Professional Documents

Culture Documents

Field Test

Uploaded by

yasamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Test

Uploaded by

yasamanCopyright:

Available Formats

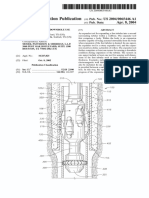

ROCKY MOUNTAIN OILFIELD TESTING CENTER

DOE/RMOTC/020120

PRODUCTION HYDRAULIC PACKER FIELD TEST

Field Report for the period of

October 21, 1999 – November 01, 1999

Date Published: June 30, 2000

Tricia Schneller, Halliburton Energy Services

Jose Salas, RMOTC (PDVSA, Venezuela)

PREPARED FOR THE U.S. DEPARTMENT OF ENERGY

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Work Performed Under Rocky Mountain Oilfield Testing Center (RMOTC)

CRADA No. 2000-001

PROTECTED CRADA INFORMATION

This product contains Protected CRADA Information which was produced on

June 30, 2000 under CRADA No. 2000-001 and is not to be further disclosed for

a period of 5 years from the date it was produced except as expressly provided

for in the CRADA.

Distribution E. Further dissemination authorized to the Department of Energy

only; other requests shall be approved by the originating facility of higher DOE

programmatic authority.

Approval:

RMOTC Manager_____________________________ Date:______________

Production Hydraulic Packer Field Test i

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Disclaimer

This report was prepared as an account of work sponsored by an agency of the

United States Government. Neither the United States Government nor any

agency thereof, nor any of their employees, nor any of their contractors,

subcontractors, or their employees makes any warranty, express or implied, or

assumes any legal liability or responsibility for the accuracy, completeness, or

any third party’s use or the results of such use of any information, apparatus,

product, or process disclosed, or represents that its use would not infringe

privately owned rights. Reference herein to any specific commercial product,

process, or service by trade name, trademark, manufacturer, or otherwise does

not necessarily constitute or imply its endorsement, recommendation, or favoring

by the United States Government or any agency thereof, or its contractors or

subcontractors. The views and opinions of authors expressed herein do not

necessarily state or reflect those of the United States Government or any agency

thereof.

Production Hydraulic Packer Field Test ii

ROCKY MOUNTAIN OILFIELD TESTING CENTER

PRODUCTION HYDRAULIC PACKER FIELD TEST

DOE CRADA No. 2000-001

Rocky Mountain Oilfield Testing Center

907 N. Poplar, Suite 150

Casper, WY 82601

(307) 261-5000

Report Date: June 30, 2000

Contract Date: October 12, 1999

Completion Date: November 1, 1999

DOE Funding: $77,276

Project Manager: Douglas Tunison

Project Engineer: Jose Salas

Other Major Contributors: Ralph Schulte

Contracting Officer’s Representative: Barbara Tucker

RMOTC Report Number DOE/RMOTC/02.0120

Production Hydraulic Packer Field Test iii

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Abstract

In October 1999, the Rocky Mountain Oilfield Testing Center and the test client

cooperated on a field test of new Production Hydraulic Packer technology on

Well 46-TPX-10 at Naval Petroleum Reserve No. 3 near Casper, WY.

Performance of the packer was evaluated in set and unset operations. The

packer ability to seal the annulus between the casing and tubing was

hydraulically tested and the results were recorded.

Production Hydraulic Packer Field Test iv

ROCKY MOUNTAIN OILFIELD TESTING CENTER

TABLE OF CONTENTS

INTRODUCTION 1

WELL INFORMATION SUMMARY 2

DESCRIPTION OF THE TECHNOLOGY TESTED 2

APPLICATION POTENCIAL OF THE TECHNOLOGY 3

GENERAL NOTES OF THE TEST 3

DAILY ACTIVITIES SUMMARY 5

21-October-99 5

25-October-99 6

26-October-99 7

27-October-99 8

28-October-99 9

29-October-99 10

1-November-99 10

ACTUAL TEST COST 10

TECHNICAL RESULTS OF THE TEST 11

Production Hydraulic Packer Field Test v

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Introduction

Hydraulic production packers are a mechanical device used to complete oil and-gas

wells in order to isolate different production zones from each other or the rest of the

wellbore. The availability of various types and sizes allows engineers to design their

wells according to their individual requirements and cost effectiveness.

The client developed a new type of production packer that uses an unconventional

setting procedure, which has to be tested before going to the market. Based upon the

requirements for packer design, a field test was designed to run a packer in a well, and

test the ability of the packer to be set and unset, as well as its sealing capability under

pressure differentials.

