuturesartajNo ratings yet

- Electrical Wiring: DN 32 DN 32Document1 pageElectrical Wiring: DN 32 DN 32juring bitolaNo ratings yet

- Gate Details (Game Fabric)Document1 pageGate Details (Game Fabric)Ramesh GaurNo ratings yet

- Dell Inspiron 5480 BUCKY - WHL 17859-1 REV X01 PDFDocument105 pagesDell Inspiron 5480 BUCKY - WHL 17859-1 REV X01 PDFFernando FloresNo ratings yet

- Electircal SLDDocument25 pagesElectircal SLDEzhu MalaiNo ratings yet

- A B C D E F G H J K Date BY Alteration Detail Location SymbolDocument1 pageA B C D E F G H J K Date BY Alteration Detail Location SymbolDhenil ManubatNo ratings yet

- QBR101 Battery Wiring DiagramDocument1 pageQBR101 Battery Wiring DiagramNguyễn Văn TrungNo ratings yet

- COCO P3 EXE TOYO PCE 000 STA GA 0001 AYBJ00120 - Rev.0 - APDocument3 pagesCOCO P3 EXE TOYO PCE 000 STA GA 0001 AYBJ00120 - Rev.0 - APNazrilMizarNo ratings yet

- Z 1081053 - GPD Dimensions - Customer Drawing PDFDocument1 pageZ 1081053 - GPD Dimensions - Customer Drawing PDFkospi46No ratings yet

- 19 Trombone 2 New PDFDocument2 pages19 Trombone 2 New PDFTristan ScottNo ratings yet

- Revision History: Hardware Architecture Schematic Page Hardwarearchitecture - SchdocDocument17 pagesRevision History: Hardware Architecture Schematic Page Hardwarearchitecture - SchdocGuilherme Pigato PaesNo ratings yet

- TJ275BD5LDocument26 pagesTJ275BD5LMehdi HassouneNo ratings yet

- KZT40 00 (A) JXDocument1 pageKZT40 00 (A) JXKhaled Mohamed ArayedNo ratings yet

- 2023.01.15 - VDRL TEMPLATE PEP - Rev.F 15 Jan 22)Document72 pages2023.01.15 - VDRL TEMPLATE PEP - Rev.F 15 Jan 22)Andy ArdianNo ratings yet

- Plano Hidráulico 988GDocument2 pagesPlano Hidráulico 988GJoel RodríguezNo ratings yet

- Rfa-S-20 Method Statement For Repair of Cracks On Level 6 SlabDocument13 pagesRfa-S-20 Method Statement For Repair of Cracks On Level 6 SlabEngr Badz de DiosNo ratings yet

- A D Section A-A: Lower Housing, R/A II, PB5X0Document7 pagesA D Section A-A: Lower Housing, R/A II, PB5X0zizouhicheNo ratings yet

- NGPDUSCHEMATICDocument7 pagesNGPDUSCHEMATICIan Bruno Rodriguez Centurion100% (1)

- Cat - Dcs.sis. 994h Hamide ControllerDocument4 pagesCat - Dcs.sis. 994h Hamide ControllerMehdi ChakrouneNo ratings yet

- Diesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelDocument6 pagesDiesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelpochoNo ratings yet

- Cummins R20 ElectricalDocument7 pagesCummins R20 Electricaljean sanchezNo ratings yet

- Electrical Schematic E185 355 Fixed Speed Star DeltaDocument5 pagesElectrical Schematic E185 355 Fixed Speed Star DeltaRudy LashleyNo ratings yet

- VP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Document1 pageVP 2025JV0P10005 V 111 101 D40 003 V01 (Crude Distillation Column Installation & Fire Proofing Clip)Vasilica BArbarasaNo ratings yet

- IndraDocument2 pagesIndravsv mnaNo ratings yet

- 25 - Guadalajara - CBDocument1 page25 - Guadalajara - CBwinaaleNo ratings yet

- Distillation - Crude Oil PDFDocument1 pageDistillation - Crude Oil PDFasif rahim100% (1)