The test well was selected to provide a real well environment required for this particular

packer. These conditions included a well about 5,000 ft deep, and cased with 7 inch

casing, with fresh water as a completion fluid.

Production Hydraulic Packer Field Test 1

ROCKY MOUNTAIN OILFIELD TESTING CENTER

WELL INFORMATION SUMMARY

Well Name 46-TPX-10

API Number 049-025-22770

Lease Naval Petroleum Reserve

#3

Field Teapot Dome

County, State Natrona County, Wyoming

Ground Level 5258

Kelly Bushing 5268

Surface Location Sec. 10, T-38N, R-78W

Surface Coordinates ’ FSL,’ FWL

Total Depth 5630 ft

DESCRIPTION OF THE TECHNOLOGY TESTED

RMOTC’s test partner developed a new system for the remote, interventionless

actuation of downhole completion equipment. Conventional methods to set

Production Hydraulic Packers employ a dropped or circular ball, coiled tubing, or

slickline to run a tubing or casing plug. The new system provides a safe, reliable

and more cost effective alternative to the conventional intervention. It is based on

a newly developed acoustic telemetry that uses the tubular fluid to propagate a

predetermined pressure pulse sequence. Upon the successful detection and

decoding of the pressure pulses by a downhole electronic module, a command is

Production Hydraulic Packer Field Test 2

ROCKY MOUNTAIN OILFIELD TESTING CENTER

issued to activate the setting of a Production Packer. An unlimited number of

packer or other hydraulically activated devices can be remotely activated in any

desired sequence.

APPLICATION POTENTIAL OF THE TECHNOLOGY

The new technology developed decreases the time to set Production Hydraulic

Packers and extends the operating depths to deep, highly deviated or horizontal

offshore environments. Since the new system eliminates the need to circulate a

ball downhole to set the service tool, a constant hydrostatic pressure can be

maintained decreasing the risk of formation collapse, fluid losses and formation

damage.

GENERAL NOTES ON THE TEST

The following information is designed to provide a general idea of the Production

Hydraulic Packer test performed in the well 46-TPX-10 at the NPR-3 lease. This

test was affected by unexpected situations during testing operations.

1. Field operations started on October 21, 1999. It was planned to conduct

the test in two phases. The first phase was designed to accomplish the

requirements or minimum conditions regarding well conditions needed to run the

packers. This phase took four days, which exceeded the planned time for this

task of two and half days. The second phase was designed to perform the packer

test, which consisted of running the packer, setting the packer, hydraulically

testing the annular seal, and unsetting the packer. This phase took three days,

as planned.

Production Hydraulic Packer Field Test 3

ROCKY MOUNTAIN OILFIELD TESTING CENTER

2. During tripping in, the casing scraper and bit would stack out (i.e., lose

string weight). At this point, the operator would work the pipe by applying

approximately 4 – 6,000 lbs of set down weight and circulating the hole. The pipe

would gain weight indicating that the obstruction had been washed out from

around the bit and scraper. The pipe would then be lowered and often

encountered another obstruction, a few feet lower. The process would then be

repeated.

The condition of the wellbore was unknown; it had not been entered since the

client’s prior test in October 1998. The heavy mud (i.e., 12.7 ppg) used during the

previous test was left in the wellbore in anticipation that the client or another

service company would require the heavier mud again. The mud even in the

liquid environment of the casing appeared to form rings along the inside diameter

of the casing. The exact nature or cause of these rings is still debatable;

however, the result was additional workover time was required to reach the

bottom.

3. Despite the first phase being completed when we reached the bottom of

the well, the condition of the well remained poor. Heavy mud was left in the hole

and the test was affected as follows:

a. The test was planned for a dual packer run in order to simulate a

multiple sand completion and test the ability of the packers to be

selectively set. Since the clean up process was ineffective, and the casing

scraper wasn’t dressed properly for 7” 20# casing (scraper undergage due

to wear), there was a potential risk of stuck pipe due to the mud

solidification around the casing wall. Therefore, the test partner decided to

run only one packer, instead of two as originally planned.

Production Hydraulic Packer Field Test 4

ROCKY MOUNTAIN OILFIELD TESTING CENTER

b. As part of the test a polymer pill had to be pumped into the well and

placed five hundred feet above the packer. However, due to the heavy

mud left in the hole the pill reversed back up to 2,500 ft above the packer,

because of the hydrostatic underbalance caused by the heavy mud in the

casing annulus. This “U-tube” effect produced thirteen barrels of backflow

from the tubing.

c. Finally the test was performed and the test partner was able to

establish communication through the pill and set the packer.

DAILY ACTIVITIES SUMMARY

Thursday, 10-21-99

Start Finish Duration Activity

7:00 9:30 2.5 Ran in the hole with 2-7/8” tubing, casing scraper, and

bit to 3,832’ without problems.

Tagged fill at 3,832’. Pumped water into the hole with

water truck, took 64 bbl down tubing to see mud in

9:30 12:00 2.5

returns. Washed down to 3,900’.

12:00 5:00 5 Washed down to 4,178. There was still gray water

coming out of the hole.

Picked up one stand and tagged approximately 1-1/2

joints in on this stand. Shut down workover unit for

5:00 6:00 1

weekend.

Production Hydraulic Packer Field Test 5

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Monday, 10-25-99

Start Finish Duration Activity

Tagged up halfway in on joint number 132,

approximately 20’ higher than Thursday afternoon.

Current depth 4,250’. Could not get deeper due to

insufficient pump rate. Decided to use maximum water

truck pumping rate available, approximately 2 bbl/min.

7:00 11:00 4 Calculated annular velocity at this rate to be 65 ft/min.

Need a minimum of 150 ft/min. to clean out hole with

clear water. Tried to start up circulating unit to get more

rate. Would not start. Rigged up stripping head to

reverse circulate.

11:00 4:00 5 Washed down to 4,300’.at a rate of six minutes per

joint. Received orders to stop reverse circulating.

The drive line broke on the water truck. Tried to find

another water truck without success. Decided to

5:00 5:30 0.5

suspend operations until next day.

Production Hydraulic Packer Field Test 6

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Tuesday, 10-26-99

Start Finish Duration Activity

7:00 8:00 1 Ran in the hole to 4,300’ without problems. Contract

water truck arrived at the location.

8:00 9:00 1 Washed down to 4,434’. Started up circulating unit, but

received orders not to use it.

9:00 9:15 0.25 RIH without circulation from 4434’ to 4591’ (5 joints)

9:15 10:00 0.75 Washed down slowly with water truck due to fill.

10:00 11:00 1 RIH without circulation until top of bridge plug at 5,332’

11:00 1:00 2 Circulating approximately 2 bbls/min.

1:00 2:15 1.25 Working on the wellhead. Contract water truck left

location.

Tripped out of the hole with 2-7/8” tubing, scraper and

bit from 5,332’ to surface. The clients’ equipment

arrived on location at 2:15 PM. The winch truck was

2:15 3:30 1.25 used for 15 minutes to unload the equipment. The

vacuum truck was hauling water from the pit.

Tried to install a 3,000 psi wellhead, but could not break

out old wellhead. Installed new nipples and valves on

old wellhead. The Blowout Preventers (BOP’s) were

3:30 6:30 3 tested with 1,500 psi for five minutes with the circulating

unit since the water truck could not reach the pressure

required.

6:30 7:00 0.5 Picked up the clients’ equipment (packers) using winch

truck.

Production Hydraulic Packer Field Test 7

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Wednesday 10-27-99

Start Finish Duration Activity

7:00 8:30 1.5 Rigged up tubing tongs and elevator with the winch

truck.

8:30 9:00 0.5 Waited for 3-1/2” slip-type tubing elevators.

9:00 9:45 0.75 Picked up packer.

9:45 1:30 3.75 Ran in the hole with packer to 5,200’.

1:30 1:45 0.25 Rigged up packer setting equipment. Mixed extender

gel pill. Held pre-job safety meeting.

Finished mixing extender gel pill. Rigged up truck

pumping line and performed hydrostatic test with 1,500

psi for five minutes. Pumped 5.8 bbl pill and 25 barrels

1:45 4:15 3.5 of water to displace pill. U tube differential pressure of

250 psi was found on the tubing, indicating that the hole

was not cleaned of the heavy mud. Opened the valve

on the tubing and the well back flowed 13 barrels of

water to equalize. The annulus still contained heavy

mud.

4:15 5:45 1.5 Tried to set packer without success. Tried again with

more pressure. Pick up one foot and gained tension,

indicating packer was set.

5:45 6:00 0.25 Performed packer test. Held 1,200 psi on casing

annulus, indicating a hydraulic seal was attained.

6:00 6:30 0.5 Performed client unset procedure twice without

success.

Production Hydraulic Packer Field Test 8

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Thursday 10-28-99

Start Finish Duration Activity

Dropped ball and applied pressure to release packer.

Tested packer. It was still set. Tried again to release

7:00 10:00 3

packer and succeeded.

10:00 10:15 0.25 Reversed circulation to recover ball. Ran out of water.