- Automotive Air Conditioning: A Compact Guide For The WorkshopDocument84 pagesAutomotive Air Conditioning: A Compact Guide For The WorkshopMarcos Paulo Rocha MirandaNo ratings yet

- Welding ProcessDocument9 pagesWelding ProcessrajuNo ratings yet

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionDocument8 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionHai NguyenNo ratings yet

- Centrifugal Pump Technical SummaryDocument52 pagesCentrifugal Pump Technical Summarychaitanya100% (1)

- GT 11. Modul Operating ProcedureDocument19 pagesGT 11. Modul Operating Procedurepraztt69No ratings yet

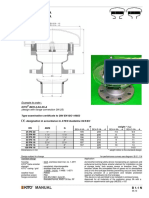

- Hooded Tank Vent Kito BEH-4-IIA-... - A Kito BEH-5-IIA-... - A: Example To OrderDocument2 pagesHooded Tank Vent Kito BEH-4-IIA-... - A Kito BEH-5-IIA-... - A: Example To Orderrob.careyNo ratings yet

- S20 Metallic SVC MANUALDocument32 pagesS20 Metallic SVC MANUALиванNo ratings yet

- C2R Compressor & Turbine ShutdownDocument10 pagesC2R Compressor & Turbine ShutdownfvaefaNo ratings yet

- Tulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster CompressorDocument6 pagesTulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster Compressorsumit kumarNo ratings yet

- Chapter 6 Flow in PipesDocument49 pagesChapter 6 Flow in PipesMamuye Busier YesufNo ratings yet

- Lab 9 Air Conditioning 1Document8 pagesLab 9 Air Conditioning 1khairi_mohammadNo ratings yet

- Exploring The Gas Laws - MathDocument2 pagesExploring The Gas Laws - Mathapi-483662721No ratings yet

- RefrigrantsDocument9 pagesRefrigrantsDevansh MehtaNo ratings yet

- Fluid Pressure Measuring DevicesDocument31 pagesFluid Pressure Measuring DevicesM Kafeel Khan100% (1)

- Horizontal and Vertical Butterfly ValvesDocument1 pageHorizontal and Vertical Butterfly ValvesAssured AutomationNo ratings yet

- Thermal Analysis of Shell and Tube Heat Exchangers For Improving Heat Transfer Rate Using Nanofluid MixturesDocument11 pagesThermal Analysis of Shell and Tube Heat Exchangers For Improving Heat Transfer Rate Using Nanofluid MixturesFawaz Bukht MajmaderNo ratings yet

- FLUID-MECHANICSDocument49 pagesFLUID-MECHANICSBong DuterteNo ratings yet

- Multicomponent Distillation Shortcut MethodDocument5 pagesMulticomponent Distillation Shortcut MethodDiegoAndréVegaDávalosNo ratings yet

- Modular Crude Oil ToppingDocument11 pagesModular Crude Oil Toppingstimayo010809No ratings yet

- Hydraulics Lecture Part I (Introduction)Document46 pagesHydraulics Lecture Part I (Introduction)Kristal AbalosNo ratings yet

- Reservoir EngineeringDocument147 pagesReservoir Engineeringjohn ngandouNo ratings yet

- Pipesim User GuideDocument843 pagesPipesim User GuideJesus Guxman100% (4)

- ME8595-Thermal Engineering-II PDFDocument19 pagesME8595-Thermal Engineering-II PDFpasrinivasan_199735233% (3)

- 071 How To Maintain Hydraulic SystemDocument10 pages071 How To Maintain Hydraulic Systemhaziq100% (1)

- Thesis Reza MalekzadehDocument180 pagesThesis Reza MalekzadehManh Tien HoangNo ratings yet

- Part I Refrigeration Chapter 1Document43 pagesPart I Refrigeration Chapter 1eskewt0% (1)

- The Flow Noise Characteristics of A Control Valve - OK OK OK TEORIADocument7 pagesThe Flow Noise Characteristics of A Control Valve - OK OK OK TEORIAJOSE MARTIN MORA RIVEROSNo ratings yet

- Fluid MechanicsDocument53 pagesFluid MechanicsNIHAR NAIKNo ratings yet