10:15 10:45 0.5 Waiting for water truck. Contract water truck left

location.

10:45 1:30 2.5 Reversed ball out and pulled out of hole with 2-7/8”

string.

1:30 6:00 4.5 Picked up another packer and ran in the hole to 5,100’.

Tried to set the packer several times without success.

Decided to pull out of the hole with packer.

Production Hydraulic Packer Field Test 9

ROCKY MOUNTAIN OILFIELD TESTING CENTER

Friday 10-29-99

Start Finish Duration Activity

7:00 10:30 3.5 Finished tripping out of the hole with packer. Packer not

there.

10:30 12:30 2 Picked up packer fishing tool and ran in the hole to

recover packer.

12:30 1:30 1 Problems trying to recover packer. Finally packer unset.

1:30 3:00 2.5 Tripped out of the hole with fishing tool and packer.

3:00 3:30 0.5 Laid down packer and shut down workover unit.

Monday, 11-01-99

Start Finish Duration Activity

Ran in the hole with the work string to break down

singles. Break down 2-7/8” tubing and shut down

7:00 12:00 5

workover unit.

ACTUAL TEST COST

The total cost associated with mobilization, well preparation, and field -testing,

and mobilization of personnel, materials, equipment and services necessary to

conduct the test is $77,276.02.

Production Hydraulic Packer Field Test 10

ROCKY MOUNTAIN OILFIELD TESTING CENTER

TECHNICAL RESULTS OF THE TEST

• Tests conducted during the week of October 25 – 29, 1999, confirmed the

successful operation of the new system, and revealed some areas for

improvement.

• A minor problem in the surface air gun control program that sets the timing

of the acoustic signal sent through the tubular content was discovered.

• Inconsistencies in the functioning of a new version of the firmware were

also identified.

• Built-in redundancy provided by the contingency setting method, improves

overall reliability performance.

Production Hydraulic Packer Field Test 11

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Heriot - Watt University - Production Technology IDocument476 pagesHeriot - Watt University - Production Technology IBrahim Letaief75% (12)

- Theory GraphDocument23 pagesTheory GraphArthur CarabioNo ratings yet

- DownloadDocument186 pagesDownloadyasamanNo ratings yet

- SPE 100747 Expandable Sandface Completions-Design and Performance Review of Single-Zone Applications and Journey To Next-Generation Multizone SystemsDocument8 pagesSPE 100747 Expandable Sandface Completions-Design and Performance Review of Single-Zone Applications and Journey To Next-Generation Multizone SystemsyasamanNo ratings yet

- Large Pipe Sizes: 2004 AnnalsDocument9 pagesLarge Pipe Sizes: 2004 AnnalsyasamanNo ratings yet

- 4O6 / Cnn. Zzxn1 ADocument15 pages4O6 / Cnn. Zzxn1 AyasamanNo ratings yet

- United States Patent (10) Patent No.: US 8,028,749 B2Document23 pagesUnited States Patent (10) Patent No.: US 8,028,749 B2yasamanNo ratings yet

- Gravitational Fall Velocity of in Viscous Fluid by Tsang-Jung Chang and Ben Chie Yen,:Z Fellow, ASCEDocument7 pagesGravitational Fall Velocity of in Viscous Fluid by Tsang-Jung Chang and Ben Chie Yen,:Z Fellow, ASCEyasamanNo ratings yet

- SES (ESS) CatalogDocument20 pagesSES (ESS) CatalogyasamanNo ratings yet

- Falling Sphere Ball in Fluid Column: 1. Kinetic Equation of An Acceleration FallDocument4 pagesFalling Sphere Ball in Fluid Column: 1. Kinetic Equation of An Acceleration FallyasamanNo ratings yet

- Research Article: Initial Velocity Effect On Acceleration Fall of A Spherical Particle Through Still FluidDocument9 pagesResearch Article: Initial Velocity Effect On Acceleration Fall of A Spherical Particle Through Still FluidyasamanNo ratings yet

- Packer Design Research Used in Hydraulic Fracturing: IOP Conference Series: Earth and Environmental ScienceDocument10 pagesPacker Design Research Used in Hydraulic Fracturing: IOP Conference Series: Earth and Environmental ScienceyasamanNo ratings yet

- Sphere Ball-EditedDocument8 pagesSphere Ball-EditedyasamanNo ratings yet

- Production and Test Packer Retrievable: Product No.: BI 781-20Document1 pageProduction and Test Packer Retrievable: Product No.: BI 781-20yasamanNo ratings yet

- Production and Test Packer Retrievable: Engineering Excellence Powered by ExperienceDocument1 pageProduction and Test Packer Retrievable: Engineering Excellence Powered by ExperienceyasamanNo ratings yet

- Reza DashtpourDocument124 pagesReza DashtpouryasamanNo ratings yet

- Tomej 8 234 PDFDocument4 pagesTomej 8 234 PDFyasamanNo ratings yet

- Matecconf Icmme2018 06004Document4 pagesMatecconf Icmme2018 06004yasamanNo ratings yet

- Production and Test Packer RetrievableDocument1 pageProduction and Test Packer RetrievableyasamanNo ratings yet

- OZO Player SDK User Guide 1.2.1Document16 pagesOZO Player SDK User Guide 1.2.1aryan9411No ratings yet

- Dalasa Jibat MijenaDocument24 pagesDalasa Jibat MijenaBelex ManNo ratings yet

- Classifications of AssessmentsDocument11 pagesClassifications of AssessmentsClaire CatapangNo ratings yet

- Post Appraisal InterviewDocument3 pagesPost Appraisal InterviewNidhi D100% (1)

- Sam Media Recruitment QuestionnaireDocument17 pagesSam Media Recruitment Questionnairechek taiNo ratings yet

- Fusion Implementing Offerings Using Functional Setup Manager PDFDocument51 pagesFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- Tetralogy of FallotDocument8 pagesTetralogy of FallotHillary Faye FernandezNo ratings yet

- Read While Being Blind.. Braille's Alphabet: Be Aware and Active !Document3 pagesRead While Being Blind.. Braille's Alphabet: Be Aware and Active !bitermanNo ratings yet

- 1.technical Specifications (Piling)Document15 pages1.technical Specifications (Piling)Kunal Panchal100% (2)

- 04 - Fetch Decode Execute Cycle PDFDocument3 pages04 - Fetch Decode Execute Cycle PDFShaun HaxaelNo ratings yet

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDocument1,092 pagesSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaNo ratings yet

- The Magic DrumDocument185 pagesThe Magic Drumtanishgiri2012No ratings yet

- Guidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17Document5 pagesGuidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17zqhnazNo ratings yet

- Mixed Up MonstersDocument33 pagesMixed Up MonstersjaneNo ratings yet

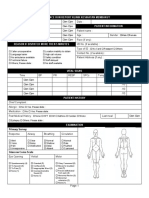

- Borang Ambulans CallDocument2 pagesBorang Ambulans Callleo89azman100% (1)

- Week 7 Sex Limited InfluencedDocument19 pagesWeek 7 Sex Limited InfluencedLorelyn VillamorNo ratings yet

- How To Identify MQ Client Connections and Stop ThemDocument26 pagesHow To Identify MQ Client Connections and Stop ThemPurushotham100% (1)

- Developing Paragraphs: Test Section - Writing Task 2Document11 pagesDeveloping Paragraphs: Test Section - Writing Task 2Cengizhan AkdağNo ratings yet

- Theories of International InvestmentDocument2 pagesTheories of International InvestmentSamish DhakalNo ratings yet

- (123doc) - Toefl-Reading-Comprehension-Test-41Document8 pages(123doc) - Toefl-Reading-Comprehension-Test-41Steve XNo ratings yet

- Prelim Examination MaternalDocument23 pagesPrelim Examination MaternalAaron ConstantinoNo ratings yet

- What Is TranslationDocument3 pagesWhat Is TranslationSanskriti MehtaNo ratings yet

- 3 Carbohydrates' StructureDocument33 pages3 Carbohydrates' StructureDilan TeodoroNo ratings yet

- Marketing FinalDocument15 pagesMarketing FinalveronicaNo ratings yet

- Biological Beneficiation of Kaolin: A Review On Iron RemovalDocument8 pagesBiological Beneficiation of Kaolin: A Review On Iron RemovalValentin GnoumouNo ratings yet

- V737 OverheadDocument50 pagesV737 OverheadnewahNo ratings yet

- How Drugs Work - Basic Pharmacology For Healthcare ProfessionalsDocument19 pagesHow Drugs Work - Basic Pharmacology For Healthcare ProfessionalsSebastián Pérez GuerraNo ratings yet

- Köppen Climate Classification - Wikipedia, The Free EncyclopediaDocument15 pagesKöppen Climate Classification - Wikipedia, The Free EncyclopediaAndreea Tataru StanciNo ratings yet

- II 2022 06 Baena-Rojas CanoDocument11 pagesII 2022 06 Baena-Rojas CanoSebastian GaonaNo ratings yet